Gates GC32-XD User manual

CRIMP DATA AND DIES

GC32-XD™ & FLEX & GC96™ - POWER CRIMP®707 & SC32™ -

GC16XD-MOBILECRIMP®4-20 DD & PS - POWER STEERING - SWAGING

VERSION 186 - 2020-11-24

EDITION 2021

GENERAL INFORMATION

HOSE ASSEMBLY GUIDE ..........................................2-7

POLAR SEAL I CRIMP DATA.......................................... 8

POWER STEERING CRIMP DATA ...................................... 9

GATES GLOBAL PART NUMBERING SYSTEM ........................... 10

SWAGING INFORMATION

SWAGING PROCEDURES ....................................... 11-12

TH7 SWAGE DATA .............................................. 13

C14 SWAGE DATA ........................................... 15-19

GC32-XD™ & FLEX & GC96™ WITH SPACER DIES

GC32-XD & FLEX CRIMP DATA................................... 20-42

GC32-XD & FLEX LIFEGUARD™ CRIMP DATA ....................... 43-45

GC96 (WITH SPACER DIES) CRIMP DATA........................... 46-67

CALIBRATION & ADJUSTMENT PROCEDURES ....................... 68-72

CRIMP DIES AND TOOLING......................................... 73

CLAMP COLLAR CRIMPING INSTRUCTIONS ........................... 74

POWER CRIMP®707 & SC32™

POWER CRIMP®707/SC32™ CRIMPERS ............................. 75

PC 707, 700 SERIES (8 FINGER) DIES CRIMP DATA.................. 76-98

PC707 LIFEGUARD CRIMP DATA ................................99-100

SC32 CRIMP DATA ..........................................101-122

SC32 LIFEGUARD™ CRIMP DATA ...............................123-124

CALIBRATION & ADJUSTMENT PROCEDURES .....................125-126

CRIMP DIES AND TOOLING........................................127

CLAMP COLLAR CRIMPING INSTRUCTIONS ..........................128

GC16XD

GC16XD CRIMP DATA ........................................129-133

GC16XD CALIBRATION PROCEDURE ............................134-135

MOBILECRIMP®4-20 DD & PS

MOBILECRIMP®4-20 CRIMPERS...................................136

MC 4-20 DD CRIMP DATA.....................................137-154

MC 4-20 PS CRIMP DATA .....................................155-172

CALIBRATION & ADJUSTMENT PROCEDURES .........................173

CRIMP TOOLING ................................................174

CLAMP COLLAR CRIMPING INSTRUCTIONS ..........................175

POWER STEERING MALE FLARELESS ASSEMBLY INSTRUCTIONS

POWER STEERING ASSEMBLY INSTRUCTIONS ....................176-177

NOTE: CRIMP DATA FOR OMNICRIMP®21, POWER CRIMP®3000B &

POWER CRIMP®2001 IS LOCATED IN ECRIMP. DOWNLOAD THE ECRIMP

APP OR GO TO WWW.GATES.COM/ECRIMP.

1

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

CRIMP DATA + DIES

GATES

HOSE ASSEMBLY

GUIDE

Wear the proper personal protection equipment when working

with fabrication equipment to make assemblies. To find the

hose use the STAMPED process to determine which product is

needed, then identify the terminations of the existing assembly

by their physical characteristics and dimensions.

Once the hose has been determined select the appropriate

coupling by looking through the crimp data to find what stem

and ferrule types may be used. Use the stem and ferrule with the

termination information to determine the best coupling to use.

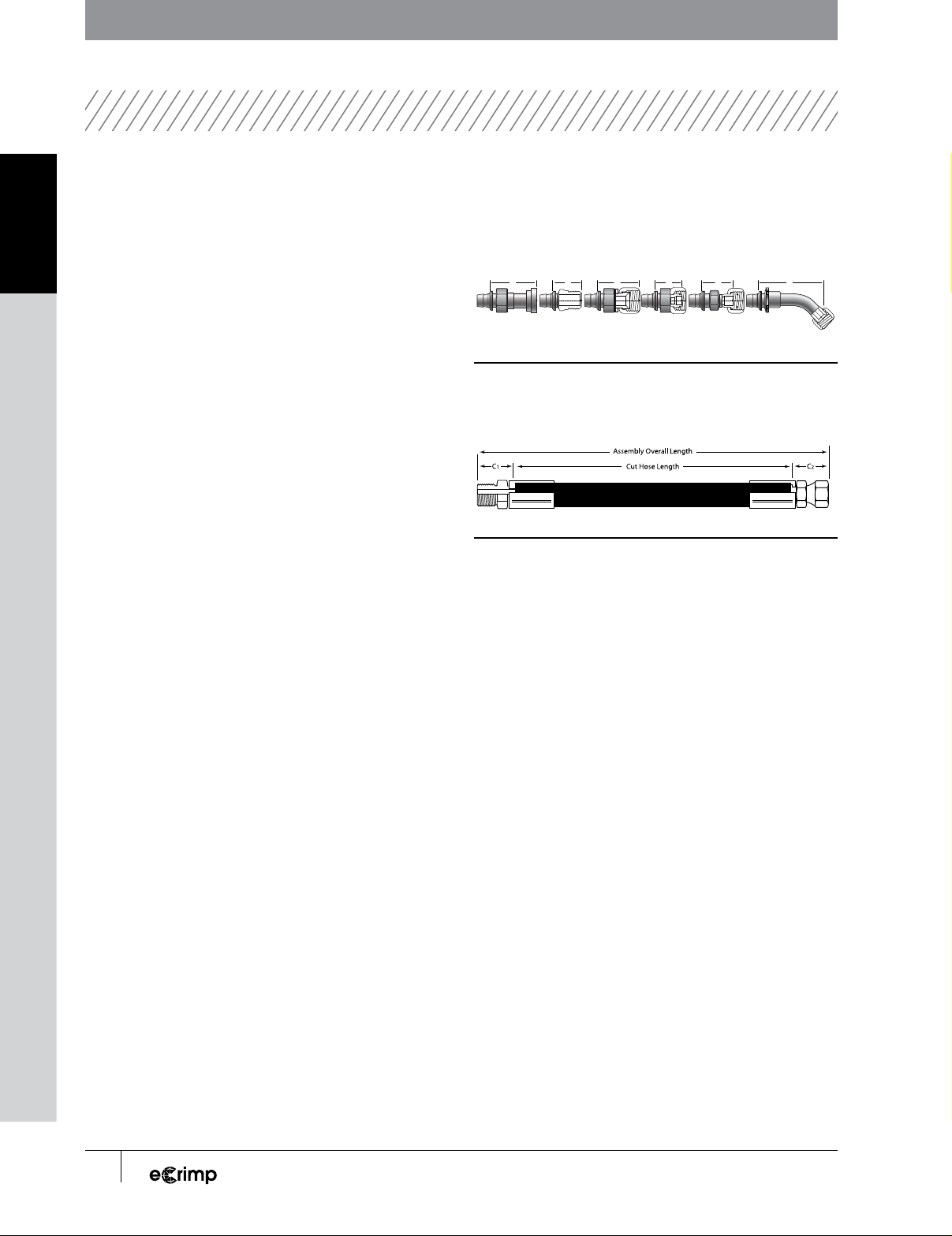

DETERMINE THE CUT LENGTH OF THE HOSE

To determine the cut length of the hose, first find the overall length

of the hose assembly. The point at which the ends of the assembly

are measured will depend on the construction of the couplings.

All flanges are measured from the center point of the flange

face, Figure 1D. All straight male couplings are measured from

the seal face, Figure 1E. Straight female couplings with SAE,

JIC (FJX), NPSM (FPX), JIS and Komatsu specifications are

measured from the farthest point which the nut will extend,

Figure 1F. Straight female couplings with DIN, BSP, GAZ

specifications are measured from the face of the seal, Figure

1G. Straight Flat Face O-ring seal (FFOR) couplings are always

measured from the face of the seal, Figure 1H. All bent and

block couplings (male and female) are measured from the point

at which the center line of the coupling intersects the seal face,

Figure 1I.

Once the overall length of the assembly is determined the cut

length of the hose will be the overall length of the assembly

minus the “C” length of each coupling, as shown in Figure 2. “C”

lengths are available in the Gates Hydraulic catalog.

CUTTING THE HOSE

Once the cut length of the hose has been determined it is time

to cut the hose section to length. Rubber hydraulic hoses should

be cut with a hose cutting saw, equipped with a scalloped,

serrated or abrasive blade.

C C

IHGFED

CCC C

FIGURE 1

From left to right: Measurement of D) flange, E) straight male, F) US spec., G)

International spec., H) FFOR and I) bent (elbow) couplings.

FIGURE 2

A hose assembly.

A serrated blade will produce the cleanest cut, but should only

be used for cutting hose with fabric, textile, wire braid or spiral

wire reinforcement. Usually serrated blades should not be

used for cutting helical wire embedded hose. If the hose saw

is equipped with a blade cooling mechanism, then a serrated

blade may be used to cut spiral wire hose. Serrated saw blades

may be flipped and also re-sharpened to extend their life.

An abrasive composite blade is capable of cutting all types of

hose, but will product much more smoke and dust than serrated

blades and leave more contamination in the hose that will need

to be removed so it does not get into the hydraulic system once

installed. Abrasive composite blades will wear down over time

and must be replaced when it cannot cut fully through a hose.

Use the hose bending fixtures on the hose cutting saw in order

to prevent blade binding and they will help achieve straight

consistent cuts. To meet SAE and ISO standards the hose cut

must be within 5° of perpendicular, on 1” hose this is less than

3/32”, Figure 3.

PTFE and thermoplastic hydraulic hoses may be cut cleanly with

a shear. Once the cut is made the tube must be deburred using

a sharp knife.

2DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

HOSE ASSEMBLY GUIDE

FIGURE 3

Hose cut length tolerance

LENGTH TOLERANCE

(PLUS OR MINUS) MM

Up to 300 mm, included 3

Over 300 mm through 450 mm, included 5

Over 450 mm through 900 mm, included 7

Over 900 mm + 1%(1)

(1) Measured to nearest whole milimeter.

FIGURE 4

SAE J517 assembly length tolerance.

When cutting any hose it is important to understand the amount

of variation in length which is appropriate. The SAE provides the

guidelines shown in Figure 4. Generally it is best to have a small

amount of extra hose in an assembly, however even a small

amount of extra length can be very problematic especially for

short hoses.

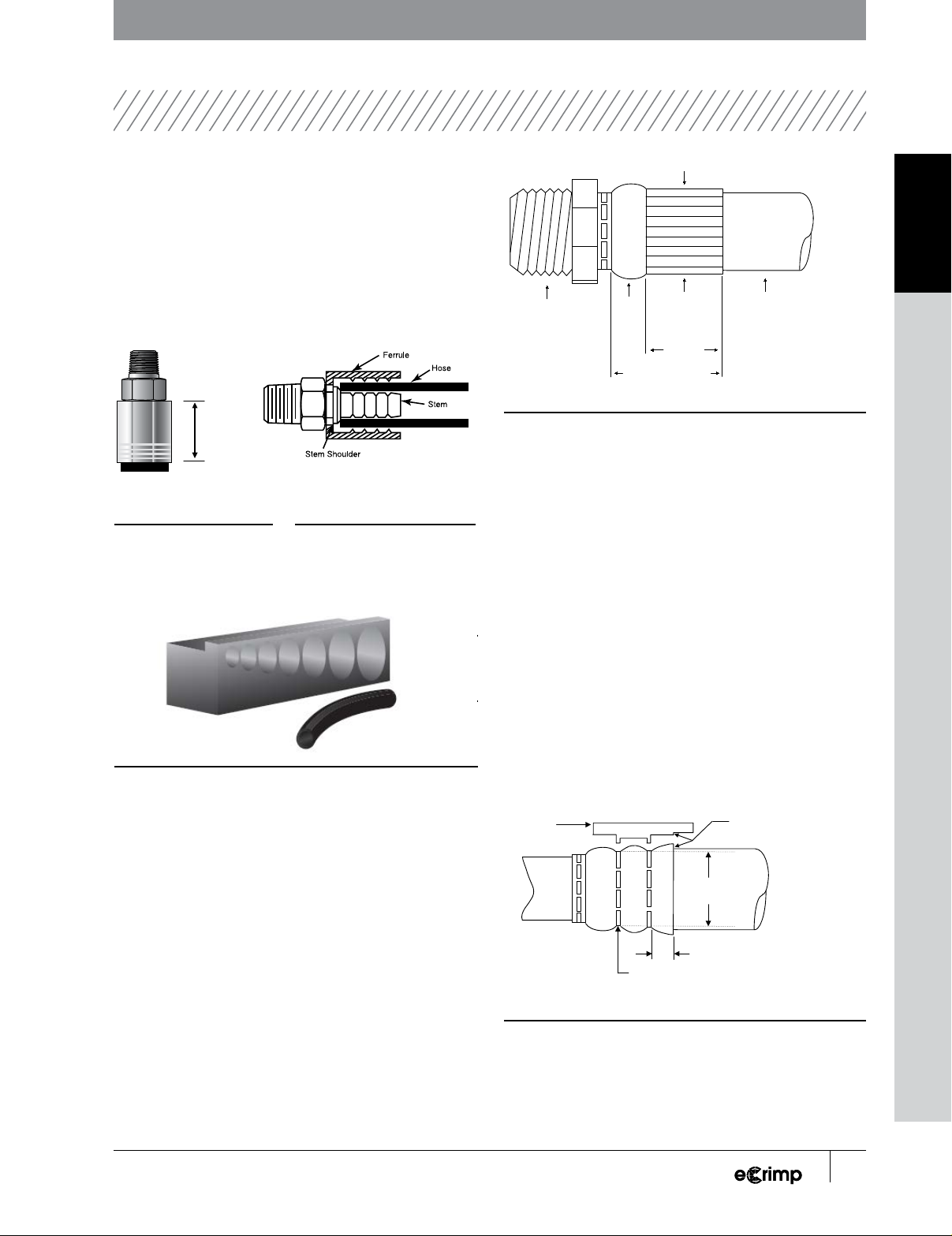

SKIVING AND BUFFING

Skiving or buffing should only be done as recommended in the

crimp specifications, most Gates products no longer require

skiving or buffing for installation.

Skiving is the removal of the hose cover down to the

reinforcement, Figure 5. Skiving may be done with a wire

abrasion wheel or a hand skiving tool. Careful attention

should be paid to ensure that skive length is correct and the

reinforcement has not been damaged in the skiving process.

Buffing is the removal of some hose cover material while still

leaving material covering the hose reinforcement. This is done

both for wire and non-wire reinforced hose construction, and

when necessary for coupling installation. A grinding wheel is

used for buffing for consistency and to help prevent damage to

the reinforcement.

FIGURE 5

Picture of a skived hose end.

COUPLING INSTALLATION

Once the hose has been completely prepared dry fit all of the

couplings to ensure that the assembly length and orientation is

correct in the final assembly.

When two bent couplings are used on an assembly orientation

is critical, per SAE specifications the couplings must be within

±3° of desired. In order to achieve this begin by orienting the

coupling on the far end of the hose vertically downward, then

measure the orientation clockwise from this position for the

near end. Once positioned place a witness mark on the hose

and coupling. For hydraulic hoses the layline makes an ideal

way to confirm the proper orientation of the couplings.

Bear in mind that during the crimping process the assembly

will grow slightly due to compression of the ferrule and hose.

For assemblies which are very critical in length, compare

measurements before and after crimping on end of the assembly

so that compensation may be made for the change in length.

3

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES HOSE ASSEMBLY GUIDE

FIGURE 6

Correct crimper usage.

CRIMPING

There are several different crimping procedures described,

depending on the coupling which is to be applied. No matter

what style of crimp is used the same safety rules apply.

■Assemblies must be fabricated only from NEW

(Unused) Gates hose and couplings.

■Always consult the most current crimp data available

to check the crimp specifications and machine

settings.

■Load the recommended die set into the crimper.

Properly lubricate the crimper dies, but do not

lubricate the bore of the die.

■Always wear safety glasses

■Keep hands away from moving parts of the crimper.

■For any questions consult the crimper operation

manual or Gates technical support.

■All settings are approximate! Variation due to

tolerances and wear may exist, always measure the

finished crimp diameter.

FULL LENGTH CRIMP ONE-PIECE COUPLINGS (G, P,

GSM, MGS)

When installing 1 piece couplings it is recommended that the

hose is marked with the insertion depth from each cut end. This

way there is a mark to verify the coupling has been fully inserted

into the hose.

These types of couplings require a full length crimp, shown in

Figure 7. In order to form the full length crimp the edge of the

coupling should be inserted into the die approximately 1/8”

past the die edge. This will ensure that the entire ferrule is

crimped, without a bubble near one end.

CRIMP

FULL

LENGTH

CRIMP

FULL

LENGTH

FIGURE 7

Full Length Crimp.

FULL LENGTH CRIMP TWO-PIECE COUPLINGS (GS,

GSP, PC, B & S STAINLESS STEEL)

When installing 2 piece couplings (with separate stem and

ferrule) place the ferrule onto the cut hose then insert the stem

into the hose. If stem insertion is very difficult the serrations

may be lubricated with light oil, and if necessary the coupling

restrained in the jaws of a vice. Be sure that the hose is fully

inserted onto the stem by moving the ferrule and visually

inspecting. When crimped the ferrule must be latched into the

stem shoulder, see figure 9.

These types of couplings require a full length crimp, see Figure

8. In order to form the full length crimp the edge of the coupling

should be inserted into the die approximately 1/8” past the die

edge. This will ensure that the entire ferrule is crimped, without

a bubble near one end. Before making the crimp be sure ferrule

is engaged in the stem latching collar.

Incorrect Correct

4DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

HOSE ASSEMBLY GUIDE

MEGACRIMP INSERTION TOOL

This tool offers an easy way to confirm the right insertion depth

for MegaCrimp, see Figure 10. To use, simply insert the hose

into its proper slot indicated by dash size, push it all the way in,

check for square cut (maximum allowable angle of cut is five

degrees), then mark the insertion depth on the hose.

CRIMP

FULL

LENGTH

CRIMP

FULL

LENGTH

FIGURE 10

Insertion tool

PARTIAL LENGTH CRIMP ONE-PIECE COUPLING (GLX)

When installing 1 piece couplings it is recommended that the

hose is marked with the insertion depth from each cut end. This

way there is a mark to verify the coupling has been fully inserted

into the hose.

When forming a GLX crimp only the tail end of the coupling is

crimped. DO NOT crimp the full length of the ferrule. In order to

achieve the proper crimp length, mark this point onto the ferrule,

and only insert the ferrule in the dies up to the mark, bear in mind

the tolerance on the crimp length is ± 0.030 inches. See Figure 11.

Measure

Crimp Here Hose

Crimp

Length

Insertion Length

Coupling

Termination

Bell

FIGURE 11

GLX coupling crimp

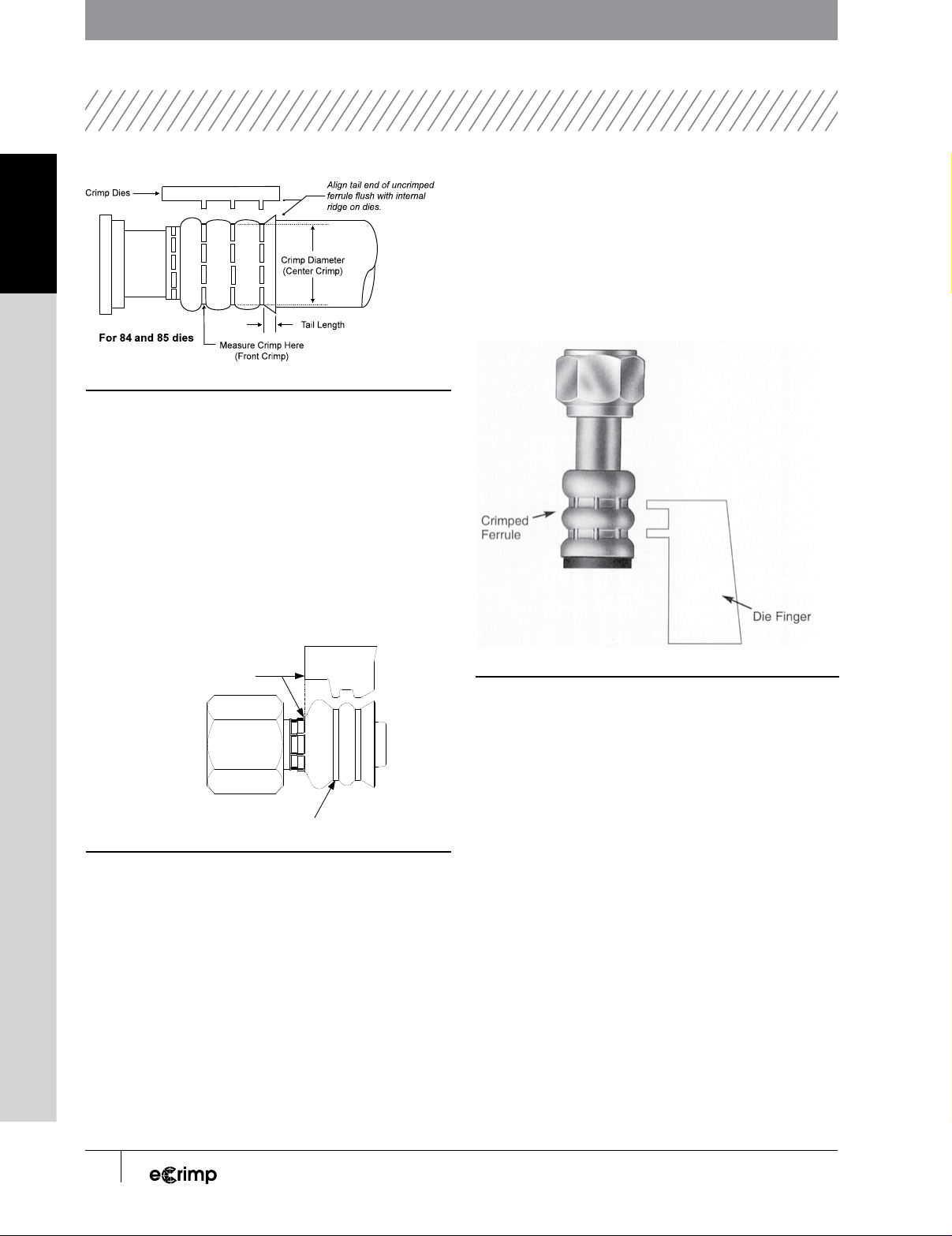

BUBBLE CRIMP ONE-PIECE COUPLING (GL)

When installing 1 piece couplings it is recommended that the

hose is marked with the insertion depth from each cut end. This

way there is a mark to verify the coupling has been fully inserted

into the hose.

The GL coupling is only intended for low pressure service,

despite this it is still critical that the correct crimp outside

diameter and tail length are achieved in order to make a leak

free connection. The tolerance on the tail length of the crimp

is ± 0.100 inches. In order to achieve this tolerance: line the

coupling up with the ridges in the appropriate die, see Figures

12 and 13. Be sure the die fingers are all the way forward and

locked in place before crimping.

Align hose end of uncrimped

ferrule flush with internal

ridge on dies.

Crimp Dies

Crimp Diameter

(Front Crimp)

For 81, 82

and 83 dies

Tail Length

Measure Crimp Here

(Front Crimp)

FIGURE 12

2 band bubble crimp (dies 81, 82, and 83)

FIGURE 9

Proper 2 - piece coupling assembly

FIGURE 8

Full length crimp

5

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES HOSE ASSEMBLY GUIDE

* See Adjustment Procedures and Footnotes at the end of GC32-XD / GC96 section.

FIGURE 13

3 band bubble crimp (dies 84 and 85)

BUBBLE CRIMP ONE-PIECE COUPLING (GLP)

When installing 1 piece couplings it is recommended that the

hose is marked with the insertion depth from each cut end. This

way there is a mark to verify the coupling has been fully inserted

into the hose.

In order to achieve the correct crimp be sure to align the

coupling in the die as shown in Figure 14.

For Die Series:

71, 72, 73, 74 & 75

Measure Crimp Here

Align staked end of the ferrule

(fitting end) flush with the die face.

FIGURE 14

GLP alignment in crimper dies (die 71, 72, 73, 74, and 75)

AIR CONDITIONING COUPLINGS (ACA)

When crimping couplings for use with refrigerants be sure to

fully insert the hose into the coupling, a small hole is located on

the ferrule for visual confirmation of the hose insertion. No skive

or buff is needed or recommended for Polarseal hose and ACA

couplings. During crimping center the bands of the crimping die

on the ferrule as shown in Figure 15.

FIGURE 15

ACA coupling alignment

6DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

HOSE ASSEMBLY GUIDE

MEASURING THE CRIMP

When measuring a crimp position the caliper at the center of

the crimp length, or the appropriate band (as indicated in the

crimping diagrams), as shown in Figure 19. This is because

some taper may exist between the ends of the crimp.

Two Piece Couplings One Piece Couplings

FIGURE 19

Correct position to measure the crimp diameter along the length of the ferrule

The crimp diameter must always be measured on the flats

180° around the coupling, NOT on the protruding ridges,

as shown in Figure 20. For -8 and larger couplings place the

coupling against the rear of the caliper jaw and use the wide

flat area to measure. For -4 and -6 couplings use Notched end

of the Gates Stainless Steel Digital Calipers, place the small

flats at the end of the jaw against the flats on the coupling.

Always measure the crimp diameter from the depressed flat

area of the ferrule; DO NOT place the notches over protruding

ridges of the coupling.

Measuring -8 and larger couplings Measuring -4 and -6 couplings

FIGURE 20

Measuring the crimp outside diameter on the flats between the ribs

CRIMPER ADJUSTMENT

Should the actual crimp diameter not be within the tolerance

specified in the crimp data charts, check the calibration of the

crimper. If the calibration is correct a slight adjustment of the

crimper setting may be necessary.

To find the right adjustment to the setting, refer to your specific

crimper’s operating manual. When the setting has been calculated

and your new crimp is within the specified tolerance, make sure to

record your new approximate setting in the space provided in this

manual under “User’s actual setting” for future reference.

CLEANING THE HOSE

After the assembly has been successfully crimped it should be

cleaned in order to prevent contamination of the system onto which

it is being installed. This should be done with all assemblies since

particulates from the cutting or crimping process and other debris

may have entered the hose during fabrication.

Common methods of cleaning the hose assembly include

blowing through the assembly with shop air or a much more

effective method is the use of a shuttle. The Gates MegaClean

system uses foam projectiles to remove debris from hoses and

assemblies. For particularly difficult jobs multiple projectiles

may be fired from each end or a solvent such as water or

alcohol may be applied to the pellets.

7

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES HOSE ASSEMBLY GUIDE

* See Adjustment Procedures and Footnotes at the end of GC32-XD / GC96 section.

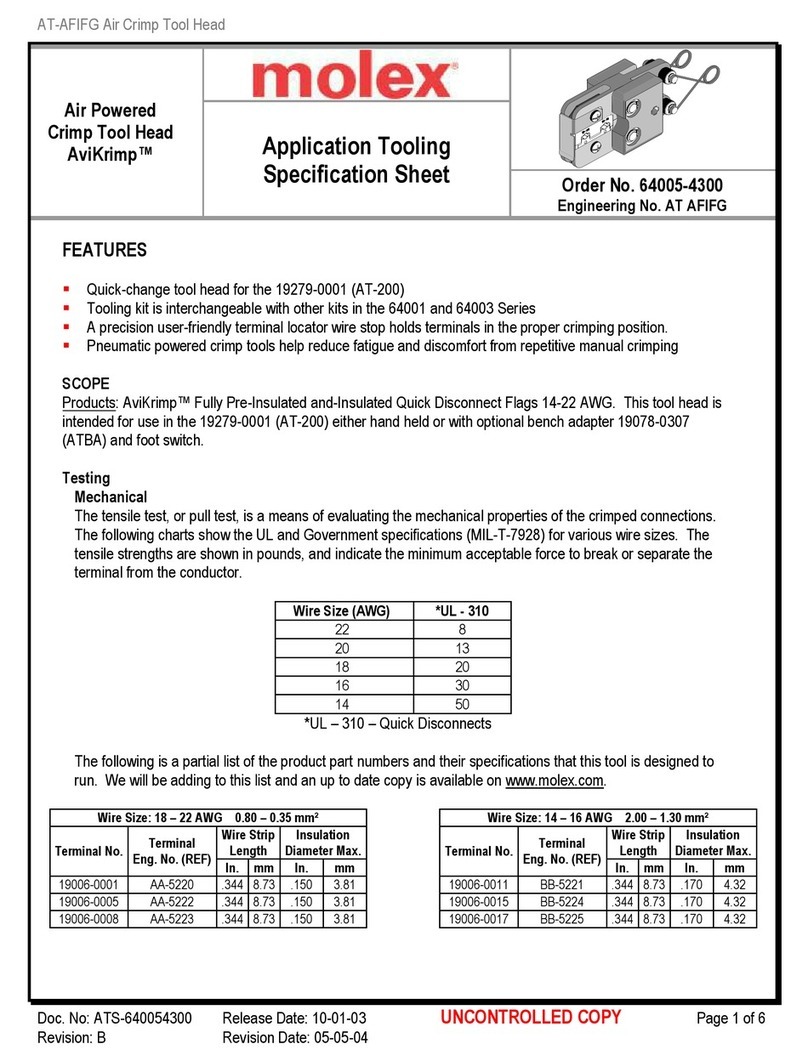

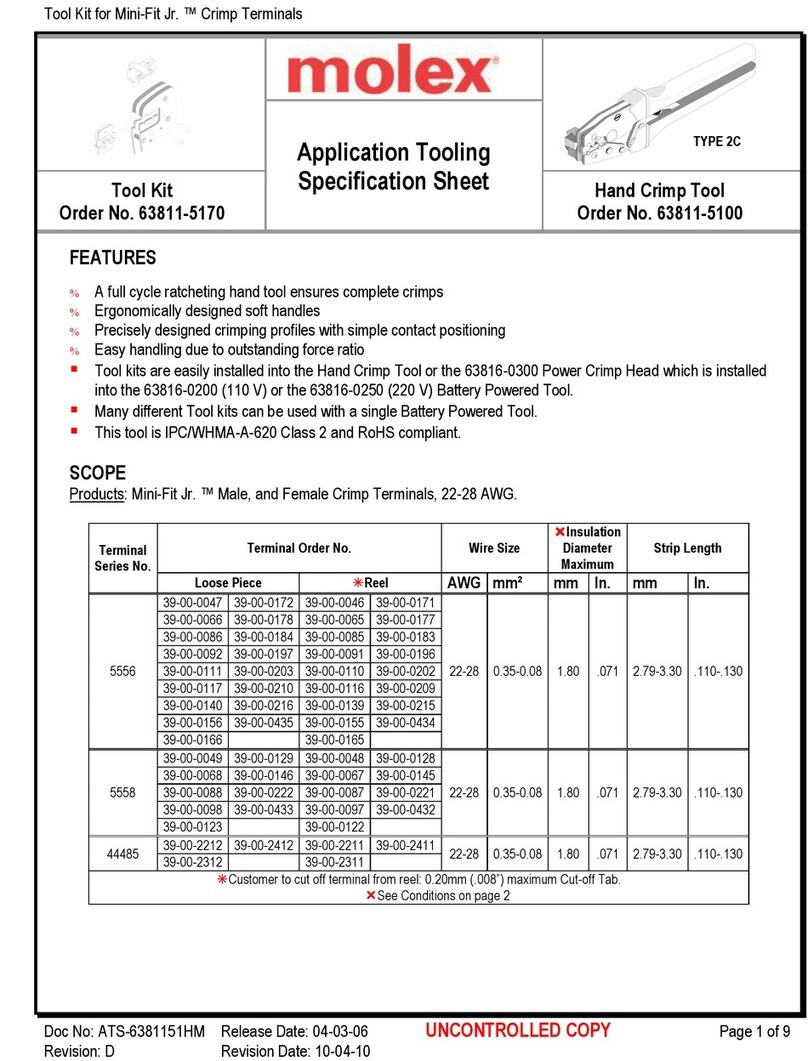

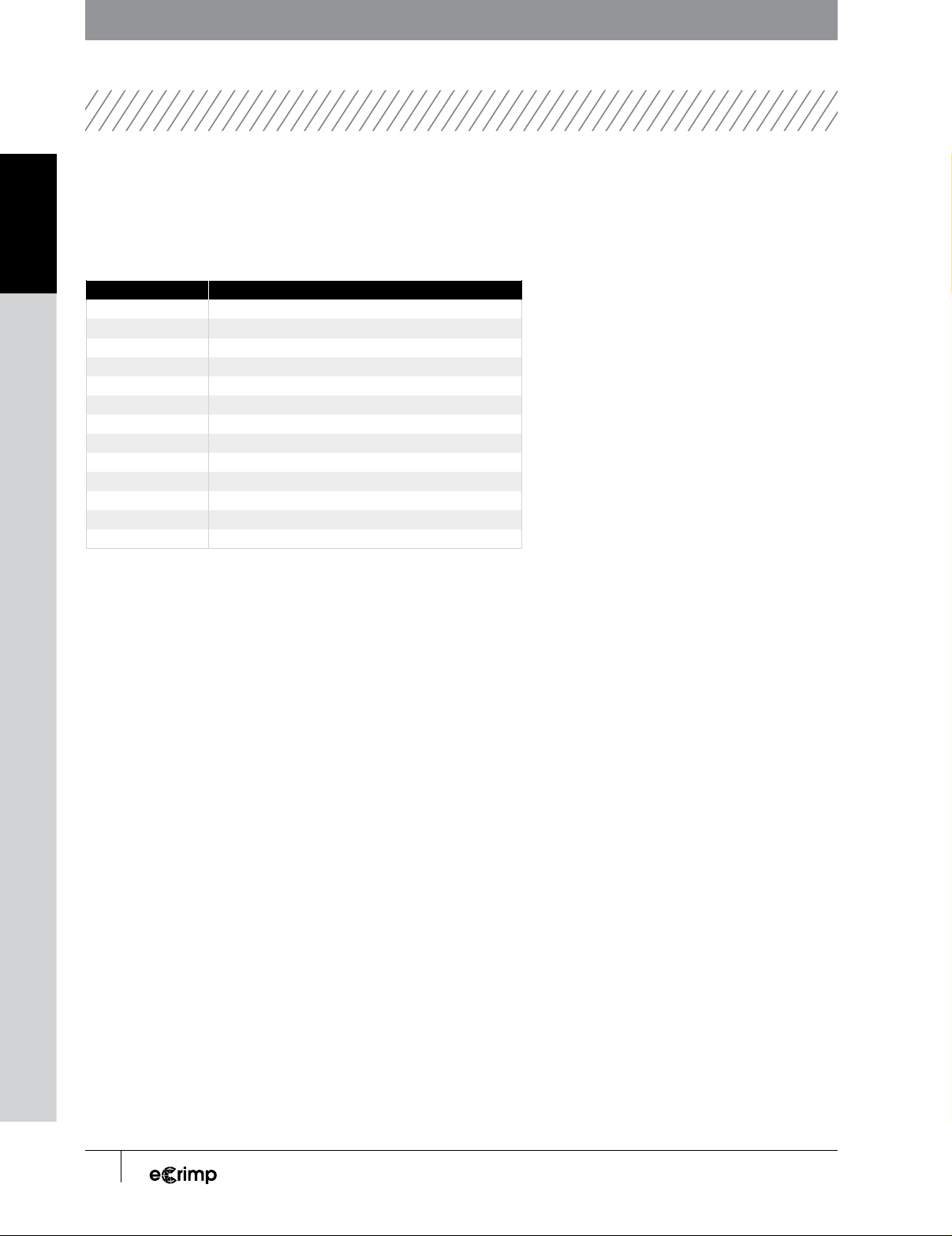

HOSE STEM CRIMP CRIMPER

DASH SIZE

1/16” DESCRIPTION SIZE

(IN)

WORKING PRES-

SURE

PSI

DASH SIZE

1/16" TYPE LENGTH

±0.03"

OD

±

0.01"

CRIMPER DIE SET APPROX.

SETTING*

USER

SETTING

6 PolarSeal 0.3125 500 6 ACA BUBBLE 0.69 GC32/GC96 32-40 0.80

8 PolarSeal 0.4063 500 8 ACA BUBBLE 0.78 GC32/GC96 32-41 0.96

10 PolarSeal 0.5000 500 10 ACA BUBBLE 0.89 GC32/GC96 32-42 0.63

12 PolarSeal 0.6250 500 12 ACA BUBBLE 1.02 GC32/GC96 32-43 0.87

6 PolarSeal 0.3125 500 6 ACA BUBBLE 0.69 MC420DD MC40 180

8 PolarSeal 0.4063 500 8 ACA BUBBLE 0.78 MC420DD MC41 220

10 PolarSeal 0.5000 500 10 ACA BUBBLE 0.89 MC420DD MC42 190

12 PolarSeal 0.6250 500 12 ACA BUBBLE 1.02 MC420DD MC43 214

6 PolarSeal 0.3125 500 6 ACA BUBBLE 0.69 MC420PS MC40 W5

8 PolarSeal 0.4063 500 8 ACA BUBBLE 0.78 MC420PS MC41 B5

10 PolarSeal 0.5000 500 10 ACA BUBBLE 0.89 MC420PS MC42 W5

12 PolarSeal 0.6250 500 12 ACA BUBBLE 1.02 MC420PS MC43 B5

6 PolarSeal 0.3125 500 6 ACA BUBBLE 0.69 OMNI21 OM6AC 1.455

8 PolarSeal 0.4063 500 8 ACA BUBBLE 0.78 OMNI21 OM8AC 1.435

10 PolarSeal 0.5000 500 10 ACA BUBBLE 0.89 OMNI21 OM10AC 1.450

12 PolarSeal 0.6250 500 12 ACA BUBBLE 1.02 OMNI21 OM12AC 1.440

6 PolarSeal 0.3125 500 6 ACA BUBBLE 0.69 PC3000B 6AC 2.00

8 PolarSeal 0.4063 500 8 ACA BUBBLE 0.78 PC3000B 8AC 2.75

10 PolarSeal 0.5000 500 10 ACA BUBBLE 0.89 PC3000B 10AC 2.00

12 PolarSeal 0.6250 500 12 ACA BUBBLE 1.02 PC3000B 12AC 2.25

6 PolarSeal 0.3125 500 6 ACA BUBBLE 0.69 PC707/SC32 740/W 6.10

8 PolarSeal 0.4063 500 8 ACA BUBBLE 0.78 PC707/SC32 741/X 6.55

10 PolarSeal 0.5000 500 10 ACA BUBBLE 0.89 PC707/SC32 742/Y 6.25

12 PolarSeal 0.6250 500 12 ACA BUBBLE 1.02 PC707/SC32 743/Z 6.50

POLAR SEAL I

CRIMP DATA

8DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

POLAR SEAL I CRIMP DATA

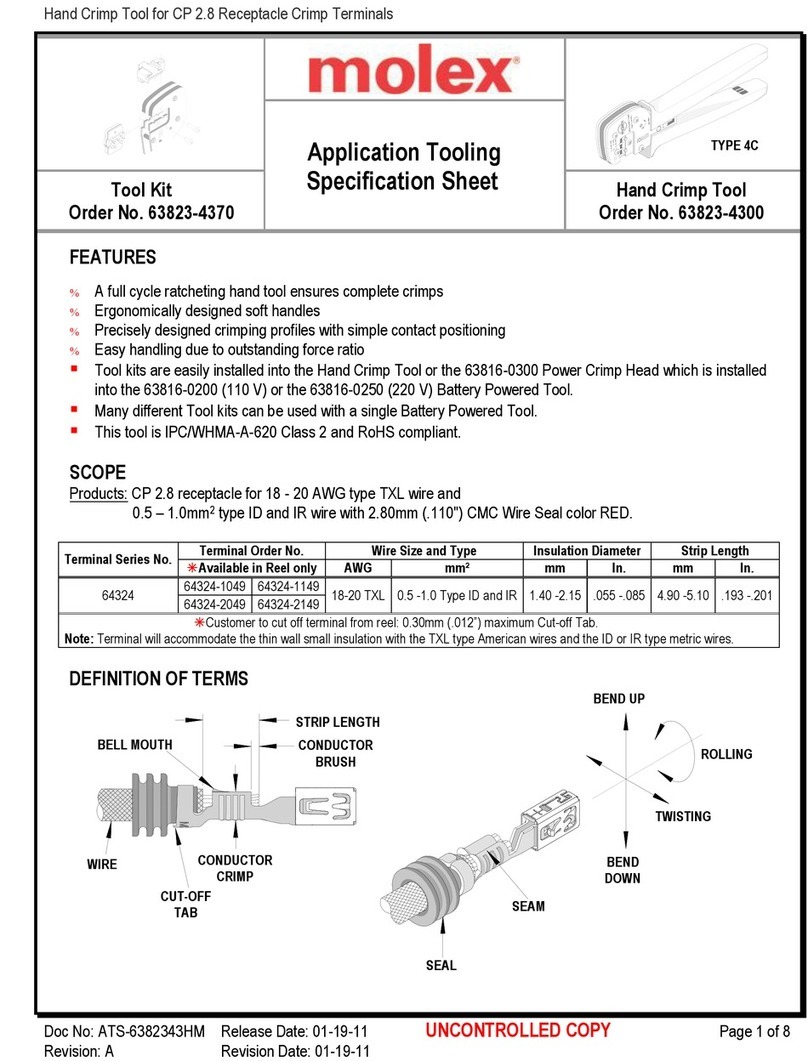

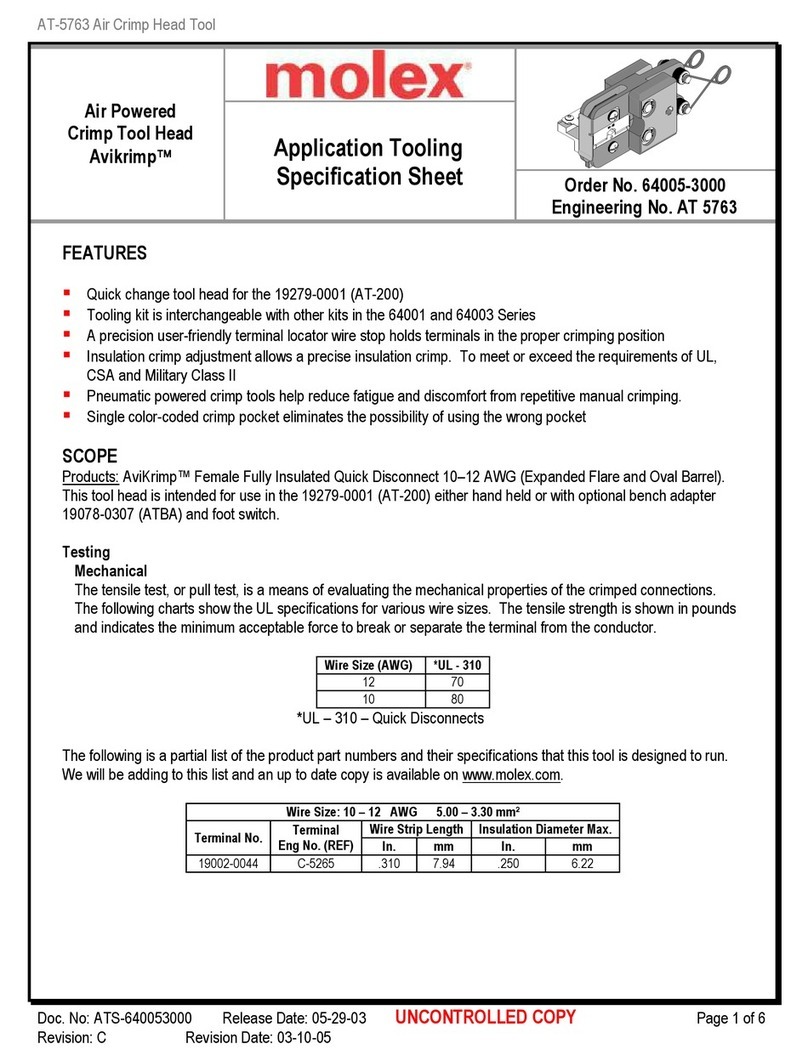

Power steering couplings come are designed for PS188 power

steering hose and come with MFA (male flareless adapter)

terminations.

COUPLING CUTOFF (INCHES)

6PS-4MFA 0.996

6PS-5MFA 0.996

6PS-6MFA 1.012

6PS-M8MFA 0.934

6PS-M10MFA 0.973

6PS-M12MFA 0.973

FIGURE 16

Cutoff lengths for PS couplings

FIGURE 18

Alignment of PS coupling in die

FIGURE 17

Diagram showing PS coupling crimp details

The MFA is a means for attaching the coupling to metal tubing

from the existing power steering assembly. At least 1 inch

of straight (unbent) metal tubing must be available for the

attachment of the MFA. Cutoff (or “C”) dimensions for the PS

couplings are given in Figure 16.

The correct insertion depth for the PS coupling is 1.25 ± 0.030

inches. Be sure to mark this on the hose prior to coupling

application to ensure full insertion depth has been achieved.

Prior to crimping the coupling also ensure that the bottom of

the stem hex is aligned with the top of the die set, as shown

in Figure 17. When the crimp is complete inspect to the

dimensions shown in Figure 18.

HOSE STEM CRIMP TAIL CRIMPER

DASH

SIZE

1/16"

DESCR. SIZE

(IN)

WORK. PRESS.

PSI

DASH SIZE

1/16” TYPE

LENGTH

±

0.03"

OD

±

0.01"

LENGTH

±

0.1"

CRIMPER DIE SET APPROX.

SETTING*

USER

SETTING

6 PS188 0.3750 1500 6 PS BUBBLE 0.675 0.25 GC32/GC96 32-44 1.17

6 PS188 0.3750 1500 6 PS BUBBLE 0.675 0.25 MC420DD MC44 190

6 PS188 0.3750 1500 6 PS BUBBLE 0.675 0.25 MC420PS MC44 Blue PS

6 PS188 0.3750 1500 6 PS BUBBLE 0.675 0.25 OMNI21 OM44 1.452

6 PS188 0.3750 1500 6 PS BUBBLE 0.675 0.25 PC707/SC32 744/PS 1.75

POWER STEERING CRIMP DATA

POWER STEERING

COUPLINGS (PS)

9

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES POWER STEERING

GATES GLOBAL PART

NUMBERING SYSTEM

STEM TYPE SERIES STEM STYLES

B-SS G17 - Stainless Steel Braid Couplings

S-SS G18 - Stainless Steel Spiral Couplings

G8K G19 - G8K Couplings

GS G20 - GlobalSpiral

MGS G21 - GlobalSpiral One Piece Couplings for MC4-20 Crimper

GSP G22 - GlobalSpiral Plus

GSM G23 - GlobalSpiral Max (-32) Pressure Couplings

GSM G24 - GlobalSpiral Max Pressure Couplings

G G25 - MegaCrimp Couplings

GL G43 - GL Couplings

GLX G44 - GLX Couplings

ACA G45 - PolarSeal Couplings

PS G50 - Power Steering Couplings

10 DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

GATES GLOBAL PART NUMBERING SYSTEM

SWAGING

PROCEDURES

Mark hose for proper insertion depth into coupling. See Gates

Hose Swage Data chart for insertion depth. Use a lightweight

oil to lubricate the inside diameter of hose. Place the coupling

hex into a vise and insert hose to insertion depth.

The following are the basic swage procedures. For specific

instructions for your crimper or swager, please refer to the

appropriate operator’s manual. Swaging can be accomplished

with either the Gates HS-1 Hand Swager (Product No. 7483-

1000) or with the Swager Conversion Kit for the Power Crimp®

707 (Product No. 7480-0040).

1. See Swage Data chart to select specific pusher and die for

each coupling and hose combination to be swaged. The

Swage Tooling page contains specific part/product number

information for each pusher and die.

2. Insert the correct die and pusher into the swaging machine.

3. Lubricate inner bore surfaces of dies with a thin film of

lightweight oil.

4. Feed hose assembly through the dies and hold hose and

coupling into the pusher. Start the swage.

5. Swage is complete when pusher bottoms out on dies.

11

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES SWAGING PROCEDURES

SWAGER CONVERSION KIT FOR THE POWER

CRIMP® 707 CRIMPER

Product No. 7480-0040

SWAGE TOOLING

12 DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

SWAGE TOOLING

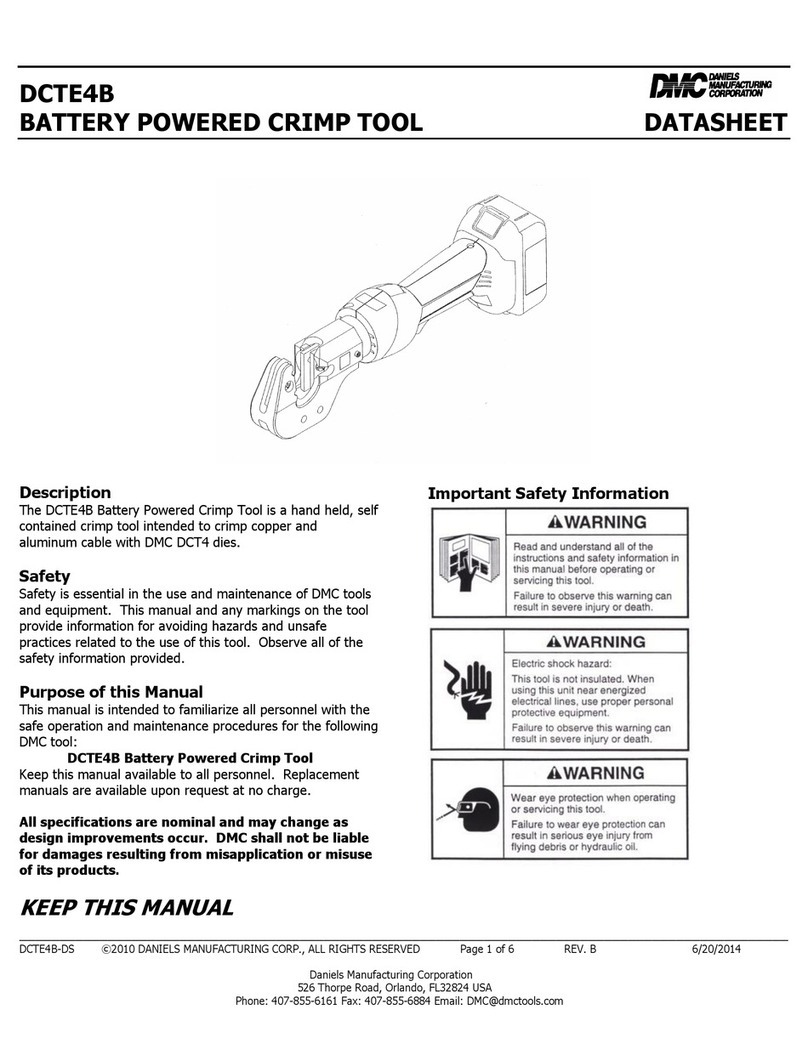

TH7 AND TH7NC THERMOPLASTIC HOSES

Use PCTS couplings with TH7 and TH7NC thermoplastic hoses.

1Denotes dual seat

COUPLING ASSEMBLY GATES SYNFLEX PARKER

DESCRIPTION PRODUCT NO.

INSERTION

LENGTH

+/-.03 (IN)

FINISHED SWAGE

OD +/- .010 (IN) PUSHER DIE PUSHER DIE PUSHER DIE

2PCTS-2MP 7336-1198-5 0.563 0.360 GM023 G302 MP023 302 PUM001 302

2PCTS-4MP 7336-1199-5 0.563 0.360 GM004 G302 MP004 302 PUM004 302

3PCTS-2MP 7336-1200-5 0.781 0.485 GM001 G303 MP001 303 PUM001 303

3PCTS-4MP 7336-1201-5 0.781 0.485 GM004 G303 MP004 303 PUM004 303

2PCTS-2MPX 7337-1198-5 0.563 0.360 GM003 G302 MP003 302 PUT008 302

3PCTS-2MPX 7337-1200-5 0.781 0.485 GM003 G303 MP003 303 PUT008 303

3PCTS-4MPX 7337-1201-5 0.781 0.485 GM003 G303 MP003 303 PUT008 303

2PCTS-3FJX 7338-1198-5 0.563 0.360 GF017 G302 FP017 302 PUF017 302

2PCTS-4FJSX17338-1199-5 0.563 0.360 GF010 G302 FP010 302 PUF010 302

3PCTS-4FJSX17338-1200-5 0.781 0.485 GF011 G303 FP011 303 PUF011 303

3PCTS-4FJX90S 7338-1269-5 0.781 0.485 GT204 G303 TP204 303 PUT001 303

GATES HOSE

SWAGE DATA

PUSHERS AND DIES FOR PCTS COUPLINGS AND

TH7 HOSE

PCTS SWAGE PUSHERS PCTS SWAGE PUSHERS PCTS SWAGE DIES

13

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES TH7 SWAGE DATA

THIS PAGE INTENTIONALLY

LEFT BLANK.

14 DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

SWAGING PROCEDURES

SWAGE TOOLING

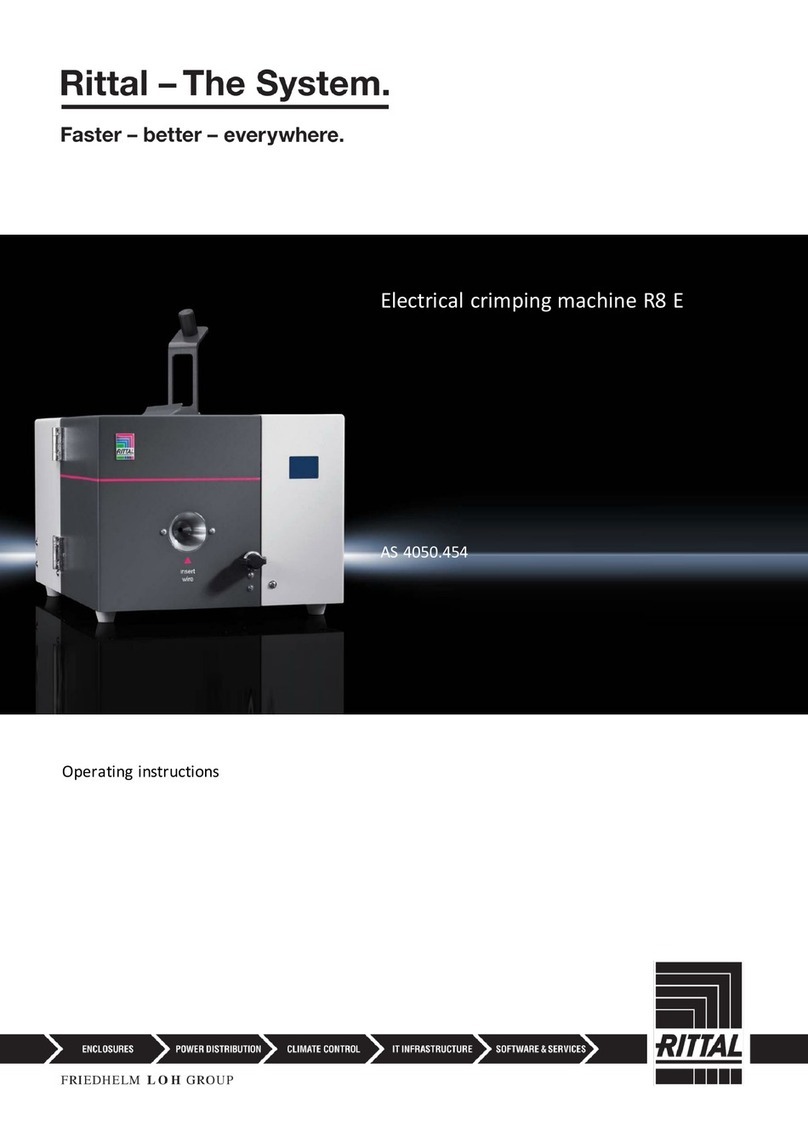

C14 PTFE HOSE

NOTE: Always use the proper personal protection equipment when making assemblies.

STEP 1 – HOSE CUTTING

After determining hose cut length by deducting for fittings, cut hose with shear. No taping

or deburring is necessary, since shearing the hose holds braid flaring to a minimum.

STEP 2 – HOSE INSERTION

Place ferrule in hose insertion die holder with tapered end down. Place insertion dies

in die holder so that taper will guide hose into ferrule. Push hose through dies with

a slight twisting motion until seated; pull hose out. Insertion dies will fall out as you

remove hose. Check end of ferrule for full insertion.

STEP 3 – HOSE EXPANSION AND STEM INSERTION

Next, select proper size expansion rod and secure in a vise. Push hose over bead several

times to expand tube. Place stem (and nut if used) on rod. Push hose onto stem until

stem is completely inserted - no gaps between shoulder on stem and ferrule. If a gap

exists, ferrule must be twisted and pushed forward until gap is eliminated.

STEP 4 – SWAGING

Select proper size dies and pusher and install them in the Gates HS-1 hand swager

(Product No. 7483-1000) or swager conversion kit for the PC707.

If using the PC707 with conversion kit installed, remove actuator rod to swage.

Lubricate bore of die set with light oil. Using one hand to hold assembly so fitting

remains seated in pusher, start swage. Swage is complete when pusher bottoms out

on dies. When swaging is complete, reinstall actuator rod into crimp position.

When swage is complete, ferrule outside diameter must be within the recommended

finished swage outside diameter.

If ferrule outside diameter is not within tolerance, check for die wear and replace

if necessary.

1Denotes dual seat

15

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES C14 SWAGE DATA

SWAGE TOOLING

PUSHERS AND DIES FOR C14 HOSE AND COUPLINGS

C14 HOSE INSERTION DIES C14 SWAGE PUSHERS C14 HOSE EXPANDERS

C14 SWAGE DIES

16 DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

C14 SWAGE DATA

1Denotes dual seat. 2 When swaging, do not keep the flange between the pusher and swage die. 3When swaging, keep the flange between the pusher and swage die.

GATES HOSE SWAGE DATA

C14 PTFE

Use C14 couplings with C14 hose.

Gates pushers and dies MUST BE USED to swage Gates C14 hose with Gates C14 couplings.

Coupling Assembly Swaging Tools

Description Product No. Insertion Length

+/-.03 (in)

C14 Hose

Insertion Die

C14 Hose

Expander Die

Finished Swage

OD +/-.005 (in) Pusher Die

4C14-2MP-SS 7753-0008-5 - HD-4C14 HE-4C14 0.353 P-C14-2MP SD-4C14

4C14-4MP-SS 7753-0001-5 - HD-4C14 HE-4C14 0.353 P-C14-4MP SD-4C14

5C14-4MP-SS 7753-0002-5 - HD-5C14 HE-5C14 0.407 P-C14-4MP SD-5C14

6C14-4MP-SS 7753-0009-5 - HD-6C14 HE-6C14 0.481 P-C14-4MP SD-6C14

6C14-6MP-SS 7753-0003-5 - HD-6C14 HE-6C14 0.481 P-C14-6MP SD-6C14

8C14-6MP-SS 7753-0010-5 - HD-8C14 HE-8C14 0.571 P-C14-6MP SD-8C14

8C14-8MP-SS 7753-0004-5 - HD-8C14 HE-8C14 0.571 P-C14-8MP-8&10ABC SD-8C14

10C14-8MP-SS 7753-0005-5 - HD-10C14 HE-10C14 0.676 P-C14-8MP-8&10ABC SD-10C14

12C14-12MP-SS 7753-0006-5 - HD-12C14 HE-12C14 0.803 P-C14-12MP-12ABC SD-12C14

16C14-16MP-SS 7753-0007-5 - HD-16C14 HE-16C14 1.047 P-C14-16MP SD-16C14

4C14-2MP-B 7753-1008-5 - HD-4C14 HE-4C14 0.353 P-C14-2MP SD-4C14

4C14-4MP-B 7753-1001-5 - HD-4C14 HE-4C14 0.353 P-C14-4MP SD-4C14

5C14-4MP-B 7753-1002-5 - HD-5C14 HE-5C14 0.407 P-C14-4MP SD-5C14

6C14-4MP-B 7753-1009-5 - HD-6C14 HE-6C14 0.481 P-C14-4MP SD-6C14

6C14-6MP-B 7753-1003-5 - HD-6C14 HE-6C14 0.481 P-C14-4MP SD-6C14

8C14-6MP-B 7753-1010-5 - HD-8C14 HE-8C14 0.571 P-C14-6MP SD-8C14

8C14-8MP-B 7753-1004-5 - HD-8C14 HE-8C14 0.571 P-C14-8MP-8&10ABC SD-8C14

10C14-8MP-B 7753-1005-5 - HD-10C14 HE-10C14 0.676 P-C14-8MP-8&10ABC SD-10C14

12C14-12MP-B 7753-1006-5 - HD-12C14 HE-12C14 0.803 P-C14-12MP-12ABC SD-12C14

16C14-16MP-B 7753-1007-5 - HD-16C14 HE-16C14 1.047 P-C14-16MP SD-16C14

4C14-4MIX 7753-2030-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

5C14-5MIX 7753-2031-5 - HD-5C14 HE-5C14 0.407 P-C14-5TUBE SD-5C14

6C14-6MIX 7753-2032-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8MIX 7753-2033-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10MIX 7753-2034-5 - HD-10C14 HE-10C14 0.678 P-C14-10TUBE SD-10C14

4C14-4MIX45 7753-2035-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

6C14-6MIX45 7753-2036-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8MIX45 7753-2037-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10MIX45 7753-2069-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12MIX45 7753-2070-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE SD-12C14

4C14-4MIX90 7753-2038-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

5C14-5MIX90 7753-2039-5 - HD-5C14 HE-5C14 0.407 P-C14-5TUBE SD-5C14

6C14-6MIX90 7753-2040-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8MIX90 7753-2041-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10MIX90 7753-2042-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12MIX90 7753-2071-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE SD-12C14

4C14-4FJSX-SS17753-0012-5 - HD-4C14 HE-4C14 0.353 P-C14-4FJSX SD-4C14

5C14-5FJSX-SS17753-0013-5 - HD-5C14 HE-5C14 0.407 P-C14-5FJSX SD-5C14

6C14-6FJX-SS 7753-0014-5 - HD-6C14 HE-6C14 0.481 P-C14-6FJX SD-6C14

8C14-8FJSX-SS17753-0015-5 - HD-8C14 HE-8C14 0.571 P-C14-8FJSX SD-8C14

10C14-10FJSX-SS17753-0016-5 - HD-10C14 HE-10C14 0.676 P-C14-10FJSX SD-10C14

12C14-12FJX-SS 7753-0017-5 - HD-12C14 HE-12C14 0.803 P-C14-12FJX SD-12C14

16C14-16FJSX-SS17753-0018-5 - HD-16C14 HE-16C14 1.047 P-C14-16FJSX SD-16C14

4C14-4FJSX-B17753-1012-5 - HD-4C14 HE-4C14 0.353 P-C14-4FJSX SD-4C14

5C14-5FJSX-B17753-1013-5 - HD-5C14 HE-5C14 0.407 P-C14-5FJSX SD-5C14

6C14-6FJX-B 7753-1014-5 - HD-6C14 HE-6C14 0.481 P-C14-6FJX SD-6C14

17

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES C14 SWAGE DATA

1 Denotes dual seat. 2 When swaging, do not keep the flange between the pusher and swage die. 3 When swaging, keep the flange between the pusher and swage die.

C14 PTFE

Use C14 couplings with C14 hose.

Gates pushers and dies MUST BE USED to swage Gates C14 hose with Gates C14 couplings.

Coupling Assembly Swaging Tools

Description Product No. Insertion Length

+/-.03 (in)

C14 Hose

Insertion Die

C14 Hose

Expander Die

Finished Swage OD

+/- .005 (in) Pusher Die

6C14-6FSX-B 7753-1019-5 - HD-6C14 HE-6C14 0.481 P-C14-6FSX SD-6C14

8C14-8FJSX-B17753-1015-5 - HD-8C14 HE-8C14 0.571 P-C14-8FJSX SD-8C14

10C14-10FJSX-B17753-1016-5 - HD-10C14 HE-10C14 0.676 P-C14-10FJSX SD-10C14

12C14-12FJX-B 7753-1017-5 - HD-12C14 HE-12C14 0.803 P-C14-12FJX SD-12C14

12C14-12FSX-B 7753-1020-5 - HD-12C14 HE-12C14 0.803 P-C14-12FSX SD-12C14

16C14-16FJSX-B17753-1018-5 - HD-16C14 HE-16C14 1.047 P-C14-16FJSX SD-16C14

4C14-4FSX45 7753-2021-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

5C14-5FSX45 7753-2022-5 - HD-5C14 HE-5C14 0.407 P-C14-5TUBE SD-5C14

6C14-6FSX45 7753-2023-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8FSX45 7753-2024-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10FSX45 7753-2063-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12FSX45 7753-2064-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE-JS SD-12C14

4C14-4FSX90 7753-2025-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

5C14-5FSX90 7753-2026-5 - HD-5C14 HE-5C14 0.407 P-C14-5TUBE SD-5C14

6C14-6FSX90 7753-2027-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8FSX90 7753-2028-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10FSX90 7753-2029-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12FSX90 7753-2066-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE-JS SD-12C14

4C14-4FJX45 7753-2049-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

5C14-5FJX45 7753-2050-5 - HD-5C14 HE-5C14 0.407 P-C14-5TUBE SD-5C14

6C14-6FJX45 7753-2051-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8FJX45 7753-2052-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10FJX45 7753-2053-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12FJX45 7753-2054-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE-JS SD-12C14

16C14-16FJX45 7753-2055-5 - HD-16C14 HE-16C14 1.047 P-C14-16TUBE-JS SD-16C14

4C14-4FJX90 7753-2056-5 - HD-4C14 HE-4C14 0.353 P-C14-4TUBE SD-4C14

5C14-5FJX90 7753-2057-5 - HD-5C14 HE-5C14 0.407 P-C14-5TUBE SD-5C14

6C14-6FJX90 7753-2058-5 - HD-6C14 HE-6C14 0.481 P-C14-6TUBE SD-6C14

8C14-8FJX90 7753-2043-5 - HD-8C14 HE-8C14 0.571 P-C14-8TUBE SD-8C14

10C14-10FJX90 7753-2060-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12FJX90 7753-2061-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE-JS SD-12C14

16C14-16FJX90 7753-2062-5 - HD-16C14 HE-16C14 1.047 P-C14-16TUBE-JS SD-16C14

8C14-8ABC-B 7753-1036-5 - HD-8C14 HE-8C14 0.571 P-C14-8MP-8 & 10ABC SD-8C14

10C14-8ABC-B 7753-1037-5 - HD-10C14 HE-10C14 0.676 P-C14-8MP-8 & 10ABC SD-10C14

10C14-10ABC-B 7753-1038-5 - HD-10C14 HE-10C14 0.676 P-C14-8MP-8 & 10ABC SD-10C14

12C14-12ABC-B 7753-1039-5 - HD-12C14 HE-12C14 0.803 P-C14-12MP-12ABC SD-12C14

10C14-8STA-B 7753-1041-5 - HD-10C14 HE-10C14 0.676 P-C14-8TUBE SD-10C14

10C14-10STA-B 7753-1042-5 - HD-10C14 HE-10C14 0.676 P-C14-10TUBE SD-10C14

12C14-12STA-B 7753-1043-5 - HD-12C14 HE-12C14 0.803 P-C14-12TUBE SD-12C14

6C14-6TBFLX27753-1025-5 - HD-6C14 HE-6C14 0.481 P-C14-6TBFLX SD-6C14

12C14-12TBFLX37753-1026-5 - HD-12C14 HE-12C14 0.803 P-C14-12TBFLX SD-12C14

16C14-16TBFLX37753-1027-5 - HD-16C14 HE-16C14 1.047 P-C14-16TBFLX SD-16C14

18 DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

GENERAL SWAGING GC32-XD/FLEX

GC96 PC707/SC32 GC16XD MC 4-20 DD & PS POWER STEERING

GATES

C14 SWAGE DATA

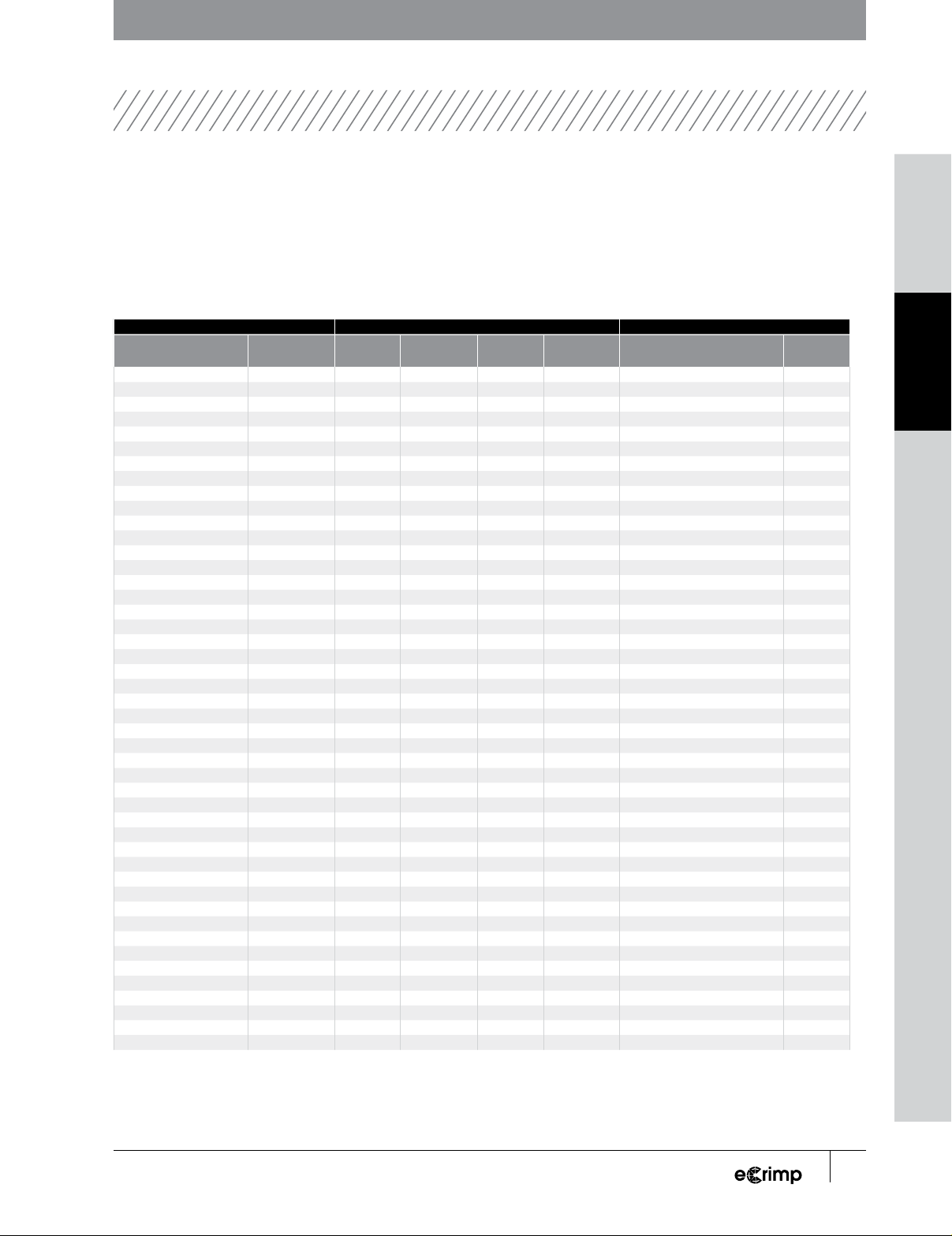

CRIMP AND MACHINE SPECIFICATIONS FOR SWAGER

HOSE STEM FERRULE SPECIFICATIONS

DASH

SIZE DESCRIPTION SIZE

(IN)

WORKING

PRESSURE

(PSI)

TYPE DESCRIPTION

SKIVE LENGTH

(IN)

(+/- 0.03) "

SKIVE DIAM-

ETER (IN)

CRIMP INSER-

TION LENGTH

(IN)

(+/- 0.03)

CRIMP LENGTH

(IN)

(+/- 0.03) "

CRIMP OUT-

SIDE DIAM-

ETER (IN)

(+/- .005)

CRIMP TAIL

LENGTH (IN)

(+/- 0.1)

DIE SET APPROX.

SETTING

MANUAL

USER

ENTRY

4 C14 0.18 1500 4C14 Included NONE NONE FULL SWAGE 0.353 NONE SD-4C14 0

4 C14 0.18 1500 4C14-B Included NONE NONE FULL SWAGE 0.353 NONE SD-4C14 0

4 C14 0.18 1500 4C14-SS Included NONE NONE FULL SWAGE 0.353 NONE SD-4C14 0

5 C14 0.25 1500 5C14 Included NONE NONE FULL SWAGE 0.407 NONE SD-5C14 0

5 C14 0.25 1500 5C14-B Included NONE NONE FULL SWAGE 0.407 NONE SD-5C14 0

5 C14 0.25 1500 5C14-SS Included NONE NONE FULL SWAGE 0.407 NONE SD-5C14 0

6 C14 0.31 1500 6C14 Included NONE NONE FULL SWAGE 0.481 NONE SD-6C14 0

6 C14 0.31 1500 6C14-B Included NONE NONE FULL SWAGE 0.481 NONE SD-6C14 0

6 C14 0.31 1500 6C14-SS Included NONE NONE FULL SWAGE 0.481 NONE SD-6C14 0

8 C14 0.4 1000 8C14 Included NONE NONE FULL SWAGE 0.571 NONE SD-8C14 0

8 C14 0.4 1000 8C14-B Included NONE NONE FULL SWAGE 0.571 NONE SD-8C14 0

8 C14 0.4 1000 8C14-SS Included NONE NONE FULL SWAGE 0.571 NONE SD-8C14 0

10 C14 0.5 800 10C14 Included NONE NONE FULL SWAGE 0.676 NONE SD-10C14 0

10 C14 0.5 800 10C14-B Included NONE NONE FULL SWAGE 0.676 NONE SD-10C14 0

10 C14 0.5 800 10C14-SS Included NONE NONE FULL SWAGE 0.676 NONE SD-10C14 0

12 C14 0.62 800 12C14 Included NONE NONE FULL SWAGE 0.803 NONE SD-12C14 0

12 C14 0.62 800 12C14-B Included NONE NONE FULL SWAGE 0.803 NONE SD-12C14 0

12 C14 0.62 800 12C14-SS Included NONE NONE FULL SWAGE 0.803 NONE SD-12C14 0

16 C14 0.87 800 16C14 Included NONE NONE FULL SWAGE 1.047 NONE SD-16C14 0

16 C14 0.87 800 16C14-B Included NONE NONE FULL SWAGE 1.047 NONE SD-16C14 0

16 C14 0.87 800 16C14-SS Included NONE NONE FULL SWAGE 1.047 NONE SD-16C14 0

6 C14CT 0.31 1500 6C14 Included NONE NONE FULL SWAGE 0.481 NONE SD-6C14 0

6 C14CT 0.31 1500 6C14-B Included NONE NONE FULL SWAGE 0.481 NONE SD-6C14 0

6 C14CT 0.31 1500 6C14-SS Included NONE NONE FULL SWAGE 0.481 NONE SD-6C14 0

8 C14CT 0.4 1000 8C14 Included NONE NONE FULL SWAGE 0.571 NONE SD-8C14 0

8 C14CT 0.4 1000 8C14-B Included NONE NONE FULL SWAGE 0.571 NONE SD-8C14 0

8 C14CT 0.4 1000 8C14-SS Included NONE NONE FULL SWAGE 0.571 NONE SD-8C14 0

2 TH7 0.12 3000 2PCTS One-Piece3NONE NONE 0.56 SWAGE 0.3604NONE G302 0

3 TH7 0.18 3000 3PCTS One-Piece3NONE NONE 0.78 SWAGE 0.4854NONE G303 0

2 TH7NC 0.12 3000 2PCTS One-Piece3NONE NONE 0.56 SWAGE 0.3604NONE G302 0

3 TH7NC 0.18 3000 3PCTS One-Piece3NONE NONE 0.78 SWAGE 0.4854NONE G303 0

1 A pusher must be selected based on the size and type of coupling end termination used.

2 Tolerance for the outside diameter of swaged couplings is +/- 0.005 inches (0.13 mm). If swages are outside of this tolerance

replace dies.

3 Buff required only if hose OD prohibits insertion.

4 Crimp outside diameter is +/- .010 inches.

19

DOWNLOAD THE ECRIMP APP OR GO TO WWW.GATES.COM/ECRIMP

POWER STEERING MC 4-20 DD & PS GC16XD PC707/SC32 GC32-XD/FLEX

GC96 SWAGING GENERAL

GATES C14 SWAGE DATA

Other manuals for GC32-XD

1

This manual suits for next models

6

Table of contents

Other Gates Crimping Tools manuals

Gates

Gates GC32TSi Guide

Gates

Gates GC96 User manual

Gates

Gates GC16XD Installation manual

Gates

Gates MCX50 Use and care manual

Gates

Gates GC20 Instruction Manual

Gates

Gates Power Crimp 707 Installation manual

Gates

Gates MC3001 Use and care manual

Gates

Gates GC16XD Installation manual

Gates

Gates GC32FLEX Guide

Gates

Gates MobileCrimp 4-20 Installation manual