ÄKTA start Maintenance Cue Card, 29-0240-43 AC 8

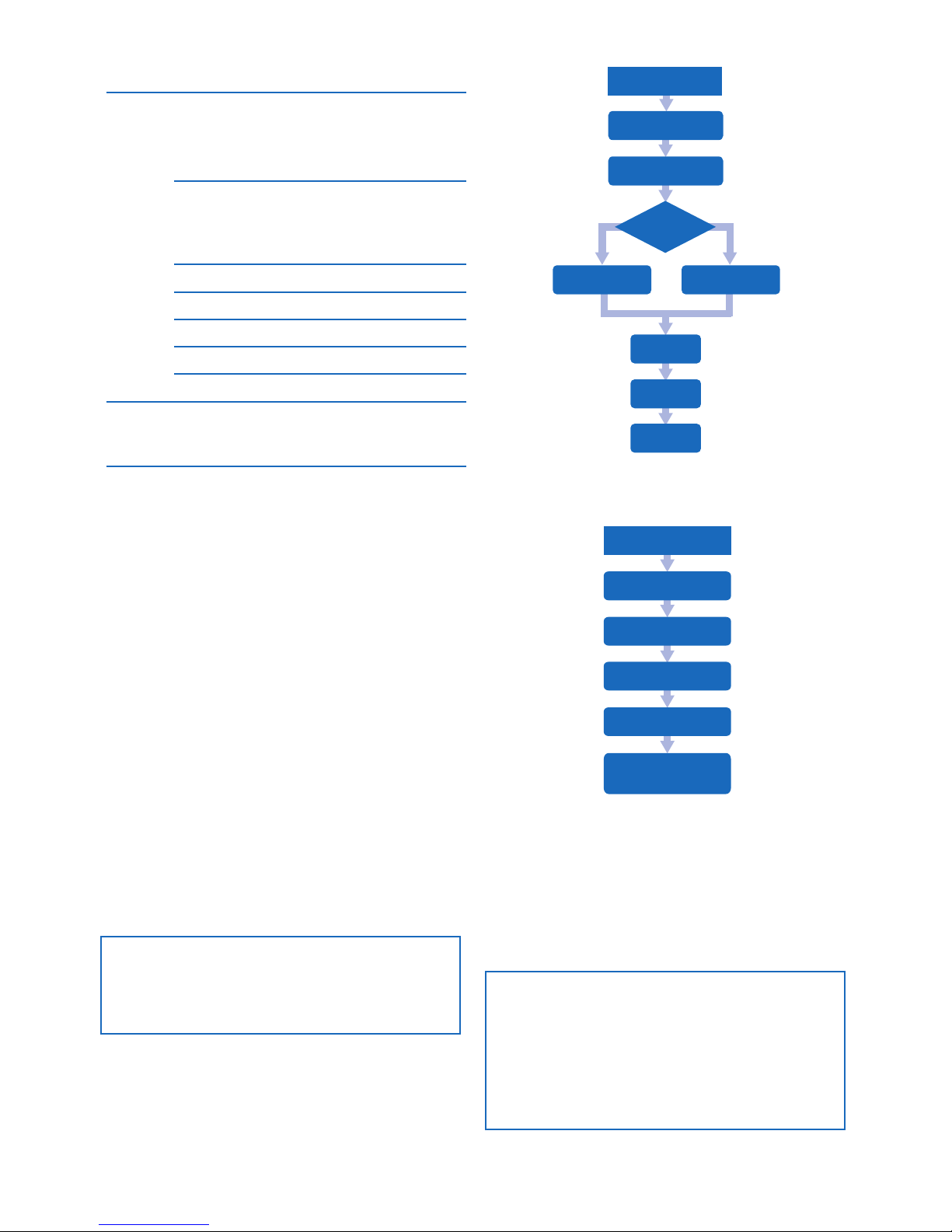

Calibrate the Pump

For detailed instructions, refer to ÄKTA start Maintenance

Manual.

Instruction

Immerse the buer inlet tubing A in DM water.

Place the outlet tubing from the Wash valve in a pre-

weighed collection tube.

In the Settings and service screen, tap Pump to access

the Pump options, then tap Calibration.

Set the intended ow rate in the range 0.5 to 5 ml/min.

Tap Start ow to start the Pump and collect water for

at least one minute in the pre-weighed collection tube.

Measure exactly the volume of the water collected,

then set Collected volume value equal to this volume.

Tap Calibrate to carry out the calibration.

1.

2.

3.

4.

5.

6.

7.

Calibrate the UV Monitor

Set the ow cell path length

If the UV ow cell was replaced, a new cell path length

value has to be set.

Instruction

In the Settings and service screen, tap UV to access

the UV Monitor options.

In the UV screen, tap Flow cell path length.

Set the cell path length, Cell, corresponding to the new

UV ow cell.

Tap Save path length to save the value.

Note: The Cell path length is provided on the packing of

the UV ow cell. If the ow cell path length is not available,

refer to Operating Instructions for instructions to calculate

the Cell path length.

Calibrate the UV LED

Note: Make sure that the UV ow cell is assembled tightly,

and the inlet and outlet tubes are tted tightly to the UV

Monitor. No stray light should enter the UV Monitor.

1.

2.

3.

4.

Calibrate the Conductivity Monitor

Set the cell constant value

Instruction

In the Settings and service screen, access

Conductivity > Conguration.

Set the cell constant value for the new Conductivity

ow cell and tap Save to save the new value.

Note: The cell constant value is provided on the packaging

of the Conductivity ow cell. If a cell constant value is not

available, calibrate the Conductivity ow cell as explained

in the ÄKTA start Maintenance Manual.

1.

2.

Temperature sensor calibration

Instruction

Place a precision thermometer in the path of the ow

cell directly after the Conductivity cell and pump DM

water through system with a ow rate of 0.5 ml/min.

Access Conductivity > Diagnostics.

Note the temperature and type it into the Set actual

temp eld, then tap Calibrate to carry out the

temperature calibration.

Conductivity ow cell calibration

Prerequisites

Calibration solution: 1.0 M NaCl or 100 mS/cm

conductivity standard solution.

Instruction

Fill the conductivity ow cell with conductivity standard

solution.

Access the Conductivity > Calibration screen.

1.

2.

3.

1.

2.

Instruction

Disconnect the inlet tubing from the Pressure sensor

to expose the sensor to atmospheric pressure only.

Access Settings and service > Pressure sensor.

In the Pressure sensor screen, tap Zero oset then tap

Ok if there is no back pressure in the system.

Note: Make sure that the Pump is OFF before disconnecting

the tubing.

1.

2.

3.

Instruction

Immerse the buer inlet tubing in DM water.

Flush the UV ow cell with DM water using Pump. Make

sure that there are no air bubbles in the UV ow cell.

In the Settings and service screen, tap UV to access

the UV Monitor options.

In the UV screen, tap UV LED calibration.

Set the Light strength value to 500.

Tap Calibrate. A conrmation screen opens. Select OK

to automatically search the Light strength value to get

a minimum Signal response of 2500 mV.

If the Signal value is above 2500 mV, tap Save. If Signal

is below 2500 mV use the arrows to increase the Light

strength until the Signal is above 2500 mV.

Tap Save to store the calibrated Light strength value.

1.

2.

3.

4.

5.

6.

7.

8.