CAUTION: HOLDING FOOD AT TEMPERATURES

OF LESS THAN 140°F (60°F) MAY BE DANGEROUS.

TEMPERATURES UNDER 140°F (60°F) PROMOTE THE GROWTH

OF HARMFUL BACTERIA AND TOXINS IN SOME FOODS.

3

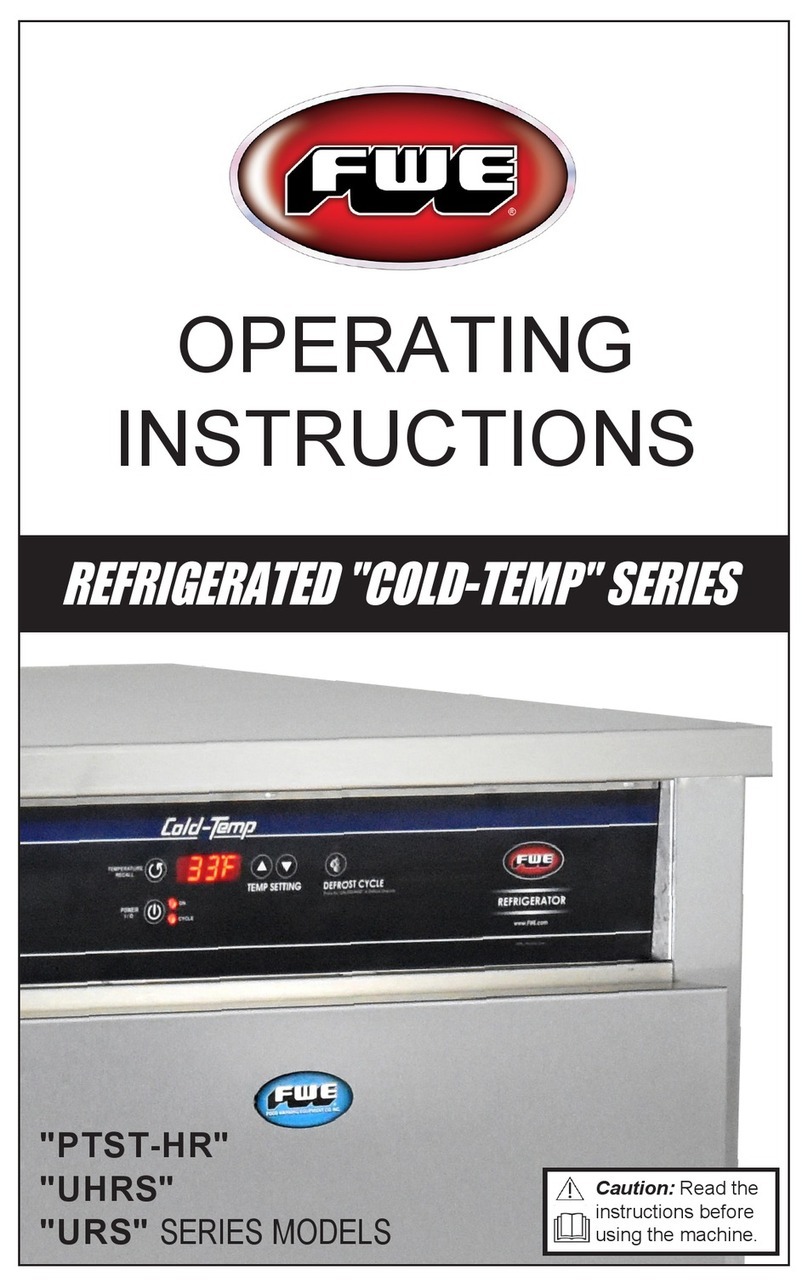

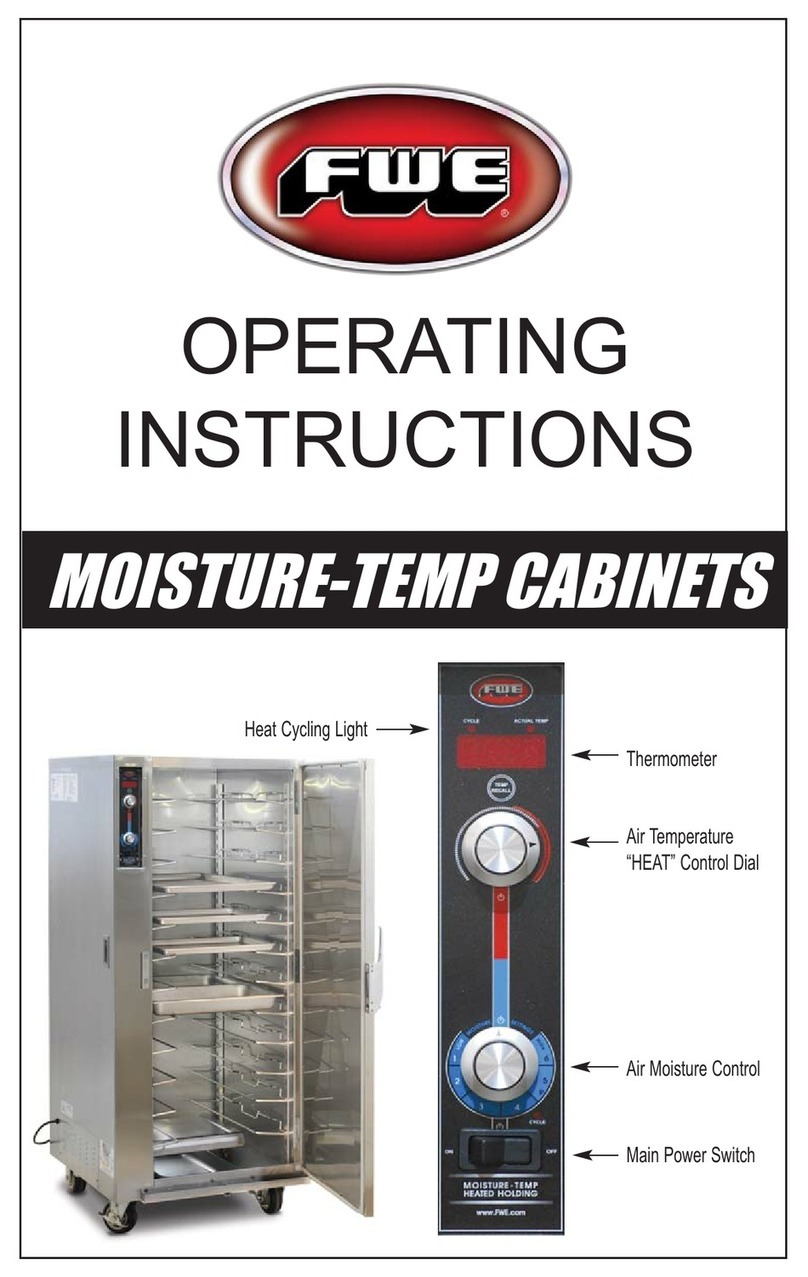

FOOD SENTRY SYSTEM

ON/OFF

Button TEMPERATURE OF

CABINET SET DIAL FOR

TEMPERATURE

LOW

TEMP

ALARM

RECALL

TEMP

SET

POINT

INDICATOR

LIGHTS

Q

Low Temp Alarm -

NOTE:THE FACTORY DEFAULT FORTHIS FEATURE IS IN THE “OFF”

OR DISABLED MODE.

Unit has a built in

“Low Temp”

alarm, allowing the operator

to have an audible and a visual indicator that the heated

cabinet has dropped below the

“Low Temperature”

set

point for more than two (2) minutes.

1.)

Adjust Set Point:

Press and hold

“Low Temp Alarm”

key. While holding,

rotate dial to desired set point between

“OFF”

and from 90°F (32°C) and

190°F (88°C). Release button to accept adjustments. When the internal

cabinet temperature falls below this “Set Point” for more than two (2)

minutes, the audible and visual alarm will alert you to this condition.

2.)

Recall Set Point:

Press

“Low Temp Alarm”

key to recall setting.

The display reverts back to the normal display after three (3) seconds.

3.)

Acknowledge:

Press any key to cancel beeping and flashing LED.

The LED remains lit until the temperature rises above the alarm set point.

4.)

Disable:

Follow the adjustment steps above.

A rotation of the dial

“down”

below 90°F (32°C) turns the alarm feature off.

Recall Temp

Set Point -

Unit may display either

“Actual Internal Cabinet”

actual temperature,

or desired

“Set Point”

temperature.

Actual:

The factory default setting

shows the actual internal cabinet

temperature and acts as a digital

thermometer. A momentary touch of

the

“Recall Temp Set Point”

key will

recall the original dial setting.The

display will then automatically return

to the actual internal temperature.

Set Point:

To have temperature read-out

display the

“Set Point”

temperature,

press and hold the

“Temp”

key for five

(5) seconds.The fourth (4th) digit on

the display will flash either

“S”

(Set), or

“A”

(Actual) to indicate which mode is

active.To switch back again, repeat this

step holding the

“Recall Temp Set”

key

for five (5) seconds. Low Temp Alarm

Indicator Light -

The

“Low Temp Alarm”

light will blink while setting the

“Low Temp Set Point”

.

When the temperature falls below the

“Low Temp”

set point, the indicator

light will blink until the alarm is cancelled/acknowledged.The light will remain

illuminated until the interior cabinet temperature reaches above the

“Low Temp Set Point”

again.

Q

Q

On/Off Switch -

A.) Turns cabinet on and off.

B.) °Celsius and °Fahrenheit Scale:

You may change the Digital thermometer

scale to either °C or °F as follows:

While unit is “Off”, press and hold the

“ON/OFF”

key for five (5) seconds.

The display will then switch from

“dgF” to

“dgC”

.Repeat to change scale again.

Dial -

Use dial to set the desired temperature.

Dial rotates completely.

Power Indicator Light -

Indicates that the power is on.

Cycling Indicator Light -

When light is

“ON”

, this indicates that the

cabinet is warming up to desired temperature.

When heating elements are activated, light will

come

“ON”

until cabinet has reached desired

temperature, and go

“OFF”

when unit has

reached desired temperature.

Temp Display -

Digital temperature display:

A.)°Celsius and °Fahrenheit Scale:You may

change the Digital thermometer scale to either

°C or °F as follows:While unit is

“Off”

, press

and hold the

“ON/OFF”

key for five (5)

seconds.The display will then switch from

“dgF” to “dgC”

.Repeat to change scale again.

B.)Unit may be set to show either actual

internal temperature, or

“Set Point

Temperature”.

(See

“Recall Temp Set Point”

)

®

Food Warming Equipment Company

7900 South Route 31

Crystal Lake, Illinois 60014

Phone:815-459-7500

Fax: 815-459-7989

sales@fweco.com

UICK-

S

TART

GUIDE