NOVUS AUTOMATION 1/4

TxBlock-USB Transmitter

TEMPERATURE TRANSMITTER - OPERATING MANUAL –V1.0x F

INTRODUCTION

The TxBlock-USB is a 4-20 mA 2-wire temperature transmitter for

head mount, powered by the current loop. The output current is

linearized and adjusted in fuction of the input sensor type and range

configured.

Its configuration is accomplished by connecting the transmitter to a

PC USB port without the need of any dedicated interface. The

configuration does not require that the transmitter be powered.

SPECIFICATIONS

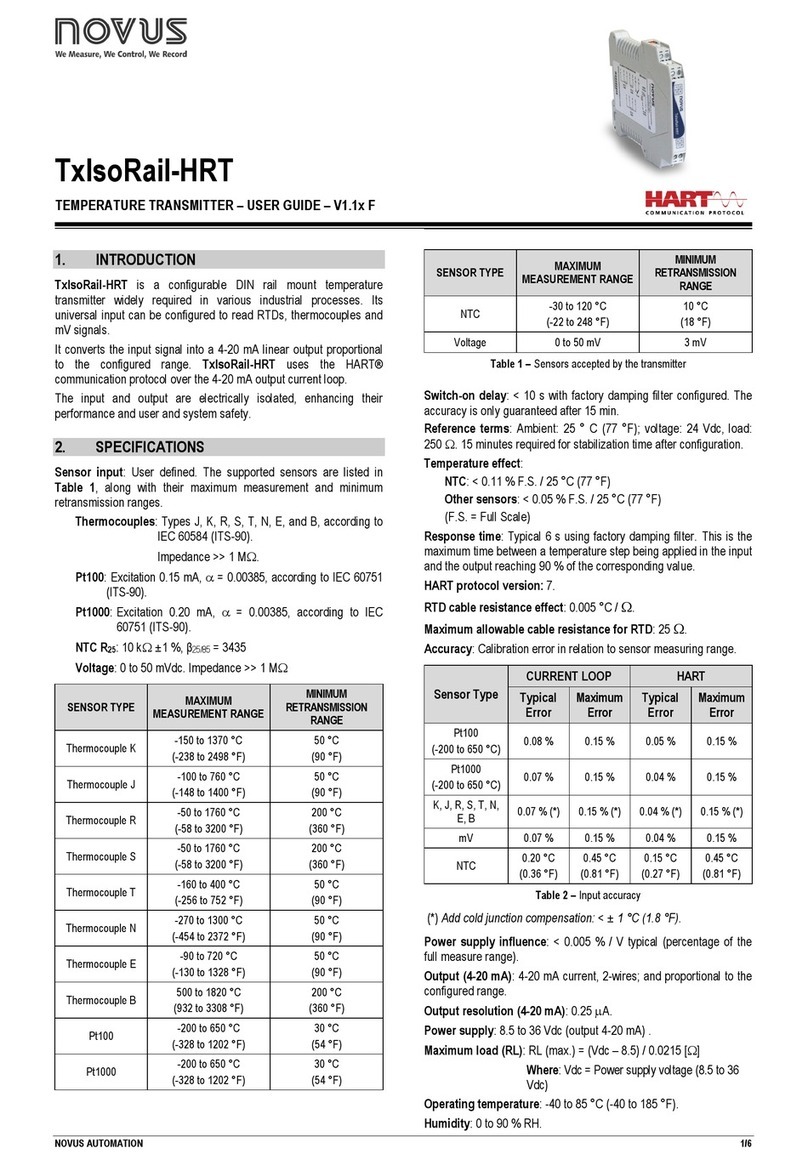

Sensor input: User defined. The supported sensors are listed in

Table 1, along with their maximum ranges.

Thermocouples: Types J, K, R, S, T, N, E and B accoding to

IEC 60584 (ITS-90). Impedance >> 1 M

Pt100: Type 3-wire, Excitation 0.8 mA, = 0.00385,

according IEC 60751 (ITS-90).

For 2-wire sensors, tie terminals 3 and 4

together.

Pt1000: Type 3-wire, Excitation 0.17 mA, = 0.00385,

according IEC 60751 (ITS-90).

For 2-wire sensors, tie terminals 3 and 4

together.

NTC R25°C: 10 k±1 %, B25/85 = 3435

Voltage: 0 to 50 mVdc. Impedance >> 1 M

Maximum Measurement

Range

Minimum Measurement

Range

Table 1 –Sensors accepted by the transmitter

Switch-on delay: < 2.5 s. The accuracy is only guaranteed after 15

min.

Terms of reference: ambient: 25 ° C; voltage: 24 Vdc, load: 250 ;

settling time: 10 minutes.

Temperature Effect: < ±0.16 % / 25 °C

Response time: typical 1.6 s.

Maximum voltage allowed at input terminals no sensor: 3 V.

RTD current: 800 A.

RTD cable resistance effect: 0.005 °C /

Maximum allowable cable resistance for RTD: 25 .

Pt100 / Pt1000

(-150 to 400 °C)

Pt100 / Pt1000

(-200 to 650 °C)

mV, K, J, T, E, N, R, S, B

Table 2 –Calibration error, percentage of the full measurement range

(*) Add cold junction compensation: < ± 1 °C.

Power supply influence: 0.006 % / V typical (percentage of the full

measure range).

Output:4-20 mA or 20-4 mA current, 2-wired; linear in relation to the

temperature measurement by the selected sensor.

Output Resolution: 2 A.

Power supply: 10 to 35 Vdc, across the transmitter;

Maximum load (RL): RL (max.) = (Vdc –10) / 0.02 []

Where: Vdc= Power supply voltage (10-35 Vdc)

Operating Temperature: -40 to 85 °C

Humidity: 0 to 90 % RH

Electromagnetic Compatibility: EN 61326-1:2006

No electrical isolation between input and output.

Internal protection against polarity inversion.

Cold junction compensation for thermocouples.

Dimensions: 43.5 mm (diameter) x 20.5 mm (height)

Connection Wire Cross Section: 0.14 a 1.5 mm²

Screw Tightening: 0.8 Nm.

Housing: ABS UL94-HB.

CONFIGURATION

When the trasmitter is used with the factory setting, no further action

is required and the transmitter is ready to be installed. Changes to

the configuration are possible through the TxConfig II software,

provided free of charge.

The TxBlock-USB Setup Kit consisting of the Txconfig II software and

USB cable can be purchased from the manufacturer or any authorized

distributor. The Txconfig II software is continuously updated and new

versions can be downloaded at no charge from the manufacturer’s

website. To install, execute the TxConfigIISetup.exe file and follow the

instructions.

Fig. 1 –USB cable connection