Gascat URANO FA User guide

Installation Manual, Maintenance and Operation

Pressure Regulating Valve

Installation Manual, Maintenance and Operation

Pressure Regulating Valve

Model URANO FA/FF

Installation Manual, Maintenance and Operation

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 2 de 61

INDEX

1.0 - GENERAL WARNINGS .......................................................................................................................................................... 4

1.1

–

INSTRUCTIONS

FOR

COMMISSIONING .................................................................................................................................... 4

1.2

–

HEALTH

AND

SAFETY ............................................................................................................................................................... 4

1.2.1 – NOISE ............................................................................................................................................................................... 4

1.2.2 – INSTALLATION ................................................................................................................................................................. 4

1.2.3 – OPERATION ...................................................................................................................................................................... 4

1.2.4 – MAINTENANCE ................................................................................................................................................................ 5

2.0 – INTRODUCTION ................................................................................................................................................................... 5

2.1

SCOPE

OF

MANUAL .................................................................................................................................................................... 5

2.2

DESCRIPTION .............................................................................................................................................................................. 5

2.3

SPECIFICATIONS ......................................................................................................................................................................... 6

2.3.1 AVAILABLE SETTINGS .......................................................................................................................................................... 6

2.3.2 AVAILABLE CONNECTIONS.................................................................................................................................................. 6

2.3.3 TEMPERATURE LIMITS ........................................................................................................................................................ 6

2.3.4 COEFFICIENTS FLOW ........................................................................................................................................................... 6

2.3.5 APPROXIMATE WEIGHT ...................................................................................................................................................... 7

2.3.6 MAXIMUM WORKING PRESSURE ...................................................................................................................................... 7

2.3.7 SETTING PRESSURES SET-POINT) ....................................................................................................................................... 7

2.3.8 ACCURACY AND LOCK UP ................................................................................................................................................... 8

3.0 – PRINCIPLE OF OPERATION ................................................................................................................................................... 8

3.1

REGULATOR

SPRING

TO

CLOSE

(FAIL

CLOSE) .............................................................................................................................. 8

3.2

REGULATOR

SPRING

TO

OPEN

(FAIL

OPEN) .............................................................................................................................. 10

3.3

OOSTER

(G-43

&

G-44) ........................................................................................................................................................... 12

3.4

PILOTS

(G-40

&

G-42) ............................................................................................................................................................... 13

3.5

FILTERS ..................................................................................................................................................................................... 14

3.6

MOUNT

MONITOR

AND

ACTIVE ............................................................................................................................................... 14

4.0 – INSTALLATION ................................................................................................................................................................... 15

4.1

FILTER ....................................................................................................................................................................................... 15

4.2

CLEANING ................................................................................................................................................................................. 16

4.3

DIRECTION

OF

FLOW

AND

SYSTEM

INTEGRITY ......................................................................................................................... 16

4.4

SENSE ....................................................................................................................................................................................... 17

4.5

SCHEME

RECOMMENDED

INSTALLATION ................................................................................................................................ 19

4.5.1 SINGLE REGULATOR ......................................................................................................................................................... 19

4.5.2 SISTEM MONITOR AND ACTIVE ........................................................................................................................................ 21

4.5.3 TWO SSV AND A REGULATOR FF ...................................................................................................................................... 23

4.6

START-UP ................................................................................................................................................................................. 25

4.6.1 GENERAL RECOMMENDATIONS ....................................................................................................................................... 25

4.6.2 COMMISSIONING SINGLE REGULATOR) ......................................................................................................................... 26

4.6.3 ADJUSTING THE LINE BOOKING ........................................................................................................................................ 27

4.6.4 COMMISSIONING SISTEM MONITOR AND ACTIVE)......................................................................................................... 28

4.6.5 ADJUSTING THE LINE BOOKING MONITOR - ACTIVE) ...................................................................................................... 31

4.6.6 LIST OF RECOMMENDED TOOLS ....................................................................................................................................... 32

5.0 TROUBLE SHOOTING ............................................................................................................................................................ 33

6.0 MAINTENANCE .................................................................................................................................................................... 34

6.1

RECOMMENDED

REPAIR

PARTS

AND

KITS ............................................................................................................................... 35

6.2

PROCEDURE

FOR

REMOVAL

THE

REGULATOR

URANO

SC

(FF) ................................................................................................ 43

6.3

PROCEDURE

FOR

ASSEM LY

REGULATOR

URANO

SC

(FF) ....................................................................................................... 45

6.4

PROCEDURE

FOR

REMOVAL

THE

REGULATOR

URANO

SO

(FO) ................................................................................................ 46

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 3 de 61

6.5

PROCEDURE

FOR

ASSEM LY

REGULATOR

URANO

SO

(FO) ...................................................................................................... 50

6.6

PROCEDURE

FOR

REMOVAL

THE

PILOT

G-40

/

42 .................................................................................................................... 50

6.7

PROCEDURE

FOR

ASSEM LY

THE

PILOT

G-40

/

42 .................................................................................................................... 53

6.8

PROCEDURE

FOR

REMOVAL

OOSTER

(PRE-EGULATOR)

G-43 ................................................................................................ 54

6.9

PROCEDURE

FOR

ASSEM LY

OOSTER

(PRÉ

REGULATOR)

G-43 .............................................................................................. 57

6.10

PROCEDURE

FOR

REMOVAL

OOSTER

(PRE-REGULADOR)

G-44 ................................................. E

RRO

I

NDICADOR NÃO DEFINIDO

.

6.11

PROCEDURE

FOR

ASSEM LY

OOSTER

(PRE-REGULADOR)

G-44 ........................................................................................... 60

6.12

LIST

OF

RECOMMENDED

TOOLS

FOR

MAINTENANCE .................................................................. E

RRO

I

NDICADOR NÃO DEFINIDO

.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 4 de 61

1.0 - GENERAL WARNINGS

1.1 – INSTRUCTIONS FOR PRE COMMISSIONING

It should be clearly understood that with the information presented in Commissioning Instructions that follow, it is not

intended to repeal or replace the instructions determined by any other competent body and should be reference to the

relevant standards and / or existing recommendations on this subject.

Before any commissioning, is implied the performance of the appropriate "Cleaning and Purification Procedures" that

must be observed and all the instructions on "Pressurization" and "Work Standards for Health and Safety", must be strictly

met.

The recommendations of valves suppliers, such as "open slowly" or "open very slowly" should be strictly observed.

1.2 – HEALTH AND SAFETY

Regulators, valves, and other pressurized components that contain toxic gases, flammable or other hazardous

products, are potentially dangerous if not operated and maintained properly. It is imperative that all users of this equipment

are adequately educated and guided to the potential hazards and make sure that staff responsible for the installation,

testing, commissioning, operation and plant maintenance are competent to do this. Instruction manuals are provided for the

guidance of operators, but it is assumed that they have a basic level of knowledge. If any doubts or ambiguities that affect

the proper procedures ask Gascat Ind e Com. Ltda. who will be happy to advise or provide the relevant service or

instruction. NO RISK. Our phone number, fax number and e-mail are described below:

Gascat Indústria e Comércio Ltda.

Rodovia SP 73, 1141 – Indaiatuba / São Paulo.

CEP 13347-990

Telefone: +55 19 3936-9300

Fax: +55 19 3935-6009

Email:

[email protected]om.br

The comments that follow, while not exhaustive, provide guidance possible sources of danger to health and safety.

1.2.1 – NOISE

Regulators, valves and pressure reducers can produce high noise levels, which may be harmful to persons exposed to

them for long periods of time. Users should ensure that adequate precautions are taken in order to provide security to the

health of employees and / or third parties as the standards and recommendations in force.

1.2.2 – INSTALLATION

All equipment, piping and vessels are designed to withstand mechanical stress, for example, torque and moments of

"bending" in addition to internal pressure. However, care must be taken during installation to not impose excessive strain,

which may cause cracks that may result in a more serious break when the regulator is put into operation. Excessive stress

can also be caused due to not supporting the length of the pipe, which must be adequately supported.

All regulators, valves shut off, relief valves, etc., should be installed with the correct flow.

Impulse lines are important components of any control system and it is essential that they are properly installed and

without isolation valves.

Impulse lines should be adequately supported to reduce excessive vibration which may cause disruption due to fatigue.

They should also be positioned so that they can not serve as a footrest or hands. Impulse lines should be slightly inclined

so that condensed liquids and to flow into the main pipe.

When necessary (in underground facilities or indoor area) should be installed a pipe ventilation from Ø threaded ¼

"NPT, positioned in the bell or diaphragm housing, which should be extended and positioned in a safe place and ventilated,

with the departure of protected vent to prevent water entering the rain and insects that may cause obstruction of ventilation.

Auxiliary systems should not be altered or modified without the knowledge of operating conditions and permission of the

people responsible.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 5 de 61

1.2.3 – OPERATION

Depending on the type of regulator, the valve may even be positioned fully open. Consequently, when a regulator put in

operation, the shutoff valves should be opened slowly so that the regulator valve can assume its regulating position. If the

valves are quickly opened the upstream pressure can pass downstream through the regulator and over-pressurize

downstream the main line.

All regulators, etc., should operate with the spring adjustment specified by the manufacturer. This is especially important

when operating relief valve or shutoff valves, since incorrect springs may prevent the relief valve to open and close the

shutoff valve.

Precautions should be taken to prevent water from entering through the openings for breathing and ventilation.

1.2.4 – MAINTENANCE

Regulators and valves contain gases at pressures that are sometimes greater than atmospheric pressure. Before trying

to investigate any problem or perform maintenance work on equipment, they must be safely depressurised. Furthermore,

as most gases may be flammable, toxic, corrosive, or hazardous, it may be necessary to purge the system with an inert

gas such as nitrogen. Special precautions are necessary for operation with gases such as oxygen or hydrochloric gas and

the user must be sure that the appropriate procedures are in place.

Eventually it is not enough to isolate the high pressure device, since high pressures can be retained downstream of

isolation valves. Do not try to remove covers, plugs, etc., before this device is properly released. Still, it is wise to consider

that the high pressure gas may be present when removing covers and plugs.

Most regulators use spiral springs as a charging device. It is important to reduce the burden these springs away your

presser as possible. In some cases, there may be some cargo residue, even when the spring is relaxed within the limits of

their house.

2.0 – INTRODUCTION

2.1 SCOPE OF MANUAL

This manual aims to provide operational information, installation and maintenance of the pressure regulators URANO

model manufactured by GASCAT.

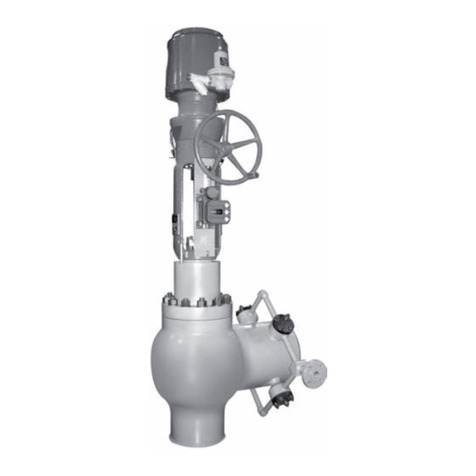

2.2 DESCRIPTION

The pilot operated pressure regulator model URANO was developed by the Engineering GASCAT, to meet the most

varied applications and can operate in various operating conditions, however, it is particularly applicable in situations where

requires high flow rates associated with high pressures, typically found in natural gas transportation and custody transfer in

natural gas delivery point and can operate with a maximum inlet pressure of 150 kgf/cm² and outlet pressures from 1.0 to

80.0 kgf/cm².

The pressure regulator of URANO GASCAT model has CE mark (product identification Number: CE-0085BU0263) and

certified tests performed in the laboratory DVGW attesting its efficiency and compliance with DIN EN 334 (Gas pressure

regulators for inlet pressures up to 100 bar) and 97/23 / EG (PED), the DVGW certificates and reports are available for

inspection at GASCAT if some of the documents necessary for your application, please contact our Headquarters in

Indaiatuba and request copies of these documents.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 6 de 61

2.3 SPECIFICATIONS

2.3.1 AVAILABLE SETTINGS

URANO FA: Pilot operated pressure regulator fail open

URANO FF: Pilot operated pressure regulator failure close

The URANO pressure regulators are classified as FA and FF according to the guidelines reported in DIN EN 334, for fault

condition

2.3.2 AVAILABLE CONNECTIONS

DN FLANGE ASME B16.5 FLANGE DIN 2634 / 2635

1” 150#RF / 300#RF / 600#RF ou RTJ / 900#RF ou RTJ PN 25 / PN 40

2” 150#RF / 300#RF / 600#RF ou RTJ / 900#RF ou RTJ PN 25 / PN 40

3” 150#RF / 300#RF / 600#RF ou RTJ / 900#RF ou RTJ PN 25 / PN 40

4” 150#RF / 300#RF / 600#RF ou RTJ / 900#RF ou RTJ PN 25 / PN 40

6” 150#RF / 300#RF / 600#RF ou RTJ / 900#RF ou RTJ PN 25 / PN 40

8” 150#RF / 300#RF / 600#RF ou RTJ / 900#RF ou RTJ PN 25 / PN 40

2.3.3 TEMPERATURE LIMITS

Operating temperature: -20°C a 60°C

Ambient temperature: -20°C a 60°C

Temperature limits reported in this manual or any standard should not be exceeded under any circumstances, at the

risk of damage to the equipment, installation and security of the people involved in the operation.

2.3.4 COEFFICIENTS FLOW

DN CV KG

1” 15 440

2” 63 1950

3” 123 3800

4” 220 6850

6” 486 15080

8” 900 28250

Note:

1) We suggest that is considered a 20% safety factor on the calculated value.

2) When scaled active-monitor system finds 25% restriction on the CV / KG of both valves.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 7 de 61

2.3.5 APPROXIMATE WEIGHT

DN 150# 300# 600# 900#

1” 24 26 30 34

2” 95 100 112 128

3” 99 105 130 149

4” 185 195 215 247

6” 475 500 570 655

8” 570 600 690 793

Note:

1) Weights reported in kilograms (Kg)

2) Considered body in carbon steel SA-216 WCB

3) For the exact weights contact the GASCAT for verification of the model.

2.3.6 MAXIMUM WOR ING PRESSURE

150# 300# 600# 900# PN 25 PN 40

19 bar 51 bar 100 bar 150 bar 25 bar 40 bar

Pressure limits reported in this manual or any standard should not be exceeded under any circumstances, at the risk of

damage to the equipment, installation and security of the people involved in the operation.

2.3.7 SET-POINT

Pressure regulators, model URANO using two models of pilots for pressure control called G-40 and G-42, here are the

adjustment ranges available for each model:

PILOT G-40

SPRING COLOR CODE ADJUSTMENT RANGE

RED 01.51.94A 25,0 – 50,0 bar

YELLOW 01.51.94 47,0 – 80,0 bar

PILOT G-42

SPRING COLOR CODE ADJUSTMENT RANGE

GREEN 01.49.65 1,0 – 4,5 bar

GRAY 01.49.64 4,5 – 12,0 bar

BLUE 01.49.33 11,0 – 17,0 bar

RED 01.51.94A 16,0 – 30,0 bar

YELLOW 01.51.94 27,0 – 55,0 bar

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 8 de 61

2.3.8 ACCURACY AND LOC UP

Accuracy; Closing: AC até 1; SG até 2,5

3.0 – PRINCIPLE OF OPERATION

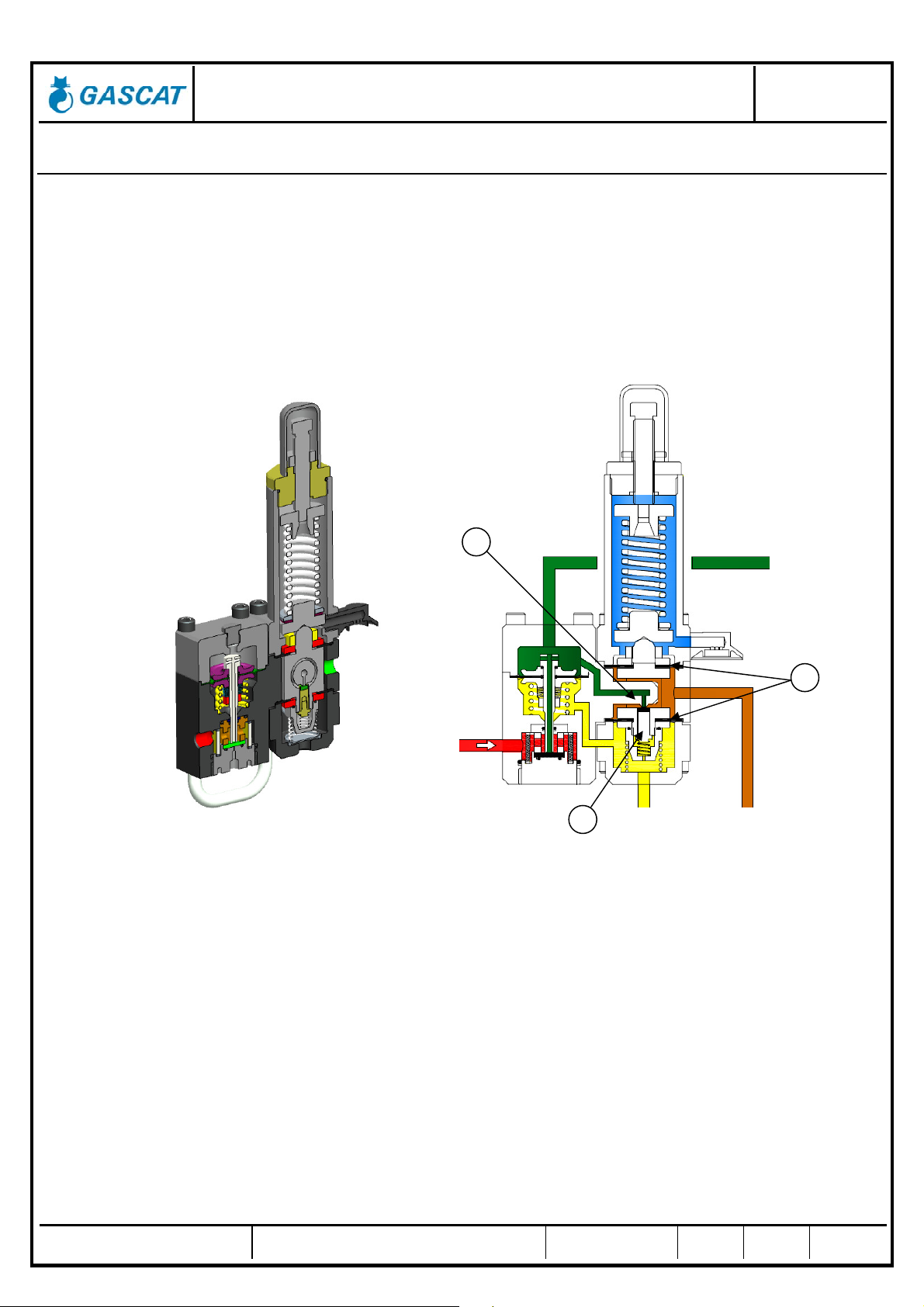

3.1 REGULATOR SPRING TO CLOSE (FF)

In the absence of pressure, the obturator (A) is kept in closing position by the closing spring (B) which keeps the gasket

pressed against (C). Importantly, even when subjected to pressure the variation of pressure upstream will have no

influence on the setting of the valve due to the balancing of the forces acting on it, as well as the actuator shaft (D) which is

also balanced.

By pressurizing the leg, the gas passes through a filter element (E) reaches a pre controller (booster) (F) reduces to a

near value of the output pressure and delivering the pilot (G) as compared to the output pressure sensed by the pilot

diaphragm (M), which controls the flow is injected under the main regulator diaphragm (L).

If a decrease in the downstream pressure (for consumption or increasing the amount of pressure drop) occurs an

imbalance between the force of the spring (R) on the pilot diaphragm (M) and the force generated by the outlet pressure

under the same diaphragm, causing the shutter driver (K) to a larger aperture, causing an increase in pressure under the

main regulator diaphragm (L), which combined with downstream pressure drop which acts on the main regulator

diaphragm and opposite the pilot pressure acting on it, determine the displacement of the shutter (A) up, thereby

increasing the passage restoring the pressure (set point).

When the pressure begins to increase, causes the shutter driver (K) to reduce the opening. The increased pressure

which operated under the regulator diaphragm (L) flows through the restriction of Bleed (M) (adjustable) that discharges

into downstream. The strength of the main regulator of the closing spring (B) plus the reduction in pilot pressure causes

displacement of the main shutter (A) down, thus making the pressure back to the preset value.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 9 de 61

FIGURE 1 - URANO FAIL CLOSED

A

D

C

E

F

G

H

L

I

K

M

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 10 de 61

3.2 REGULATOR SPRING TO OPEN (FA)

In the absence of pressure, the obturator (A) is in the open position by the main regulator spring (B) which keeps away

from the sleeve (C). Importantly, even when subjected to pressure the variation of pressure upstream will have no

influence on the setting of the valve due to the balancing of the forces acting on it, as well as the actuator shaft (D) which is

also balanced.

To pressurize the leg, the gas passes through a filter element and reaches the pre regulator (booster) (F) that reduces

to a value near the outlet pressure, and delivery to the pilot (G), it is important to note that unlike what happens in URANO

artifact closes regulator, the pressure provided by the booster is also injected directly into the upper chamber of the

diaphragm, it is necessary for the regulator to close at normal operating conditions, since the main regulator spring

pressing this the shutter so that it is in the open position.

The pilot compares the output pressure sensed by the diaphragm (M) and controls the flow that is injected under the

main regulator diaphragm (G) to open the valve.

If a decrease in the downstream pressure (for consumption or increasing the amount of pressure drop) occurs an

imbalance between the force of the spring (R) on the pilot diaphragm (M) and the force generated by the outlet pressure

under the same diaphragm, causing the shutter driver (K) to a larger aperture, causing an increase in pressure under the

main regulator diaphragm (L), determining the displacement of the shutter (A) up, thereby increasing the pressure restoring

passage (Sept -point).

When the pressure begins to increase, causes the shutter driver (K) to reduce the opening. Most operated under

pressure regulator diaphragm (L) flows through the restriction of Bleed (M) (variable) discharges into the downstream,

thereby causing the pressure acting on the diaphragm is greater than the driving force and the strength of the combined

spring, moving the shutter down and closing the main valve.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 11 de 61

FIGURE 2 - URANO FAIL OPEN

A

D

C

L

F

K

I

G

H

M

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 12 de 61

3.3 BOOSTER (G-43 & G-44)

The Booster is nothing more than a pre regulator that automatically adjusts the process conditions depending on

input pressure and output, and aims to reduce the pilot inlet pressure, causing it to operate in a milder condition, thus

eliminating any chance of interference on the regulator pilot by the input pressure variation.

The use of pre regulators or booster is recommended only for applications where the differential pressure exceeds

4.0 bar.

The boosters G-43 and G-44 model are designed to keep the inlet pressure of the pilots always adjusted to 1-2 bar

above the set-point desired, eg if we are adjusting the throttle to 20 bar the booster will be sending for the rider a 21-22 bar

pressure.

The boosters G-43 and G-44 model have similar principle of operation, although they have constructive

differences, such as different internal, this differentiation is necessary for one to be able to operate with regulatory pressure

valve FA and the other regulators for use with FF, where the pressure regulator valve model G URANO pre-regulators are

used in model 43 assemblies with valves and FF G-44 in FA valve assemblies.

The boosters G-43 and G-44 normally have three connections to the process, represented in red line in the figure

above is from the regulator inlet and is loaded with the inlet pressure, the yellow line is the output pressure of the main

regulator also sensing called socket and is responsible for acting on the diaphragm (A) of the booster, moving the axis (B)

causing it to move away from the sleeve (C), thus allowing the passage of gas from the regulator input pressure 1 to 2

kgf/cm² above the set point pressure of the main regulator, which in turn is represented by the color green and is taken to

proceed to the Pilot.

Please note: In some assemblies the booster can be integrated into the pilot, this amendment is merely to reduce

ergonomic spaces, number of components and ease of operation, however it is important to note that the operating

principle is exactly the same as noted above.

A

C

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 13 de 61

3.4 PILOTS (G-40 & G-42)

The number of drivers G-40 and G-42 is comprised of dual diaphragm pilot that can achieve much higher precision

adjustment to other drivers due to their constructional characteristics.

Pilots are responsible for sending the exact loading pressure for pressure regulating valves open or close under normal

process conditions by the balance between the force of the regulating spring and the outlet pressure received by the

sensor outlet.

The green line represents the pressure from the booster or pre regulator, the yellow line is the regulator output

pressure (sensor outlet) and this is responsible for moving the diaphragm assembly (A) upward or downward, causing the

driver shutter (B) Move it headquarters (C) thus permitting the reduction in inlet pressure and sending the appropriate gas

pressure to perform charging of the main valve causing the valve to open or close according to the process conditions.

A

C

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 14 de 61

3.5 FILTERS

The GASCAT called pilot blocks consisting of pilot regulator and pre always possess a mechanical barrier against solid

impurities, the barrier comprises filter elements polypropylene filtration degree of 10 microns.

This barrier aims to prevent solid contaminants in the pipe can clog or damage the internal pre regulator and the pilot,

but it is important to note that this filter does not replace the filtration system that should be provided in the

previous steps to pressure regulating so as to leave the clean fluid and correct operating conditions, the filter is

designed to serve as a barrier to the last solid contaminants.

The URANO pressure regulators are available with F-10 filter, mounted separate from the pilot block or compact

version with the filter element already attached to the pre regulator.

3.6 ACTIVE MONITOR MOUNT

The so-called active monitor mounting configuration is much used in the distribution and natural gas transmission this

setting is usually adopted when the difference between the inlet pressure and the outlet pressure is greater than 16 bar

and the stress test pressure pipe and other components downstream the setting is less than the inlet pressure as specified,

for example DIN EN 12186, in this case the goal of the monitor regulator is use to increase the station's security level.

But it is valid to remember that this is the recommendation of DIN EN 12186, there are other standards that specify

different conditions for the use of the active monitor system.

The active monitor system is the use of two pressure regulators in series one being called which will be in active

operation (adjusting) process under normal conditions and should be of the open type failure SO (FA), and closes the

failure monitor type SC (FF) which shall remain fully open under normal operating conditions and only take the adjustment

in the case of active regulator failure.

As previously disclosed in this manual is important to remember that the classification of AF or FF is given by the

failure of the diaphragm only the main valve and the lack of power to shutter operation according to DIN EN 334, however

it is quite possible that the regulator FA eg fail closed due to some other unforeseen condition in the process, see below

some regulators failed positions SC URANO and URANO SO due to possible situations in the field:

SITUATION

URANO SC (FF)

URANO SO (FA)

FAIL OPEN

FAIL CLOSE

FAIL OPEN

FAIL CLOSE

FAILURE VALVE DIAPHRAGM MAIN

X X

FAULT PILOT DIAPHRAGM

X X

DIRT BETWEEN THE PLUG AND VALVE SEAT

MAIN

X X

DIRT BETWEEN THE PLUG AND THE PILOT

SEAT

X X

AXIS MAIN CAUGHT

X X X X

TAKE BREAK SENSING

X X

OBSTRUCTION OF PILOT SEAT

X X

FAILURE DIAPHRAGM BOOSTER

X X

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 15 de 61

The URANO regulators operating in the active monitor system exactly as described 3.1 and 3.2 of this manual, but

as can be seen in the previous scheme the sensor making the SC controller (FF) is downstream controller active OS (FA)

and its set-point must be adjusted to a slightly higher pressure to the set-point controller active (5% - 10% depending on

the application).

Thus during normal operation the monitor regulator will be completely open while the active regulator is in

operation and if there is any failure in the active regulator and the pressure begins to rise the monitor regulator will come

into operation.

4.0 – INSTALLATION

4.1 FILTER

We recommend installing a filter type "cartridge", with grade 5 Micra filtration, as close to the regulator inlet, without

being united flange to flange, therefore, the filter installed immediately upstream of the regulator may cause turbulence

causing disturbance in the regulator pressure control. Care for the filter installation is essential to the smooth operation of

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 16 de 61

the instrument as any existing particles in the pipe can become lodged between the seat and the shutter, damaging them

and causing feedthrough.

4.2 CLEANING

Check the pipe cleaning before valve installation. We recommend a complete purge of the line with nitrogen or

compressed air.

4.3 DIRECTION OF FLOW AND SYSTEM INTEGRITY

Before proceeding with the installation of the equipment you must ensure that:

1) The equipment is in perfect condition or has function in damaged evidence in the handling during transport, if

you have a fault not proceed with the installation and contact the GASCAT.

2) The area in which access and installation of the equipment is suitable, including for future maintenance.

3) The facility was designed to support the load imposed by equipment.

4) The input and output connections where the pressure regulator is installed are perfectly aligned.

5) All outlets of necessary pressure in the pipeline downstream equipment for sensing, were provided and are

respecting the dimensions recommended by the manufacturer.

6) It was predicted gauge or any other equipment upstream pressure indicator and downstream equipment to

allow the correct fit for the start-up.

7) was provided a line of vent between the regulator and the first output block valve to assist the operator during

start-up.

8) Check the direction of flow of the body marked throttle valve and pay attention to the time of installation so that

it is properly positioned.

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 17 de 61

4.4 SENSE

The correct positioning of making impulse in the pipeline is essential for the proper functioning of the throttle valve,

therefore install the pilot impulse outlet regulator downstream at a minimum distance of 5 times the nominal pipe

diameter and stretch obstruction-free pipe with a pipe diameter where the gas flow rate does not exceed the maximum

speed of 25 m / s (considering the lower output pressure and the maximum flow).

To obtain a better pneumatic signal, use ½ OF tubbings "stainless steel AISI 316 to connect the regulator to the

process.

In order to avoid the accumulation of impurities and condensate in the impulse taken recommend that they be

installed with a slope of 5% to 10% towards the connector on the pipe.

Pay attention to the connections welded pipe for it to be totally clear, without any welding residue that could

interfere with pneumatic signal.

Each throttle model URANO SC (FF) needs three process connections: one directly to the actuator on the

diaphragm, one that will be connected directly below the pilot and a third for the purpose of discharging the actuator

under the diaphragm.

IMAGE URANO FF

They should be installed block valves of any kind into the pressure

regulators pulse taken.

UNLOADING

LINE

SENSING LINE

PILOT

SENSING LINE

VALVE

FRONT VIEW

REAR VIEW

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 18 de 61

For valves model URANO SC (FF) mounted to operate in active monitor systems the booster is shipped with a

connector more on this socket is connected to the input of the booster control valve active pressure, thus serving as

food for the booster active valve.

When URANO SC (FF) valve is mounted to operate in a system where it will be the only pressure reduction stage

this jack is provided sealed by a plug and should not be used.

Each throttle model URANO OS (FA) requires two connections to the process: one directly below the pilot and a

second that will serve as unloading the actuator under the diaphragm.

IMAGE URANO FA

UNLOADING LINE

SENSING LINE PILOT

FRONT VIEW

REAR VIEW

MOUNTING SYSTEM

ONLY IN ACTIVE

MONITOR

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 19 de 61

4.5 SCHEME RECOMMENDED INSTALLATION

4.5.1 SINGLE REGULATOR

1 – Inlet shut-off valve . 6 – Partial relief valve

2 – Filter cartridge type degree of filtration 5 micra 7 – Output pressure gauge + manifold 2 way

3 – Entry gauge + manifold 2 way 8 – Valve vent

4 – Automatic shut-off valve for over pressure (SSV) 9- Output block valve

5 – Pressure regulator valve model URANO GASCAT

Note: The position indicated for the sensor outlet may be less than 5D from the installation project to be reviewed and

approved by engineering GASCAT.

5 ND

1

6

5

4

3

2

9

8

7

Installation Manual, Maintenance and Operation

Pressure Regulating Valve – Model Urano

MI-31

Elaborate Verified / Approved CSQ Date Review Page

Raphael Pereira Vanízio Lizo Gustavo Nieto

05/06/14

04 20 de 61

Another recommended installation option is the use of a lung to connect the sensor taken near the equipment, among

the advantages of adopting this configuration include:

1) Greater convenience during maintenance.

2) Pneumatic signal of better quality (stable).

3) Reduction of damage to tubbings during maintenance and transport.

Note: The position indicated for lung outlet may be less than 5D from the installation project to be reviewed and

approved by engineering GASCAT.

5 ND

Other manuals for URANO FA

1

This manual suits for next models

1

Table of contents

Other Gascat Control Unit manuals

Popular Control Unit manuals by other brands

Seeed

Seeed Grove-Speaker manual

Graco

Graco SDP8 Series Installation and operation

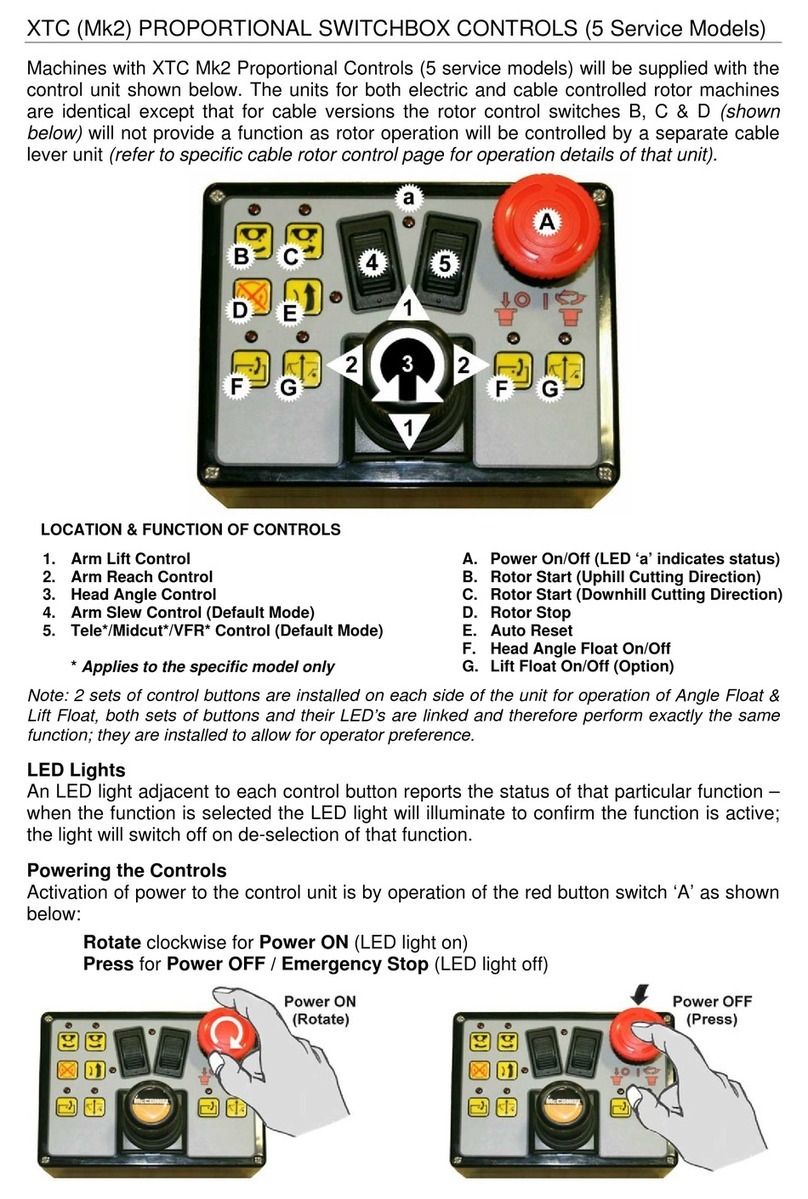

McConnel

McConnel 5 Service XTC Mk2 PROPORTIONAL SWITCHBOX... quick start guide

YASKAWA

YASKAWA S-II Series instructions

Racal Instruments

Racal Instruments 1260-43 user manual

PR electronics

PR electronics 9203 Series Safety manual

Emerson

Emerson Fisher TBX instruction manual

Raritan

Raritan I34M-1 Troubleshooting and Replacement

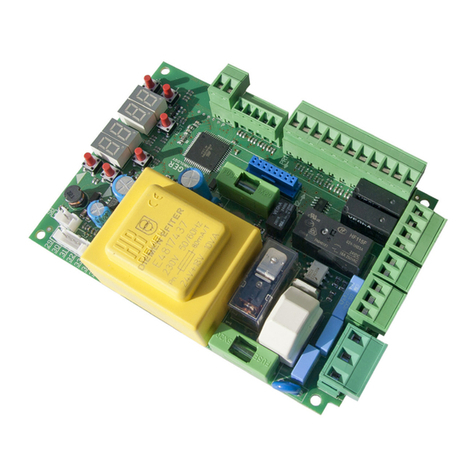

Roger Technology

Roger Technology H70/104AC Instruction and warnings for the installer

Victaulic

Victaulic 5-Year Rebuild Kit instructions

Cisco

Cisco ASA5506-AP702 user guide

Roger

Roger H70/200AC Instruction and warnings for the installer