2

Use and Limitations

This document provides recommendations where there

is no established company procedure or practice.

Safety

The purchaser and user of this

product is warned that compli-

ance with the manufacturer’s

instructions and procedures is

required in order to avoid the

hazards of leaking gas result-

ing from improper installation,

start-up or use of this prod-

uct. The user is responsible to

comply with all federal, state

and local building and safety

regulations. The manufacturer

recommends that a qualified

technician install this product

for safe and proper operation.

Refer to “Installation Operation

and Maintenance: ES3” (IOM) for

complete instructions. Consult

Factory to obtain the IOM.

Receiving, Handling and Storage

Although of very rugged construction, reasonable

care should be taken during handling and storage.

At Time of Delivery

1. Check the packing list to account for all items

received

2. Inspect each item for damage

3. Record any visible damage or shortages on the

delivery record

a. File a claim with the carrier if necessary

b. Notify your Roots Meter supplier immediately

IMPORTANT NOTE

Do not attempt repairs or adjustments, as doing so

may be a basis for voiding all claims for warranty.

The ES3 Electronic TC does not require lubrication.

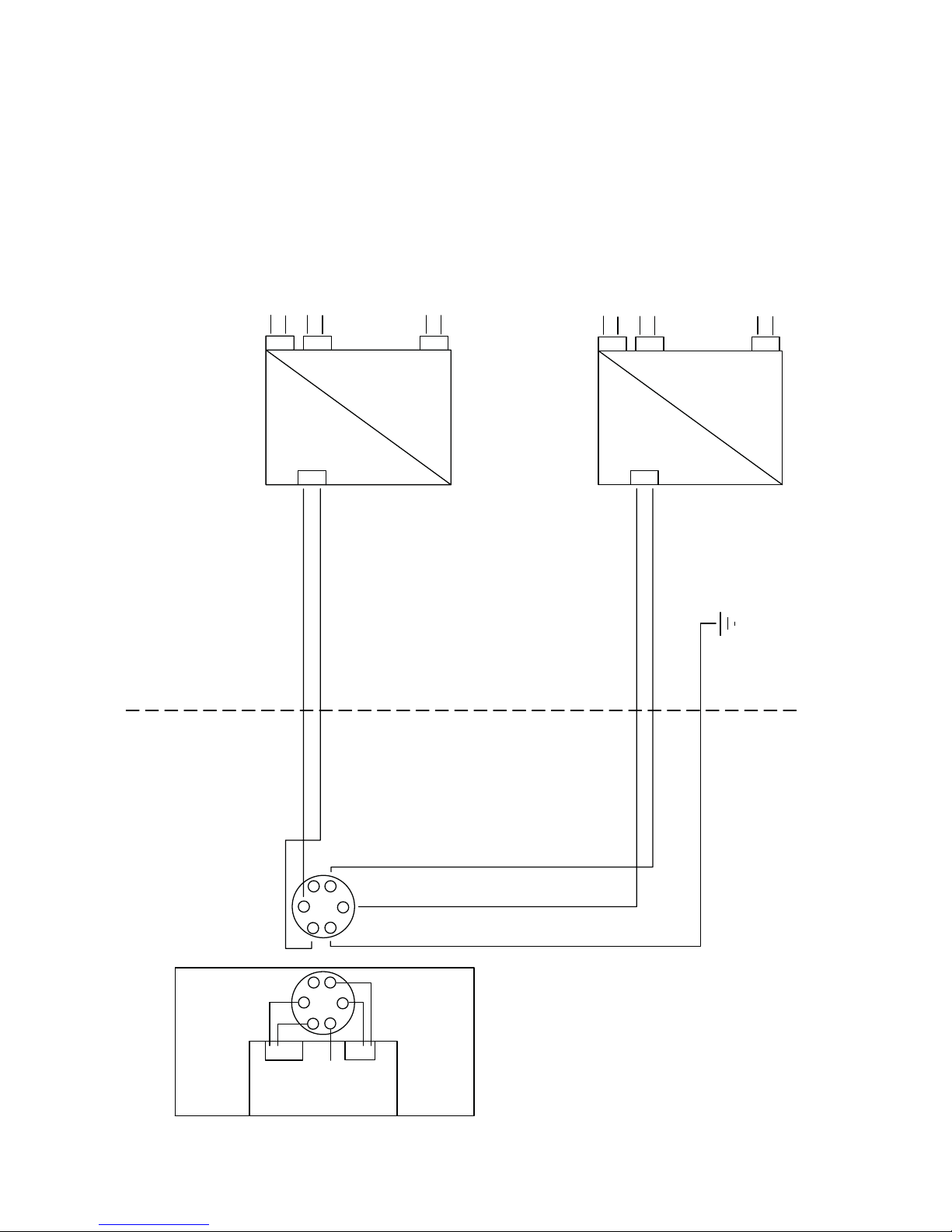

1. Meter Installation

Refer to “Installation Supplement IS:B3” for Meter

installation procedures.

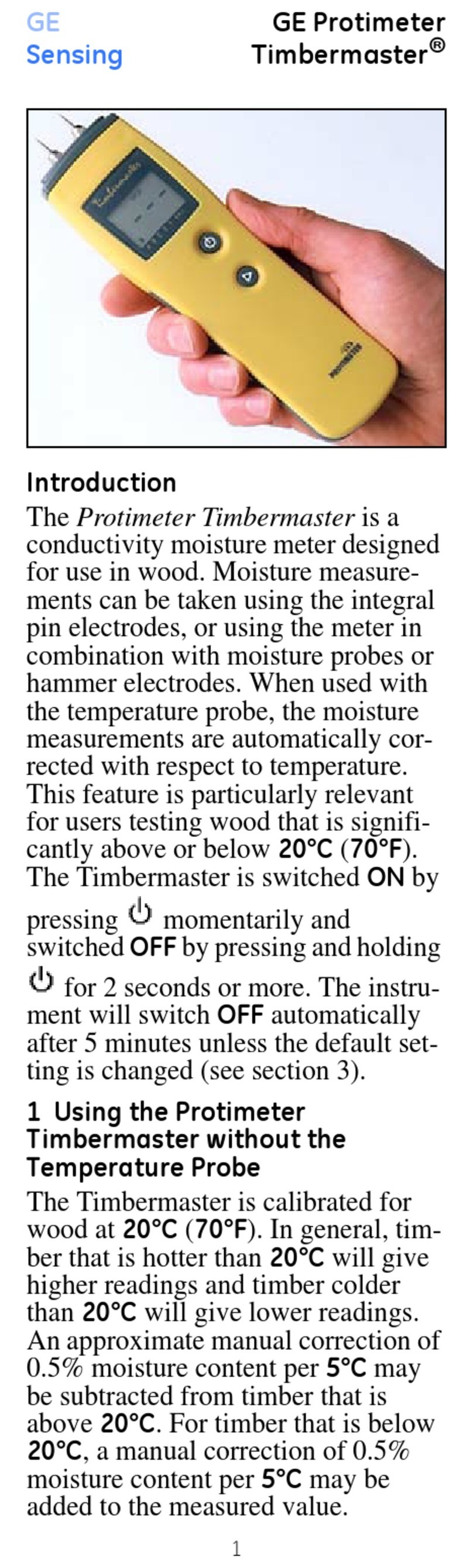

Figure 1 - Label on ES3

Electronic TC

Figure 2 - Swipe magnet across the

words “Roots ES3 Index” to change the

screen displays

2.1 LCD Screen Displays

1. The default screen is either Compensated Volume or

Non-Compensated Volume, depending on customer

configuration.

a. This parameter is the home/default screen.

b. After a time out of approximately 30 seconds, the

home screen always will appear.

2. Repeat the swiping motion of the magnet across

the words “Roots ES3 Index,” and the screens will

appear in sequential order as shown in Table 1.

Note: Using the Dresser MeterWare Software, the

screens are configured by checking and un-checking

the parameter to be displayed. Depending on the

ES3 configuration, some screens may not appear.

ROOTS* ES3 Electronic Temperature Compensator (TC)

Installation Procedures

WARNING

This equipment is designed to operate at temperatures

between -40° F to 140° F. Prior to going on-site for

installation or maintenance, make sure proper safety

equipment is worn before handling the equipment and

that you are properly dressed for the work site

environment temperatures.

2. LCD Display

Scrolling through the screen displays and connecting

to the ES3 Electronic TC requires use of the magnet.

The magnet can be purchased as part of the

Communications Kit, P/N 060542-000 or as an individual

item, P/N 060541-000. Consult Factory for pricing.

Swipe the magnet across the words “Roots ES3 Index”

as shown in Figures 1 - 2.

Note: the magnet will not change screen displays if

swiped on another area of the label.

WARNING

If equipment is installed/serviced/maintained at

elevated heights, ensure proper safe site work practices

are in place to prevent fall and drop hazards.

WARNING

For installations in confined spaces, allow adequate

room to safely handle product and equipment without

causing bodily strain. Also verify proper ventilation is

in place to maintain a breathable atmosphere.