Gates MCX50 Use and care manual

Operating Manual MCX50

Gates Europe NV Fluid Power- 1 - www.gates.com/europe

MCX50

Operating and Calibration Instructions

15-03-2010 Version 2.3

Copying and distributing this document and the use or communication on the contents thereof are forbidden without expressed authority.

Offenders are liable to the payment of damages. All rights are reserved in the event of the grant of a patent of the registration of a utility

model or design.

Paste the duplicate of the machine tag

plate in this box, so you can easily keep

track on the details of your Gates

MCX50 for maintenance & repair.

Operating Manual MCX50

Gates Europe NV Fluid Power- 2 - www.gates.com/europe

Table of contents

1. Certificate of conformity ..............................................................................................3

2. General Information ....................................................................................................4

3. Machine Characteristics..............................................................................................5

3.1 Design.......................................................................................................................5

3.2 Characteristics ..........................................................................................................6

3.3 Options......................................................................................................................6

3.4 Working Principles ....................................................................................................6

4. Safety..........................................................................................................................7

4.1 General Safety Instructions.......................................................................................7

4.2 Safety Measures.......................................................................................................8

5. Instructions for use......................................................................................................10

5.1 Unpacking.................................................................................................................10

5.2 Filling with hydraulic oil .............................................................................................10

5.3 Ventilate the Hydraulic System.................................................................................10

5.4 Connecting to the electric supply..............................................................................11

5.5 Operating instructions...............................................................................................12

6. Maintenance................................................................................................................16

6.1 Requirements............................................................................................................16

6.2 Spare Parts...............................................................................................................19

6.3 Warranty and Liability................................................................................................21

Declaration of Trained Personnel....................................................................................22

Appendixes

Operating Manual MCX50

Gates Europe NV Fluid Power- 3 - www.gates.com/europe

1. Certificate of Conformity

CE Declaration of Conformity

within the meaning of CE Directive Machines 2006/42/EC

The following machine:

MCX50

was developed, designed and manufactured in accordance with Directive 2006/42/EC under the sole

responsibility of

Company

UNIFLEX - Hydraulik GmbH

Robert-Bosch-Straße 50 - 52

D - 61184 Karben

Documentation officer Carsten Baumgartner

The following harmonized standards were applied:

• CE Directive 2006/42/EEC

• CE Directive 2006/95/EEC

• EMC Directive 2004/108/EEC

• EN 12100-2: 2004

• EN 60204: 2006

If the machine is changed in any way without consulting us beforehand or if any non-tested and non-

accepted outside parts are used, this declaration shall lose its validity.

Complete technical documentation is available.

The operating instructions supplied with the machine is the original version.

---------------------------------- -------------------------------------- -----------------------------------

Place, Date Signature Function of the signee

Karben, 15/09/2009 Geschäftsführer - President

Operating Manual MCX50

Gates Europe NV Fluid Power- 4 - www.gates.com/europe

2. General Information

You have just acquired a GATES MCX50. It is necessary you adhere to the enclosed instructions for best

performance.

The MCX50 has been designed specially for crimping the complete range of Gates hoses and couplings

which are being used in today’s hydraulic world. This user manual contains all information concerning the

operation, use and maintenance of your MCX50.

Even if you have attended a training course for operating this machine, please read these operating

instructions completely before starting up the machine.

This hose crimper is a state-of-the-art machine and it is safe to use. However, certain rules have to be

observed to minimize the risk of injuries and protect the machine. Please pay particular attention to

chapter 4 – “Safety” in these operating instructions.

Operating Manual MCX50

Gates Europe NV Fluid Power- 5 - www.gates.com/europe

3. Machine Characteristics

3.1. Design

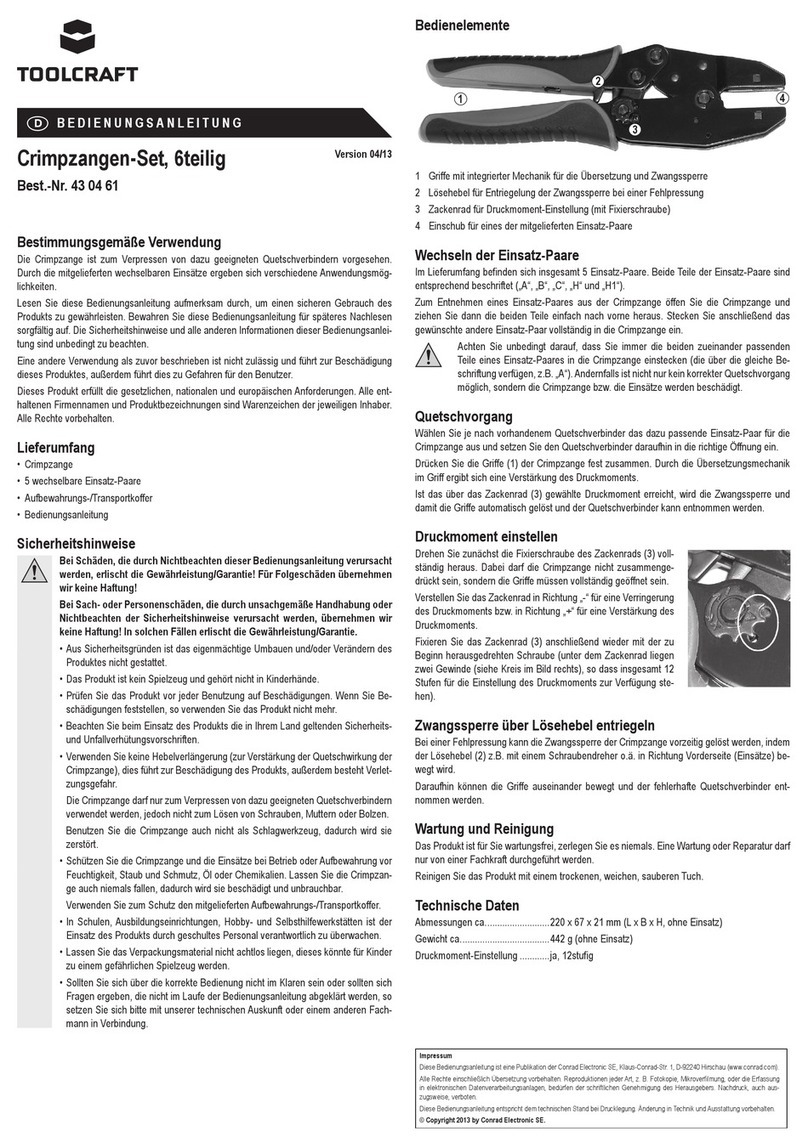

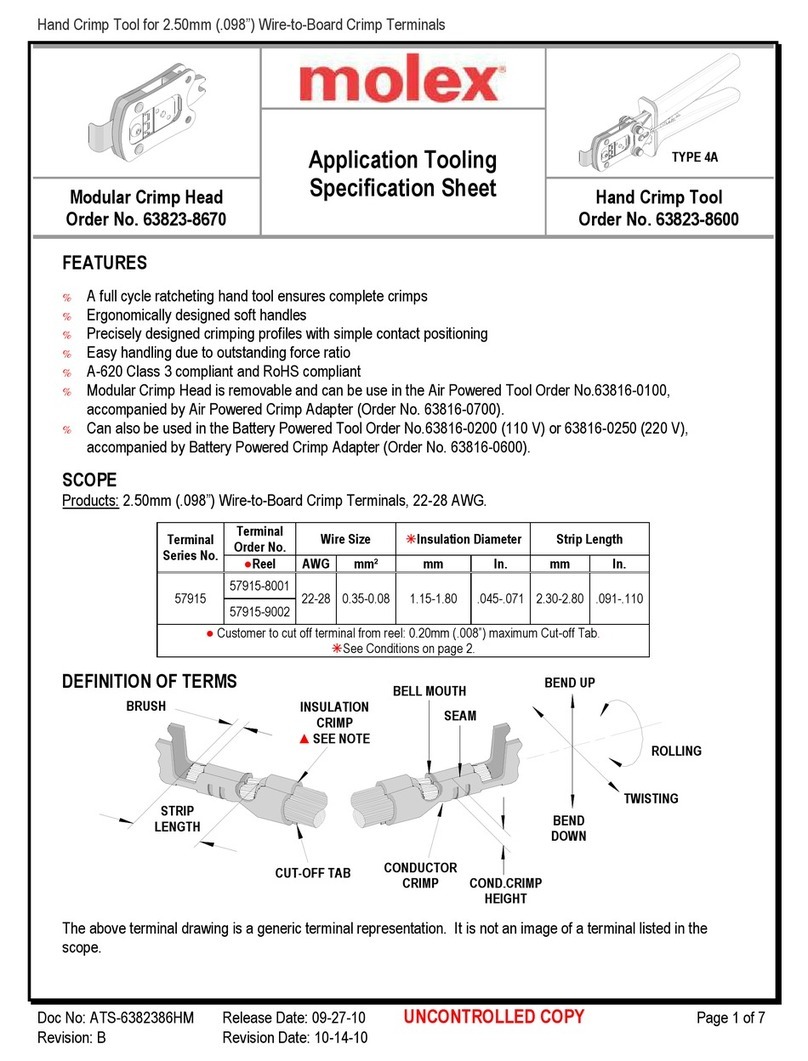

Fig.1 Front View MCX50

1 Emergency button to operate in any situation where people, machines or other things are in

danger.

2 Main Switch.

3 Motor on – to switch on the motor.

4 Motor off – to switch off the motor.

5 Open the crimp tool – to open the crimp tool for example after finishing the crimping.

6 Close the crimp tool – to close the crimp tool for example to close or to crimp.

7 Gauge.

8 Crimping Tool.

9 Double Foot Pedal Switch.

7

5

1

3

6

2

8

4

9

Operating Manual MCX50

Gates Europe NV Fluid Power- 6 - www.gates.com/europe

3.2. Characteristics

Technical Data MCX50

Crimping Force 280 ton

Control Micrometer

Max. capacity

WB 2”

4SW 2”

6SW 2”

90° Elbows * 2”

Max. Crimp Range 139 mm

Opening Path + 45 mm

Opening without dies 190 mm

Speed

Closing 6,1 mm/sec

Crimping 1,7 mm/sec

Opening 10,3 mm/sec

Noise level 63 dBA

Drive 5.5 kW

L-W-H (mm) 690 x 600 x 1400

Oil 55 l

Oil type HLP46, DIN 51524

Oil change Annually

Weight 390 kg

Type of dies 239L / 237L

*depending on the fitting drop dimension

3.3 Options

See Appendix IV

3.4 Working Principles

This machine is comprised of 2 main systems:

The hydraulic circuit: see Appendix II

The electrical circuit: see Appendix III

Operating Manual MCX50

Gates Europe NV Fluid Power- 7 - www.gates.com/europe

4. Safety

4.1. General Safety Instructions

All rules and regulations regarding the prevention of accidents, which are applicable at the place of use,

have to be observed.

Obligations of the owner

The owner undertakes to allow only people work on the machine, who are familiar with the basic

regulations on work safety and accident prevention, have been instructed in the operation of the hose

crimper, and have read and understood the operating manual and signed the >Declaration of Trained

Personal< page . The owner shall check at regular intervals whether the personnel is operating the

machine according to the safety regulations.

The operating manual needs to be at the location of the machine at all times. Additionally to the operating

manual the local regulations for accident prevention and environmental protection need to be available

and they need to be observed. All safety notes and danger indication need to be kept in legible condition.

Obligations of the user

All persons authorized to work with this Gates machine are obliged to observe the basic regulations on

work safety and accident prevention and read the operating manual.

Only adequately trained and instructed users should be authorized to work on the machine. The

responsibilities of the user as to the assembly start up, operation, maintenance and repair of the machine

should be clearly defined. Users undergoing training should only work at the machine under the

supervision of an experienced person

By signing your name on the last page, you confirm that you have read completely and understood this

Operating Manual.

Usage to the intended purpose

This GATES machine is designed only for crimping hose assemblies. Operating the machine in a

potentially explosive atmosphere is prohibited. Any other usage or any usage exceeding the tasks

described below shall not be considered usage to the intended purpose. Usage to the intended purpose

also includes the observance of all information and instructions provided in the operating manual and the

timely execution of the inspection and maintenance work

This machine has been constructed according to state-of-the-art engineering and acknowledged safety

regulations. Nonetheless, dangers can arise for the operator and third persons. Additionally the machine

and/or other property can be damaged during incorrect operation. The machine may therefore only be

used:

for its proper purpose and intended use,

when it is in perfect and safe working order.

Any faults have to be remedied immediately.

Operating Manual MCX50

Gates Europe NV Fluid Power- 8 - www.gates.com/europe

4.2 Safety measures

Operating environment

The machine must only be operated when all protective coverings have been mounted correctly

Prior to switching on the machine it must be certain that no one can be injured or endangered by

the working machine. Inspect the outside of the machine at least once during every shift to check

for any damages.

For optimal operation of the machine the surrounding temperature has to be between 10°C and

35°C.

Personal safety

Irrespective of the local accident prevention regulations, the following instructions should be observed as

a means of protecting the health and safety of the maintenance and operating personnel:

Before each use of the crimping machine or the system, all safety installations must be fitted and

working correctly. Authorized personnel may only remove safety installations:

oAfter the complete stop of the machine.

oAfter safeguarding against accidental switching on.

Always keep a copy of the operating manual at the place of use of the machine.

Make sure that all safety and danger notices on the machine (if applicable) are always legible.

Only operate the machine when all safety devices are in working order.

Before starting up the hydraulic unit, make sure that the running machine can endanger no one.

Do not place any objects on the floor near the workplace.

Wear working gloves, especially when heavy work pieces have to be loaded.

Do not bring work materials to the machine with a fork lift truck.

Wear safety shoes.

Do not put your hand in the crimping head during operation.

Never reach into the crimp tool with your hands while the electric motor is running! Always make

sure that there is an adequate safety distance of at least 120 mm to the crimp tool when you are

inserting a hose fitting.

Switch off the machine using the main switch during all

maintenance and setting works.

When the machine is handled improperly, there is the danger of

hands getting caught and crushed.

The emergency button must be activated in all situations where

injuries of people or damage on the machine can arise:

The emergency button is located on the control board (Design

p.5)

Serious accidents may occur if the machine is handled

incorrectly!

Operating Manual MCX50

Gates Europe NV Fluid Power- 9 - www.gates.com/europe

Hazards caused by electrical energy

Only qualified electricians should carry out work on the electric power supply. The electrical components

of the machine need to be checked at regular intervals. Any loose connections and damaged cables

should be repaired immediately. The housing must always be kept closed and access should only be

permitted to authorized personnel. When performing any kind of maintenance upon the electrical system,

ensure that the machine is isolated from the power supply.

Do not cover the electric motor ventilator.

Disconnect the machine from electrical supply when working on the dies, die-carriers or intermediate dies.

The electrical components of the machine need to be checked at regular intervals. Any loose connections

and damaged cables should be repaired immediately.

If works are needed on any electrical components of the machine, a second person must take part to

activate the main switch in case of an emergency.

Dangers of hydraulic oil

Be sure to prevent any hydraulic oil from seeping into the ground, water and/or sewage system. Hydraulic

oil, especially synthetic is not water soluble and hardly biologically degradable. Therefore hydraulic oil

especial is water polluting. Avoid long and intensive skin contact.

All substances and materials used have to be handled and disposed of properly, in particular when work

with lubricants was carried out. The national regulations on waste disposal have to be observed.

Maintenance and servicing, trouble-shooting

Carry out prescribed maintenance work in time. Inform the operating personnel before you begin with the

maintenance and servicing work. Always make sure that the machine is isolated when any maintenance,

inspection or repair work is to be carried out and that the main switch cannot be switched on

unexpectedly (i.e. by securing it accordingly). Put up a warning sign prohibiting any third persons from

starting up the machine. Replace all protective and safety guards again as soon as the maintenance work

has been completed and check that all screwed connections are fastened.

Constructional modifications of the machine

The machine may not be modified and no parts may be built on or modified without the manufacturer’s

approval. Any modifications need to be confirmed in writing by Gates. Any parts that are not in perfect

working order should be replaced immediately. Only original spare parts and wearing parts should be

used. Any parts used that are not for genuine Gates manufacture cannot be guaranteed as they may not

meet the load and safety requirements

your Gates representative if you need more advice from the Gates

service engineer or require expert maintenance & repair for your

Gates MCX50!

5. Instructions for use

Operating Manual MCX50

Gates Europe NV Fluid Power- 10 - www.gates.com/europe

5.1. Unpacking

The GATES machine was tested prior to delivery and is ready for operation.

1) Carefully unpack the machine without destroying the packaging. From then on, the machine

should only be transported in its original packaging. Please retain for future use.

2) Check the delivery for completeness using the delivery note.

3) To remove the lid from the box remove the screws at the bottom of the lid; lift the lid off the box.

Place lifting slings under the machine, or raise it with a lift truck. Use a fork lift truck to lift the hose

crimping machine off the palette. Never lift the machine by the crimping head or any of its

components!

4) Set the hose crimper on a level and stable surface (e.g. floor). The work bench needs to be able

to support the weight.

5) The hose crimper needs to be placed so that it is accessible from all sides for maintenance

works.

5.2. Filling with hydraulic oil

Recommended oil: HLP46, DIN 51524

Close the oil filler on the tank plate when the correct oil level

has been reached. The oil level can be checked on this oil side-

glass

The machine is delivered without hydraulic oil, so it must be filled with the

appropriate oil before using it (55l)

5.3. Ventilate the Hydraulic System

1) Take off the screws

2) Prior to ventilation, the machine must be opened and closed

several times.

3) Ventilate the opening- and closing-chamber on the bore holes as

shown in the picture.

4) Re-assemble the cover

5) The machine is now ready for operation

Always ventilate when changing the hydraulic oil!

Operating Manual MCX50

Gates Europe NV Fluid Power- 11 - www.gates.com/europe

5.4. Connecting the electric supply

This work should only be performed by a qualified electrician. Note the marked voltage on the type plate

and select the appropriate electric circuit diagram.

Switch the main connection of the hose crimper off-circuit and make sure that it cannot be

switched on again. Works on live wires are hazardous!

Connect the electric connecting cable to the connection of the power supply.

For the correct voltage refer to the type plate

The connecting plug must comply to current local electrical regulations!

Check the rotating direction of the electric motor (only with 3-Phases)

The rotating direction of the electric motor is indicated by an arrow on the motor

If the motor does not rotate in the direction indicated by the arrow, two phases must be switched

as shown:

The machine will be damaged if the motor rotates in the wrong direction

for some time!

Operating Manual MCX50

Gates Europe NV Fluid Power- 12 - www.gates.com/europe

5.5. Operating instructions

General notes for crimping

Set the correct crimp diameter

The crimp data sheets are available online. Go to http://www.gates.com/europe/e-crimp for the latest

crimp settings. After logging in, you can access the Crimp Data Sheets, sorted by machine type. Select

your machine type and print out an up-to-date sheet or download the pdf documents.

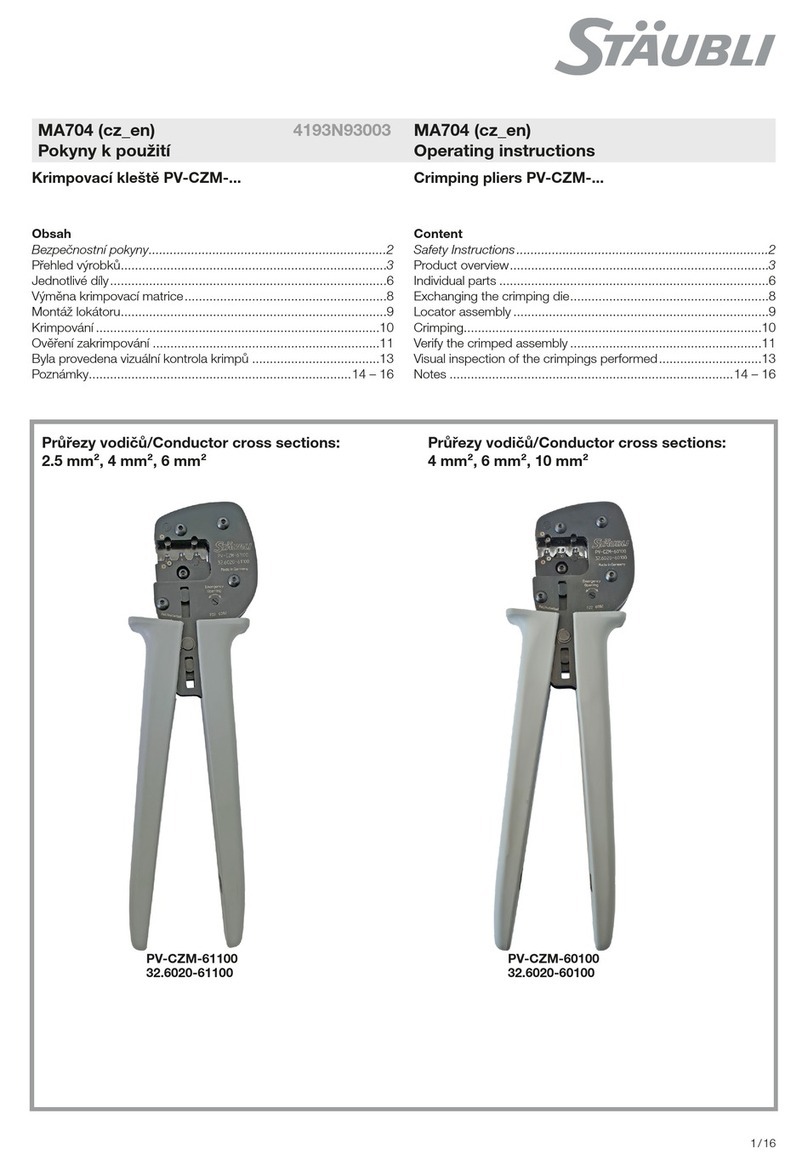

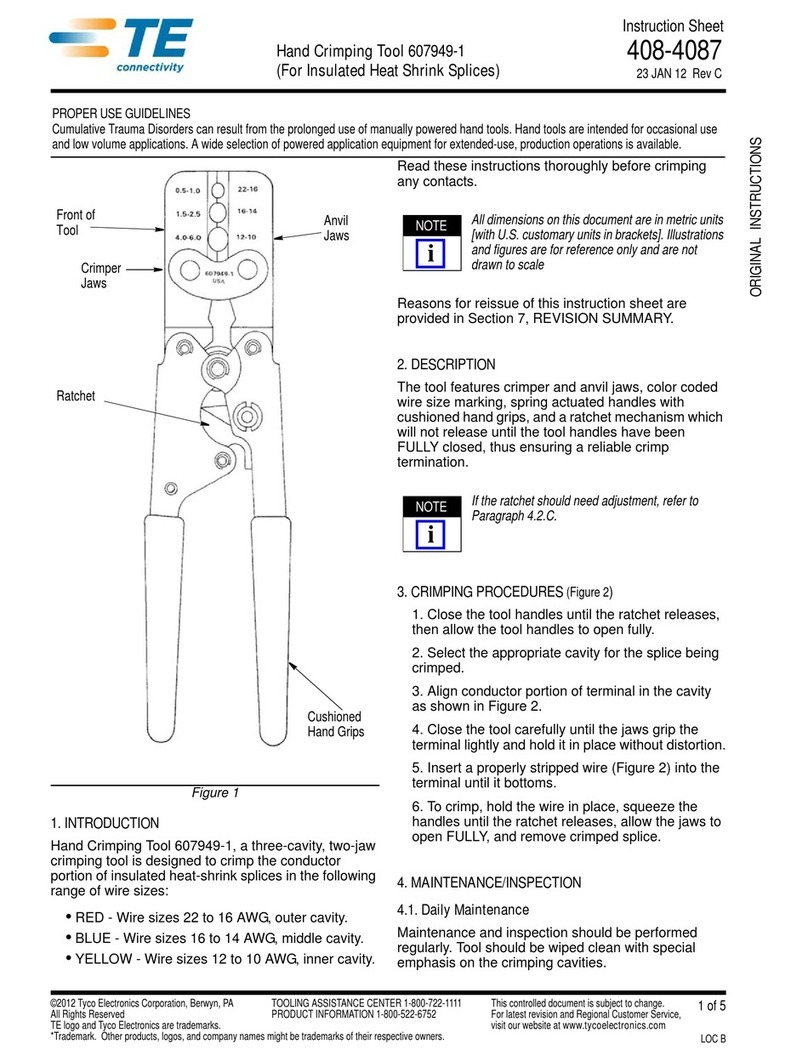

+ +

+

Fig.2 fictive crimp instruction

Operating Manual MCX50

Gates Europe NV Fluid Power- 13 - www.gates.com/europe

Operating Instructions (Ref. Fig. 1)

1) Turn the main switch (2) on and push the motor on button (3).

2) Press the opening button (5) in order to fully open the die-carriers.

3) Set the gauge (7) to 0.00 mm.

4) Select set of dies required from the die storage using the Quick Die Change (QDC)Tool.

5) Always insert a full set of equal crimp dies with equal marking and diameter in the crimper head.

6) Press the closing button (6) until machine automatically stops and the die closing button (6) goes out

7) Gently remove the QDC when the die pins are fixed in the die carriers.

8) Press the opening button (5)

9) Set the gauge setting mechanism (7) to the correct setting as indicated on the crimp data PDF (Ref

fig.2) for the particular hose and connector being crimped

10) Position the hose and the connector between the dies in the crimp head

11) Place the assembly in the position as specified on the Crimp data sheet (Ref. fig.2)

12) Press the closing button (6) to carry out the crimping operation until the machine automatically stops

and the closing button (6) goes out.

13) Press the opening button (5) to release the crimped assembly

14) Check the crimp diameter of the ferrule with a vernier or digital caliper. The measured crimp diameter

must be within the tolerance published on the crimp data PDF. If not, the hose assembly cannot be used

an adjustment will be required. Correct the gauge setting required. In order to decrease the crimp

diameter reduce the value of the gauge setting mechanism; reverse the procedure to increase crimp

diameter.

It is important to always crimp centrically, otherwise the result may be

conical crimping or increased abrasion. The crimp tool should only be

opened far enough to insert or take out the hose easily. Too large

opening paths may lead to crushing injuries and time loss.

Holding pins or crimp dies will be damaged if they do not slide in the bore holes

of the master or intermediate dies!

Operating Manual MCX50

Gates Europe NV Fluid Power- 14 - www.gates.com/europe

Die change

A) Quick Die Change (QDC) Tool

The universal QDC allows fast and easy change of dies (up to die set 239-D310) without risk of damage

to the die sets or holding pins. The transparent shield of the QDC allows you to quickly and safely position

die sets into the die carriers of the crimper head.

To take out the crimp dies do the above in reverse order.

2) Open the crimp tool

completely.

1) Set the crimp micrometer to

1.00 mm. 3) Take the tool and the

correct dies out of the Quick

Die Storage.

6) Take out the QDC and

check the tight fit of the

crimp dies.

5) Close the crimp tool and

make sure that the holding

pins slide smoothly in the bore

hole in master or intermediate

dies and make sure that they

lock in.

4) Hold the in the centre of

the crimper head.

Operating Manual MCX50

Gates Europe NV Fluid Power- 15 - www.gates.com/europe

B) Die key

Change the crimp dies (up to die type 237-D314) and intermediate dies (type 237.239) with a die key

1) Switch off the machine on the main switch.

2) Use the included die key to push and hold the pin A in the master die C. Insert the crimp die as shown

with the holding pin in the bore hole B. Release the pressure on holding pin A by pulling out the die key.

The crimp die is fastened in the master die. Insert the other dies equally.

3) To take out the crimp dies hold the crimp die to be changed in one hand. With the other hand push and

hold the die key in the bore hole A in the master die C. Take out the crimp die and release the pressure

on holding pin A by pulling out the die key. Take out the other dies the same way.

4) After the crimping of heavy assemblies with the die systems 237 the pin A may be a bit hard to release.

In this case use a rubber hammer to loosen the pin A.

Operating Manual MCX50

Gates Europe NV Fluid Power- 16 - www.gates.com/europe

6. Maintenance

Always switch the machine off on the main switch during any maintenance works!

6.1 Requirements

Daily Maintenance works

Open the crimp tool completely.

Switch off the motor and switch off the machine on the main switch.

Clean crimp tool of plating debris with some pressurized air.

Check the emergency-off-switch by operating it.

Check the level of oil through the glass.

Check visually for oil leakage.

Check the machine for outer damages or dismounting of parts (e.g. covers)

Monthly maintenance

Check the hydraulic hose assemblies for porosity and leaks.

Check the screwed joints and clamps of the hose assemblies for leaks.

Six-month maintenance

Check the bearing plates for wear. Worn bearing plates can lead to damages on the machine or

imprecise crimp values. Worn bearing plates need to be exchanged!

Annual maintenance

You need to change the oil after a year.

Open the crimp tool completely

Switch off the motor and turn off the machine on the main switch.

Pump the oil out and fill in new, clean and filtered (10 µ) hydraulic oil.

The user has to ensure that the hose assemblies are replaced at

appropriate intervals even if there are no obvious safety-related defects

in the hose assemblies. The hydraulic hoses are high-pressure hoses.

When a hose is replaced, care must be taken that the new one is of the same

quality.

The hose assembly must be replaced at least within ten years of the production

date (see marking).

New bearin

g

p

late

Worn bearin

g

p

late

Operating Manual MCX50

Gates Europe NV Fluid Power- 17 - www.gates.com/europe

Calibrate the crimp micrometer

Before delivery, each machine is calibrated and should be ready for use upon receipt. However, machine

calibration should be checked on a monthly basis and when gauge settings consistently produce

diameters away from that required in the crimp specification. Calibration procedure is as follows:

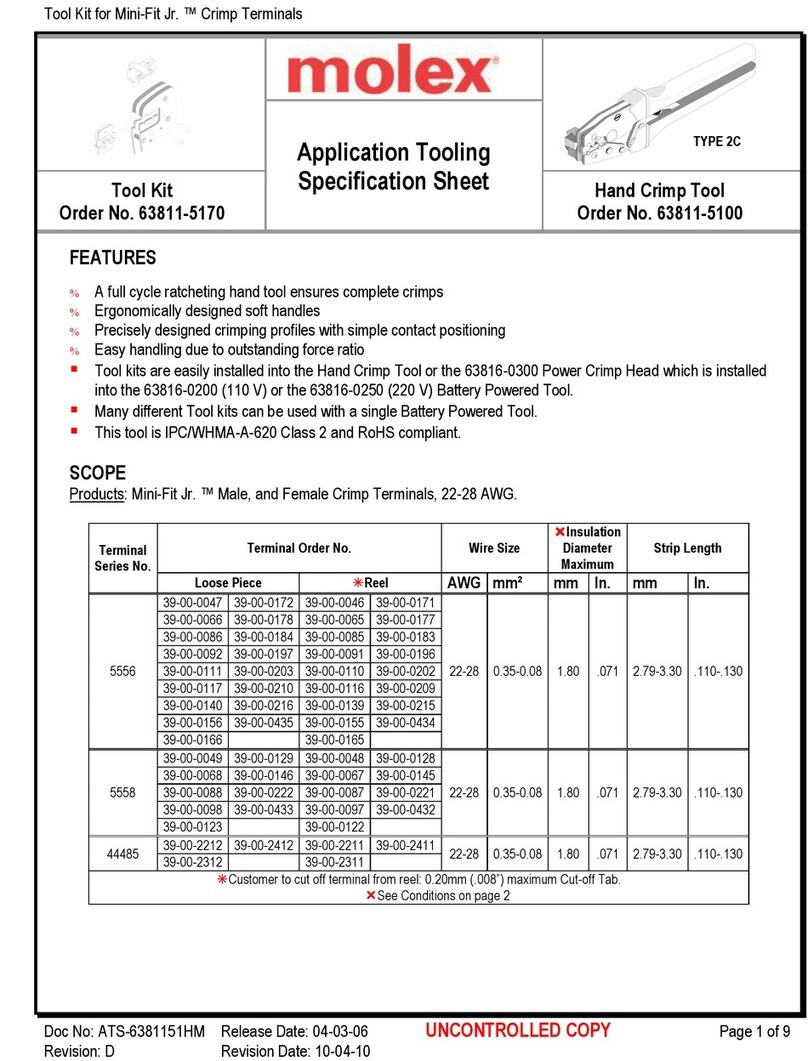

To calibrate using Megacrimp coupling (8G)

1. Place die set (D 33) in the machine.

2. Set the gauge setting mechanism to 2.00.

3. Crimp the megacrimp coupling.

4. Measure the crimped diameter of the shell — it should read 26.0.

5. If the crimp diameter is as specified, the machine is correctly calibrated.

6. If the crimp diameter is outside the stated dimensions, it is necessary to recalibrate the machine

as follows:

i. Isolate the machine from power supply.

ii. Note by how much the measured crimp diameter differs from the required 26.0

mm calibration diameter.

iii. Remove cover.

iv. Calibration adjustment is now via the Contactscrew and Counternut 1.6 of screw

clockwise (when viewed from the screw end) will reduce the crimp diameter by 1

mm. Turning the Contactscrew anti-clockwise increases the crimp diameter 1

mm. One full turn of the Contactscrew equals a difference in crimp diameter of

0.64 mm.

v. Unlock the Counternut and turn the Contactscrew the required amount according

to the difference between the achieved and the required crimp diameter.

vi. Lock the Counternut and, tightening the Contactscrew.

vii. Crimp a new calibration shell 8G (use the same type as before) and check that

the correct crimp diameter has now been achieved.

viii. If the required crimp diameter is not achieved, repeat the recalibration process.

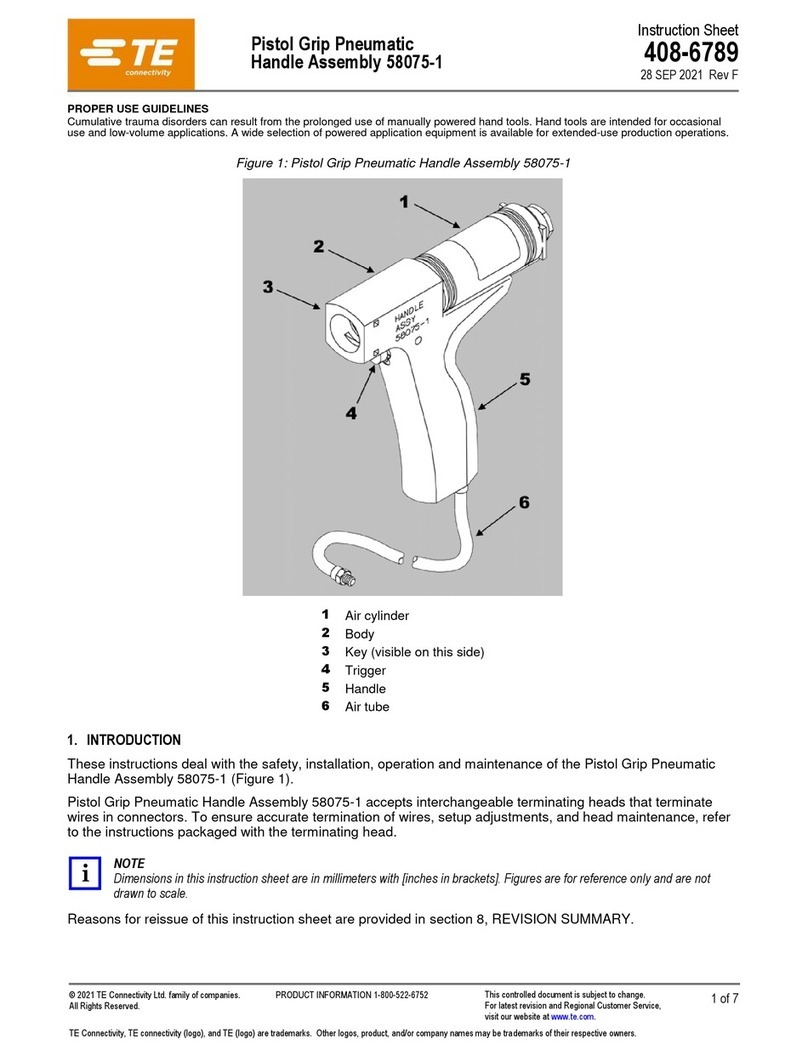

Counternut

Contactscrew

Operating Manual MCX50

Gates Europe NV Fluid Power- 18 - www.gates.com/europe

Exchange slide bearing plates MCX50

1) Open the machine completely.

2) Disassemble the ring in the back of the machine (8 screws) .

3) Pull out the old slide bearing plate

and push a new slide bearing plate on.

4) Washer must be placed in the same position!

5) After exchanging the bearing plates recalibrate the machine!

Operating Manual MCX50

Gates Europe NV Fluid Power- 19 - www.gates.com/europe

6.2 Spare Parts

See also Appendix I

Position Gates PN Description

1 8000-10253 Hydro-Pump

2 Tube Nipple

3 8000-10254 Suction Filter B

4 8000-10255 Suction Filter A

5 Hose Assembly MCX50 / MCX Matic

6 Hydraulic Tube

7 Tank Lid MCX 50

8 Tube Nipple

9 8000-10270 Bell Housing

10 Tube Nipple

11 Flange

12 Suction Flange

13 8000-10256 Slide Bearing

14 8000-10257 Pressure Spring

15 8000-10258 T-shaped Nut

16 8000-10259 Master Dies

17 Cover Gates

18 Clamping Ring

19 Hollow Piston

20 Flange

24 8000-10260 Potentiometer

29 8000-10261 Limit Switch

30 Cover

31 Guide Block

32 8000-10262 Spring

36 8000-10263 Electric Motor 5,5 kW

37 8000-10264 Solenoid Valve NG 6

38 8000-10265 Complete Hydraulic Block MCX50 Matic

41 Hose assembly MCX50

42 Hose assembly MCX50 MATIC

43 8000-10266 Solenoid Valve NG 10

44 8000-10267 Complete Hydraulic Block MCX50

45 8000-10268 Seal

46 Ventilating Plug

47 Oil Viewing Glass

48 Tank MCX Matic

49 8000-10269 Tank Seal

50 8000-10270 Bell Housing

51 8000-10271 2 Way Valve A

52 8000-10272 2 Way Valve B

53 8000-10273 2 Way Valve C

56 8000-10274 Pressure Switch

57 8000-10275 Pressure Limit Valve A

58 8000-10276 Pressure Limit Valve B

59 8000-10277 Check Valve

60 8000-10278 Way Valve Y4

61 8000-10279 Way Valve Y5

62 8000-10280 Way Valve Y3

63 8000-10281 Positioning indicator

64 Micrometer holder

65 Billow

66 Guide

Operating Manual MCX50

Gates Europe NV Fluid Power- 20 - www.gates.com/europe

67 8000-10282 Spindle

68 8000-10283 Socket countersunk

69 End switch holder

70 Connecting rod

71 8000-10284 MCX50 Control Panel

72 Frontplate

Table of contents

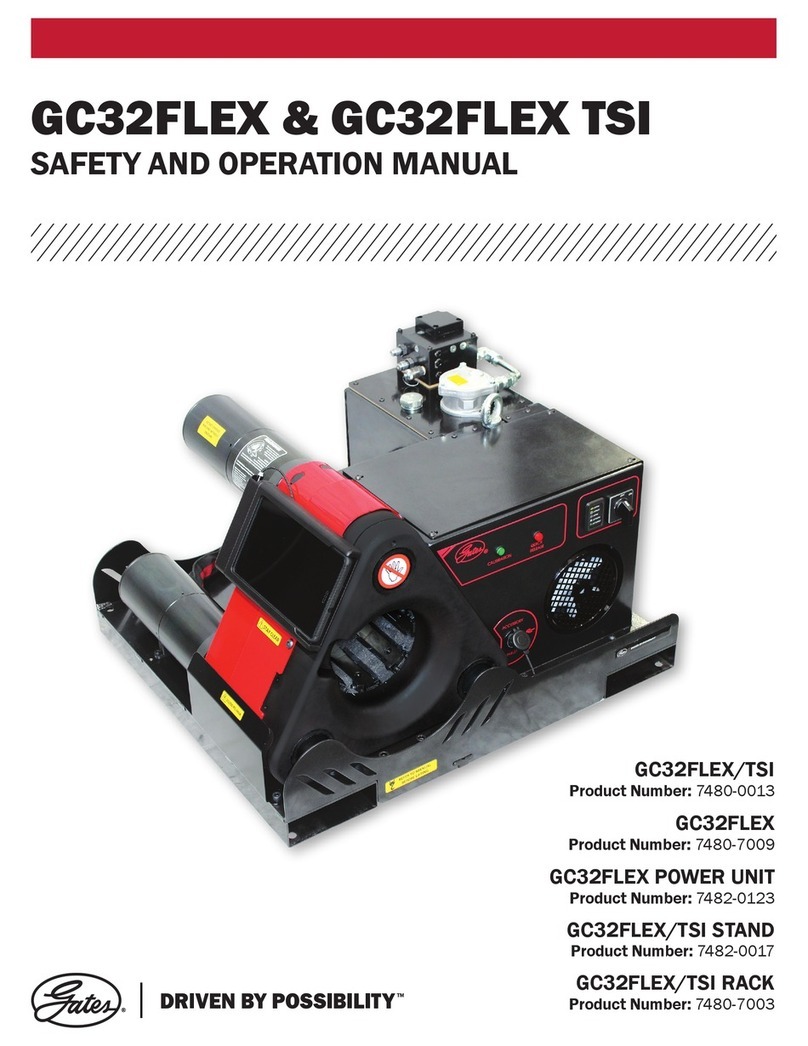

Other Gates Crimping Tools manuals

Gates

Gates GC16XD Installation manual

Gates

Gates Power Crimp 707 Installation manual

Gates

Gates GC32-XD User manual

Gates

Gates GC32FLEX Guide

Gates

Gates MobileCrimp 4-20 Installation manual

Gates

Gates GC16XD Installation manual

Gates

Gates GC20 Instruction Manual

Gates

Gates MC3001 Use and care manual

Gates

Gates GC32TSi Guide

Gates

Gates GC96 User manual

Popular Crimping Tools manuals by other brands

Tyco Electronics

Tyco Electronics AUTOPRESS C120 Technical handbook

JST

JST WC Series instruction manual

molex

molex 207129 Series Specification sheet

TE Connectivity

TE Connectivity 607949-1 Original instructions

Textron

Textron Greenlee GATOR EK12IDLT Operation manual

molex

molex 207129 Series Specification sheet