1. DESCRIPTION

MT-518Ri is a temperature controller with two outputs that can be configured as double stage of

refrigeration, double stage of heating or heating and refrigeration. Its second output also can be

configuredforalarmintra,extra-rangeor,even,relativeextra-range.

Product complies with CE (European Union) and UL Inc. (United States and Canada).

2. APPLICATION

• Winter/Summer automatic system in air conditioning

3. TECHNICAL SPECIFICATIONS

- Power supply: MT-518Ri 115 or 230 Vac ± 10% (50/60Hz)

MT-518RiL 12 or 24 Vac/dc

- Control temperature: -50 to 105ºC (decimal resolution between -10 and 100 ºC)

- Input: NTC sensor

- Load current: 8(3)A/250Vac 1/4HP each output

- Dimensions: 71 x 28 x 71mm

- Operation temperature: 0 to 50 ºC

- Operation humidity: 10 to 90% RH (without condensation)

UL-Underwriters Laboratories

MT-518Ri

DIGITAL TEMPERATURE CONTROLLER

WITH TWO STAGES

Ver. 12

MT518V12-01T-10873

CLASSIFICATION ACCORDING TO IEC60730-2-9 STANDARD:

- Temperature limit of the installation surface: 50°C

- Type of construction: Built-in electronic controller

- Automatic action: Type 1

- Control of pollution: Level 2

- Impulse voltage: 1,5kV

- Temperature for the test of sphere pressure: 75°C and 125°C

- Insulation: Class II

4. CONFIGURATIONS

4.1 - Control temperatures adjust (SETPOINTS)

-Press for2 seconds until appears,then release it. willappear and theadjusted

temperaturefor1ststage.

-Usethekeys and tochangethevalueandthenpress torecordit.

-Now andtheadjustedtemperaturefor2ststagewillappear.(onlyifF08=0orF08=1).

-Usethekeys and tochangethevalueandthenpress again.

SET

SET

SET

Description Min Max Unit

Fun

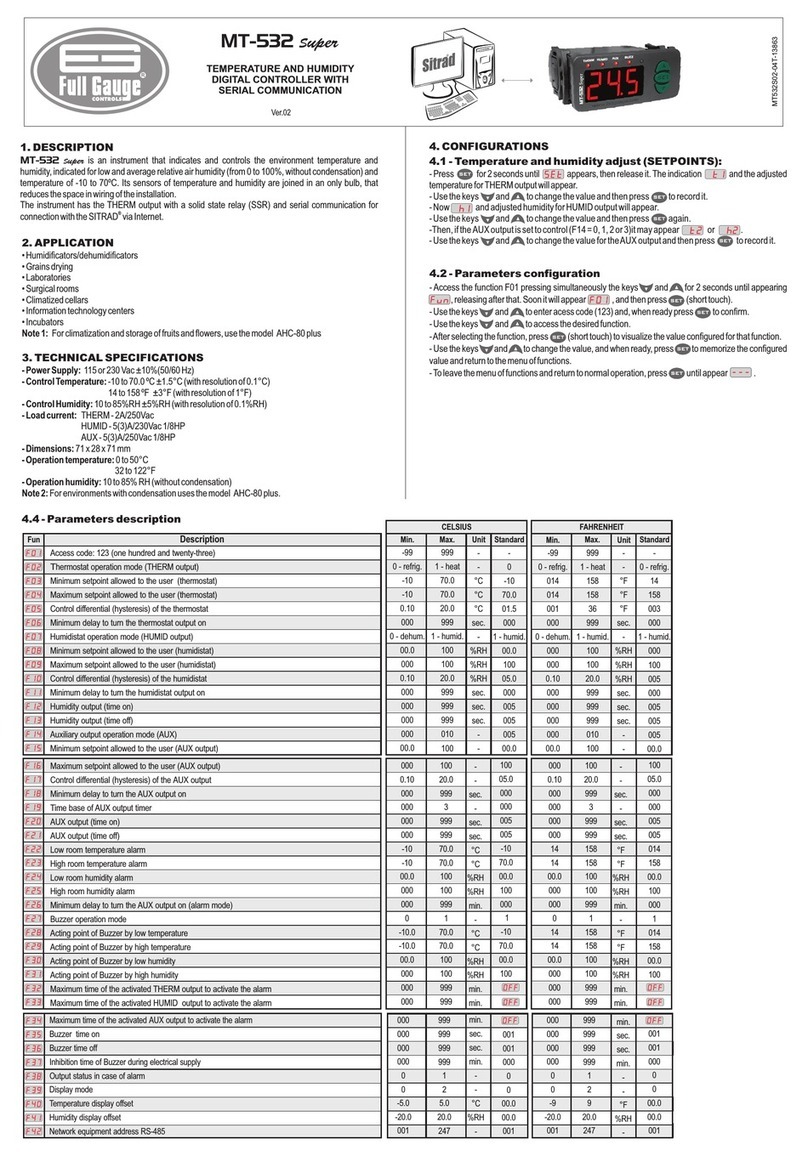

4.2 - Parameters table

Configuration parameters protected by access code.

Note: F02 function allows to correct eventual shuting lines in the reading, proceeding of the sensor

exchangeoralterationofsensorlength.

(4)2nd stage operation

mode:

0 - refrigeration

1 - heating

2 - alarm (inside of

range)

3 - alarm (outside of

range)

4 - relative alarm

(outside of range)

(1)First stage

operation mode:

0 - refrigeration

1 - heating

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

Access code 123 (one hundred and twenty-three)

Display (offset) (1)

1st stage operation mode

Minimum setpoint allowed to the end user (1st stage)

Maximum setpoint allowed to the end user (1st stage)

Control differential (hysteresis) of 1st stage

Minimum delay to turn on the 1st stage output

(2)

2nd stage operation mode

Minimum setpoint allowed to the end user (2nd stage)

Maximum setpoint allowed to the end user (2nd stage)

Control differential (hysteresis) of 2nd stage

Minimum delay to turn on the 2nd stage output

Alarm delay when the instrument is powered on

Alarm output time on

Alarm output time off

-

-5.0

0

-50

-50

0.1

0

0

-50

-50

0.1

0

0

0

0

-

5.0

1

105

105

20.0

999

4

105

105

20.0

999

999

999

999

-

°C

-

°C

°C

°C

sec.

-

°C

°C

°C

sec.

min.

sec.

sec.

4.3 - Parameters alteration

Accessthe functionF01 pressing simultaneouslythe keys and for 2 secondsuntil appearing

,releasingafterthat.Soonitwillappear ,andthenpress (shorttouch).

-Usethekeys and toenterwiththeaccesscode(123),andthenpress toenter.

-Usethekeys and toaccessthedesiredfunction.

-Afterselectingthefunction,press (shorttouch)todisplaythe configuredvalueforthatfunction.

-Usethekeys and tochangethevalueandthenpress torecordthenewvalueandreturn

tothefunctionsmenu.

-Toreturntothenormaloperation,press until appear.

5. FUCTIONS WITH FACILITATED ACCESS

Registers of minimum and maximum temperatures

Press . The minimum registered temperature appears and after soon the maximum registered

temperature.

Nota: To reset the registers, keep the key pressed during the visualization of the minimum and

maximumtemperaturesuntil tobeshowed.

SET

SET

SET

SET

SET

If the instrument is configured as alarm, set the F09 and F10 act points normally and ignore ST2 and

F11.Ifthetemperaturegoesoutthespecifiedrangeandringthealarm,press and toinhibitthe

sound.

6. SIGNALING

ST1 -1ststageoutputon

ST2 -2ndstageoutputon

-Detachedsensorortemperatureoutsidethespecifiedrange

With F08=4 the ST2 output is activated when the temperature reaches a value equal ST1 minus the

configurated value in F09 (ST1-F09), or when the temperature reaches a value equal ST1 plus the

configuratedvalueinF10(ST1+F10)

Ex.:

- Temperature in ST1 = 25 ºC

- Value in F08 = 4

- Value in F09 = 2

- Value in F10 = 5

TheST2 outputwillbekeptonwhenthetemperatureisbelow23ºC(25-2)orabove30ºC(25+5).IfST1

valueischangedto24ºCthealarmvalueswillbeautomaticallymodifiedto22and29ºC.

IF the functions F14 and F15 are set with zero, the ST2 output will be kepped on while the alarm

conditionpersist.

SET

ensoS r

Power

supply

Load 1

COMMON

Loads

supply

ST1 (NO)

ST2 (NO)

12345678910 11 12

115 V

(12 V)

230 V

(24 V)

0

72 mm

29 mm

7. WIRING DIAGRAM

7 - 8

7 - 9 115V

230V 12V

24V

MT-518Ri MT-518RiL

Load 2

- Refrigerator

- Heating

- Contactor

- Solenoid

- Refrigerator

- Heating

- Contactor

- Solenoid

Load 1 Load 2

Above specified current use contactors.

Dimension of the clipping for

setting of the instrument

IMPORTANT

For more information contact our application eng. department through e-mail

support@ fullgauge.com or dial +55 51 3475.3308.

AccordingtothechaptersofnormIEC60364:

1: Installprotectoragainstovervoltageonthepowersupply

2: Sensorcablesandsignal cables ofthe computer maybe joined, butnotin the sameelectric conduit

throughwhichtheelectricinputandtheactivationoftheloadsrun

3: Install transient suppresors (RC filters) parallel to the loads as to increase the product life of the

relays.

Contact suppresor connection diagram

Suppresor

A1

A2

A1 e A2 are the

contactor coils.

Diagram for suppresor installation

for direct drive load inputs

Load

Suppresor

For direct activation the maximum

specified current should be taken

into consideration.

Note: Theusercanincreasethelengthofthesensorcabletoupto200meters,byusingPP2X24AWG

cable.Forimmersioninwater,usethermometricwell.

PROTECTIVE VINYL:

This adhesive vinyl (included inside the packing) protects the instruments against

waterdrippings,asincommercialrefrigerators,forexample.

Dotheapplicationafterfinishingtheelectricalconnections.

1. DESCRIPTION

MT-518Ri is a temperature controller with two outputs that can be configured as double stage of

refrigeration, double stage of heating or heating and refrigeration. Its second output also can be

configuredforalarmintra,extra-rangeor,even,relativeextra-range.

Product complies with CE (European Union) and UL Inc. (United States and Canada).

2. APPLICATION

• Winter/Summer automatic system in air conditioning

3. TECHNICAL SPECIFICATIONS

- Power supply: MT-518Ri 115 or 230 Vac ± 10% (50/60Hz)

MT-518RiL 12 or 24 Vac/dc

- Control temperature: -50 to 105ºC (decimal resolution between -10 and 100 ºC)

- Input: NTC sensor

- Load current: 8(3)A/250Vac 1/4HP each output

- Dimensions: 71 x 28 x 71mm

- Operation temperature: 0 to 50 ºC

- Operation humidity: 10 to 90% RH (without condensation)

UL-Underwriters Laboratories

MT-518Ri

DIGITAL TEMPERATURE CONTROLLER

WITH TWO STAGES

Ver. 12

MT518V12-01T-10873

CLASSIFICATION ACCORDING TO IEC60730-2-9 STANDARD:

- Temperature limit of the installation surface: 50°C

- Type of construction: Built-in electronic controller

- Automatic action: Type 1

- Control of pollution: Level 2

- Impulse voltage: 1,5kV

- Temperature for the test of sphere pressure: 75°C and 125°C

- Insulation: Class II

4. CONFIGURATIONS

4.1 - Control temperatures adjust (SETPOINTS)

-Press for2 seconds until appears,then release it. willappear and theadjusted

temperaturefor1ststage.

-Usethekeys and tochangethevalueandthenpress torecordit.

-Now andtheadjustedtemperaturefor2ststagewillappear.(onlyifF08=0orF08=1).

-Usethekeys and tochangethevalueandthenpress again.

SET

SET

SET

Description Min Max Unit

Fun

4.2 - Parameters table

Configuration parameters protected by access code.

Note: F02 function allows to correct eventual shuting lines in the reading, proceeding of the sensor

exchangeoralterationofsensorlength.

(4)2nd stage operation

mode:

0 - refrigeration

1 - heating

2 - alarm (inside of

range)

3 - alarm (outside of

range)

4 - relative alarm

(outside of range)

(1)First stage

operation mode:

0 - refrigeration

1 - heating

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

Access code 123 (one hundred and twenty-three)

Display (offset) (1)

1st stage operation mode

Minimum setpoint allowed to the end user (1st stage)

Maximum setpoint allowed to the end user (1st stage)

Control differential (hysteresis) of 1st stage

Minimum delay to turn on the 1st stage output

(2)

2nd stage operation mode

Minimum setpoint allowed to the end user (2nd stage)

Maximum setpoint allowed to the end user (2nd stage)

Control differential (hysteresis) of 2nd stage

Minimum delay to turn on the 2nd stage output

Alarm delay when the instrument is powered on

Alarm output time on

Alarm output time off

-

-5.0

0

-50

-50

0.1

0

0

-50

-50

0.1

0

0

0

0

-

5.0

1

105

105

20.0

999

4

105

105

20.0

999

999

999

999

-

°C

-

°C

°C

°C

sec.

-

°C

°C

°C

sec.

min.

sec.

sec.

4.3 - Parameters alteration

Accessthe functionF01 pressing simultaneouslythe keys and for 2 secondsuntil appearing

,releasingafterthat.Soonitwillappear ,andthenpress (shorttouch).

-Usethekeys and toenterwiththeaccesscode(123),andthenpress toenter.

-Usethekeys and toaccessthedesiredfunction.

-Afterselectingthefunction,press (shorttouch)todisplaythe configuredvalueforthatfunction.

-Usethekeys and tochangethevalueandthenpress torecordthenewvalueandreturn

tothefunctionsmenu.

-Toreturntothenormaloperation,press until appear.

5. FUCTIONS WITH FACILITATED ACCESS

Registers of minimum and maximum temperatures

Press . The minimum registered temperature appears and after soon the maximum registered

temperature.

Nota: To reset the registers, keep the key pressed during the visualization of the minimum and

maximumtemperaturesuntil tobeshowed.

SET

SET

SET

SET

SET

If the instrument is configured as alarm, set the F09 and F10 act points normally and ignore ST2 and

F11.Ifthetemperaturegoesoutthespecifiedrangeandringthealarm,press and toinhibitthe

sound.

6. SIGNALING

ST1 -1ststageoutputon

ST2 -2ndstageoutputon

-Detachedsensorortemperatureoutsidethespecifiedrange

With F08=4 the ST2 output is activated when the temperature reaches a value equal ST1 minus the

configurated value in F09 (ST1-F09), or when the temperature reaches a value equal ST1 plus the

configuratedvalueinF10(ST1+F10)

Ex.:

- Temperature in ST1 = 25 ºC

- Value in F08 = 4

- Value in F09 = 2

- Value in F10 = 5

TheST2 outputwillbekeptonwhenthetemperatureisbelow23ºC(25-2)orabove30ºC(25+5).IfST1

valueischangedto24ºCthealarmvalueswillbeautomaticallymodifiedto22and29ºC.

IF the functions F14 and F15 are set with zero, the ST2 output will be kepped on while the alarm

conditionpersist.

SET

ensoS r

Power

supply

Load 1

COMMON

Loads

supply

ST1 (NO)

ST2 (NO)

12345678910 11 12

115 V

(12 V)

230 V

(24 V)

0

72 mm

29 mm

7. WIRING DIAGRAM

7 - 8

7 - 9 115V

230V 12V

24V

MT-518Ri MT-518RiL

Load 2

- Refrigerator

- Heating

- Contactor

- Solenoid

- Refrigerator

- Heating

- Contactor

- Solenoid

Load 1 Load 2

Above specified current use contactors.

Dimension of the clipping for

setting of the instrument

IMPORTANT

For more information contact our application eng. department through e-mail

support@ fullgauge.com or dial +55 51 3475.3308.

AccordingtothechaptersofnormIEC60364:

1: Installprotectoragainstovervoltageonthepowersupply

2: Sensorcablesandsignal cables ofthe computer maybe joined, butnotin the sameelectric conduit

throughwhichtheelectricinputandtheactivationoftheloadsrun

3: Install transient suppresors (RC filters) parallel to the loads as to increase the product life of the

relays.

Contact suppresor connection diagram

Suppresor

A1

A2

A1 e A2 are the

contactor coils.

Diagram for suppresor installation

for direct drive load inputs

Load

Suppresor

For direct activation the maximum

specified current should be taken

into consideration.

Note: Theusercanincreasethelengthofthesensorcabletoupto200meters,byusingPP2X24AWG

cable.Forimmersioninwater,usethermometricwell.

PROTECTIVE VINYL:

This adhesive vinyl (included inside the packing) protects the instruments against

waterdrippings,asincommercialrefrigerators,forexample.

Dotheapplicationafterfinishingtheelectricalconnections.

Remove the protective paper

andapplythevinylontheentire

superior part of the device,

foldingtheflapsasindicatedby

thearrows.