it should be handled by a qualified organization.

The " " safety warning sign in the instrument and manual must be operated

strictly in accordance with the contents of this manual.

II.Introduction

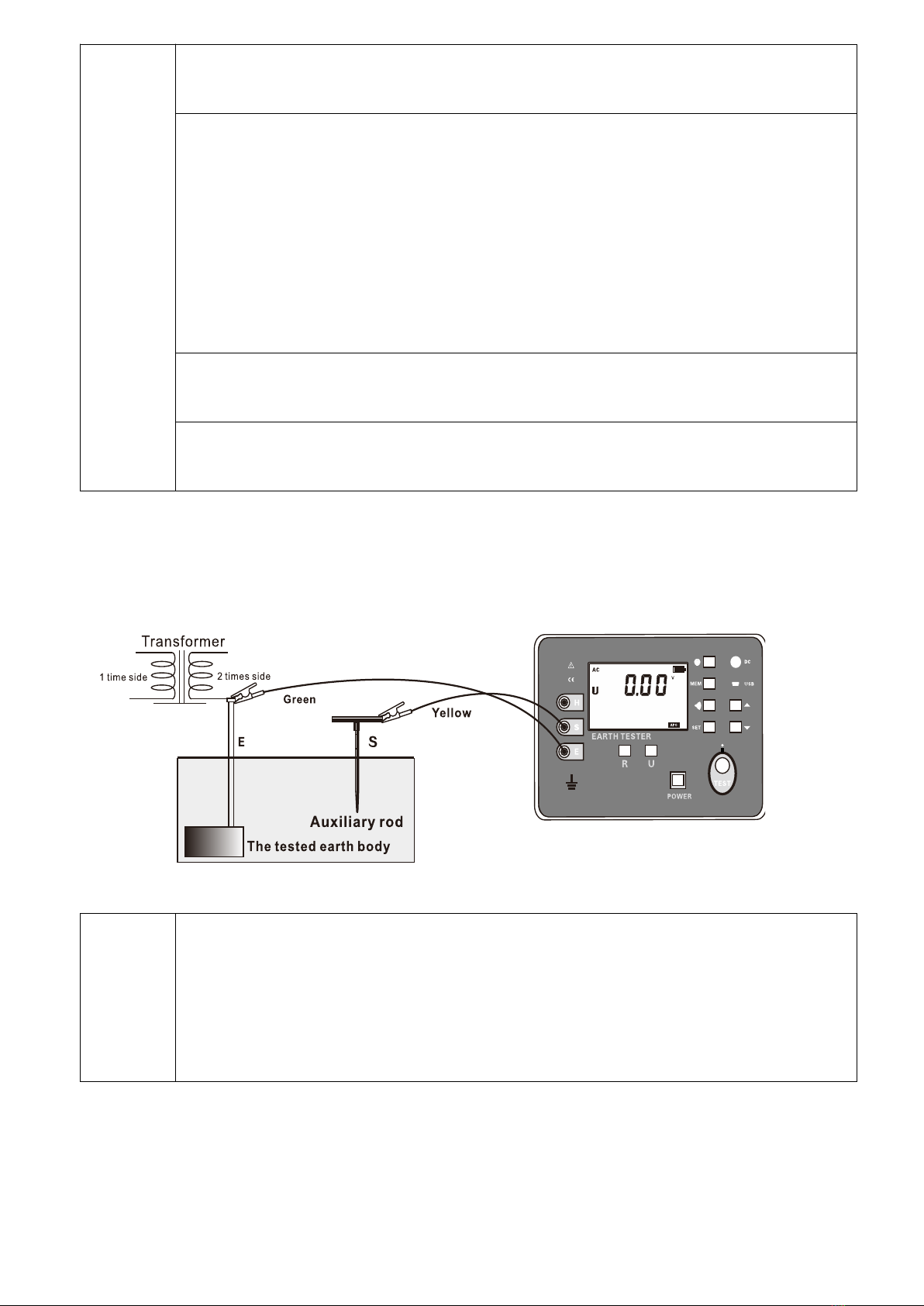

Digital grounding resistance tester, also known as the three-wire

grounding resistance tester, grounding resistance meter, etc., is a commonly

used meter for measuring grounding resistance. It adopts a large LCD

gray-white screen backlight display and microprocessor technology to meet

the requirements of two-wire and three-wire test resistance. Suitable for

telecommunications, electricity, meteorology, computer rooms, oil fields,

power distribution lines, iron tower transmission lines, gas stations,

factory grounding networks, lightning rods and so on. Instrument testing is

precise, fast, simple, stable and reliable.

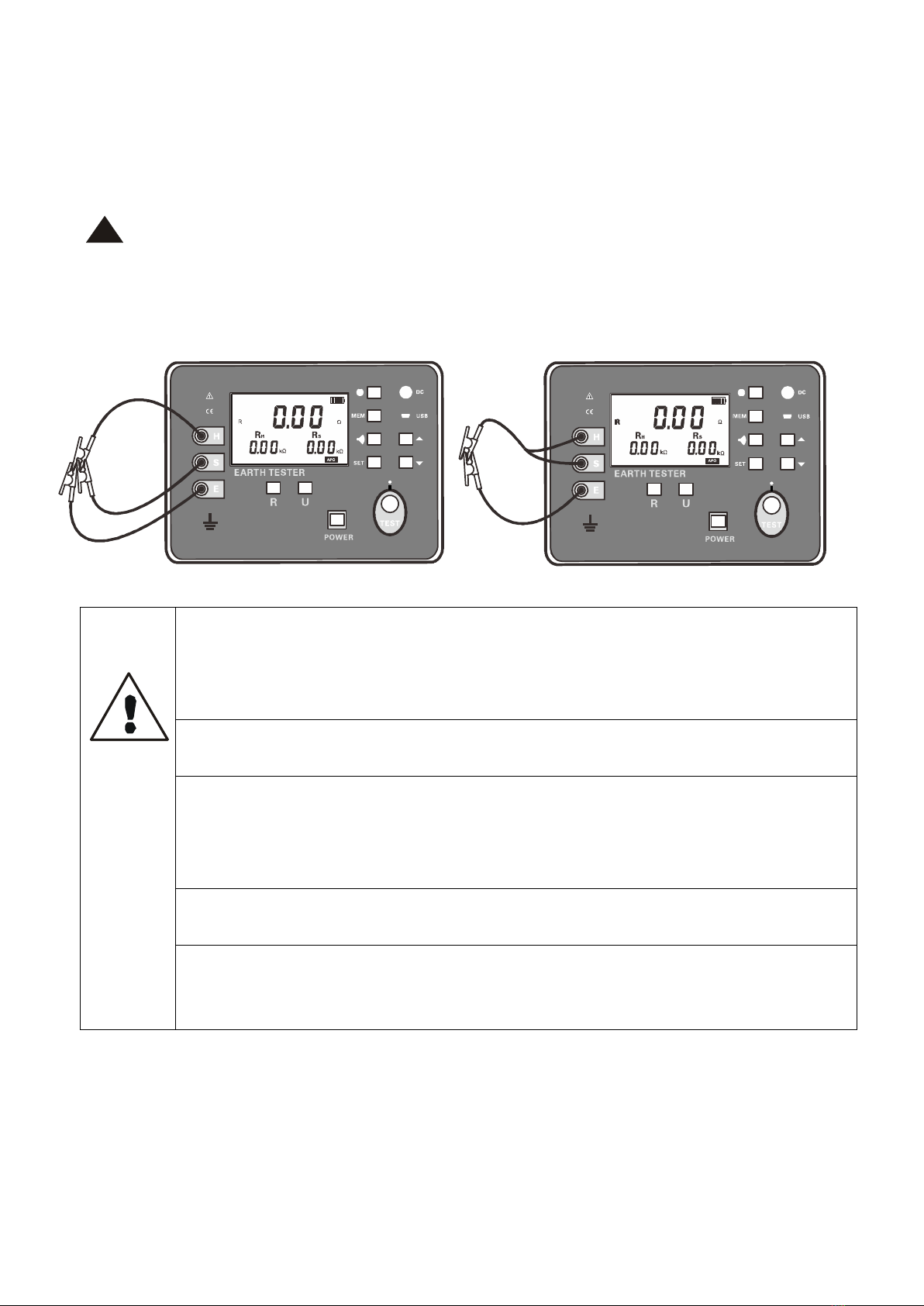

The digital grounding resistance tester is controlled by the

microprocessor and can automatically detect the connection status of each

interface and the interference voltage and interference frequency of the

ground network, and has the function of testing the auxiliary grounding

resistance value. At the same time store 500 sets of data, resistance

measurement range: 0.01Ω ~ 3000Ω, grounding voltage range: 0.01 ~ 100.0V.

Online monitoring data through monitoring software, USB data uploaded to PC

and unique features such as intelligent alarm alert

The digital grounding resistance tester consists of host, monitoring

software, test line, USB cable, and grounding rod. It has the functions of

reading, checking, saving, reporting and printing of historical data.

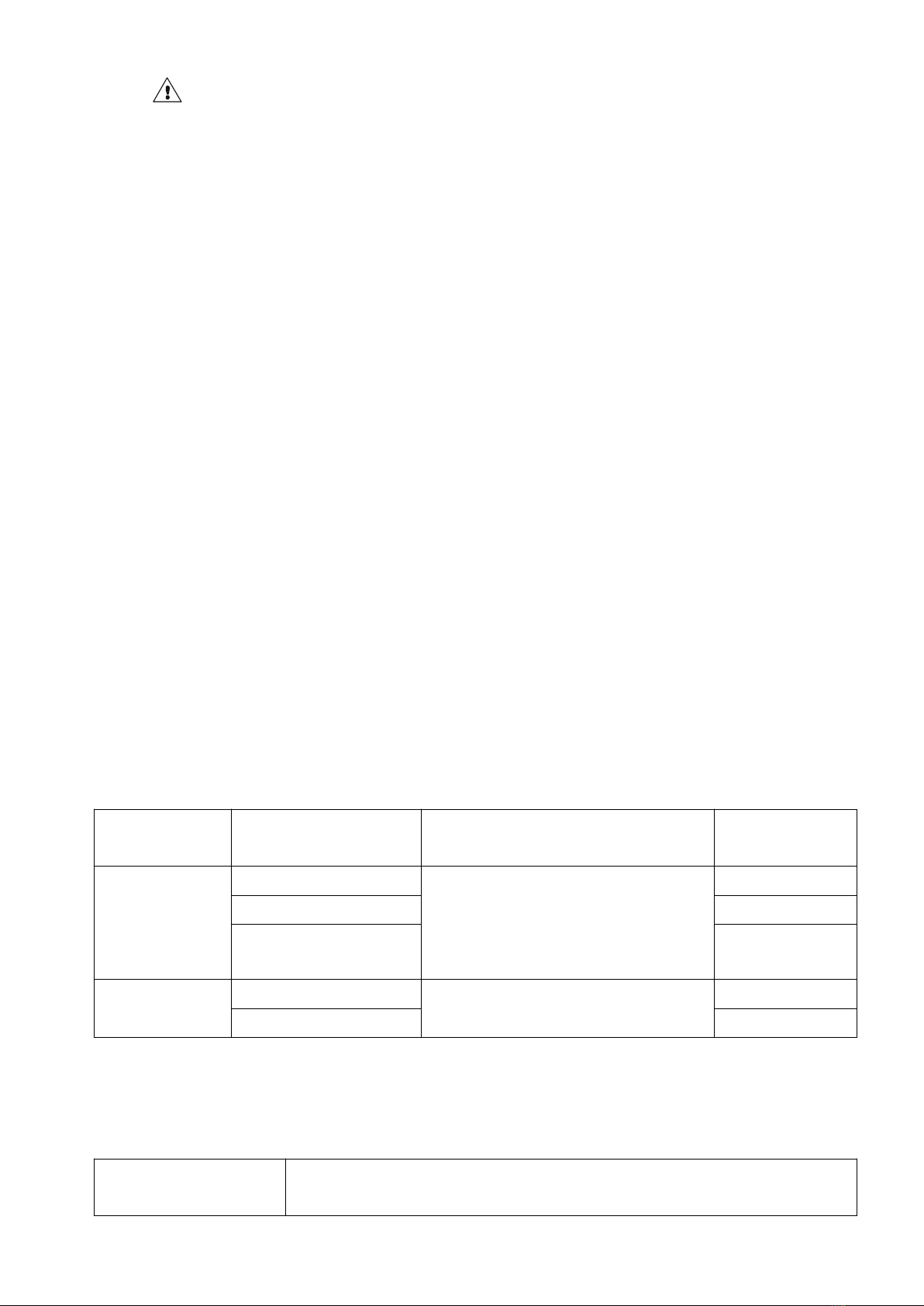

III. Rang and Accuracy

±1.5%rdg±5dgt

(Auxiliary ground

resistance 100Ω ± 5%,

voltage to ground <10V)

(Remark:23℃±5℃,below 75%rh)

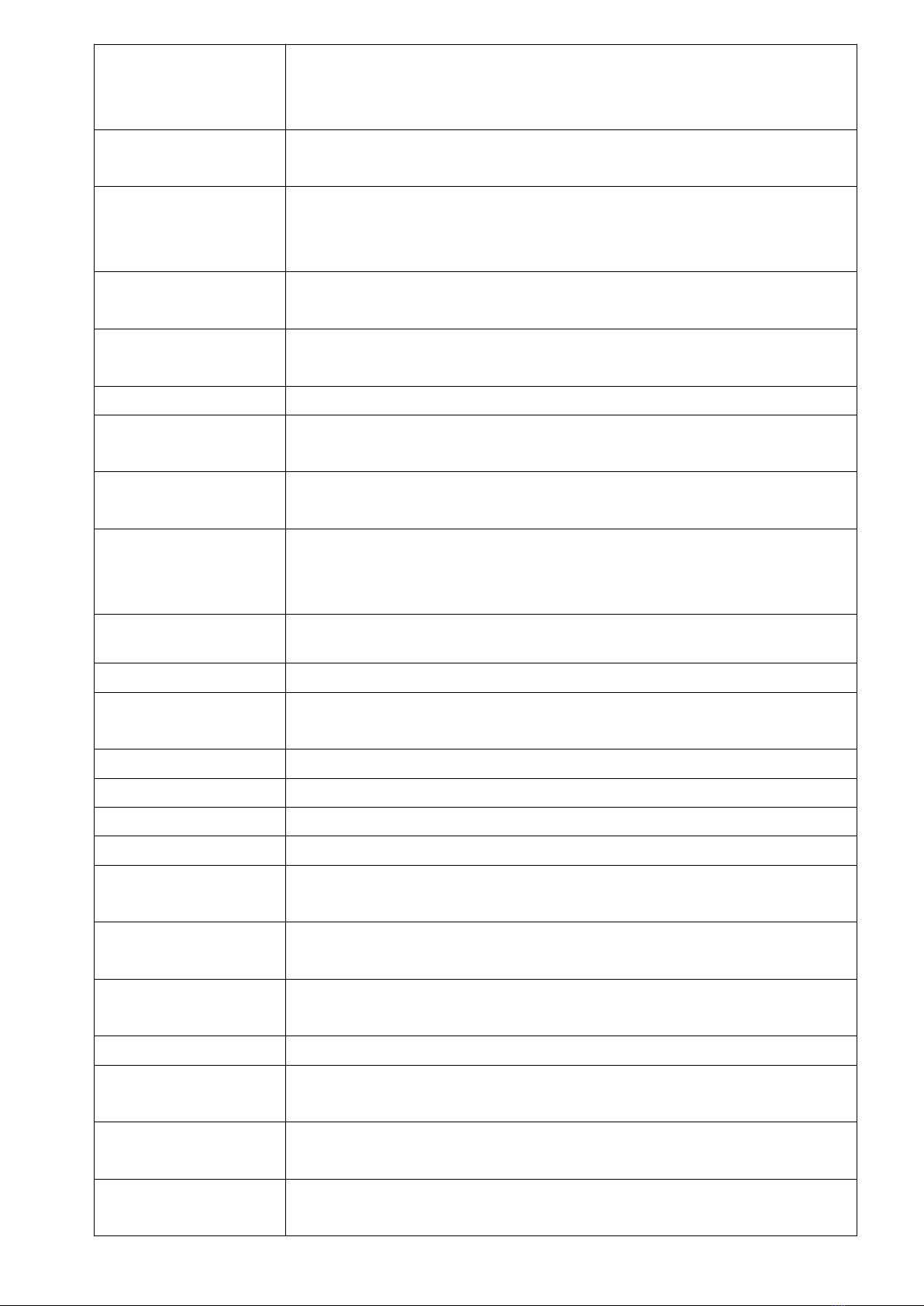

IV.Technical Specifications

Grounding

Resistance Range

0.01Ω~3000Ω Accuracy ±1.5%rdg±5dgt