GAS GC-IMS-SILOX User manual

G.A.S. Gesellschaft für

analytische Sensorsysteme mbH

GC-IMS-SILOX

USER MANUAL

1

GC-IMS-SILOX – User Manual

Version 1.4.0, March 2021

All data, texts, designs, images and other elements used in this user manual are

protected by copyright law. Any infringement may be subject to legal action.

Passing it on to third parties and producing copies of any kind or form –on the

whole or in parts - is not permitted without written agreement of G.A.S. Any

infringement may be subject to legal action.

G.A.S. reserves the right to realize technical changes to the product without

explicitly mentioning them.

CE-Marking according to:

International Standard EN ISO 17050-1:2004

European Union Low Voltage Directive 2006/95/EC

European Union Electromagnetic Compatibility Directive 2004/108/EC

© Copyright 2015-2021

G.A.S. Gesellschaft für analytische Sensorsysteme mbH

44227 Dortmund - Germany

All Rights Reserved.

2

Table of Content

1Preface..................................................................................5

1.1 Symbols Used in this User Manual ...........................................5

1.2 Notation for Describing Dialogs and Elements in Dialogs ................6

1.3 Liability and Guarantee ......................................................6

1.4 Return and Disposal ...........................................................7

1.5 Packing..........................................................................7

1.6 Transport .......................................................................8

1.7 Software Updates..............................................................8

1.8 Contacting G.A.S. .............................................................8

2Safety ................................................................................. 10

2.1 Intended Usage Only ........................................................ 10

2.2 Responsibilities of the Operator........................................... 10

2.3 Ionization Source ............................................................ 11

2.4 Explosion Protection ........................................................ 11

2.5 Protection from High Voltage.............................................. 12

3Scope of Supply and Storage Conditions ......................................... 13

3.1 Scope of Supply .............................................................. 13

3.2 Storage Conditions .......................................................... 14

4Cleaning of the Housing and Maintenance ....................................... 15

4.1 Cleaning of the Housing .................................................... 15

4.2 Maintenance.................................................................. 15

5Intended Use and Working Principle.............................................. 16

5.1 Intended Use ................................................................. 16

5.2 Calculating Concentrations ................................................ 16

5.3 Working Principle and Internal Gas Flow................................. 18

6Workflow: Physical Setup .......................................................... 21

6.1 Housing of the Device....................................................... 21

6.2 Device Type/Serial Number Plate on the Rear Side .................... 23

6.3 Unpacking, Placement and Connections ................................. 24

7Workflow: Initial Operation / Cleaning .......................................... 29

7.1 Using the Cleaning Mode ................................................... 29

3

7.2 Workflow ..................................................................... 29

8Device Parameters During Measurements and Standby ........................ 32

8.1 Introduction .................................................................. 32

8.2 Values ......................................................................... 32

9Workflow: Single Manual Measurement .......................................... 33

9.1 Introduction .................................................................. 33

9.2 Workflow ..................................................................... 34

10 Workflow: Manual Calibration ..................................................... 38

10.1 Introduction .................................................................. 38

10.2 Workflow ..................................................................... 38

11 Workflow: Running Automatic Measurements................................... 42

11.1 Introduction to the Interval Mode ........................................ 42

11.2 Workflow ..................................................................... 43

12 Workflow: Current Loop Setup .................................................... 49

12.1 Introduction .................................................................. 49

12.2 Electrical Interface ......................................................... 50

12.3 Configuring the Current Loop.............................................. 50

13 Workflow: Tag Lists ................................................................. 53

13.1 Introduction .................................................................. 53

13.2 Creating and Editing Tag Lists............................................. 54

13.3 Usage.......................................................................... 57

13.4 Exporting Tag Lists .......................................................... 59

13.5 Importing Tag Lists.......................................................... 62

14 Workflow: File Transfer Setup .................................................... 66

14.1 Overview...................................................................... 66

14.2 Connecting to a Server in a LAN .......................................... 68

15 Workflow: PDF Reports - Setup and Usage...................................... 74

15.1 Introduction .................................................................. 74

15.2 Workflow ..................................................................... 76

16 Workflow: Firmware Upgrade ..................................................... 80

16.1 Introduction .................................................................. 80

16.2 Workflow ..................................................................... 81

17 Graphical User Interface ........................................................... 84

17.1 Introduction .................................................................. 84

4

17.2 Start Page..................................................................... 85

17.2.1 Overview ............................................................ 85

17.2.2 Results View ........................................................ 87

17.2.3 Scope View.......................................................... 88

17.3 MEA Mode Start Dialog ...................................................... 89

17.4 Calibration Mode Start Dialog ............................................. 90

17.5 Substances and the Substance Calibration Dialog ...................... 91

17.6 Interval Mode Start Dialog ................................................. 93

17.7 Date and Time Input Dialogs ............................................... 95

17.8 Status Bar..................................................................... 97

17.9 Substances Page ............................................................. 99

17.10 System Page .................................................................100

17.10.1 System Page Info Tab............................................. 101

17.10.2 System Page Plan Tab ............................................102

17.10.3 System Page Settings Tab........................................ 103

17.10.4 System Page Transfer Tab .......................................107

17.10.5 The System Page Modes Tab ....................................109

17.11 Current Loop Settings Dialog .............................................110

17.12 Log Messages Dialog........................................................111

17.13 IP Address Input Dialog ....................................................112

17.14 Text Input Dialog ........................................................... 113

17.15 Number Input Dialog .......................................................113

18 Tag Lists File Formats.............................................................. 115

18.1 Overview.....................................................................115

18.2 CSV Format Specification..................................................115

18.3 JSON Format Specification ................................................116

19 Technical Specifications........................................................... 118

19.1 Measurement Ranges....................................................... 118

19.2 Device ........................................................................119

19.3 Current Loop Interface ....................................................121

19.4 Consumables ................................................................121

19.5 Ionization Source Specifications.......................................... 122

19.6 Modbus TCP Specification .................................................123

20 Calculating of silicon ’Total Si’ and silica ’Total SiO2’ in GC-IMS-SILOX ... 132

5

1Preface

1.1 Symbols Used in this User Manual

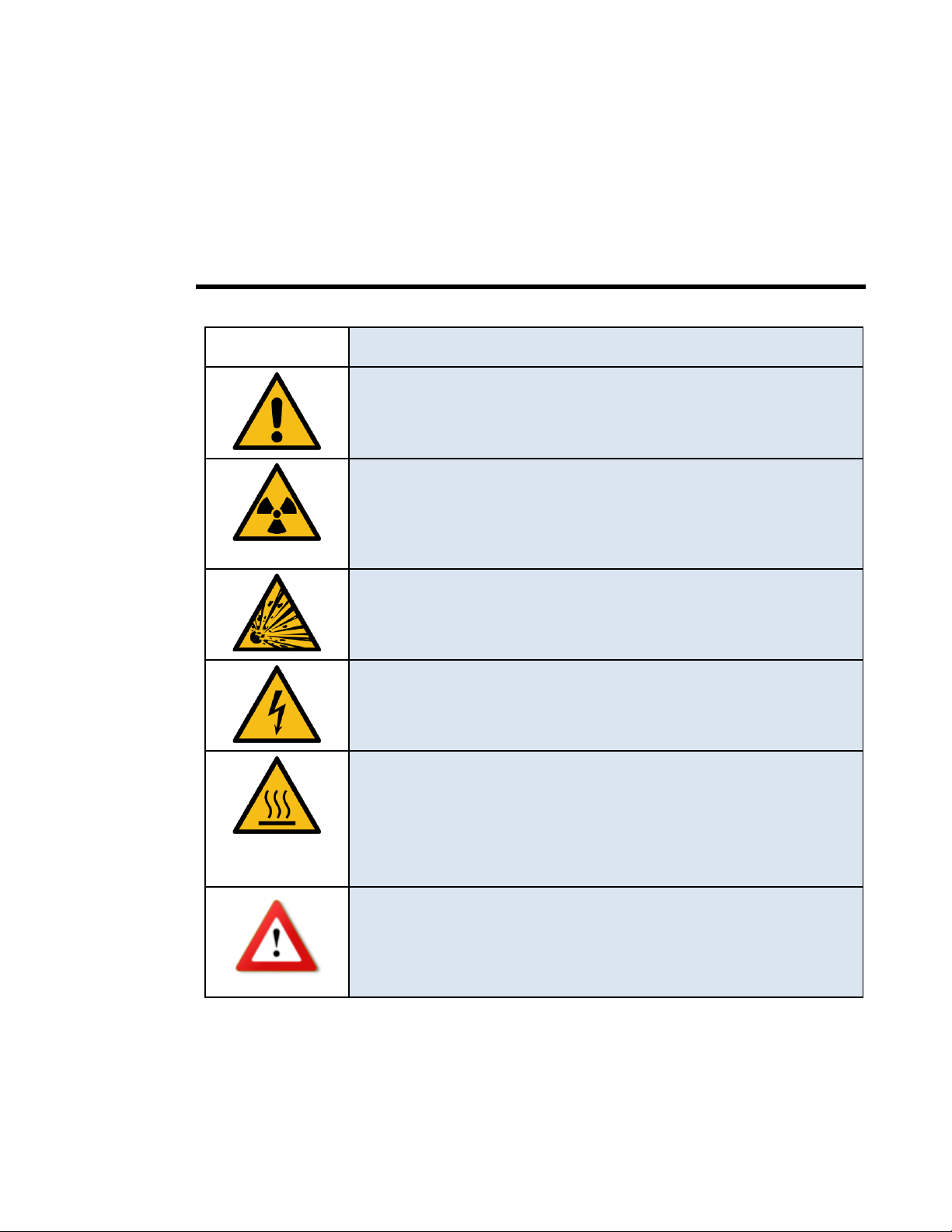

Symbol

Description

Danger

This symbol marks paragraphs that describe situations that

can potentially damage the device.

Danger –Radioactive Radiation

This symbol marks paragraphs that describe potential

dangers and damage due to exposure to radioactive

radiation.

Danger –Explosive Substances

This symbol marks paragraphs that describe potential

dangers and damage due to explosions.

Danger –High Voltage

This symbol marks paragraphs that describe potential

dangers to life and health due to electric current.

Danger - Hot Surface

This symbol marks paragraphs that describe situations in

which surface parts of the device can heat up to a point

where touching it or bringing objects close to it may be

hazardous.

Important

This symbol marks paragraphs that describe important

instructions or information that may prevent the operator

from making common mistakes.

6

1.2 Notation for Describing Dialogs and Elements in

Dialogs

Example:

System ›Connections ›LAN File Transfer ›Settings…›Test Connection

Describe the logical path for arriving in a particular dialog or at an element in

a dialog. In this example the path starts with the System page. On that page

the Connections page must be selected. On that page in the LAN File Transfer

row the button Settings… must be selected and in that dialog the button Test

Connection must be selected.

Example:

Gas Out, S-Free

Casing socket names, choice menu elements etc. are marked in this way.

1.3 Liability and Guarantee

This user manual describes the safe and proper handling of the device.

Usage other than described in this manual may damage the device

and/or harm persons involved.

Do not use the device for other purposes. Damages due to misuse are

not covered by the guarantee. Such damage claims will be rejected.

This user manual should be available to all personnel operating the device.

7

Follow the safety instructions in this manual and the national and/or local rules

and general safety regulations regarding the prevention of accidents at all

times.

Before starting to operate the device read the manual completely and

thoroughly. Make sure that all personnel operating the device understand the

instructions described.

G.A.S. does not assume any liability for damages resulting from neglect or

ignorance of the instructions in this manual or provided in other ways by G.A.S.

The graphics in this user manual are schematic and may differ from the actual

conditions. The firmware and PC software screen shots in this user manual may

slightly differ from the actual conditions.

The actual scope of supply might differ due to customization. For further

information please contact G.A.S.

1.4 Return and Disposal

For an appropriate disposal, the device and the associated equipment must be

returned to G.A.S. or to a third party authorized by G.A.S.

1.5 Packing

If no return agreement regarding the packing was agreed upon dispose the

packaging material always in an environmentally friendly way and according to

valid local regulations. If necessary, ask a recycling company.

8

1.6 Transport

To prevent damages to the equipment it should be moved only in the provided

carrying case.

Protective caps should be put on gas sockets in case the device is

stored or transported.

1.7 Software Updates

To receive information on available updates for the components of the system

please contact G.A.S. Gesellschaft für analytische Sensorsysteme mbH. If there

are any updates customers will be contacted by G.A.S. Gesellschaft für

analytische Sensorsysteme mbH as soon as the updates are available. Users will

be provided with information about the changes and instructions for executing

the updates.

1.8 Contacting G.A.S.

For questions concerning G.A.S. products a customer service is available:

9

G.A.S. Gesellschaft für analytische Sensorsysteme mbH

Otto-Hahn-Straße 15

44227 Dortmund

Germany

Phone: +49 (0) 231 / 97 42 - 65 50

Fax: +49 (0) 231 / 97 42 - 65 55

The telephone hotline is available from Monday to Friday from 9:00 to 16:00

hours. In urgent cases or if you use fax or email please provide a telephone

number for callbacks.

10

2 Safety

2.1 Intended Usage Only

Usage other than described in this manual may damage the device

and/or harm persons involved. Do not use the device for other

purposes. Damages due to misuse are not covered by the guarantee.

Such damage claims will be rejected.

2.2 Responsibilities of the Operator

The device should only be operated in a perfect technical condition. Before

putting the device into operation the condition of the device and its equipment

must be checked. The information and instructions provided in this manual must

be followed at all times.

Besides the instructions provided in this manual the local rules for the

prevention of accidents, general safety regulations - valid for the area of

application of the device - as well as the valid environment protection

regulations must be considered and respected.

Responsibilities of the involved persons regarding installation, operation,

maintenance and cleaning must be made clear.

Only authorized and trained personnel may operate the equipment. The

operators must know potential dangers and how to avoid them and should be

regularly trained on safety procedures and environmental protection

regulations.

11

Persons under the influence of drugs or alcohol must not operate the device.

Any changes to the equipment, which may endanger the operators must be

reported immediately to the operators and any person handling it.

2.3 Ionization Source

The device contains a Tritium radioactive ionization source of 300 MBq (Below

exemption limit according to EURATOM Directive 96/26).

Do not open the device! Do not try to repair any internal malfunctions

of the device! Internal malfunction recovery, repairs and any

maintenance work may only be carried out by G.A.S. or by personnel

authorized by G.A.S.

2.4 Explosion Protection

The device is not certified for deployment in areas with explosive gas/air

mixtures or other explosive substances.

Do not deploy the device in areas exposed to explosive substances or

mixtures.

12

2.5 Protection from High Voltage

Exercise great care in handling current-carrying parts like the power

supply cord. Do not get directly in touch with current-carrying parts.

Do not open the housing. Do not use damaged parts.

13

3Scope of Supply and Storage

Conditions

3.1 Scope of Supply

Ensure that you have received the full scope of supply. If there is any part

missing, please contact G.A.S. immediately.

Standard Scope of Supply

Device

Power Supply

Power Supply Cable

Gas tubes (6 x 2 m) with 3mm Swagelok Connectors

Drift Gas / Carrier Gas Adapter with 3mm Swagelok Connectors

Sample Gas Bypass Adapter with 3mm Swagelok Connectors

D-Sub Plug, Male, Wireable for Current Loop Connection

Moisture Trap

Device User Manuals

Software-CD with IMScontrol TFTP-Server

Document - Technical Approval Certificate

Document - Analytical Approval

Document - Declaration of Conformity

Document - Radiation Source Certificate

14

Optional Items

Large Moisture Trap

Transport Case

Notebook PC for direct file transfer

3.2 Storage Conditions

Check the storage conditions regularly

Storage Conditions

When not in use store the equipment in the supplied casing

Prevent unauthorized access

Do not store outside

Protect the equipment from moisture and dust

Put protective caps on all gas sockets of the device and the molecular sieve

Avoid mechanical vibrations

Do not expose the equipment to aggressive substances

Protect the equipment from direct sun light

Storage temperature: 15 to 40 °C

Relative Air Humidity: Max 60 %

15

4Cleaning of the Housing and

Maintenance

4.1 Cleaning of the Housing

Regular use of the device requires periodic cleaning.

Clean the outside of the device casing only with a dry or slightly damp

cloth. Do not use cleaning agents that contain solvents, acids or bases.

4.2 Maintenance

Natural aging and the wear of certain components of the equipment require

regular cleaning and maintenance.

The recommended maintenance interval is 12 months.

Maintenance of the equipment must be carried out by G.A.S. or

personnel authorized by G.A.S.

Please contact G.A.S. 6-8 weeks in advance to optimize the turn-

around time!

16

5Intended Use and Working

Principle

5.1 Intended Use

The intended use of the GC-IMS-SILOX device is the measurement of siloxane

concentrations in biogas from landfills, digestors and sewage.

5.2 Calculating Concentrations

The device can measure siloxanes within the following concentration ranges:

Substance

Measurement Range

Siloxane –L2

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

Siloxane –D3

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

Siloxane –L3

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

Siloxane –D4

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

Siloxane –L4

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

Siloxane –D5

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

Siloxane –L5

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

TMSOL

Up to 10 mg/m³ - Standard 0.03 to 2.0 mg/m3

The actual ranges may differ and may be customized to specific

requirements. They are displayed in the Substance Calibration Dialog.

→17.5 Substances and the Substance Calibration Dialog

17

When the calculated concentration value exceeds the respective maximum

value MaxVal it is displayed as “›MaxVal”.

When the calculated concentration value is below the respective minimum value

it is displayed as “n.d.”standing for “not detected”.

The concentration value of compound substances like Total Siloxanes is

derived from base substances (L2, L3, …). When one or more base

substance concentrations exceed their concentration ranges the value

for the compound substance is derived from the limits.

When for all base substances (L2, L3, …) a “n.d.” is calculated the

result for the compound substances is “n.d.” as well.

20 Calculating of silicon ’Total Si’ and silica ’Total SiO2’ in GC-IMS-

SILOX

18

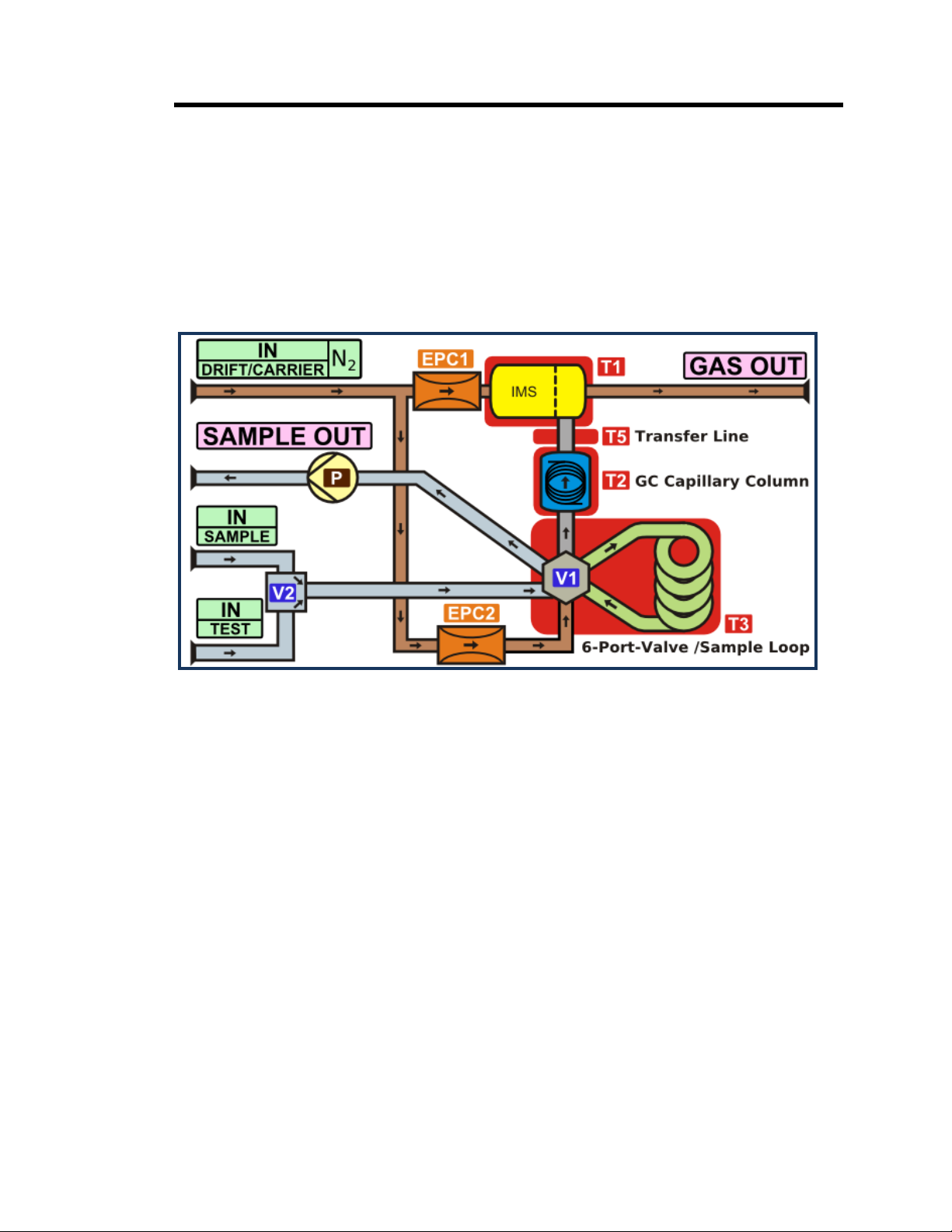

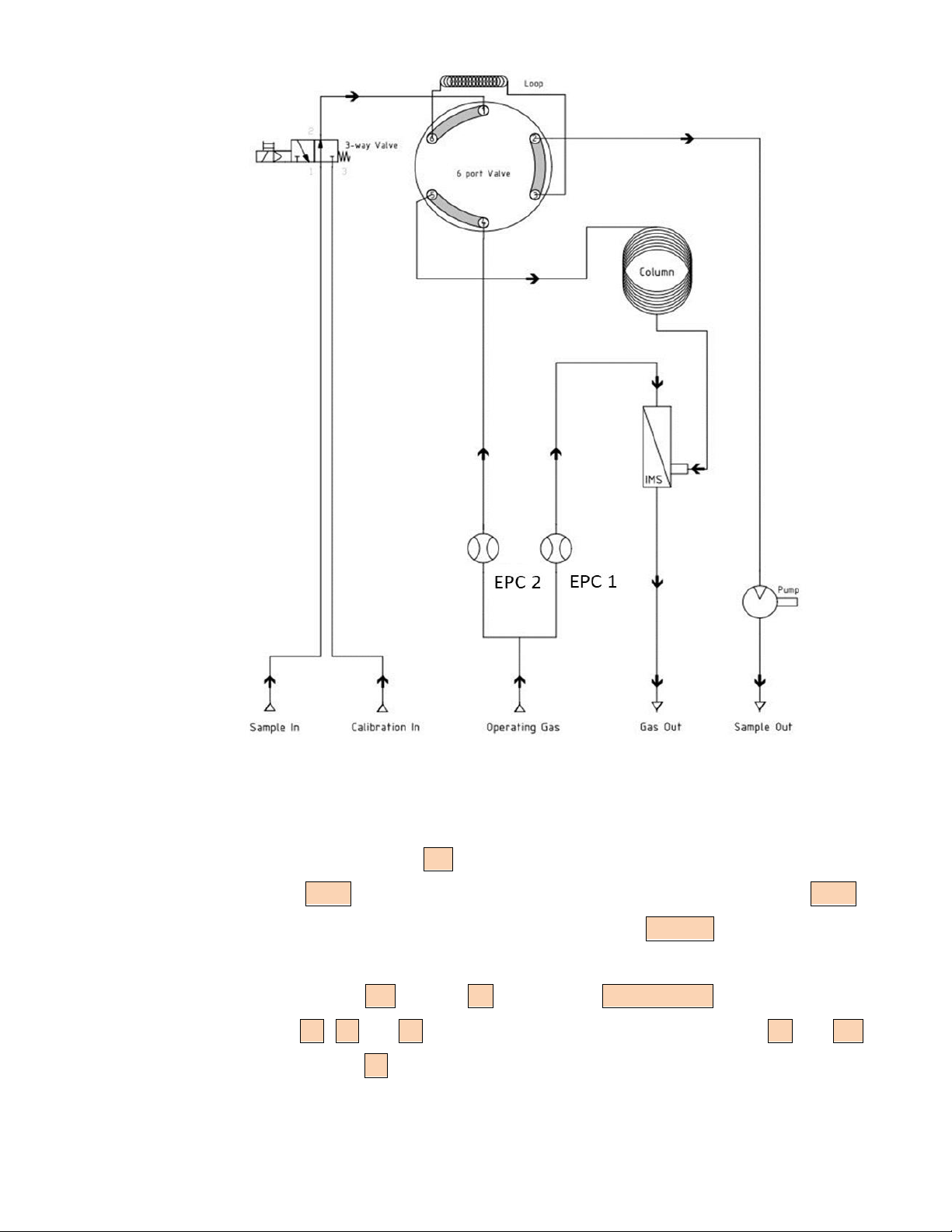

5.3 Working Principle and Internal Gas Flow

The schematics below show the main elements of the gas flow system of the

device. The system consists of a gas chromatograph (GC) using a capillary

column coupled to an ion mobility spectrometer (IMS).

For displaying the plan on the device see 17.10.2 System Page Plan

Figure 1: Device Plan

19

Figure 2: Flow-chart

The drift gas flow to the IMS sensor is controlled by the electronic pressure

control unit EPC1. The carrier gas flow to the column is controlled by EPC2.

Carrier gas and drift gas leave the device through the Gas Out outlet at the rear

side of the device, which should be connected to an appropriate waste gas

ventilation system. IMS sensor, GC column and 6-Port-Valve with sample loop

are heated (T1, T2 and T3 respectively). The transfer line between GC and IMS

sensor is heated by T5.

Table of contents

Other GAS Analytical Instrument manuals

Popular Analytical Instrument manuals by other brands

Agilent Technologies

Agilent Technologies 16702B installation guide

Dostmann Electronic

Dostmann Electronic LM 100 Instructions for use

Eclipse Combustion

Eclipse Combustion EGA4 instruction manual

Sparky Group

Sparky Group UDD 16 Original instructions

Red Technology

Red Technology CB-1005 user manual

Storz

Storz OR1 .avm installation instructions

SICK

SICK MCS300P technical information

Vividia

Vividia YE-4-8015 user manual

Pickering Laboratories

Pickering Laboratories Pinnacle PCX Operator's manual

Calculated Industries

Calculated Industries LaserDIMENSIONMASTER 3336 user guide

SonTek

SonTek ADP Software manual

Eddyfi Technologies

Eddyfi Technologies INUKTUN MINIMAG user manual