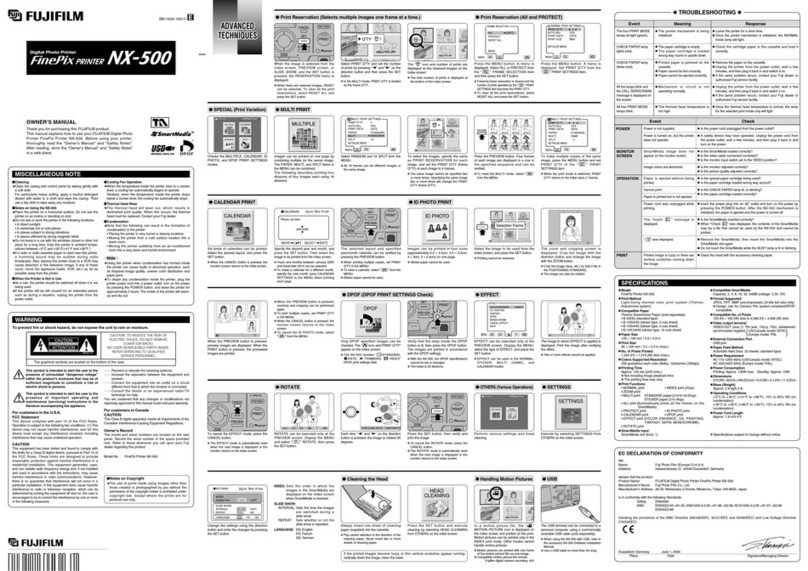

e-2 Circulation Filter Replacement

Be sure to turn OFF the power before

replacing the circulation filters.

If the circulation filter is not replaced,

abnormal temperature due to

insufficient circulation may turn ON the

safety thermostat, requiring system

restart. In addition, dirt in the solution

may adhere to the paper. In the worst

case, replacement of originally supplied

solution is required.

To prevent processing solution

contamination, replace the filters one at a

time in the following order: P1

®

P2 .

1. Turn the P1 filter rod 90 degrees

counterclockwise, lift out and place it on

the circulation filter tray.

Do not let the solution drip or run.

L2233

2. Remove the filter from the rod.

3. Install a new filter into the rod.

4. Reinstall the rod by aligning its fastening

tab with the cutout, and turn it 90 degrees

clockwise to secure it.

L2234

5. Replace the P2 filter by repeating Steps 1

to 4.

6. Wipe off solution off the circulation filter

tray and reinstall the tray.

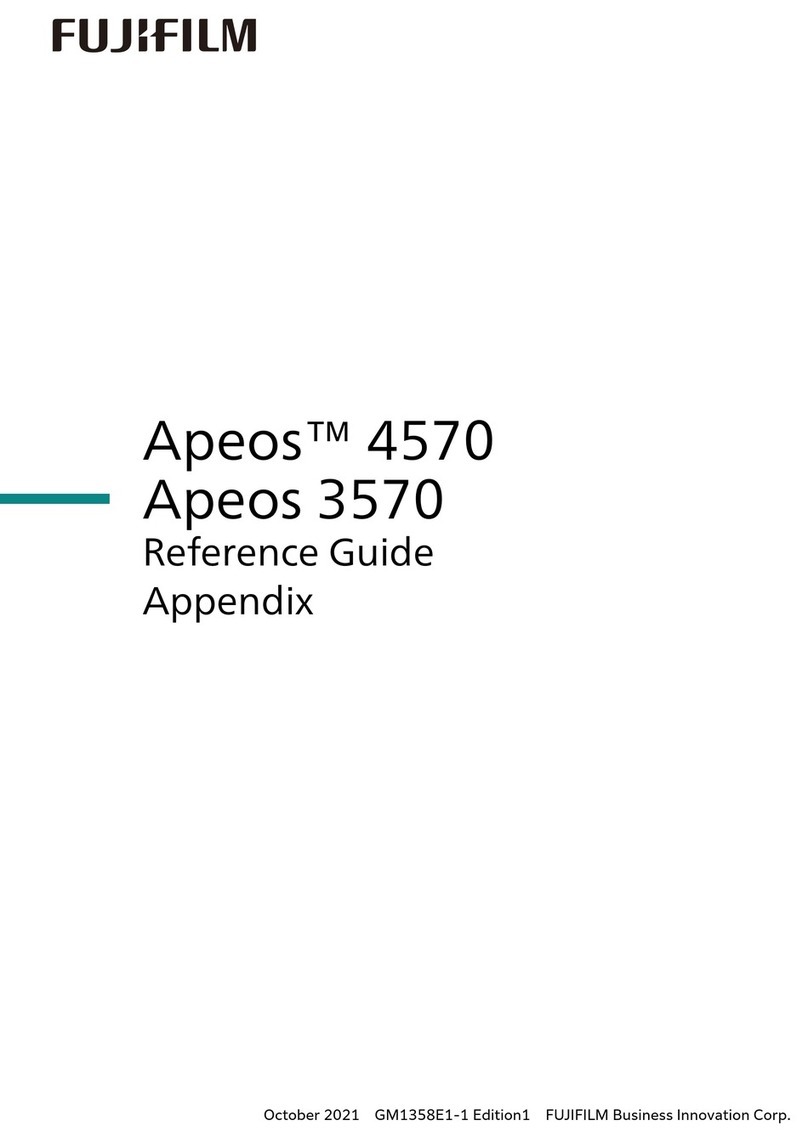

e-3 Washing the Processing Racks

If any dirt adheres to the processing

racks, stain or scratches on prints or

paper jamming may result.

If the P1 solution is contaminated by the

P2 and/or PS solutions, it will become unfit

for use. To prevent solution

contamination, always attach the

contamination-prevention cover onto the

P1 rack when removing or returning all the

processing racks except for the P1 rack.

Clean the racks in the following order: P1

®

P2

®

PS1

®

PS2

®

PS3

®

PS4.

1. Remove the P1 Rack, run about one liter of

water over the entire rack. Collect the

waste water in the waste solution

collection tank.

L21043

2. Run warm water (30 to 40 :/86 to 104 <)

over the rack, and thoroughly wash the

roller bearing sections and parts that come

in contact with the solution in the tank.

CAUTION:

To avoid scalding injuries and rack

deformation, do not use water hotter than

40

:

(104

<

).

Do not brush the rollers and paper guides

or processing marks on the prints may

result.

L2983

3. Repeat the above steps for the PS2 to PS4

processing tanks.

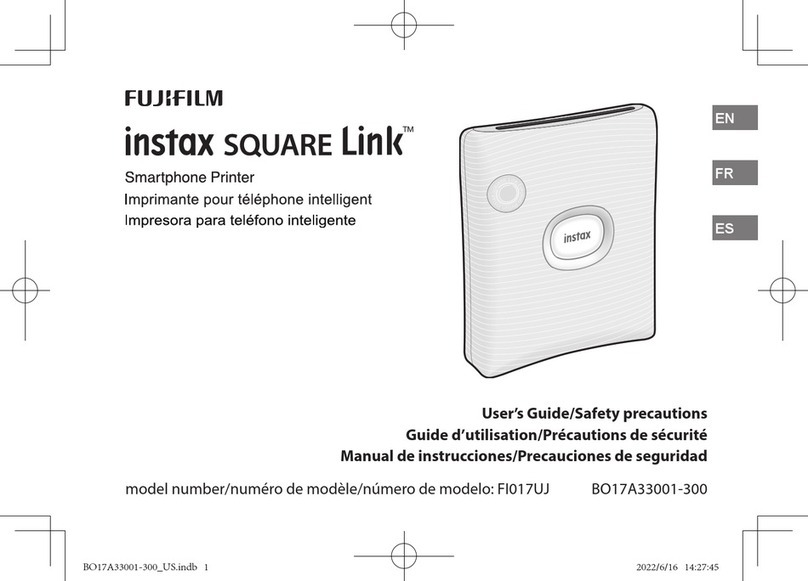

e-4 Washing the Auto-washing

Nozzles

If the nozzle is clogged, the amount of

sprayed washing solution may be

decreased, and insufficient cleaning of

the crossover and dryer entrance racks,

or stain or scratches on the paper may

result. In addition, dirt adhering to the

nozzle may cause paper jamming.

1. Make sure the washing jets are not

clogged and there is no foreign matter

around them. Clean the washing jets with

a toothbrush if necessary.

L2230

L2231

2. Reinstall the No.1 to No.3 crossover racks

and dryer entrance rack.

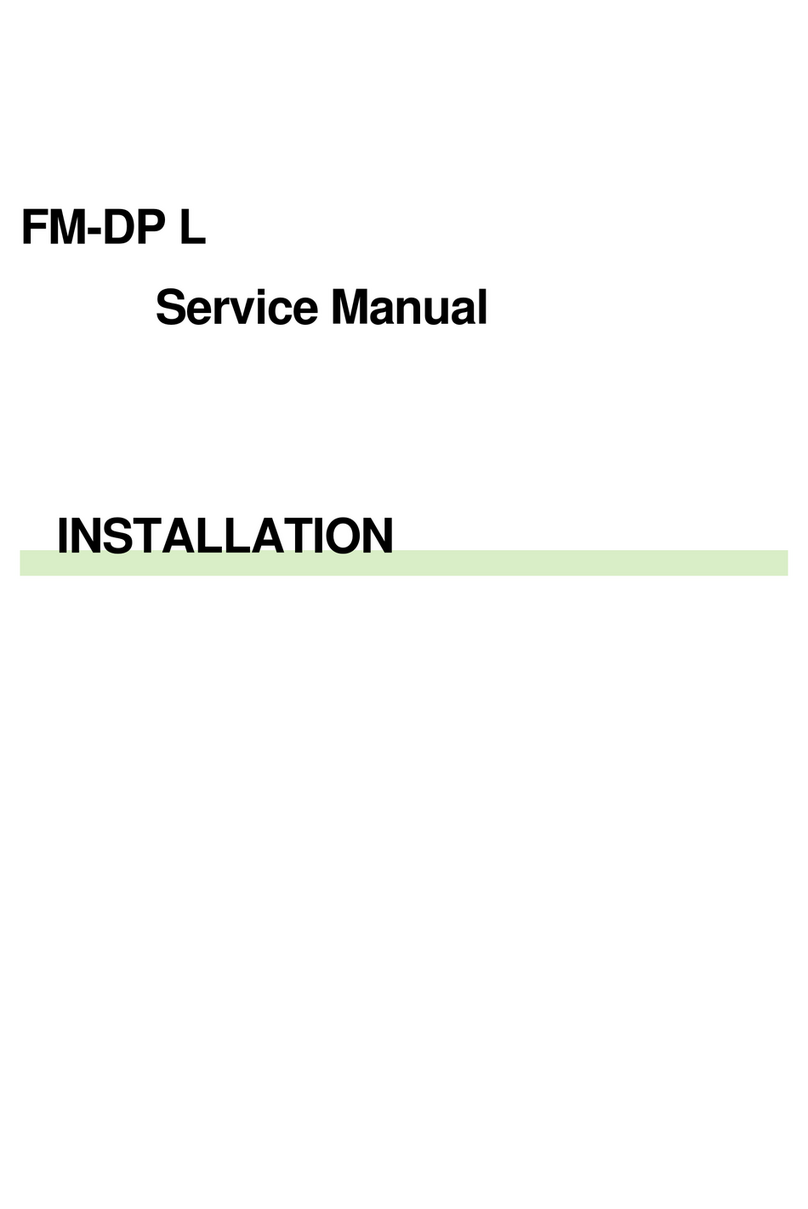

e-5 Cleaning the Paper Feed

Section Rollers

If the rollers become dirty, paper feed

force is weakened and images may be

printed at a slant. (Back printing may

also be slanted.) In addition, paper

jamming in the paper feed section may

occur.

1. Wipe dirt off the surfaces of the feed rollers

using a cloth moistened with water and

wrung dry.

L2188

2. Wipe dirt off the surfaces of the back

printer entrance roller using a cloth

moistened with water and wrung dry while

turning the lower knob.

L2189

3. Wipe dirt off the surfaces of the back

printing section rollers using a cloth

moistened with water and wrung dry while

turning the upper knob.

L2190

P1 Filter Rod

Circulation Filter Tray

Fastening Tab

Cutout

Processing Rack

Water (1R)

Rack Tray

Warm Water (30 to 40 :/86 to 104 <)

Auto-washing Nozzles

Toothbrush

Washing Jet

Auto-washing Nozzles

Auto-washing Nozzles

Toothbrush

Rollers Roller

Knob

Roller

Knob

Rollers