Furuno CH-37 User manual

Other Furuno Sonar manuals

Furuno

Furuno FSV-75 User manual

Furuno

Furuno CH-500 User manual

Furuno

Furuno CH-34/36 User manual

Furuno

Furuno FCV-1000 User manual

Furuno

Furuno CH-37BB User manual

Furuno

Furuno CH-18 User manual

Furuno

Furuno COLOR SCANNING CSH-55 User manual

Furuno

Furuno COLOR SCANNING CSH-23F/24F User manual

Furuno

Furuno CSH-53 User manual

Furuno

Furuno FCV-381 User manual

Furuno

Furuno CH-37 User manual

Furuno

Furuno CSH-21 User manual

Furuno

Furuno CSH-83 User manual

Furuno

Furuno Black Box Searchlight Sonar CH-250BB User manual

Furuno

Furuno CSH-8L User manual

Furuno

Furuno FSV-75 User manual

Furuno

Furuno DS-30 Manual

Furuno

Furuno FE-700 User manual

Furuno

Furuno FCV-582 User manual

Furuno

Furuno FSV-24 User manual

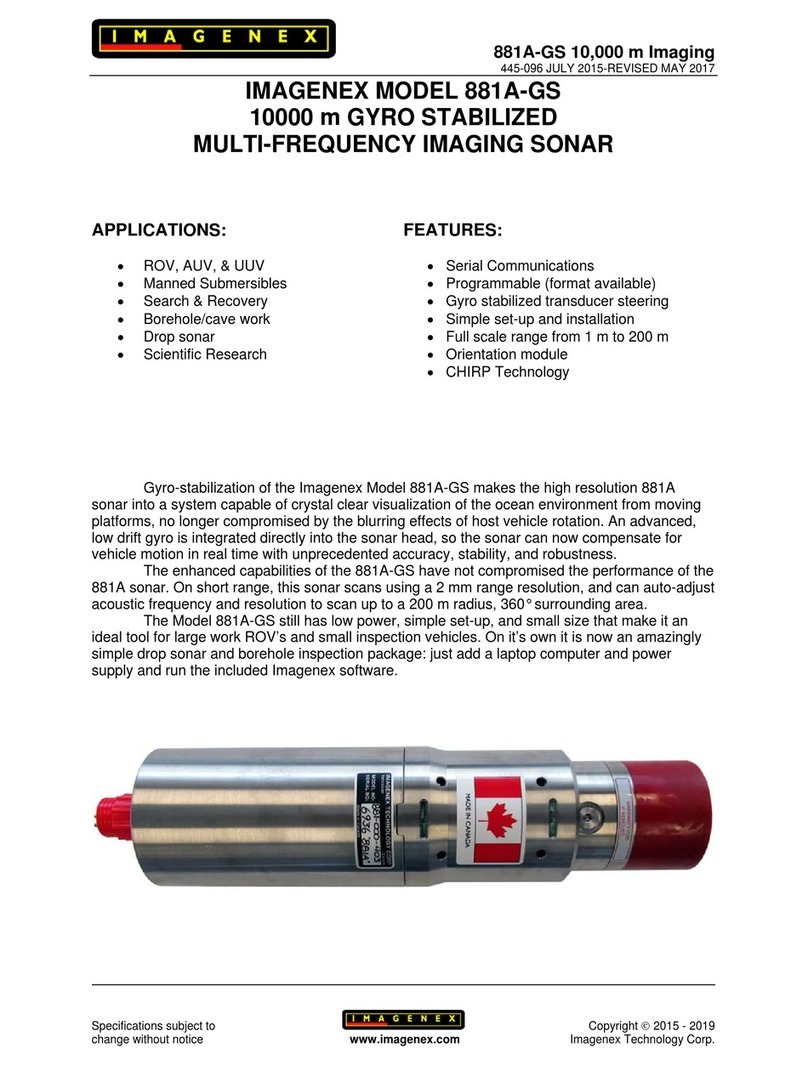

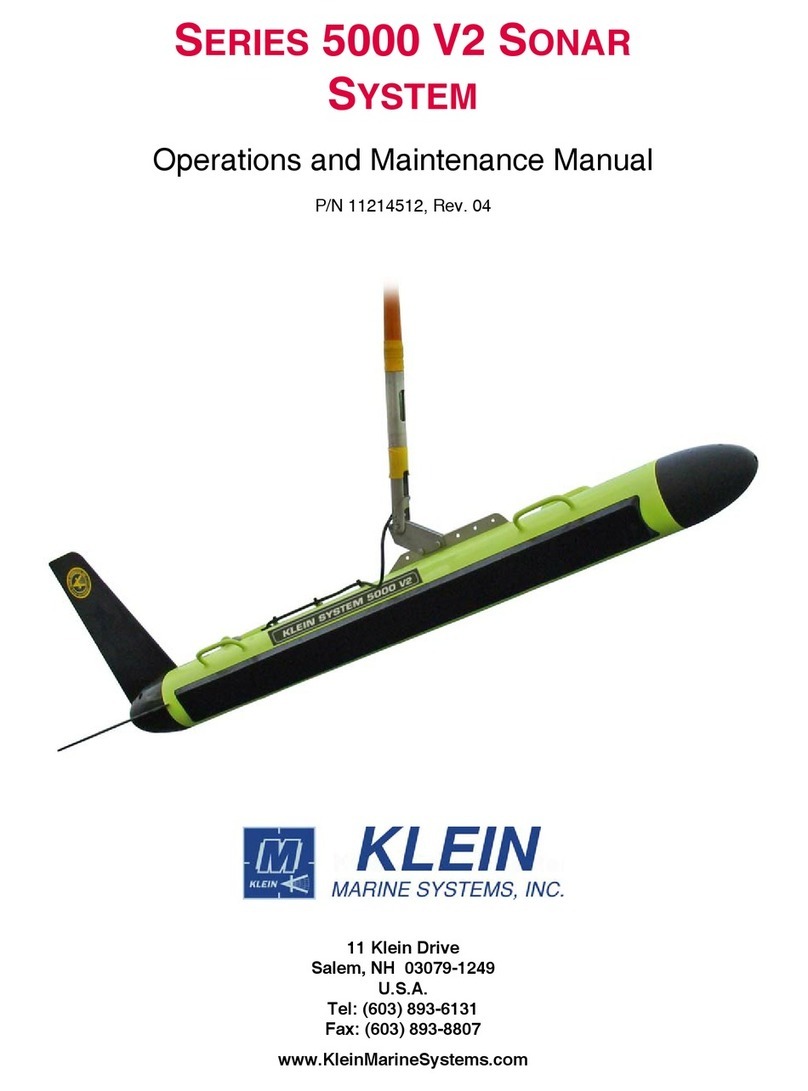

Popular Sonar manuals by other brands

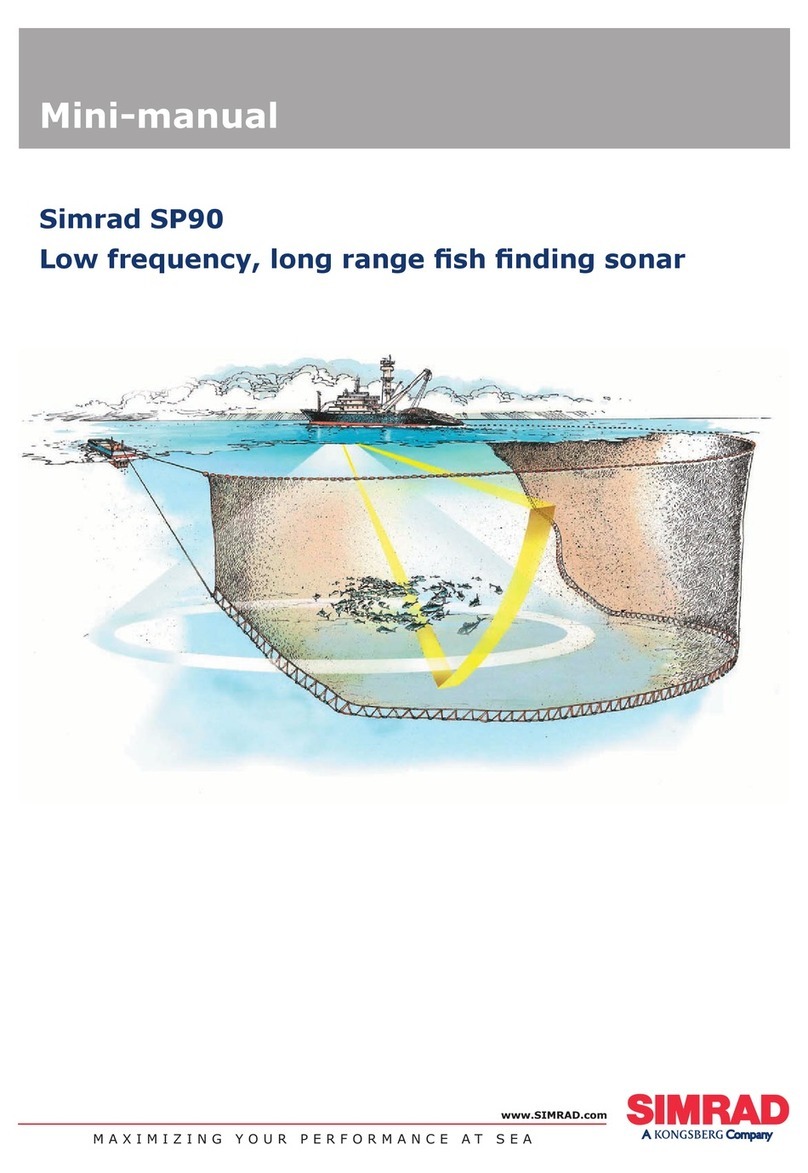

Kongsberg

Kongsberg Simrad SP90 Series manual

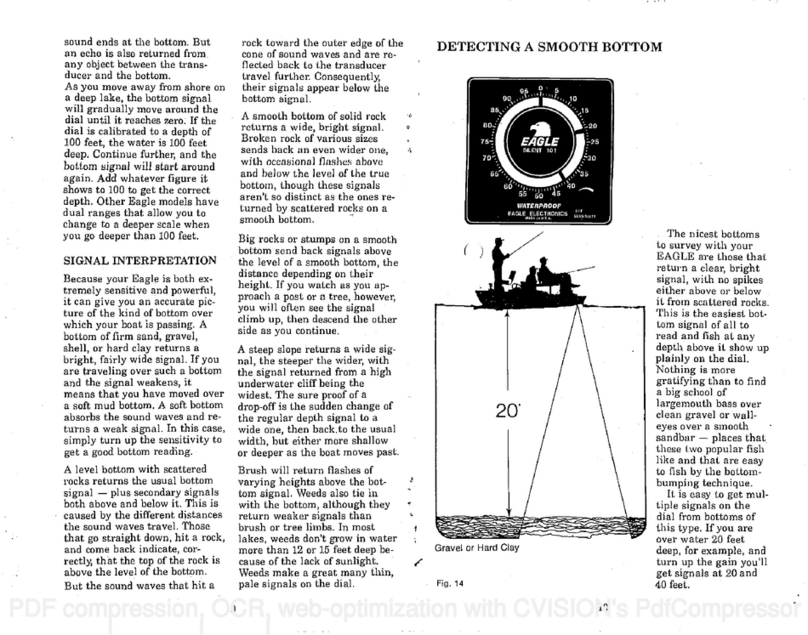

Eagle

Eagle TriFinder 2 Installation and operation instructions

Lowrance

Lowrance X-70A Installation and operation instructions

Lowrance

Lowrance LMS-150 GPS Installation and operation instructions

Simrad

Simrad EQ 55 Operator's manual

Lowrance

Lowrance Traditional Installation