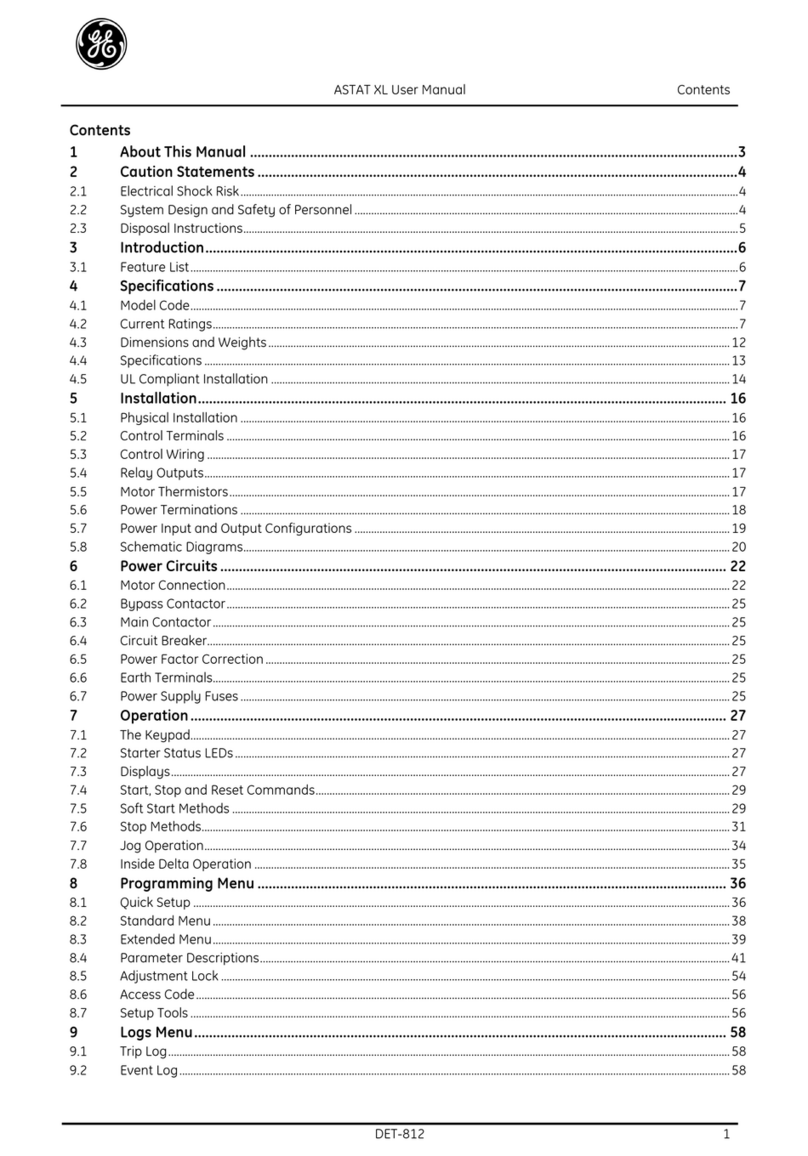

Frequency

(Hertz)

115-

120V

200-

208V

230-

240V

-----

460-

480V

575-

600V

60 002 023 003 ------

004 005

Frequency

(Hertz) 110V

----- 220V

380V

440V

550V

50 002 ----- 003 064 004 005

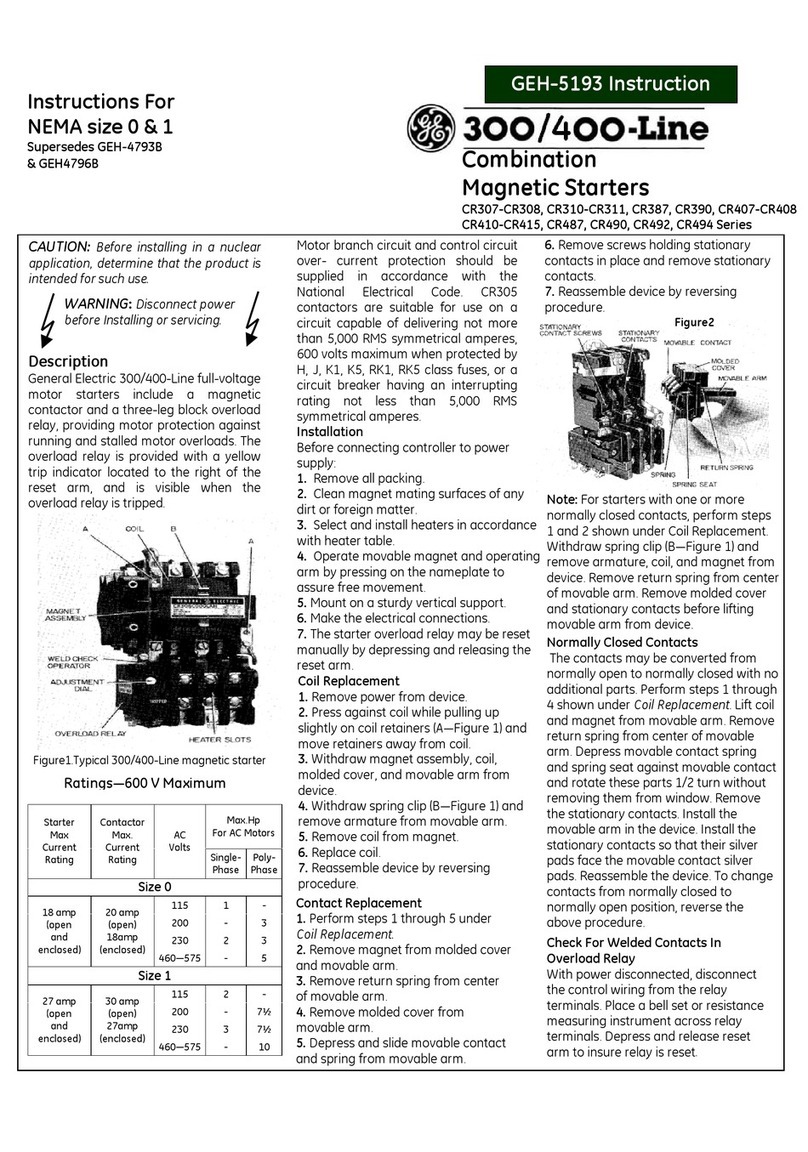

Ref.No

De cription Catalog

Number Quantity Required

1

2

3

4

5

6

7

8

9

10

Coil retainer assembly

Overload relay (3-heater, non- ompensated form, 1 NC onta t)

Overload relay (3-heater, non- ompensated, 1 NO-1 NC onta ts)

Set of stationary and movable onta ts with springs for three pole

Molded over for stationary and movable onta ts-three-pole

Return spring for movable arm

Molded movable arm for 2-, 3-pole forms

Armature and frame (magnet) with spring retainer

Operating oil for 2-and 3-pole forms

Spring retainer for armature

55-153677G053

CR324E310F

CR324E360F

55-153677G002

55-152655G008

55-152821G005

55-750320P007

55-153677G052

55-501336G***

55-501321P001

2

1

1

1

1

1

1

1

1

1

CHECK FOR WELDED CONTACTS IN

OVERLOAD RELAY

This feature permits the maintenan e

man to he k for welded relay onta ts

by simply depressing the white operator

lo ated at the top of the overload relay

onta t housing. When the relay is in the

reset ondition, an audible “ li k” will be

heard when the operator is depressed,

indi ating that the onta ts are

operating normally. A ontinuity he k

an also be made by dis onne ting the

ontrol wiring from the terminals of the

relay and pla ing a bell set or a

resistan e-measuring instrument in the

ir uit. Conne ting either of these a ross

the relay terminals will indi ate the relay

onta t is losed until the onta t- he k

operator is depressed, opening the

ir uit.

The ex lusive manual onta t operation

he k gives positive assuran e that

onta ts have not welded due to short

ir uits in the ontrol wiring.

300/400-Line starters and onta tors require

virtually no orre tive maintenan e. Preventive

maintenan e will assure many years of

dependable on-line servi e.

1. Always remove power from devi e before

performing any maintenan e.

2. Keep magnet mating surfa es free of

a umulated dirt or dust.

3. DO NOT OIL OR GREASE the magnet mating

surfa es.

4. Conta ts are arefully designed for maximum

life. They need only

be repla ed when nearly all the

silver tip is gone and the onta t tip support is ex

posed. DO NOT FILE the onta ts. Filing or

otherwise dressing the onta ts only results in lost

tip material and redu es onta tor or starter life.

5. The ultimate tripping urrent of the installed

relay heater an be adjusted ±10% by using

General Ele tri Company

41 Woodford Avenue, Plainville, CT 06062

DEH-40628 R01 08/10, 10-2049 © 2010 General Ele tri

Visit us on the web at www.Geindustrial. om

Perform steps 1 through 5 under

“Coil Removal”.

2. Remove magnet from molded

over and movable arm.

3. Remove return spring from enter

of movable arm.

4. Remove molded over from

movable arm.

5. Depress and slide movable

onta t, spring, and spring seat from

movable arm.

6.

Remove s rews holding stationary

onta ts in pla e and remove

stationary onta ts

7. Reassemble devi e by reversing

pro edure

Do not attempt to remove or

repla e ar traps in ar hute over.

When rea

ar hute over will only fit one way and

is marked “TOP”

orner. Magnet and movable arm will fit

either way but will be quieter if

reassembled the same way they were

taken apart.

*** Insert numbers for parti

ular oil rating required. See Coil Table above

1st NO aux. ont. for Conta tor right side mtg……………. CR3O5X300A

1st NC aux. ont. for Conta tor right side mtg……………. CR3O5X300B

1st NO—NC aux. ont. for Conta tor right side mtg…… CR3O5X300C

Additional NO aux. ont. for all forms……………………………… CR3O5X100D

Additional NC aux. ont. for all forms …………………………… CR3O5X100E

Pushbutton, START-STOP ……………………………………………………. CR305X320B

Sele tor Swit h, H—O—A ………………………………………… CR305X330B

Sele tor Swit h, OFF—ON ………………………………………… CR305X330D

Indi ating Light …………………………………………………………… CR305X350B

Control Cir uit Fuse …………………………………………………… CR305X341A, B, C, D

Surge Suppressor ……………………………………………………………………CR305X146C

For two-and three-

pole devi es, order Cat. No.

55-501336G plus number in table below.

For four- and five-pole devi es, ord

55-153608G plus number in table below.

Example: 55-501336G002 is rated 115—120 V,

60 Hz/110V, 50 Hz.