8

INTRODUCTION

Thankyou for purchasing this product which has

passed through our extensive quality assurance

process. Every care has been taken to ensure that it

reaches you in perfect condition.

SAFETY FIRST

Before attempting to operate this power tool the

following basic safety precautions should always be

taken to reduce the risk of fire, electric shock and

personal injury. It is important to read the instruction

manual to understand the application, limitations and

potential hazards associated with this tool.

CERTIFICATE OF GUARANTEE

This product is guaranteed for a period of 2 Years,

with effect from the date of purchase and applies only

to the original purchaser. This guarantee only applies

to defects arising from, defective materials and or

faulty workmanship that become evident during the

guarantee period only and does not include

consumable items. The manufacturer will repair or

replace the product at their discretion subject to the

following. That the product has been used in

accordance with the guide lines as detailed in the

product manual and that it has not been

subjected to misuse, abuse or used for a purpose for

which it was not intended. That it has not been taken

apart or tampered with in any way whatsoever or has

been serviced by unauthorised persons or has been

used for hire purposes. Transit damage is excluded

from this guarantee, for such damage the transport

company is responsible. Claims made under this

guarantee must be made in the first instance, directly

to the retailer within the guarantee period. Only under

exceptional circumstances should the product be

returned to the manufacturer. In these case it shall be

the consumer’s responsibility to return the product at

their cost ensuring that the product is adequately

packed to prevent transit damage and must be

accompanied with a brief description of the fault and

a copy of the receipt or other proof of purchase. The

manufacturer shall not be liable for any special,

exemplary, direct, indirect, incidental, or consequential

loss or damage under this guarantee. This guarantee

is in addition to and does not affect any rights, which

the consumer may have by virtue of the Sale of Goods

Act 1973 as amended 1975 and 1999.

STATUTORY RIGHTS

This guarantee is in addition to and in no way affects

your statutory rights.

PRODUCT DISPOSAL

When this product reaches the end of it’s life or is

disposed of for any other reason, it must not be

disposed of in household waste. In order to preserve

natural resources, and to minimise adverse

environmental impact, please recycle or dispose of

this product in an environmentally friendly way. It

should be taken to your local waste recycling centre

or other authorised collection and disposal facility.

If in doubt consult your local waste authority for

information regarding available recycling and / or

disposal options.

HEALTH ADVICE

Warning: When drilling, sanding, sawing or grinding,

dust particles will be produced. In some instances,

depending on the materials you are working with, this

dust can be particularly harmful to you (e.g. lead from

old gloss paint).You are advised to consider the risks

associated with the materials you are working with

and to reduce the risk of exposure.

You should:

Work in a well-ventilated area.

Work with approved safety equipment, such as dust

masks that are specially designed to filter microscopic

particles.

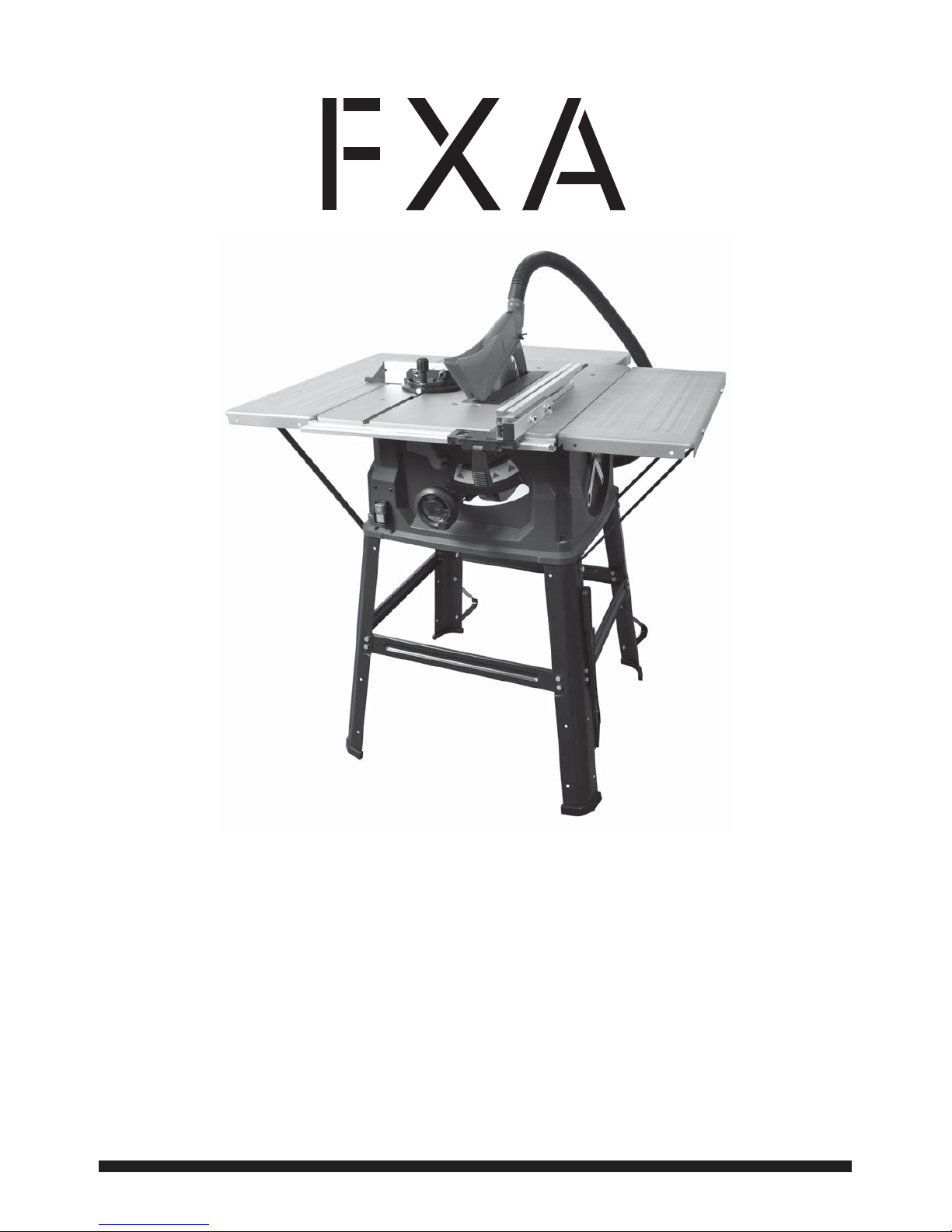

INTENDED USE

The bench-type circular saw is designed for the

slitting and cross-cutting of all types of timber,

commensurate with the machine’s size.

The machine is not to be used for cutting any type of

roundwood.

The machine is to be used only for its prescribed

purpose. Any use other than that mentioned is

considered to be a case of misuse.

The user/operator and not the manufacturer shall be

liable for any damage or injury resulting such cases of

misuse. The user/operator and not the manufacturer

shall be liable for any damage or injury resulting such

cases of misuse.

The machine is to be operated only with suitable saw

blades. It is prohibited to use any type of cutting-off

wheel. To use the machine properly you must also

observe the safety regulations, the assembly

instructions and the operating instructions to be found

in this manual. All persons who use and service the

machine have to be acquainted with this manual and

must be informed about its potential hazards. It is also

imperative to observe the accident prevention

regulations in force in your area. The same applies for

the general rules of occupational health and safety.

Important! When using the equipment, a few safety

precautions must be observed to avoid injuries and

damage. Please read the complete operating

instructions and safety regulations with due care.

Keep this manual in a safe place, so that the

information is available at all times. If you give the

equipment to any other person, hand over these

operating instructions and safety regulations as well.

We cannot accept any liability for damage or

accidents which arise due to a failure to follow these

instructions and the safety instructions.

The manufacturer shall not be liable for any changes

made to the machine nor for any damage resulting

from such changes.