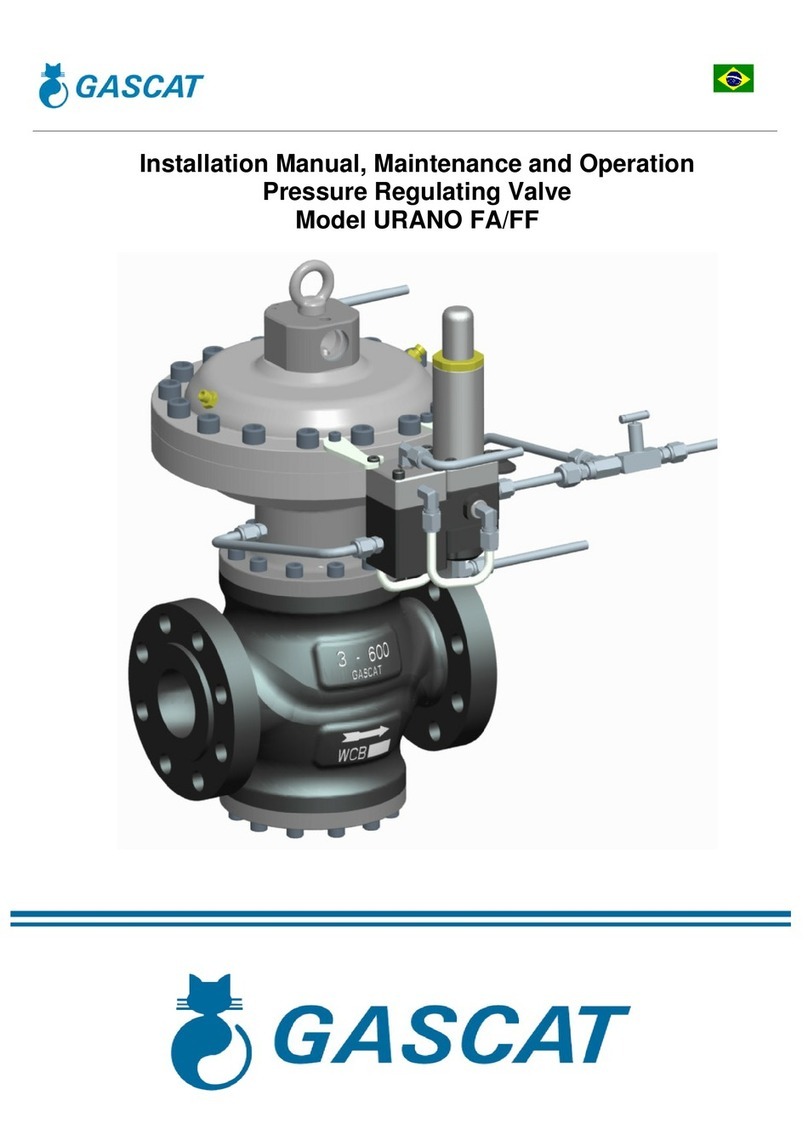

Gascat JR Series User manual

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

Gascat –Indústria e Comércio Ltda

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

2 of 10

CONTENTS

1 –INSTRUCTIONS PRIOR TO COMMISSIONING

Page 3

2 –HEALTH AND SAFETY

Pages 3 / 4

3 –INTRODUCTION

Page 4

4 –OPERATING PRINCIPLE

Page 4

5 –CHARACTERISTICS

Page 5

6 –INSTALLATION

Page 5

7 –OPERATION (START-UP)

Page 6

8 –MAINTENANCE

Page 6

9 –STORAGE

Page 7

10 –GENERAL RECOMMENDATIONS

Page 7

11 –WARRANTY

Page 7

12 –REGULATOR DRAWINGS

Pages 8 / 10

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

3 of 10

1 –INSTRUCTIONS PRIOR TO COMMISSIONING

It should be clearly understood that the information given under the Commissioning Instructions below do not intend to

revoke or substitute instructions laid out by any relevant entity, and reference should be made to the relevant Standards

and/or existent recommendations on the subject.

It is implied that before Commissioning, the performance of the appropriate "Cleaning and Purification Procedures"

shall be observed and all the instructions contained in "Pressurization" and "Labor Safety and Health Standards" shall be

strictly followed.

The recommendations of valves' suppliers, as for instance, "open slowly" or "open very slowly" should be strictly

observed.

2 –HEALTH AND SAFETY

Regulators, valves, and other pressurized components that contain toxic or flammable gases, or other hazardous

products, are potentially dangerous if not correctly operated and maintained. It is mandatory that all users of these

equipments are properly instructed and warned on their potential danger, and certify yourself that the personnel

responsible for installation, testing, commissioning, operation, and maintenance of the plant are properly skilled to perform

their duties. Instruction manuals are provided for orientation of the operators, but it is supposed that they have a basic

knowledge level. If any doubts or ambiguities remain that could affect the proper procedures ask Gascat Indústria e

Comércio Ltda., which will be pleased to instruct, or to provide the suitable service or instruction. NOT TO TAKE ANY

RISK. Our telephone, fax numbers, and e-mail are the following:

Gascat Indústria e Comércio Ltda.

Rodovia SP 73, 1141 –Indaiatuba / São Paulo.

CEP 13347-990

Brazil

Phone: 55 19 3875-7511

Fax: 55 19 3894-5674

Email: vendas@gascat.com.br

The comments below, while not completely inclusive, provide guidance on possible sources of risk to safety and health.

2.1 –NOISE

Regulators, valves, and other pressure reducers can produce high noise levels, which can be harmful to persons

exposed to them for long time periods. Users should assure themselves that appropriate provisions will be taken, in order

to foresee health safety of employees and/or third parties, according to standards and recommendations in force.

2.2 –INSTALLATION

All equipment, piping, and vessels are designed to support mechanical efforts, as, for instance, torque and bending

momentum, in addition to internal pressure. However, careful shall be exercised during installation not to develop

excessive efforts, which can cause cracks that may result in serious breakage when the regulator is put into operation.

Excessive tensions can also be caused if the equipment is overburden by piping, which should be otherwise appropriately

supported.

All regulators, shutoff valves, relief valves, etc., shall be installed taking into account the correct flow sense.

Impulse lines are important components of any control system and it is essential for them to be correctly installed

according to instructions.

Impulse lines should be appropriately supported to reduce excessive vibration, which can provoke fatigue breakdown.

They should also be positioned so that they cannot serve as support to feet or hands. Impulse lines should have a slight

slope so that liquids and condensates drain towards the main piping.

Auxiliary systems should not be changed, or modified, without knowledge of the operation conditions and permission of

the responsible in charge.

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

4 of 10

2.3 –OPERATION

Depending on the regulator type, its valve can be positioned fully open. Consequently, when a regulator is put into

operation, the shutoff valves should be opened slowly so that the regulator valve can assume its regulating position. If the

valves are quickly opened, the upstream pressure can pass downstream through the regulator and over-pressurize

downstream the main line.

All regulators, etc., should operate with the regulating spring specified by the manufacturer. This provision is particularly

important when operating relief or shutoff valves, since incorrect springs can hinder a relief valve to open and a shutoff

valve to close.

Provisions should be taken to avoid water input through breathing and ventilation openings.

2.4 –MAINTENANCE

Regulators and valves contain gases under pressure that sometimes are higher than the atmospheric pressure. Before

trying to investigate any problem or to perform service maintenance of the equipment, they should be safely de-

pressurized. Furthermore, as most gases can be flammable, poisonous, corrosive, or somehow, dangerous, it may be

necessary to purge the installation with an inert gas, as nitrogen. Special precautions are necessary for operation with

oxygen or hydrochloric gas and the user should be reassured that appropriate procedures are implemented.

Eventually, it is not enough to isolate the high-pressure device, since high pressures can be retained downstream of

isolation valves. Do not try to remove covers, plugs, etc., before these parts are properly freed-up. Even so, it is advisable

to consider if high-pressure gas can be present at the time of removal of covers and plugs.

Most regulators use spiral springs as the loading device. It is important to reduce the load of these springs relieving their

loaders as much as possible. In some cases, some residual load may last, even though the spring is relaxed to the limits of

its housing.

3 –INTRODUCTION

The Series JR regulators are single stage, self-operated regulators for heavy duty work under high, medium, and low

pressure applications, for all types of non-corrosive gases and for corrosive gases, when built in special versions.

These regulators were developed with the purpose of facilitating their maintenance, or parts substitution, as much as

possible. Therefore, because of their top entry characteristic, there is no need to remove them from the line for

maintenance or cleaning. The JR Series regulators are also known for their small weight, constructive simplicity and

soundness.

For valves intended for use with oxygen, all necessary precautions shall be taken for operation with this gas, avoiding

oil or grease presence in tools, and use of lubricants that are not compatible with oxygen. Always use building materials for

the valve that are compatible with the type of used gas.

4 –OPERATING PRINCIPLE

Pressure regulators of the JR Series operate by direct spring action on the output pressure sensor element (diaphragm)

that, with consumption variation and consequent pressure change on the sensor element, will re-position the shutter stem

increasing or reducing the valve aperture, in order to keep the adjusted output pressure constant.

A variation of this system uses external piloting for JR Regulators. Operation is by action of this pilot pressure directly

on the sensor element of the output pressure (diaphragm) that, with consumption variation and consequent pressure

change on the sensor element, in the same way as for regulators operated by direct spring action, will re-position the

shutter shaft increasing or reducing valve aperture, in order to keep constant the adjusted output pressure.

5 –CHARACTERISTICS

FITTINGS: ½” thread (with reduction adapter), ¾”, ¾” x 1”, 1” NPT (according to ANSI B1.20.1) or BSP (according to

BS 21 –DIN 2999); with ½”, ¾” 150# flange, and with 1” 150/300# flange (pursuant ANSI B16.5).

Self-operated regulator by direct spring action.

Open or closed fail-safe condition (the closed condition implies the regulating spring with no pressure at all).

Topy Entry

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

5 of 10

6 –INSTALLATION

6.1 –Filter

We recommended the installation of a basket type or “Y” filter of 150 mesh (minimum), as close as possible to the

regulator inlet. A careful filter installation is essential to the perfect operation of the equipment, because eventual particles

existing in the piping can lodge themselves between the seat and the shutter, damaging them and provoking direct flow

passage.

6.2 –Cleaning

Check pipeline cleaning before the regulator installation. We recommended a complete purge of the line with nitrogen or

compressed air.

6.3 –Flow Direction

Check the flow direction engraved in the valve body before installation. Junior Series regulators can be installed in any

position.

6.4 –Line Ø

Piping diameter downstream of the regulator should, preferably, be larger than ¾”.

6.5 –Other important devices for a safe installation

A safe installation shall contain, at least (see outline drawing proposed below):

1. Manual blocking valve (ball type, or similar).

2. Filter.

3. Pressure gauge for input pressure reading.

4. Pressure regulator.

5. Pressure gauge for output pressure reading.

6. Manual blocking valve (ball type, or similar).

INSTALLATION OUTLINE

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

6 of 10

7 –OPERATION (START-UP)

Slowly open the gas inlet valve.

Check if there are no leaks in connections connecting to the regulator.

Adjust the outlet pressure (set-point) turning the regulating screw in the clockwise sense to increase pressure, or in the

counterclockwise sense to reduce it. Perform this operation with a small gas flow.

When the wanted outlet pressure (set-point) is reached, lock the regulating screw with the lock nut.

Check tightness of the shutter/seat assembly. Without gas consumption the output pressure gauge shall present a

quick increase in pressure at closing that shall stabilizes after some seconds.

8 –MAINTENANCE

Defect

Probable Cause

Solution

Outlet pressure

decrease/insufficient flow

Dirt in filter

Check the filter and to proceed its cleaning. For

regulators with external pilot check piloting pressure.

Outlet pressure increasing/direct

passage

Presence of particles between

shutter/seat or worn out shutter

packing.

Remove the shutter by removing the lower plug or,

for JR II regulator, by removing the spring cover and

the seat.

Check if the same is not damaged or dirty,

proceeding its cleaning or replacement as needed.

Check the condition of the sealing border of the

seat, proceeding its replacement if necessary.

Gas passage through the spring

cap vent

Diaphragm rupture.

To loosen the cover of the spring and to replace the

diaphragm.

Vibration.

Worn out shutter and seat

shaft.

Replace the shutter and seat shaft assembly.

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

7 of 10

9 –STORAGE

The regulators should not suffer mechanical shock, not to risk internal components' damages.

The regulators should be stored at a clean and dry place, protected from bad weather.

10 –GENERAL RECOMMENDATIONS

We test our regulators and valves at the requested operation conditions.

Criteria and maintenance steps are contained in manuals, however, for any doubt on the use, operation, or

maintenance, contact Gascat's technical department that will provide you proper guidance.

Gascat supplies, on request, a complete replacement kit.

11 –WARRANTY

We warrant our products, for a 12 months period from the date of invoicing, if the products are in operation, extending

the warrant up to 18 months, in case they are in stock. Such warranty only covers those cases for which the occurrence of

production defects are evidenced, which remained unnoticed at the time the product delivery.

To present warranty is not valid if it is found that the defect or mishap was caused by accident, normal wear, inadequate

installation, improper maneuvering or use, inadequate storage, assembly disregarding technical standards or if the buyer

undertook repairs or changes in equipment by himself, without the manufacturer's previous authorization.

The information contained in this manual contains Gascat's supply conditions, independently of the verified

performance.

The information herein contained shall not be interpreted or suggest performance warranty in relation to the final

products, or the system usage purpose, nor should they serve as usage recommendation for any product or process

mentioned in the specifications. This system should only be operated by qualified technician trained for this purpose; and

no changes that may affects the system safety can be executed without our previous authorization.

Gascat Ind. and Com. Ltda. withholds the right to make changes without notice, introducing improvements in the

described products drawings or specifications.

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

8 of 10

Item

Qty.

DESCRIPTION

Drawing Nº

Material

Remarks

1

01

BODY

See Table 1

2

01

TOP COVER

21.005.3

SAE 323

3

01

SEAT

21.007.4

4

01

STEM

21.012.4

5

01

SPRING FOLLOWER

21.010.4

SAE 1020

Yellow Dichromate

6

01

DIAPHRAGM PLATE (For JR A, B & HP)

21.009.4

BRASS

6.1

01

DIAPHRAGM PLATE (For JR A & HP)

21.009.4

BRASS

7

01

PLUG

21.011.4

8

01

SHUTTER

21.008.4

9

01

REGULATING SPRING

SAE 1070

Painted

10

01

SHUTTER SPRING

01.038.4

AISI 302

11

01

REGULATING SCREW

21.014.4

SAE 1020

Yellow Dichromate

12

01

DIAPHRAGM SCREW (For JR A & HP)

21.015.4

12.1

01

DIAPHRAGM SCREW (For JR B)

05.001.4

13

01

NUT 5/8” W.

EB-283

Yellow Dichromate

14

01

NUT 1/2” W.

EB-283

Yellow Dichromate

15

06

HEX. HEAD SCREW ¼” W x ¾”

EB-168

Yellow Dichromate

16

01

PLUG

17

01

SHUTTER GASKET

04.004.4

18

01

DIAPHRAGM

04.001.4

19

02

O’RING

20

01

O’RING for JUNIOR A & HP

21

01

SPRING WASHER

SAE 1070

Yellow Dichromate

22

01

TAG NAMEPLATE

SS

If requested

23

01

PRESSURE GAUGE WITH EXTENSION

24

02

RIVET

SAE 1020

25

01

NAMEPLATE

ALUMINUM

NOTE: () Denotes items of the spare parts kit

Building detail for

Regulating Valve Junior B

TOP VIEW

Flow

Direction

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

9 of 10

Item

Qty.

DESCRIPTION

MateriaL

Drawing Nº

Remarks

1

01

BODY

FORGED BRASS

21.012.2

SEE NOTE 1.

2

01

SHUTTER STEM

AISI 410

21.012.4

2.1

01

SHUTTER GASKET

VITON

04.004.04

2.2

01

SHUTTER BODY

BRASS

21.008.4

3

01

SIX (6) HOLES SEAT

TM-360

21.024.4

4

01

DIAPHRAGM SCREW

SAE 1020

21.026.4

5

01

TOP PLATE

SAE 1020

21.027.4

6

01

SPRING FOLLOWER

SAE 1020

21.029.4

7

01

REGULATING SCREW

SAE 1020

21.028.4

8

01

COVER

SAE 323

21.013.3

9

01

DIAPHRAGM

BUNA N

04.036.4

10

01

SHUTTER SPRING

AISI 302

01.038.4

11

01

REGULATING SPRING

SAE 1070

SEE TABLE

12

01

O-RING

BUNA N

06.49.18

13

01

¼” NPT VENT

BUNA N

03.49.10

14

08

HEX. HEAD SCREW 5/16” NC x 18 FPP x 11/16”

CLASS 8.8

05.50.66

15

01

HEX. NUT 1/16” NC

CLASS 8.8

05.50.67

16

01

LOWER NUT 9/16” NC

CLASS 8.8

05.50.68

17

01

HOOD

ABS

28.01.54

18

01

HEX PLUG 1/8” NPT

BRASS

03.49.01

19

01

PRESSURE GAUGE

NOTE: () Denotes items of the spare parts kit

Optional

Gascat Ind Com Ltda

JR Series - Pressure Regulating Valve

Installation, Maintenance and Operation Manual

MI-03

Prepared by

Approved by

CSQ

Date

Revision

Page

Severino Araújo

Hélcio Teixeira

Rubens Ribeiro

May/18/02

02

10 of 10

Item

Qty.

DESCRIPTION

Drawing Nº

Material

Remarks

1

01

BODY

21.00.01

NODULAR

2

01

TOP COVER

21.00.25

BRONZE

3

01

SEAT

21.01.01

BRASS

4

01

SHUTTER STEM

21.01.54

AISI 410

5

01

O-RING

06.49.45

BUNA-N

6

01

DIAPHRAGM PLATE

21.01.27

BRASS

7

01

PLUG

21.01.05

SAE 1020

8

01

SHUTTER BODY

21.01.02

BRASS

9

01

DIAPHRAGM

04.49.36

BUNA-N

10

01

SHUTTER SPRING

01.49.40

AISI 302

11

01

SHUTTER GASKET

04.49.47

VITON

12

02

O-RING

06.49.18

BUNA-N

13

01

DIAPHRAGM SCREW

21.01.26

BRASS

14

01

NUT ½” W

05.49.41

EB-283

Yellow Dichromate

15

06

HEX HEAD SCREW ¼” w x ¾”

05.49.55

EB-168

Yellow Dichromate

16

01

SPRING WASHER

05.49.73

SAE 1070

Yellow Dichromate

17

01

PLUG

03.49.01

BRASS

NOTE: () Denotes items of the spare parts kit

PILOT DRIVEN JR REGULATOR

TOP VIEW

Flow Direction

Table of contents

Other Gascat Control Unit manuals

Popular Control Unit manuals by other brands

HPE

HPE G2 R5000 Product End-of-Life Disassembly Instructions

DTS INSIGHT

DTS INSIGHT Micom Pack FH808M07 instruction manual

ICP DAS USA

ICP DAS USA M-7069 quick start guide

Emerson

Emerson Spence K5 instruction manual

Carel

Carel Ultra 3PH user manual

Raven

Raven ISOBUS Product Control Installation & operation manual

Rockwell Automation

Rockwell Automation Allen-Bradley EtherNet/IP user manual

Eaton

Eaton PowerXL DX-NET-DEVICENET manual

SMC Networks

SMC Networks JSY1000 Series manual

SKF

SKF Lincoln 85307 operating instructions

Parker

Parker MT-700 Series Installer's guide

United Technologies

United Technologies Edwards SIGA-CT1 Installation sheet