1

About This Manual

This manual provides information for planning, installing,

programming, and testing this security system. When nec-

essary, this manual refers you to other documentation

included with compatible devices.

Planning sheets are included for you to record hardware

layout and software programming settings.

Special Installation Requirements

This security system can be used as a fire warning system,

an intrusion alarm system, an emergency notification sys-

tem, or any combination of the three.

Some installations may require configurations dictated by

city or state codes, insurance, or Underwriter’s Laborato-

ries (UL). This section describes the various component

and configuration listings.

UL Listed Systems

This section describes the requirements for UL Listed sys-

tems.

Basic System

Control Panel (60-806-95R)

Backup Battery, 12 VDC, 4 AH (60-681)

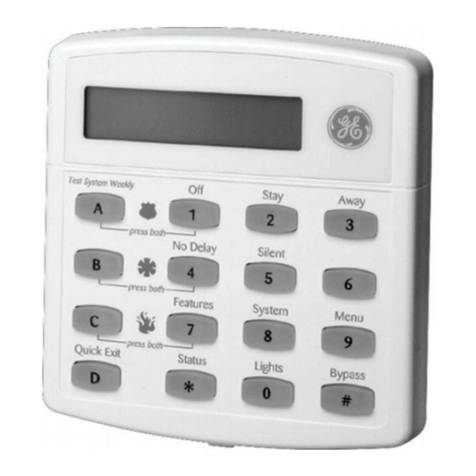

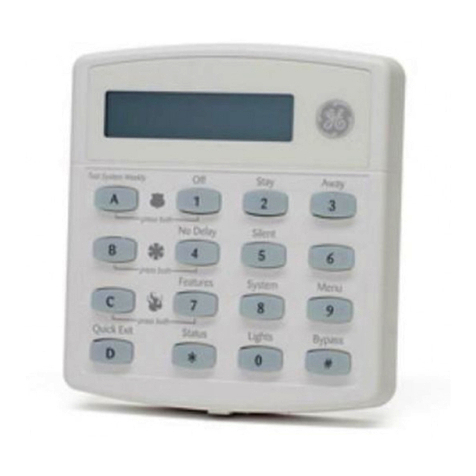

SuperBus 2000 2x16 LCD Touchpad (60-746-01),

SuperBus 2000 Fixed Display Touchpad (60-820),

SuperBus 2000 2x20 LCD Touchpads (60-803, 60-

809), or SuperBus 2000 2x20 VFD Touchpads (60-

804, 60-810)

Standard Class II 16.5 VAC, 25 VA Power Trans-

former; manufacturer—Tech Electro Ind, Inc. Part

No. 48A0164 (60-822)

15-Watt, Dual Tone Siren (13-469) or Hardwire Siren

(13-046)

Household Burglary Alarm System Unit (UL 1023)

Basic system, plus:

Hardwire Magnetic Contact (13-068 or 13-071) or

Wireless Learn Mode Door/Window Sensor (60-362),

Wireless Learn Mode PIR Motion Sensor (60-703-95,

60-511, or 60-639)

IMMEDIATE TROUBLE BEEPS set to on

UL 98 OPTIONS set to on (see page page 28)

RECEIVER FAILURE set to on

AC FAILURE set to on

EXIT DELAY set to 60 seconds or less

QUICK EXIT set to off

EXIT EXTENSION set to off

SIREN TIMEOUT set to 4 minutes or more

SIREN VERIFY set to on

ENTRY DELAY set to 45 seconds or less

Household Fire Warning System (UL 985)

Basic system plus:

Hardwire Smoke Detector:

System Sensor models 2100D, 2100TD, 2100S,

2100TS, 2400, or 2400TH learned into Sensor Group

26

Sentrol (ESL) models 429AT, 521B, or 521BXT

learned into sensor group 26

Wireless Smoke Sensor 60-506-319.5 learned into

sensor group 26

IMMEDIATE TROUBLE BEEPS set to on

UL 98 OPTIONS set to on (see page page 28)

RECEIVER FAILURE set to on

AC FAILURE set to on

SIREN VERIFY set to on

UL 1023 & 985 24-Hour Backup

For 24-hour backup, the total current draw for all con-

nected devices is limited to 90 mA continuous using a

4.0 AH battery.

Central Station Reporting

The panel has been tested with the following central sta-

tion receivers using SIA and Contact ID reporting formats:

CS-5000 Central Station Receiver

Sur-Gard Central Station Receiver with models SG-

DRL2A and SG-CPM2

UL-Canada Listed Systems

This section describes the requirements for ULC (UL Can-

ada) Listed systems.

CSA Certified Accessories

The UL-Canada Basic System is nearly the same as

the “UL Basic System” described previously, the only

difference being that you must use the 60-679-CN

Class II transformer (Basler part number BE 116250-

AAA) to power the panel.

Residential Burglary Alarm System Unit

(CAN/ULC-S309)

Same as “UL Basic System and Household Burglary

Alarm System Unit (UL 1023)” described previously.

Residential Fire Warning System Control Unit

(CAN/ULC-S545-M89)

Same as “UL Basic System and Household Fire Warning

System (UL 985)” described previously.

Ìi

For 24-hour backup, external power drain is limited

to 90 mA continuous using a 4.0AH battery.

California State Fire Marshall Listed Systems

Same as Household Fire Warning System (UL 985),

plus:

SMOKE VERIFY must be set to off