FTP-639MCL354 SPECIFICATION

A1NA02273-0354

Dept. to control the original documentDate

Rev.

FUJITSU COMPONENT LIMITED

Name

Drawing

No.

Page

Submit to

*Turn off all electric power to the head immediately when condensation occurs. Use

the head only after the head is completely dried.

*Depending on the environment where the printer is used (the low temperature or high

humidity), condensation may be caused by water vapor generated from the used paper

when performing the printing of the high printing rate (solid fills, zigzag printing);

therefore, the environment should be considerably evaluated.

(7)When any paper is not set at the printer,be sure to lift down the platen-release lever. If the

paper is run out during the printing,stop all actions of the printer in order to prevent the

printing without the paper fed. If the printing is continued without any paper fed,it may

cause the trouble of the printer.

(8)When using this printer for the continuous actions, the temperature of the head printer board

(the detected temperature with the thermistor) should be equal or less than 65 degrees

Centigrade for the temperature protection of IC inside of the printer as well as the surface

temperature of the motor should be equal or less than 90 degrees Centigrade for he

temperature protection of the motor coil.

2-2Notice on installation and settings

(1) When installing the printer,fix the edge part with a hook at two places and fix the rear part

with screws of M3 at two places. Flatness of the installing surface of the printer should be

within equal or less than 0.1mm. It is recommended that the printer is connected to the

main body FG with screws of M3 at two places (refer to the figure of the installation

dimension). Pay attention not to apply any extra force to the printer main body,FPC since

any of such force will give unfavorable effects to the printing quality,paper traveling

property (meandering,running short of the paper,and the paper jam),and life time.

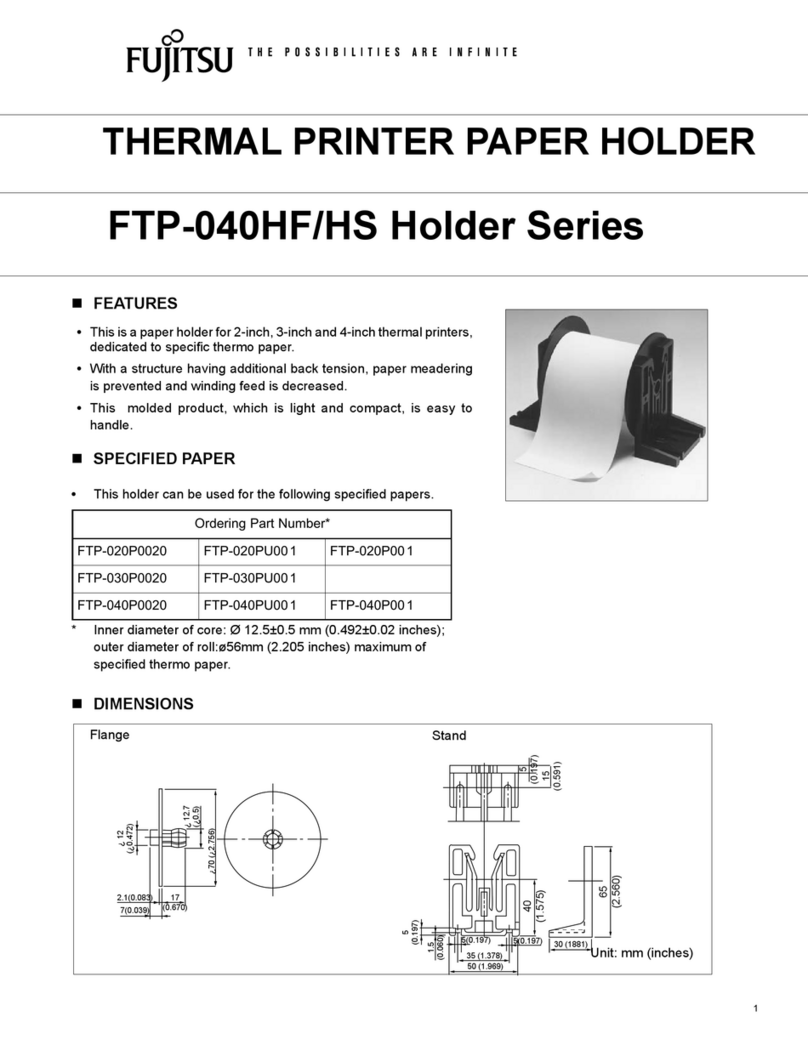

(2) Then installing the printer,install it so that the printer and the rolled paper should be parallel

as much as possible. When designing the casing,it should be designed so that the printer

and the holder part of the roller paper are located at the place shown in the bellow figure.

The roller paper should be ejected smoothly so that the paper does not hit anything such as

the cover. If the above is not conformed,troubles such as meandering of the printing paper,

the running short of the paper,and the paper jam may occur.