toc–ii MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Metering ............................................................................................................ 4 - 2

Current metering............................................................................................................................4 - 2

Voltage metering............................................................................................................................4 - 2

Power metering ..............................................................................................................................4 - 3

PQ metering......................................................................................................................................4 - 3

Status................................................................................................................. 4 - 4

Status messages ............................................................................................................................4 - 4

Input and output status ..............................................................................................................4 - 4

System Page.....................................................................................................................................4 - 5

Flex Page............................................................................................................................................4 - 5

5. SETPOINTS Understanding setpoints................................................................................ 5 - 1

Setpoint text abbreviations .......................................................................................................5 - 2

Configuration setpoints ................................................................................. 5 - 3

ATS setpoints....................................................................................................................................5 - 3

ATS types............................................................................................................................................5 - 4

Chicago Transfer Alarm Panel (CTAP) option ....................................................................5 - 7

Common ATS setpoints ...............................................................................................................5 - 8

Current and voltage transformers.........................................................................................5 - 9

Inputs................................................................................................................................................5 - 10

Outputs ............................................................................................................................................5 - 10

Communications setpoints.....................................................................................................5 - 10

System..............................................................................................................................................5 - 12

Events ...............................................................................................................................................5 - 13

Zenith................................................................................................................................................5 - 13

Operation setpoints ...................................................................................... 5 - 14

Timers ...............................................................................................................................................5 - 15

Control............................................................................................................. 5 - 16

General.............................................................................................................................................5 - 16

Interlock...........................................................................................................................................5 - 18

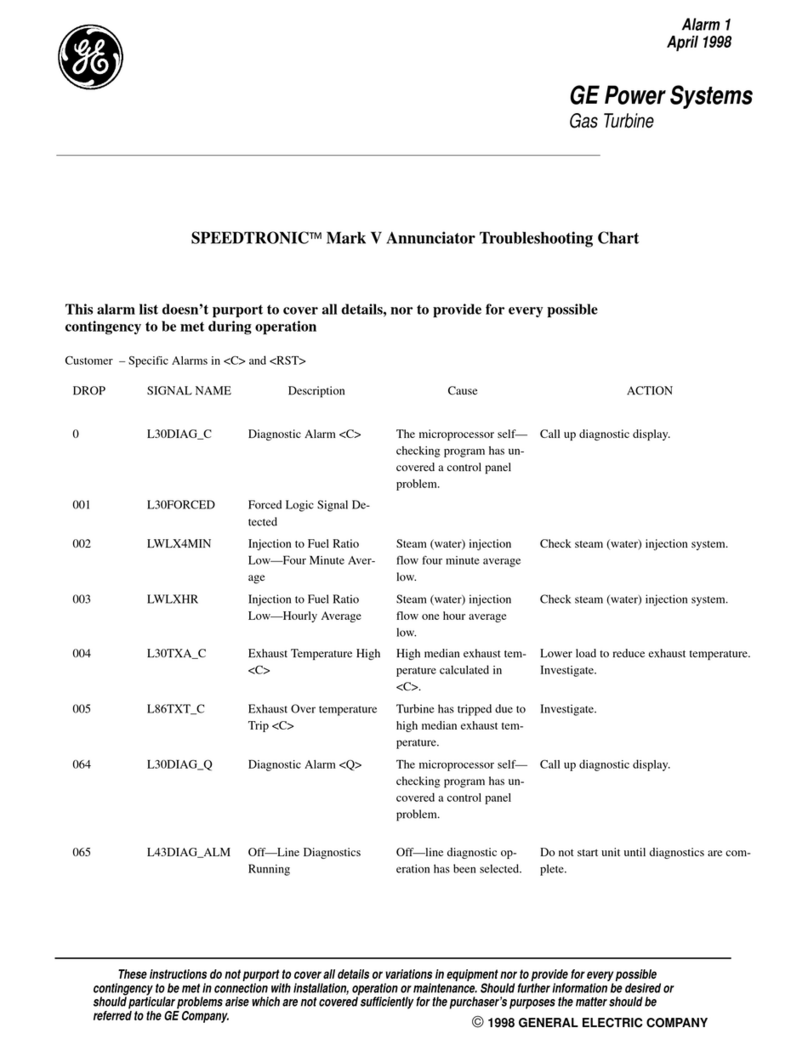

Alarms ..............................................................................................................................................5 - 19

Security............................................................................................................ 5 - 20

6. EXERCISER Information....................................................................................................... 6 - 1

Setup....................................................................................................................................................6 - 2

Test........................................................................................................................................................6 - 2

7. DIAGNOSTICS Events ................................................................................................................ 7 - 1

Statistical information.................................................................................... 7 - 3

Phasors.............................................................................................................. 7 - 4

Product information........................................................................................ 7 - 5

Reports .............................................................................................................. 7 - 6

Waveform ......................................................................................................... 7 - 7

Datalog.............................................................................................................. 7 - 8

8. FLEXLOGIC™ FlexLogic™ overview....................................................................................... 8 - 1

Introduction to FlexLogic™........................................................................................................8 - 1

9. COMMUNICATIONS Communications interfaces .......................................................................... 9 - 1