GC®32TSi™ Safety and Operation Manual | 1

TABLE OF CONTENTS

Crimper Safety............................................................................................................................................................................. 2

Location Preparation ................................................................................................................................................................. 3

Box Contents................................................................................................................................................................................. 4

Crimper Installation .................................................................................................................................................................... 5

Moving the Crimper......................................................................................................................................................... 6

Electrical............................................................................................................................................................................ 8

Ergonomics ....................................................................................................................................................................... 8

Operating Instructions

Power Up............................................................................................................................................................................ 9

eCrimp.............................................................................................................................................................................. 10

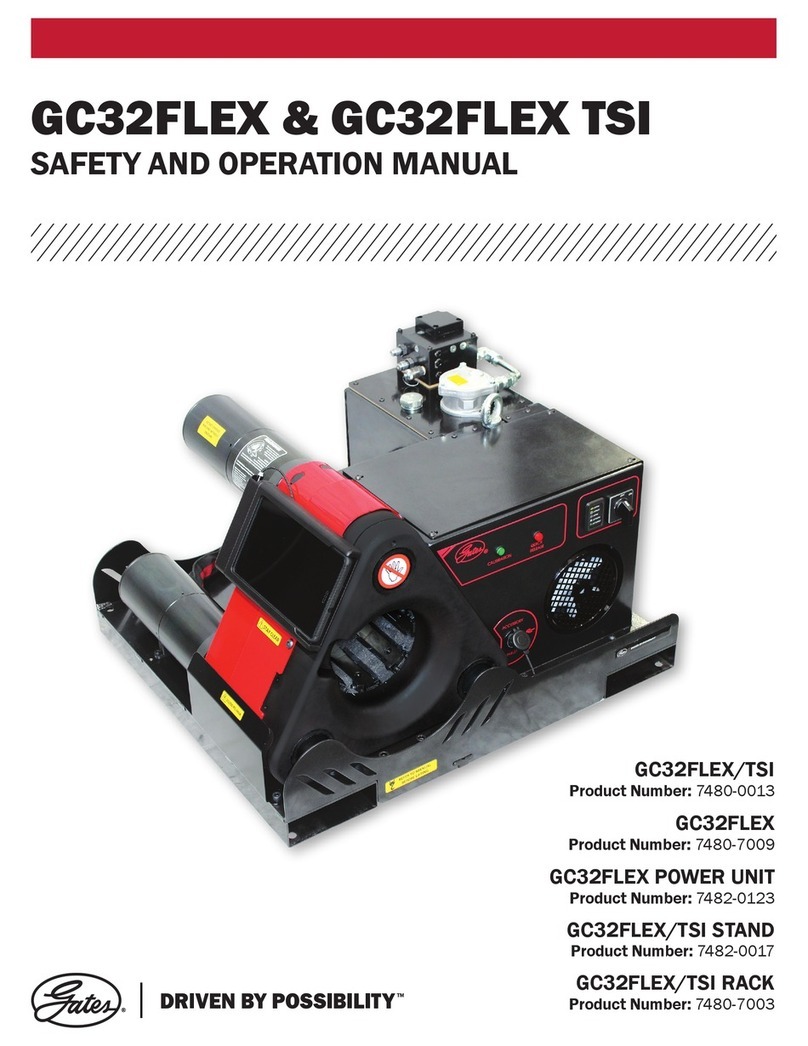

Verify Crimp..................................................................................................................................................................... 12

Hose Preparation...................................................................................................................................................................... 13

Load Crimper Dies ......................................................................................................................................................... 14

Crimp Aasembly ............................................................................................................................................................ 15

Unload Die Set................................................................................................................................................................ 17

Calibration .................................................................................................................................................................................. 17

Periodic Maintenance.............................................................................................................................................................. 18

Lubrication .......................................................................................................................................................................18

Torque Bolts.....................................................................................................................................................................18

Foam Filler Pads .............................................................................................................................................................18

Check Oil Level.................................................................................................................................................................19

Add Oil................................................................................................................................................................................19

Oil & Filter Change..........................................................................................................................................................19

Replace or Add Oil...........................................................................................................................................................19

Tooling ......................................................................................................................................................................................... 20

Troubleshooting ........................................................................................................................................................................ 22

Operating Instructions

Using the Gates Insertion Tool.....................................................................................................................................23

Warranty ..................................................................................................................................................................................... 24

GC32TSi Safety and Operating Manual-A4.indd 1 1/11/17 12:36 PM