TECHNICAL MANUAL

P/N 703073 Rev C CoolSystems, Inc. – Confidential Proprietary Page 8 of 43

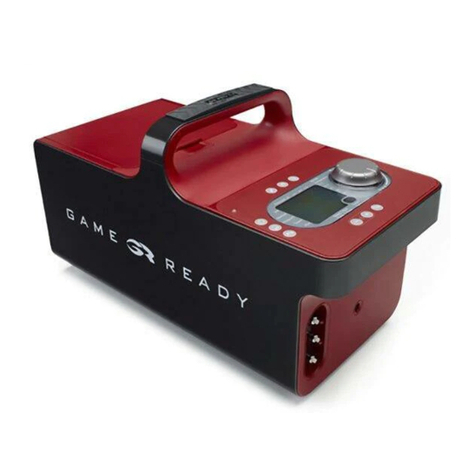

Temperature Control for GR2.1 Control Units

GR2.1 Control Units utilize a patented temperature control system. The temperature

control knob is connected to a digital encoder and allows the user to set the desired

temperature (Target Temp.). The Control unit will adjust the fluid pump speed to deliver

water from the Control Unit at a temperature close to the Target Temp. This is achieved

by using a Baffle inside the GR2.1 ice box. Water returning from the Wrap is typically

warmed by the user’s body heat. If the water is moving fast (high pump speed), it is sent

far into the ice box and readily mixes with the ice and water and cold water is drawn into

the baffles. If the water returns more slowly, it falls within the baffle walls and the water

temperature inside the baffles becomes warmer than the temperature in the rest of the

ice box. Therefore, by varying the pump speed, the temperature of the water leaving the

Control Unit may be controlled. This is all done by the Control unit automatically.

This is a significant improvement over other variable flow rate temperature control

systems. With other systems, the water leaving the Control Unit is still ice cold, and in

order to achieve a desired “Average Wrap Temperature”, much lower flow rates would be

required, which leads to significant temperature variation within the Wrap which is

undesirable.

Temperature of the water is measured at only one place in the GR 2.1 Control Units - just

before leaving the Control Unit (T1). Two different temperatures are displayed on the

Control Panel. The “Target Temperature” is the desired temperature, or temperature

“set” by the user. The “Actual Temperature” is the temperature of the water leaving the

Control Unit (T1).

The following notes regarding the GR2.1 Control Unit also may be of interest:

•When set to “full cold” the fluid pump will always pump at full speed regardless of the

water temperature.

•If the ice box runs low on ice, there may not be enough ice to achieve desired Target

Temperature.

•If the ice box is too full of water (i.e. above the return nozzle) the ability to regulate to

warmer temperatures may be limited. Always fill the Control Unit according to the

user manual and Fill Labels inside the ice box.

•When the “Play” button is pressed, water will flow at 100% until return flow is sensed

by the flow measurement system inside the Control Unit. Once return flow is sensed,

the fluid pump will modulate in order to achieve its Target Temperature.

•The maximum set point on a GR2.1 is 50°F (10°C). If warmer temperatures are desired,

less or no ice may be used, but the Control Unit will not be able to control

temperature above 50°F, and the fluid pump will pump at full speed during treatment.

CoolSystems Inc., Effective Date: 12/23/14