GASER Super User manual

HAMBURGER FORMING MACHINE

Mod. SUPER

-2-

INDEX

1. INDUSTRIAS GASER .............................................................................................3

2. EC DECLARATION OF CONFORMITY ..................................................................4

3. HYGIENE CERTIFICATE ........................................................................................5

4. INTRODUCTION.....................................................................................................6

4.1 Safety................................................................................................................6

4.2 Hygiene.............................................................................................................6

5. TECHNICAL SPECIFICATIONS..............................................................................7

6. RECEIPT AND START-UP ......................................................................................8

6.1 Receipt..............................................................................................................8

6.2 Start-up..............................................................................................................8

6.3 Notes...............................................................................................................11

6.3.1 Changing patty shape ..............................................................................11

6.3.2 Paper dispenser.......................................................................................11

7. CLEANING............................................................................................................12

9. TROUBLESHOOTING...........................................................................................16

10. GENERAL DIAGRAM..........................................................................................17

10.1 Overview ......................................................................................................17

10.2 Chassis overview ..........................................................................................19

10.3 Former shaft overview...................................................................................21

10.3.1 Overview complete former bearing housing...........................................22

10.4 Tank overview................................................................................................23

10.4.1 Overview complete tank bearing housing ..............................................26

10.4.2 Gear motor.............................................................................................27

10.5 Ejector overview............................................................................................28

10.6, Paper dispenser overview............................................................................29

10.7 External thickness control overview ..............................................................30

10.8 Safety mechanism overview..........................................................................31

10.9 Protectors overview.......................................................................................32

10.10 Electrical cabinet overview..........................................................................33

12. WIRING DIAGRAMS...........................................................................................34

-3-

1. INDUSTRIAS GASER

Since its foundation in 1969, INDUSTRIAS GASER has specialised in manufacturing a range of

stainless-steel machinery for the meat industry.

Since 1985 we have constantly developed technology for GASER-brand hamburger-forming

machines, developing a distinctive system based on a SIMPLER, MORE EFFECTIVE AND MORE

ECONOMICAL TECHNIQUE.

In the 1990s, INDUSTRIAS GASER expanded into markets in various countries around the world, and

not just in the hamburger sector.

We are aware that our work would be of no value without the trust of our existing clients and partners

or the interest shown by those who wish to join them.

We thank them all.

INDUSTRIAS GASER GASER EUROPA

Salt, Girona, SPAIN L’viv, UKRAINE

INDUSTRIAS GASER Ctra, Bescanó, 15, Pol. Torre Mirona 17190 Salt (Girona) - Spain

Tel. 34 972 23 65 72 | Fax 34 972 23 63 66 | Whatsapp: (34) 679 49 65 06

email: [email protected]

GASER EUROPA вул.Б.Лепкого,1 81160 смт.Щирець Пустомитівский р-н Львівська область

Украіна - Ukraine

Tel. 38 (03230) 67251/84

Fax 38 (03230) 67191

email: gasereuropa@gaser.com

For more information about the company and its products: www.gaser.com

-4-

2. EC DECLARATION OF CONFORMITY

We declare under our responsibility that the following machine:

Brand: GASER

Model: SUPER

Serial no.

Year of construction:

is in conformity with the following regulations

UNE-EN ISO 12100:2012

UNE-EN ISO 14120:2016

UNE-EN ISO 14121-1:2008

UNE-EN 60204-1:2007 60204-1:2007 CORR. 2010 60204-1:2007/A1:2009

UNE-EN ISO 13849-1:2008/AC:2009

and is in conformity with the following directives

Machinery directive: 2006/42/CE

Low voltage directive: 2014/35/UE

Electromagnetic compatibility directive: 2014/30/UE

It is forbidden to make any change or modification to the machine without the prior written permission

of our technical department. Use of the machine in these conditions could cause accidents, in which

case INDUSTRIAS GASER S.L. accepts no liability for the improper use of the machine.

Salt,

CARLOS GARGANTA SERRAMITJA

TECHNICAL DIRECTOR INDUSTRIAS GASER S.L.

-5-

3. HYGIENE CERTIFICATE

We declare the machine:

Brand: GASER

Model: SUPER

Serial no.

Year of construction:

is in conformity with the following regulations

Regulation (EC) 1935/2004, materials and articles in contact with food, repealing Directives

80/590/EEC and 89/109/EEC.

This means that all of the types of steel and plastic from which the machine is constructed and which

are in contact with the meat comply with the hygiene rules and regulations in force.

* Plastic material: polyethylene terephthalate (PETP), white, density 1.37 g/cm3,

Manufactured in accordance with DIN 50014.

* Stainless steel: AISI 304, manufactured in accordance with European regulations EN-10088,

Chemical composition: C≤0.07% Si≤0.75% Mn≤2% Cr=18-19% Ni=8-10%

Salt,

CARLOS GARGANTA SERRAMITJA

TECHNICAL DIRECTOR INDUSTRIAS GASER S.L.

-6-

4. INTRODUCTION

Before using or handling the machine, you must read this manual carefully.

The instructions in this document are, whenever possible, accompanied by illustrations to help with

understanding of how to start, use and clean the machine.

This manual is subject to amendment.

4.1 Safety

It is forbidden to make any change or modification to the machine without the prior written permission

of our technical department. Use of the machine in these conditions could cause accidents, in which

case INDUSTRIAS GASER S.L. accepts no liability for improper use of the machine.

The machine has been designed for use with food products and must be used in the way described in

this manual. Any use other than the specified one will involve risk for the user and for the machine.

INDUSTRIAS GASER S.L. accepts no liability either for damage to the machine or personal injury or

injury to third parties that this use might cause.

4.2 Hygiene

All of the materials used in the manufacture of the machine and which come into contact with food

comply with Regulation 1935/2004. Consequently, the machine has the CE mark.

It is not recommended to use detergents containing chlorine, any of its derivatives or any other product

that could damage the construction materials of the machine.

-7-

5. TECHNICAL SPECIFICATIONS

1. Tabletop machine

2. Can be dismantled for ease of cleaning

3. Easy maintenance

4. Made from stainless steel and plastics suitable for use with food

5. Frequency converter

6. Capable of placing paper on one side

7. Produces round patties of 30 to 120 mm diameter and other shapes (these must be concentric

with a circle and of the measurements mentioned above)

8. Weight controllable with a maximum patty thickness of 25 mm

9. Produces 20 to 60 patties/minute

10. Capacity: 15 kg mixture

11. Motor power (single-phase) 750W, 220V, 50Hz.

12. Dimensions of assembled machine: 650 × 450 × 740 mm

13. Machine weight: 77 kg

-8-

6. RECEIPT AND START-UP

6.1 Receipt

When you receive the machine, you must first check that it is in perfect conditions, without any

damage, dents or knocks.

If there is any problem, we advise you notify the distributor or INDUSTRIAS GASER S.L. directly.

6.2 Start-up

1. These machines essentially consist of 3 parts: chassis, former unit and tank.

Image 1. Main parts

2. It is important that when the machine starts working, it is completely clean to ensure it works

properly.

3. The SUPER model hamburger forming machine works on single phase 220 V 50 Hz electrical

current.

-9-

4. Before starting production, if it has not been calibrated previously, the thickness of the patty must

be calibrated. To do so, follow these steps:

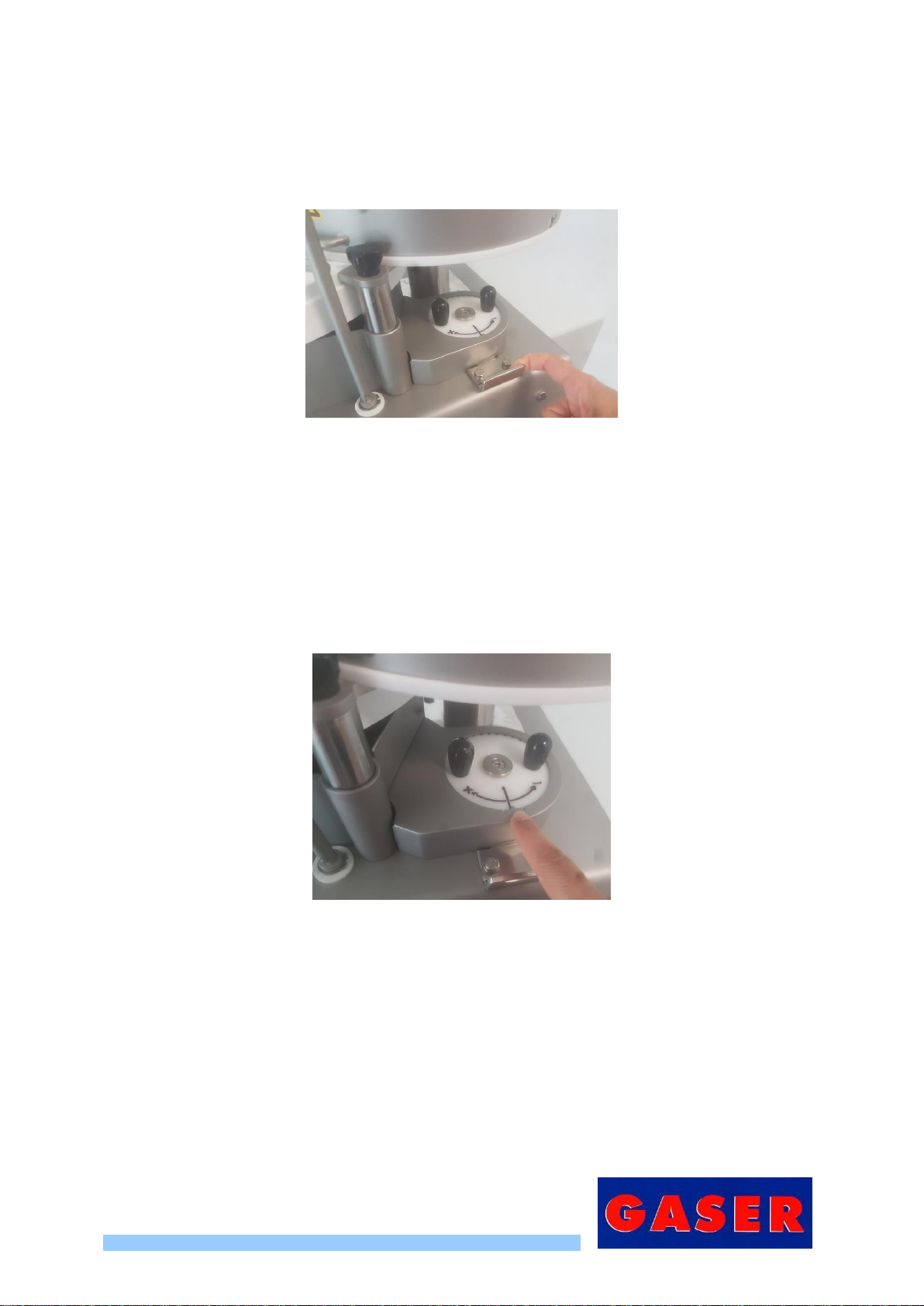

4.1.Pull on the latch (Pos. 8, external weight control overview) to expose the calibration gears

(Pos. 1, external weight control overview).

Image 2, Calibration 1

4.2.Turn the plate (Pos. 1, external weight control overview) clockwise to increase the

thickness and anti-clockwise to reduce it. Each turn of the plate changes the thickness of

the patty by 1 mm.

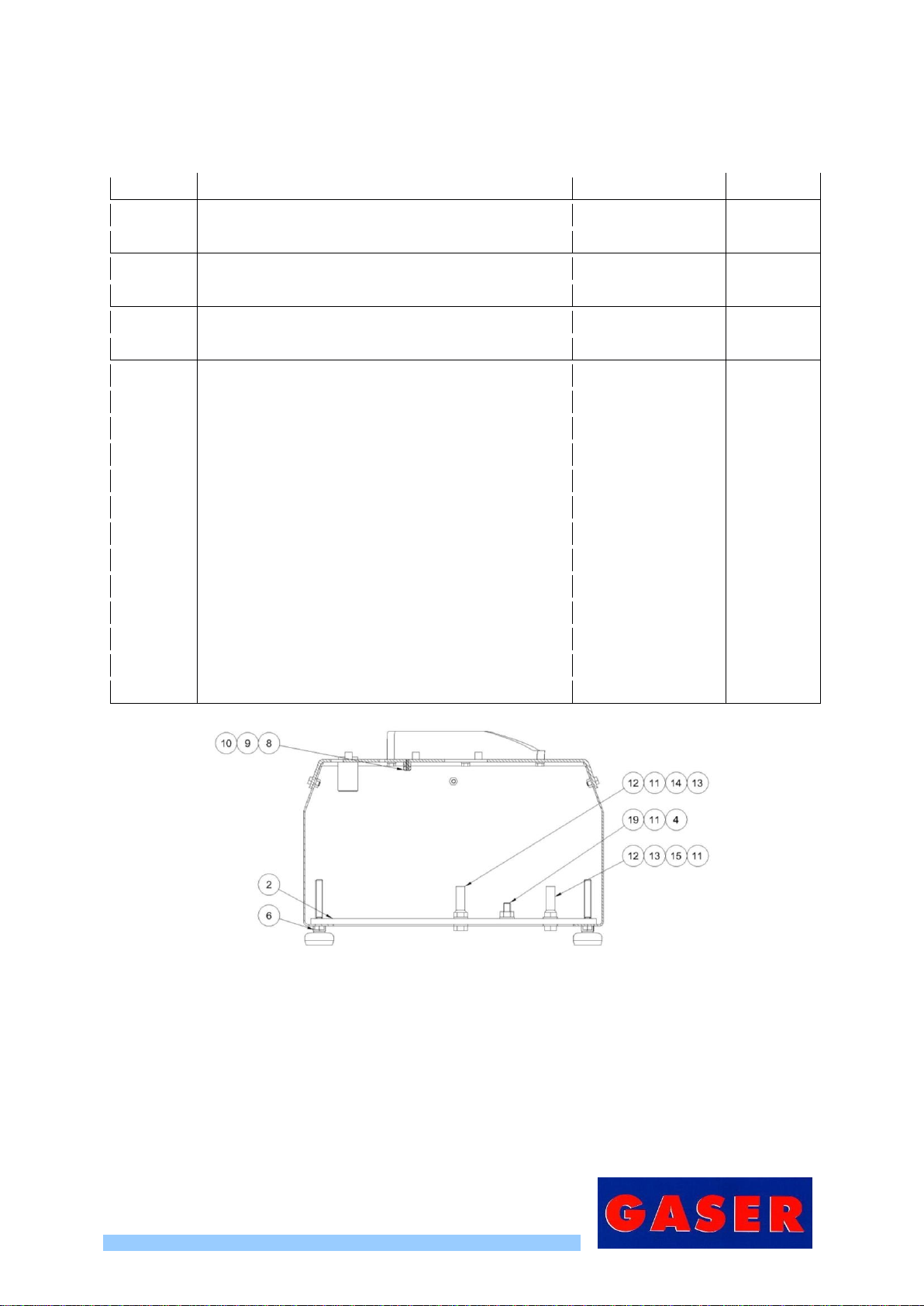

It is vital that when you perform the calibration of the thickness of the patties, the

calibration gear makes full turns, so that the mark on the gear lines up with the arrow on

the protection.

Image 3, Gear position

5. To start production, first fill the machine’s tank (Pos. 8, tank overview) with the mixture you wish to

use.

6. Next, start the machine up using the main switch (Pos. 3, electrical cabinet overview). Once the

machine is ON, press the green “START” button (Pos. 15, overview) and make 2 or 3 patties in

manual mode (Pos. 4, electrical cabinet overview) to check that the weight is correct. If the weight

of the product has to be modified with meat in the machine, it is vital that all of the plate holes

-10-

(Pos. 2, former shaft overview) are exposed. Once the desired weight has been found, select the

automatic mode and press the green start button again.

Image 4, Position of the plate

7. If the patties are seen to come out with a layer above the plate or they are not well compacted, this

can be adjusted using the weight calibration gear. Turn it a few degrees to the left or right until the

mark on the gear lines up with the grooves on the protection.

Image 5, calibration 1

Image 6, calibration 2

8. To extract the patties, use the slice designed for this purpose, sliding it over the plate (Pos. 12,

overview), keeping it completely flat.

The slice must be kept clean at all times. We recommend providing a container with water to wet

the slice and keep it damp during this process.

-11-

6.3 Notes

6.3.1 Changing patty shape

To change the shape of the patties, first disassemble the machine as shown in point “7 CLEANING”.

Once the machine has been disassembled, you can change the shape of the patties and reassemble

the machine by reversing the order of disassembly.

Remember that when you change the shape, the weight might vary.

6.3.2 Paper dispenser

To place paper on the patties, fit the paper dispenser (Pos. 5, overview). First, insert the shaft. Next,

insert the guide into the former shaft keeping it as horizontal as possible.

Image 7, Inserting axle

Image 8, Inserting guide

Insert the paper discs so that the waxed side faces downwards in the dispenser, as this is the side that

will be in contact with the mixture.

-12-

7. CLEANING

When you have finished using the machine, it must be cleaned. To do so, follow these steps:

1. First, remove the paper dispenser unit, keeping it as horizontal as possible when lifting it.

Image 9, Removing paper positioner

2. Next, remove the tank (Pos. 8, tank overview). To do this, lift the cover of the tank (Pos. 15, tank

overview), extract the safety mechanism guide tube (Pos. 9, safety mechanism overview) and

then turn the tank clockwise.

Image 10, Lifting lid

Image 11, Safety guide tube

-13-

Image 12, Turning tank clockwise

Image 13, Removing tank

3. Remove the vanes (Pos. 16, tank overview), loosening the safety screw (Pos. 9, tank overview) by

turning it clockwise.

Image 14, Removing safety screw

Image 15, Removing vanes

4. Next disassemble the base of the tank (Pos. 3, tank overview). The two knobs must be removed

(Pos. 14, tank overview).

Image 15. Removing knobs

Image 14, Removing tank base

-14-

5. Finally, remove the former (Pos. 2, former shaft overview) by loosening the former shaft nut (Pos.

5, former shaft overview).

Image 16. Removing former shaft nut

Image 17. Removing former unit

6. Clean the disassembled components with pressurised water and dry well, using compressed air if

possible. Clean the machine’s chassis with a damp cloth. Never clean it with pressurised water.

Image 18. Machine ready for cleaning

-15-

8. MAINTENANCE

This machine requires virtually no maintenance. Even so, there are a few details that must be taken

into consideration.

1. Periodically check the condition of all moving parts: retainers, gears and bearings.

2. Periodically check the condition of the extractor slice thread (Pos. 12, overview).

If it is necessary to change the thread, to remove it, bend the slice, then you can easily remove the

thread and replace it with a new one.

Image 19, Folding to remove thread

Image 20, removing thread

3. Periodically check the condition of the gear motor.

4. Periodically check the condition of the safety elements.

5. Periodically check the general condition of the machine.

-16-

9. TROUBLESHOOTING

The table below lists the problems that might occur with the machine, their potential causes and how

to solve them.

Problem

Cause

Solution

The machine does not start

Machine unplugged

See manual “6.2. Start-up”, point 3

The safety elements have not

been fitted

Fit safety elements

The machine still does not start

Safety sensors have come lose.

Calibrate security sensors

Electrical connections or

components in poor condition

See manual “8. Maintenance”,

point 4

The patties do not come out well

formed (too little or too much

mixture)

Too little or too much mixture

See manual “6.2. Start-up”, point 7

The patty deforms with the

extractor slice.

The mixture is not correct.

The mixture should be smoother

or colder.

Incorrect use of the slice

See manual “6.2. Start-up”, point 8

Slice thread in poor condition

Change thread

-17-

10. GENERAL DIAGRAM

10.1 Overview

Number

Description

Reference

Units

1

CHASSIS UNIT

S1010000

1

2

FORMER SHAFT UNIT

S1020000

1

3

TANK UNIT

S1030000

1

4

EJECTOR UNIT

PLEASE CONSULT

3

5

PAPER DISPENSER

PLEASE CONSULT

1

6

EXTERNAL THICKNESS CONTROL UNIT

S1120000

1

7

SAFETY MECHANISM UNIT

S1150000

1

8

MAIN PROTECTION UNIT

S1160000

1

9

ELECTRICAL CABINET UNIT

S1250000

1

10

STAINLESS CHEESE HEAD SCREW M6 × 16

DIN84

FE0108M060160084

2

11

STAINLESS CHEESE HEAD SCREW M6 × 20

DIN84

FE0108M060200084

2

12

EXTRACTOR SLICE

S1000100

1

13

POTENTIOMETER

EL102010KM22

1

14

EMERGENCY STOP

SS530000

1

15

GREEN PUSH BUTTON

SS510000

1

16

TEARDROP TYPE GASER BRAND STICKER

PA0230GGASER

1

17

GASER BRAND STICKER

PA0230SUPER

1

18

BASIC/SUPER/MAXI TANK STICKER

PA0230TSUPER

1

-18-

Figure 1, Standard overview 1

Figure 2, Standard overview 2

-19-

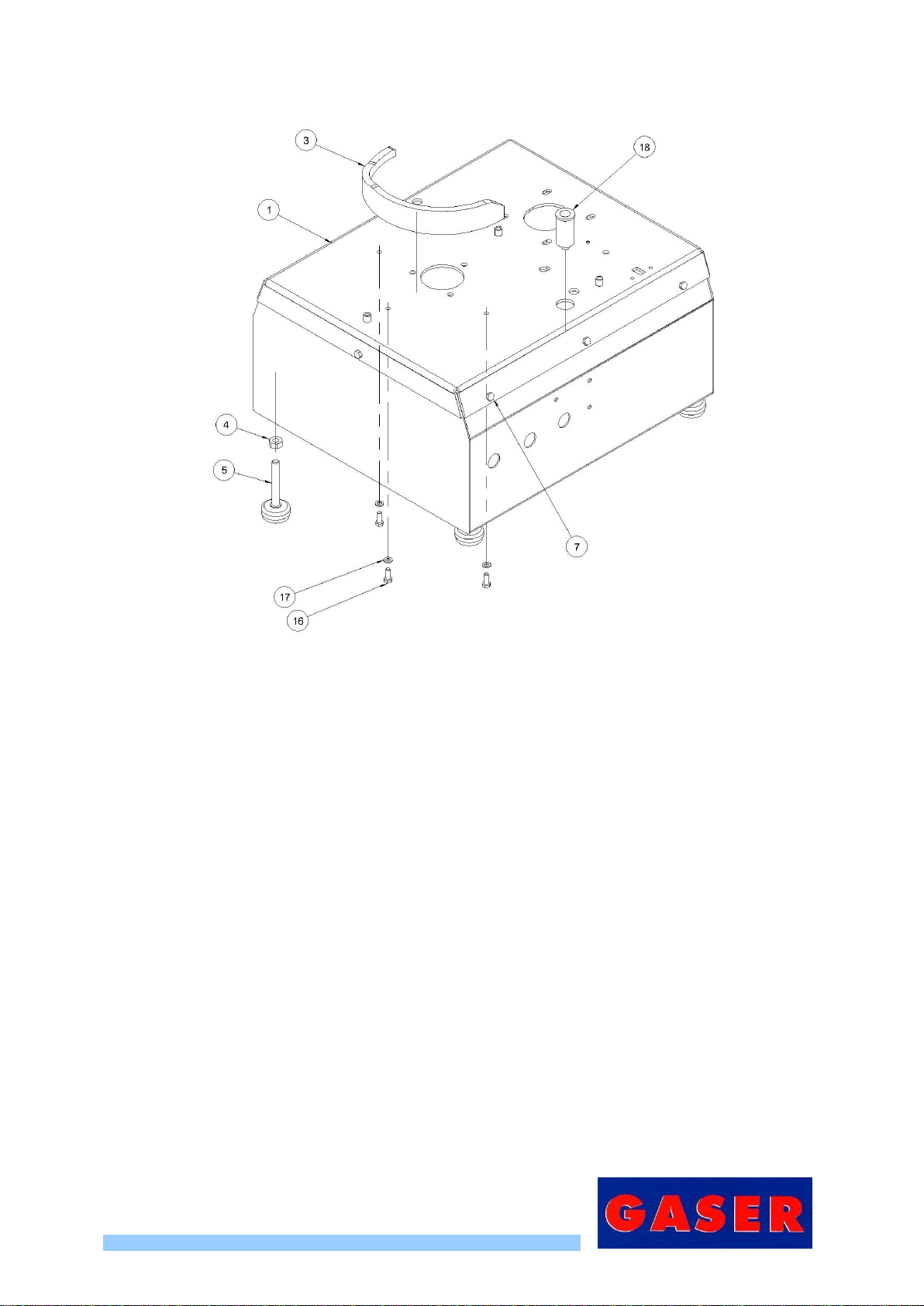

10.2 Chassis overview

Ref. S1010000

Position

Description

Reference

Units

1

CHASSIS

S1010100

1

2

MOTOR SUPPORT

S1010400-E

1

3

LIFTING RAMP

S1020900

1

4

STAINLESS HEX NUT M10 DIN934

FE0108M100000934

5

5

STAINLESS STEEL/RUBBER FOOT D-40

SI0226PID40M10

4

6

STAINLESS HEX SCREW M10 × 12 DIN933

FE0108M100120933

2

7

STAINLESS HEX SCREW M6 × 12 DIN933

FE0108M060120933

8

8

STAINLESS HEX LOCK NUT M6 DIN985

FE0108M060000985

1

9

STAINLESS HEX NUT M6 DIN934

FE0108M060000934

1

10

STAINLESS ALLEN GRUB SCREW M6 × 16 DIN913

FE0108M060160913

1

11

STAINLESS WASHER M10 DIN125

FE0108M100000125

5

12

NATURAL POLYAMIDE TUBE 12 × 10 mm

SI0236TPA1210

2

13

STAINLESS HEX LOCK NUT M10 DIN985

FE0108M100000985

2

14

STAINLESS HEX SCREW M10 × 45 DIN933

FE0108M100450933

1

15

STAINLESS HEX SCREW M10 × 55 DIN933

FE0108M100550933

1

16

STAINLESS HEX SCREW M6 × 16 DIN933

FE0108M060160933

3

17

STAINLESS WASHER M6 DIN125

FE0108M060000125

3

18

SAFETY MECHANISM SLEEVE

S1150100

1

19

MOTOR SUPPORT THREADED ROD

S1012000

1

Figure 3, Chassis overview 1

-20-

Figure 4, Chassis overview 2

Table of contents

Other GASER Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Blodgett

Blodgett XR8-G/AB Installation operation & maintenance

Lincat

Lincat UM50 Installation, operating and servicing instructions

CombiSteel

CombiSteel 7292 Series user manual

Falcon

Falcon DOMINATOR PLUS E3405 Installation and servicing instructions

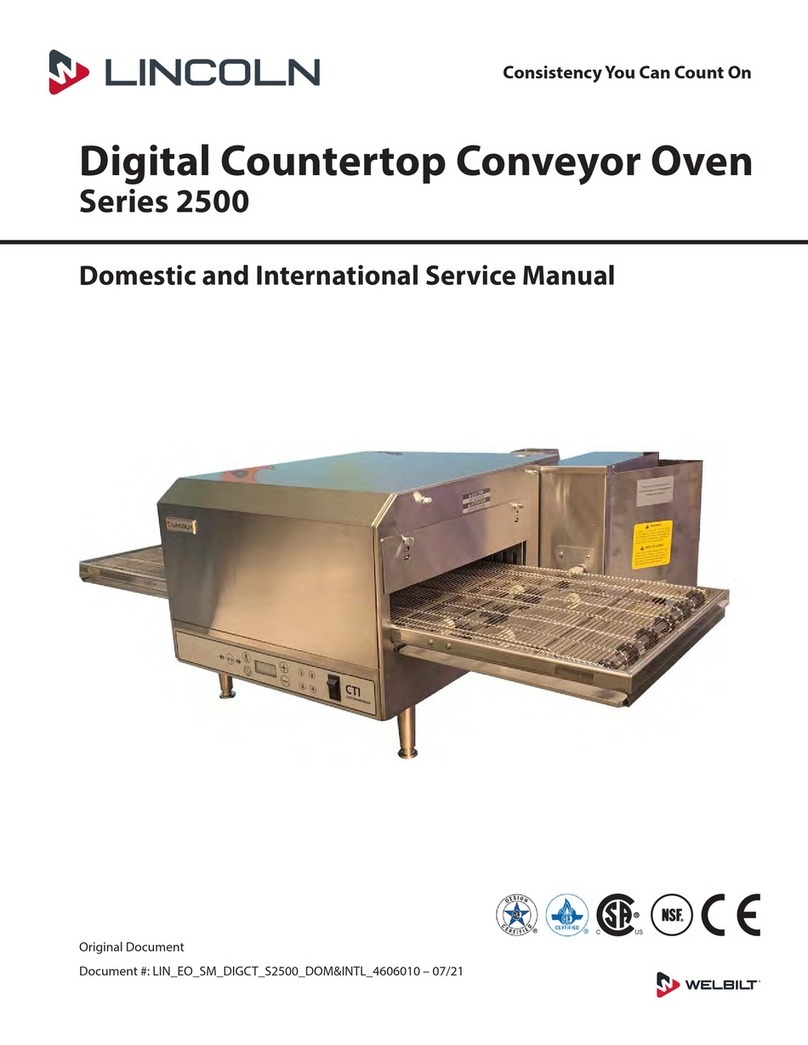

Lincoln

Lincoln V2500 Series Service manual

Electrolux

Electrolux SkyLine ChillS 202 user manual

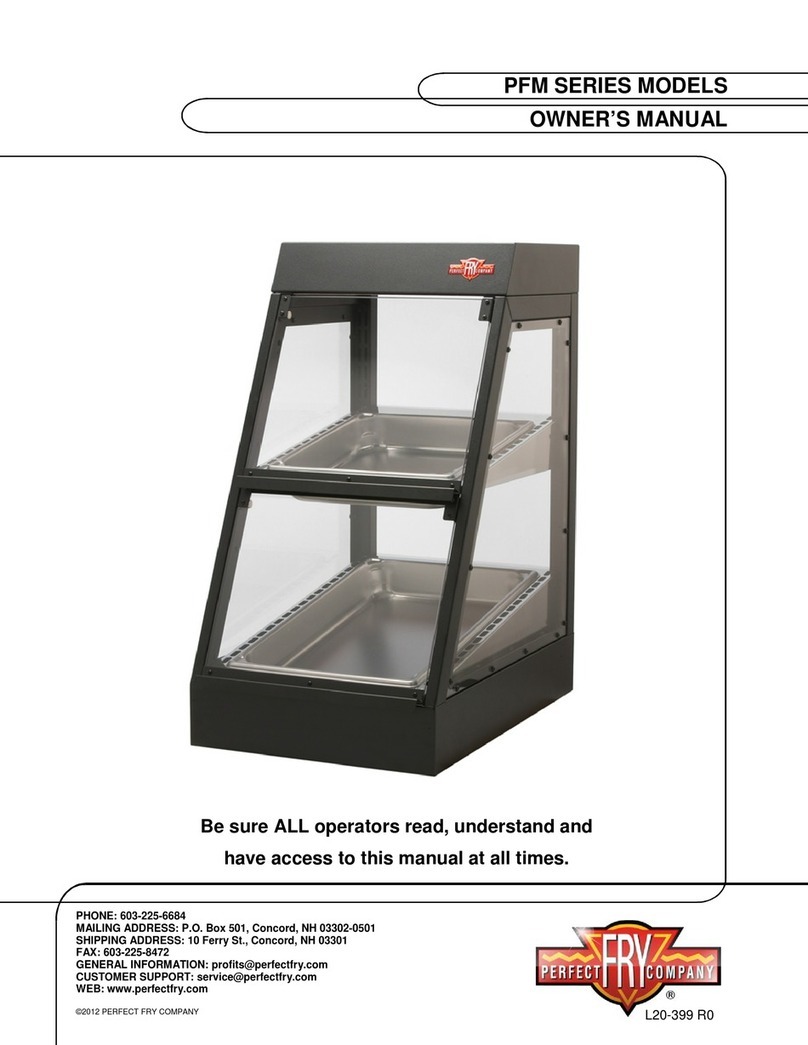

PERFECT FRY COMPANY

PERFECT FRY COMPANY PFM Series owner's manual

CHEFOOK

CHEFOOK Wi-food 69085003LF User and maintenance manual

KYONE

KYONE ADVANCE PRO manual

LKK

LKK Wok Series User Manual & Servicing Instructions

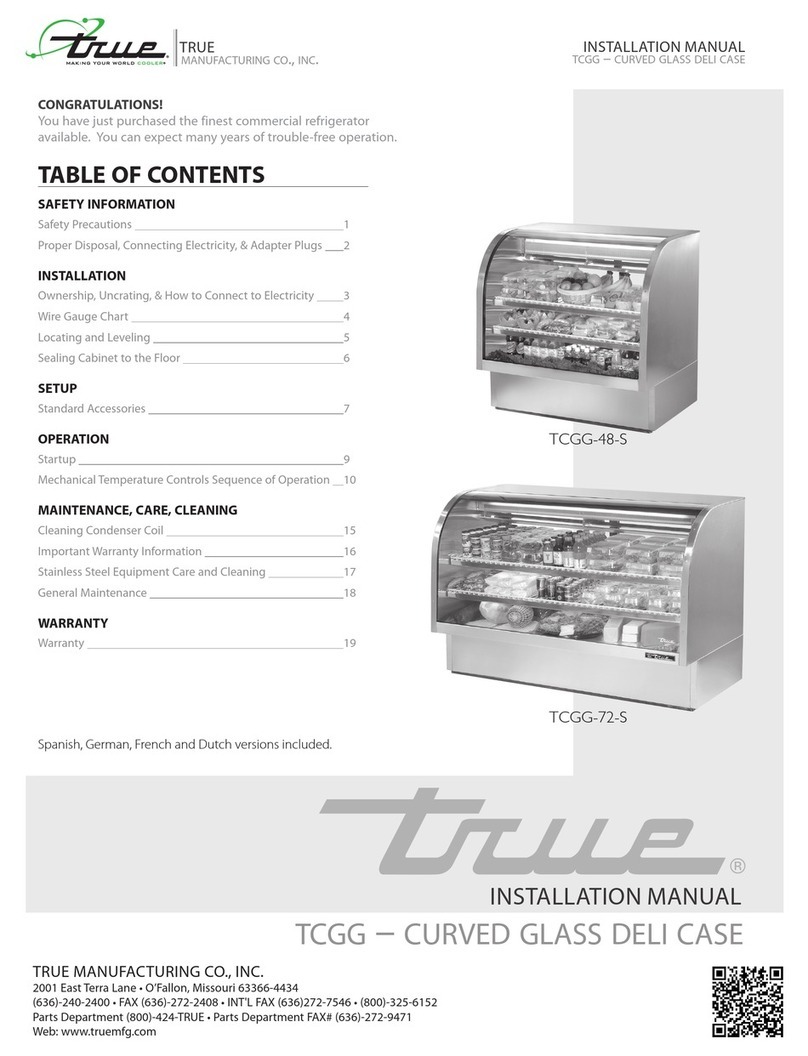

True

True TCGG-72-S-LD installation manual

Frigomat

Frigomat Taylor CH03 Series Operating instructions and maintenance