Gates GC32FLEX Guide

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GC32FLEX & GC32FLEX TSI

SAFETY AND OPERATION MANUAL

GC32FLEX/TSI

Product Number: 7480-0013

GC32FLEX

Product Number: 7480-7009

GC32FLEX POWER UNIT

Product Number: 7482-0123

GC32FLEX/TSI STAND

Product Number: 7482-0017

GC32FLEX/TSI RACK

Product Number: 7480-7003

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

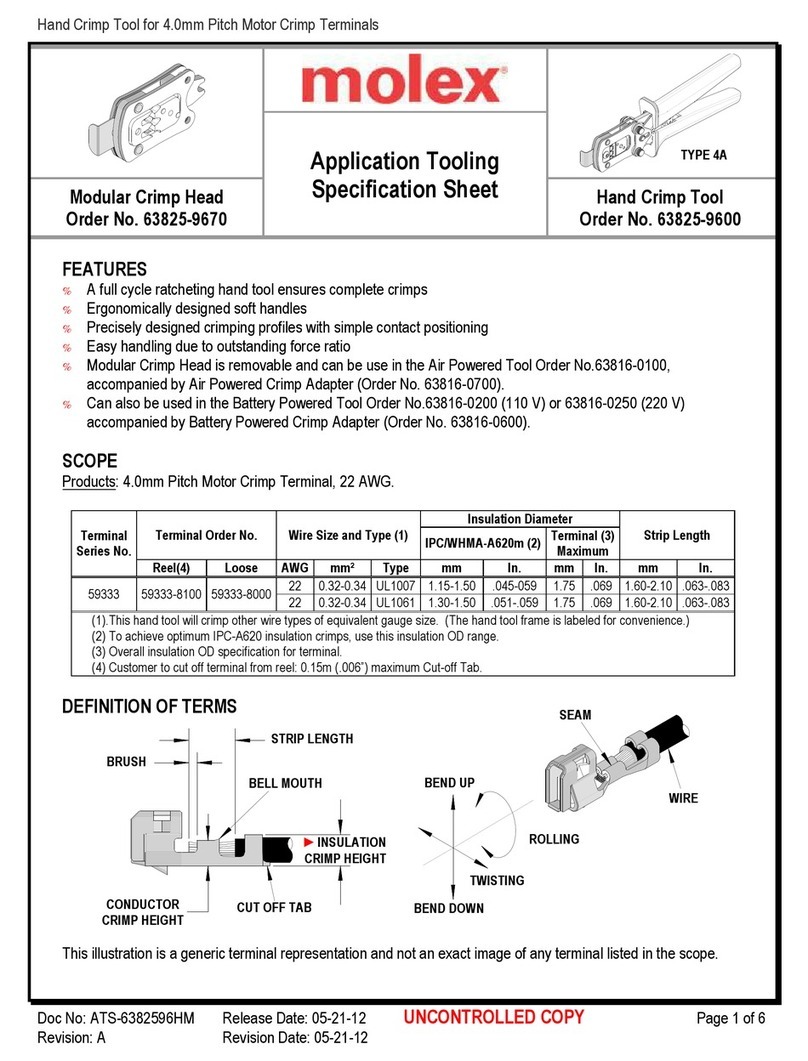

CRIMPER DETAILS GC32FLEX/TSI SAFETY AND OPERATION MANUAL

Serial No. ____________________________

Date of Purchase _____________________

YOUR CRIMPER DETAILS

CRIMPER SPECIFICATIONS

GC32FLEX GC32FLEX TSI

DYNAMIC

Nom. Size (Hydraulic Hose Size) 2 Inches

Die Set Type 32 Series

Crimping Range (Inch with Std. Die Set) 1/4 to 2 Inches

Crimping Range (Inch with optional. Die Set) 3/16 to 2 1/2 Inches

Crimping Force 3700 kN / 370 tonne

PHYSICAL (UNIT) Unit Dimensions (W x D x H) 28.6 x 25.5 x 18 Inches

Unit Weight (Without Dies & Oil) 380lb / 173kg 485lb / 220kg

PHYSICAL

(SHIPPING)

Shipping Space 161gal / 610L

Shipping Weight 530lb / 241kg 662lb / 300kg

Shipping Crate Size (W x D x H) 40 x 31 x 30 Inches

ELECTRICAL

Supply (Voltage/Current/Frequency) ** 220VAC / 20A /

60Hz

Plug Type (North America) ** NEMA L6 20

Phase ** Single Phase

Power ** 1.5kW

HYDRAULIC

Rated Pressure 690 Bar / 10,000 PSI

Reservoir Capacity (Min) 2L / 0.5gal 14L / 3.7gal

Recommended Filtration ** 10um

Oil Specification ** ISO 22

MAINTENANCE Grease Specification Tungsten Disulphide (7482-0172)

**Dependant on Power Unit

1

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

TABLE OF CONTENTS GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SAFETY 3-6

BOX CONTENTS 7

CRIMPER SET-UP (GC32FLEX/FLEX TSI) 8-10

Unboxing.........................................................................................8

Lifting and Installation GC32FLEX ....................................................................9

Lifting and Installation GC32FLEX TSI ................................................................10

GC32FLEX

GC32FLEX TSI General Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Power Unit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tablet Installation and e-Crimp™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operational Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

Electronic Dial Indicator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Electronic Dial Indicator Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Full Operating Procedure Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

GC32FLEX TSI

GC32FLEX TSI General Layout ......................................................................19

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-21

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Foot Pedal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tablet and Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operational Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-28

Software Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

e-Crimp™ Selection/Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

e-Crimp™ Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

e-Crimp™ Sensor Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

e-Crimp™ Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

e-Crimp™ Calibration Offset Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Full Operating Procedure Overview 29

GC32FLEX POWER UNIT GENERAL LAYOUT 30-33

Unboxing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Lifting and Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation and Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

QUALITY ASSURANCE FEATURES 34-39

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-37

Bluetooth Calipers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-39

OPERATIONAL INFORMATION 40-42

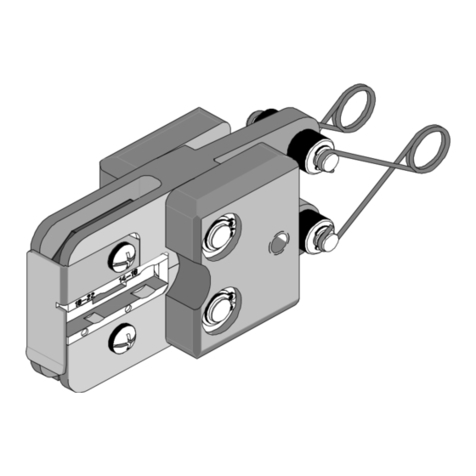

Quick Change Tool Operation (Die loading/unloading) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-41

Elbow Fittings Fitment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

HOSE PREPARATION AND MEASURING 43-44

Prepare Hose Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Measure Hose Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

PERIODIC MAINTENANCE 45-46

GC32FLEX/GC32FLEX TSI Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

GC32FLEX TSI Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

TROUBLE SHOOTING 47-50

Control Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Incorrect Loading of Set Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sensor Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Retract Limitation and Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

REPLACEMENT PARTS 52-55

GC32FLEX TSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51-52

GC32FLEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-54

DIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

WARRANTY 56

NOTES 57-59

TABLE OF CONTENTS

3

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SAFETY

WARNING

An incorrect hose assembly can rupture or blow apart in use, resulting in property damage, serious injury

or death.

REMEMBER: Others depend on you to make correct assemblies.

Hose Assembly Fabrication.

■Component inspection: Before creating an assembly be sure to inspect all components to ensure

they are the correct product, cut correctly, without any visually identifiable defects.

■Couplings (compatibility): Hose fitting components from one manufacturer are not usually

compatible with fitting components supplied by another manufacturer. Never mix and match hose

couplings from different manufacturers unless approved by both parties.

■Hose assembly equipment (crimpers): Hoses and fittings from one manufacturer should not generally

be assembled with the equipment of another manufacturer.

NOTE: Gates recommends only those hose and coupling combinations specified in the Gates Hydraulic

Product catalogs. Gates disclaims any liability for any hose assemblies which have not been produced in

conformance with Gates assembly recommendations.

WARNING

Carefully read and understand the following warnings before operating this crimper.

FOR SAFETY’S SAKE USE THIS MACHINE ONLY IF YOU:

1. Receive hands-on TRAINING with this Gates crimper and assemblies.

2. Follow current GATES OPERATING MANUAL and CRIMP DATA for the GC32FLEX/GC32FLEX TSI crimper.

3. Use only GATES, NEW and UNUSED hose and fittings.

4. Wear SAFETY GLASSES.

5. Keep hands clear of moving parts.

!

4

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SAFETY

WARNING

This Safety & Operation Manual is provided for your safety and the safety of others. Every operator MUST

have completed training and have an understanding of the crimper and the requirements of hose assemblies

before using this machine.

It is the responsibility of the owner of this crimper to ensure that ONLY persons who have an understanding

of the local regulations for work safety and accident prevention in addition to having undertaken training on

using this crimper be allowed to operate this machine.

It is the responsibility of the operator of this crimper to observe the rules and guidelines set out in this manual

and those provided by the owner of this machine.

This Safety & Operation Manual MUST be located near the crimper at all times and be used as a reference

when required. Regulations for Work Safety and Prevention of accidents MUST also be available to the

operator of this crimper.

WARNING

Every crimper has been engineered to the highest possible standard and thoroughly tested prior to release.

Regardless of this, dangerous situations can arise if the safety rules and regulations are not adhered to when

using the crimper.

!

5

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SAFETY

WARNING

This Gates crimper has been engineered and qualified for Gates product ONLY. Crimping any NON-GATES

fluid power product, including miscellaneous items (cable/pipe) through the machine will not only VOID the

warranty but also breach the intended use and purpose of the machine and contravene basic regulations of

Work Safety and Prevention of accidents.

Intended use and purpose outlined in this manual also includes regular maintenance. Failure to use the

specified grease will also VOID Warranty.

Warranty and Liability

The terms and condition(s) of sale and delivery shall apply. A copy of these terms and condition can be

provided on request, but generally include conditions for intended use and purpose, improper procedure

concerning transport, storage & maintenance, unauthorized use, constructional changes or repairs and failure

to detect wear.

Only authorized/qualified electricians are allowed to work on the electrical system of Gates crimpers.

It is the responsibility of the operator to ensure that no oil from this crimper is allowed to seep into the

ground, in accordance with the pollution rules of the Water Resource Management Laws.

1. Avoid contact with oil for prolonged periods.

2. Keep workplace clear of objects and trip hazards.

3. Wear safety equipment at all times when operating the machine.

4. Keep body parts away from the machine when in use, do not put hands in crimper when operational.

6

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SAFETY

WARNING

Intended Design Use

Using this machine for other than its intended purpose will void the manufacturer’s warranty and may cause

serious or fatal injury.

Personal Safety

Regardless of local accident prevention regulations, the following procedures should be observed to maintain

the health and safety of operators.

1. Always wear protective clothing and apparatus as outlined in the local accident prevention regulations.

2. Ensure that safety and danger notifications have been observed.

3. Make sure the work area is clear of obstructions and is a suitable work environment.

4. Never start the machine unless intending to make a hose assembly and ensure the head is free of objects

and persons.

5. ONLY operate this machine if the ambient temperature is between 50ºF ~ 95ºF (10ºC and 35ºC)

6. Never reach into the crimper while the head is moving.

7. Never change die sets unless the head is completely open.

8. The power MUST be disconnected from the crimper machine before maintenance.

9. Observe the machine balance point when moving the crimper.

10. Always refer to Safety and Operation Manual for correct procedure when lifting machine.

7

GC32FLEX / GC32FLEX TSI

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

BOX CONTENTS

DIE RETAINER SPARE

AND ADJUSTMENT KIT

BLUETOOTH CALIPERS

GC32FLEX and GC32FLEX TSI

GC32FLEX (7480-7009) Only

GC32FLEX TSI (7480-0013) & GC32FLEX TSI Power Unit (7482-0123) Only

POWER UNIT

TIE-DOWN STRAPS TABLET HOLDER

7482-0143

POWER UNIT HOSE

3/8” NPT

7482-0151

AIR BREATHER CHARGEABLE TABLET

HOLDER

7482-0148

FOOT PEDAL

7482-7111

TUNGSTEN

DISULPHIDE GREASE

7482-7121

QUICK CHANGE TOOL

7482-7246

CALIPERS

7369-0322

8

GC32FLEX / GC32FLEX TSI

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SET-UP

CRIMPER SET UP: UN-BOXING

1. Assemble the optional crimper stand (P/N 7482-0017). The

crimper stand MUST be secured to the floor.

2. Remove the plastic wrapping from the outside of the box.

3. Remove the staples from the bottom and top of the carton with

a screwdriver and pliers.

4 Slit the tape on the top of the carton with a sharp knife, then

open the lid and remove the wooden side supports.

5. Lift off the carton.

9

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SET-UP

1. Remove 4x mounting bolts using a 5/8” (16mm) Wrench.

2. GC32FLEX Lifting and Movement (Forklift Option)

Lift the machine off the pallet using a forklift.

Always ensure that designated tine channels are used when moving

or lifting the machine.

Place the machine on a suitable bench, or the GC32FLEX crimper

stand (7482-0017).

3. GC32FLEX Lifting and Movement (Sling Option)

Remove the tabs in the middle of the tray on both front and rear

using a flat head screwdriver.

Attach an appropriately rated sling through the left side forklift

channel.

Attach another appropriately rated sling through the middle of the

cut-out channel from the front to the rear.

4. GC32FLEX Lifting and Movement (Sling Option)

Lift using both slings attached to a crane or hook.

Do not lift the GC32FLEX with 2 slings in the left and right forklift

channel. The Crimper centre of gravity is over the head - it will

lean to one side. Move slowly during lifting to avoid excessive

swinging.

Secure to the crimper stand or bench with 4x 5/8” (M10) Bolts/

nuts/washers.

Lifting Slings not included.

LIFTING AND INSTALLATION - GC32FLEX (HEAD ON TRAY) ONLY

Do Not Sling or Lift machine by the head as this will cause damage to the crimper.

See Crimper Specifications for the Gross Mass of the GC32FLEX Machine.

!

10

GC32FLEX TSI

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

CRIMPER SET-UP

1. Remove 4x mounting bolts using a 5/8” (16mm) wrench.

2. GC32FLEX TSI Lifting and Movement (Forklift Option)

Lift the machine off the pallet using a forklift. Always ensure that

the designated tine channels are used when moving or lifting

the machine. Place the machine on a suitable bench, or the

GC32FLEX crimper stand (7482-0017).

3. GC32FLEX TSI Lifting and Movement (Sling Option)

Attach appropriately rated sling through the left side forklift

channel.

Attach another appropriately rated sling through the right-side

forklift channel.

4. GC32FLEX TSI Lifting and Movement (Sling Option)

Lift using both slings attached to a crane or hook.

The GC32FLEX TSI Crimper centre of gravity is centralised and will

lift evenly. Move slowly during lifting to avoid excessive swinging.

Secure to the crimper stand or bench with 4x 5/8” (M10) Bolts/

nuts/washers.

Lifting Slings not included.

LIFTING AND INSTALLATION:- GC32FLEX TSI (HEAD WITH FACTORY POWER UNIT) ONLY

Do Not lift machine by the head as this will cause damage to the crimper.

See Crimper Specifications for the Gross Mass of the GC32FLEX TSI Machine.

!

11

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

CRIMPER GENERAL LAYOUT

A precision 2” hose crimp press for the production

of Gates hose assemblies of all types. The unit is

designed for low volume shop production and can be

used with any 10,000 PSI hydraulic power unit.

A tablet command interface with Gates e-Crimp™

allows the user to look up relevant crimp data quickly

to ensure efficient operation of the machine. The Unit

can be upgraded to a TSI variant at any time by order-

ing the part number 7482-0123.

Tablet Holder:

Holds Tablet Supplied with Gates e-Crimp™

and Support Material.

Dial Indicator:

Identifies Set Point for each hose assembly.

Forklift Channels:

Used to lift/move Crimper machine.

Crimper Opening:

Operational Zone to Crimp Hose.

Power Unit Position:

Space for External Power Unit (10,000 PSI).

Power Unit not included.

Inlet:

3/8” NPT Swivel.

Min Oil Capacity Requirement:

2 Litres (0.5 gal).

Strap Points

Inlet: Swivel 3/8” NPT

Power Unit Position

Crimper Opening

Forklift Channels

Electronic

Dial Indicator

Tablet

Holder

GC32FLEX

12

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

POWER UNIT

Power Unit Selection

Any Hydraulic power unit capable of 10,000 PSI can be used to

run the machine. These can range from a hand pump through to

pneumatic assisted or battery operated pumps.

See your Gates Representative for more details.

Power Unit Placement

Ensure the power unit is positioned next to the crimper head in

designated area. Follow the power unit instructions at all times

during operation.

If the power unit is electrically operated check the voltage and

frequency on the serial plate.

Ensure it is in a suitable location.

Secure Power Unit

Place the supplied strap over the power unit and through the base

slots to secure it to the tray.

Connect Power Unit Crimper

Connect the supplied hose to the chosen power unit.

Note: both ends of hose are 3/8” NPT Male.

Connect the other end of the hose to the crimper head using a

15/16” wrench.

The fitting in the Crimper head is a 3/8” NPT Swivel connection.

Hold hex on hose end with 3/4” Spanner while tightening swivel

connection with 15/16” Spanner.

Crimper Ready

The crimper is now ready for operation.

Ensure that the machine does not go over 10,000 PSI at any

time during operation. Use of an External Power unit with an

internal relief valve is strongly recommended. Crimp speed is

determined by the external power unit when in use.

!

13

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

Application access is required to operate the machine if

Integrated (7482-0123) power unit is installed.

NOTE:

Tablet Fixed Mount

The GC32FLEX includes a fixed tablet holder on the side of the

head (See Page 11).

The mount can carry any tablet or phone from 4,3” to 11,6”.

A tablet is supplied with the machine in order to access the latest

e-Crimp™ Numbers for Electronic Dial Indicator Operation.

Tablet Fixed Mount Operation

Tabs are provided on the mount which can move in both horizontal

and vertical directions.

Once the tablet is positioned in the bottom tabs - move the main

top arm down to secure the tablet in position.

Any tablet or phone can be used in the holder. The tablet holder

does not include integrated charging. Any device used must be

charged separately following the manufactures instructions.

e-Crimp™ Mobile and Tablet

Gates e-Crimp™ Data including set point and die requirements are

available as an application on the included tablet.

Note: Gates e-Crimp™ is also available as a mobile application

which shows the same data as the included tablet program.

TABLET OPERATION/E-CRIMP™

14

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

Electronic Dial Indicator

The Electronic Dial Indicator (EDI) is the device which will notify the

operator when a crimp is completed. It is located on the bottom

left (see page 11) of the machine with a Red LED on the front. The

EDI is adjustable to suit different crimp diameters with different die

sets.

Electronic Dial Indicator (Optional Position)

The EDI can be moved to the right side of head if it is obstructing

machine operations.

Electronic Dial Indicator (Optional Position Set-Up)

Remove the 2x SHCS on the top and the 2 x SHCS

on rear (1/8” / 3mm Hex Key) and reposition the entire assembly

on the right side.

Replace the 4 screws as required.

ELECTRONIC DIAL INDICATOR

x2x2

15

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

ELECTRONIC DIAL INDICATOR

INDICATOR PIN

POSITION 1.5MM:

INDICATOR PIN

POSITION 3MM:

INDICATOR PIN

POSITION 0MM:

Set Point Reached

The user will be notified that a crimp is nearing completion when the silver indicator pin is almost flush

with the front of the EDI knob. At this position, jog (activate in short intervals) the external power unit

until crimped (if power unit function allows). The hose assembly is crimped when the red LED illuminates

on the EDI.

The displayed number on the dial shown on the above illustration 0123 is equivalent to 01.23 whereby

the numbers shown with red background indicate the numbers after the decimal place.

If the EDI’s batteries are dead the unit can still be used to identify a completed crimp. When the silver

indicator is flush with the front face of the knob, the crimp is completed. You may wish to use your finger

to feel when the indicator pin is flush with the front of the knob. If the hose assembly is over-crimped, the

silver indicator pin will protrude past the knob face.

The operator MUST stop hydraulic flow to the machine before the indicator reaches the set point posi-

tion (light on).

The crimp accuracy is dependent on operator reaction and as such every completed hose assembly

MUST be measured.

Battery replacement work instructions are included with start-up kit. Replacement battery 1.55V,

377/376 button cell.

WARNING: Do Not hold the machine under pressure for extended periods of time

on the power unit. As soon as the crimp is complete, release pressure to allow

the machine to retract.

!

16

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

ELECTRONIC DIAL INDICATOR - CALIBRATION EXAMPLE

OPEN E-CRIMP™ > SELECT HOSE ASSEMBLY AND DIE SET

Any hose and fitting combination in e-Crimp™ can be used

for calibration.

Example: Select hose 8M3K with an 8G coupling.

LOAD DIE SET

Load specified die set from e-Crimp™ into machine.

For QCT operation, follow steps on page 40 for further details.

Example: 8M3K with an 8G coupling uses GC32-33 die set.

SET DIAL INDICATOR

Adjust the Dial Indicator Knob to the number specified in e-Crimp™.

Example: 8M3K with 8G coupling is 1.07 with a COD of 1.00".

Follow steps on page 14/15 for further details.

ASSEMBLE AND CRIMP SELECTED ASSEMBLY

Crimp hose assembly. Hose and fitting must be assembled for successful

calibration crimp.

Follow steps on page 43/44 for hose assembly procedure.

DIAL SETTING ADJUSTMENT

Measure crimped assembly.

If adjustment of COD required, follow steps on page 17.

17

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

ELECTRONIC DIAL INDICATOR - CALIBRATION

Activate Crimper

To activate the crimper, press and hold the pump power switch while watching

the LED on the front of the indicator Knob. The crimper will begin to close and

the central indicator pin on the knob will rise. Once the LED is illuminated,

release the pump power switch. Stopping the pump (Activate the release knob on

power unit) will allow the oil to drain back to the tank and the crimper will then

open.

Measure Assembly

Remove the assembly from the machine and measure across the flats of the

crimped area. Refer to page 44 of the manual for correct measuring procedure.

The measurement should read the diameter stated on the e-Crimp™ application

for the specified coupling. If the measurement does not read the specified

dimensions the dial indicator needs to be calibrated until the crimped outside

diameter of the Mega Crimp® coupling is correct.

Measurement Adjustment for a LARGER DIAMETER

On the rear of the machine a hexagon knob is located on the Dial Indicator.

Push the arm of Dial Indicator towards the front of the machine while holding the

hexagon knob. Gently turn the knob one flat CLOCKWISE (1/6 of a full turn) and

release the Dial Indicator arm. The Arm will lock the hexagon knob back into position.

1 flat (1/6 full turn) of rotation is equivalent to 0.0018” of crimped outside

diameter.

2 flats (2/6 full turn) of rotation are equivalent to 0.0036” of crimped outside

diameter.

Measurement Adjustment for a SMALLER DIAMETER

Push the arm of Dial Indicator towards the front of the machine while holding the

hexagon knob. Gently turn the knob one flat COUNTER-CLOCKWISE (1/6 of a full turn)

and release the Dial Indicator arm. The Arm will lock the hexagon knob into position.

1 flat (1/6 full turn) of rotation is equivalent to 0.0018” of crimped outside

diameter.

2 flats (2/6 full turn) of rotation are equivalent to 0.0036” of crimped outside

diameter.

Measure Assembly

Crimp the same Mega Crimp® coupling again to check the calibration. If the

crimper is still not accurate, follow the adjustment instructions above to suit

requirements.

18

GC32FLEX

GC32FLEX/TSI SAFETY AND OPERATION MANUAL

GETTING TO KNOW YOUR CRIMPER

FULL OPERATING PROCEDURE OVERVIEW

Power Unit Selection and Set Up

Select a suitable 10,000 PSI power unit and connect to the 3/8” NPT

Input of the Head.

See page 12 for more details.

e-Crimp™ setting selection on EDI

Search e-Crimp™ on the included tablet or mobile application for the

assembly you wish to crimp. The EDI setting will be displayed after

selecting an assembly.

Twist the knob on the EDI to match the e-Crimp™ setting specified.

See page 13 for more details.

Load Dies

Load the required dies as specified by e-Crimp™ into the machine using

the Quick Change Tool.

See page 40 for more details.

Crimp Hose Assembly

Place the hose assembly into the crimper (follow procedure for correct

hose assembly process page 43).

Activate the power unit and release when the light on the EDI turns red

(see silver indicator for notice).

See page 15 for more details on EDI Operation.

Measure Assembly

Remove the crimped assembly and measure across the flats as per

correct hose measuring procedure (See page 44 for details).

If the assembly is not within the specified tolerance discard the fitting

and follow the EDI calibration procedure (Page 16 & 17) for next crimp.

This manual suits for next models

1

Table of contents

Other Gates Crimping Tools manuals

Gates

Gates GC96 User manual

Gates

Gates MobileCrimp 4-20 Installation manual

Gates

Gates GC32TSi Guide

Gates

Gates Power Crimp 707 Installation manual

Gates

Gates GC20 Instruction Manual

Gates

Gates MC3001 Use and care manual

Gates

Gates GC16XD Installation manual

Gates

Gates GC32-XD User manual

Gates

Gates MCX50 Use and care manual

Gates

Gates GC16XD Installation manual