[EN] English - 3

K335 Issue 3

To start - Items on the display

To start - Prepare the instrument

Before you use the instrument for the first time:

• Make sure that there is no damage to the instrument,

and that there are no missing items.

• Remove the plastic film that protects the display. Use

the tag (◗) in the top right-hand corner.

• Install the batteries (refer to B1). Then re-attach the

cover.

To start - Power on or off

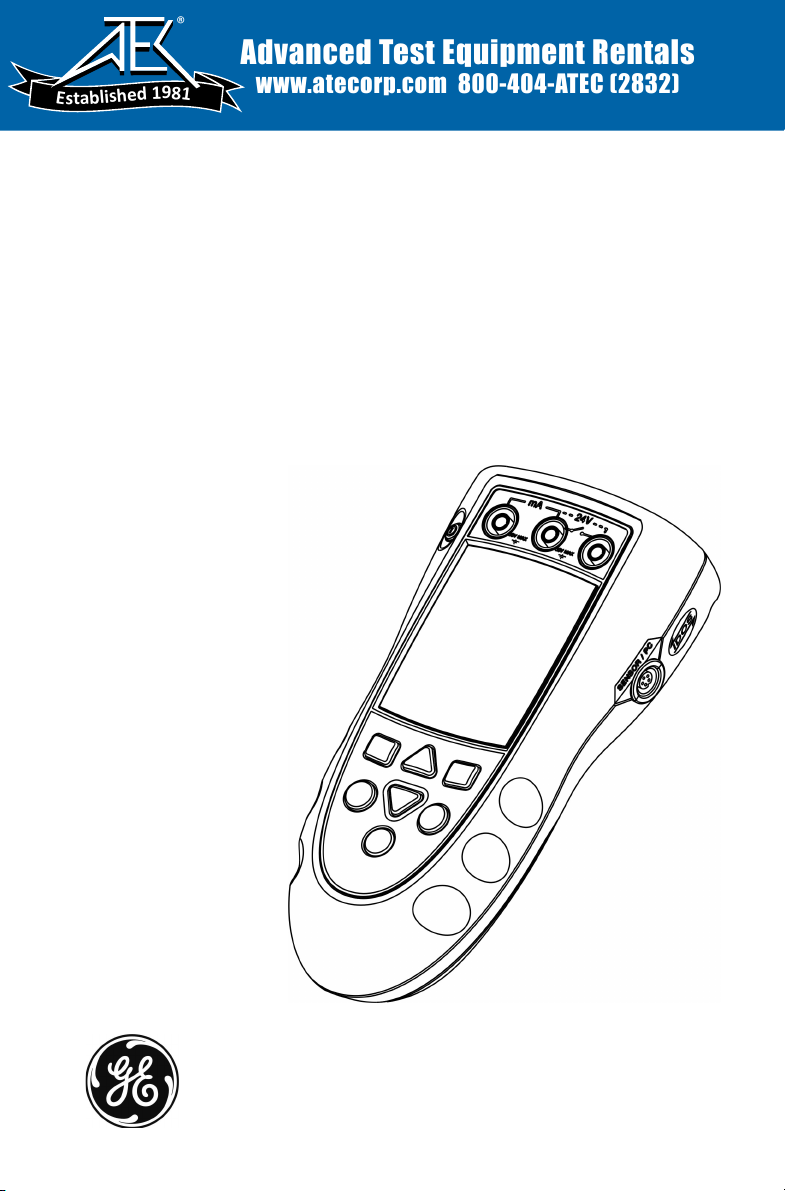

To turn the instrument on or off, press ❍(A1 - item [1]). The

instrument does a self test and then shows the applicable

data.

When the power is off, the last set of configuration options

stays in memory. Refer to “Maintenance”.

To start - Set up the basic operation

Use the Set Up menu to set up the basic operation of the

instrument.

If there is additional data for a menu option, select

Settings (■■) to see the values that are set up. If

necessary, adjust the values.

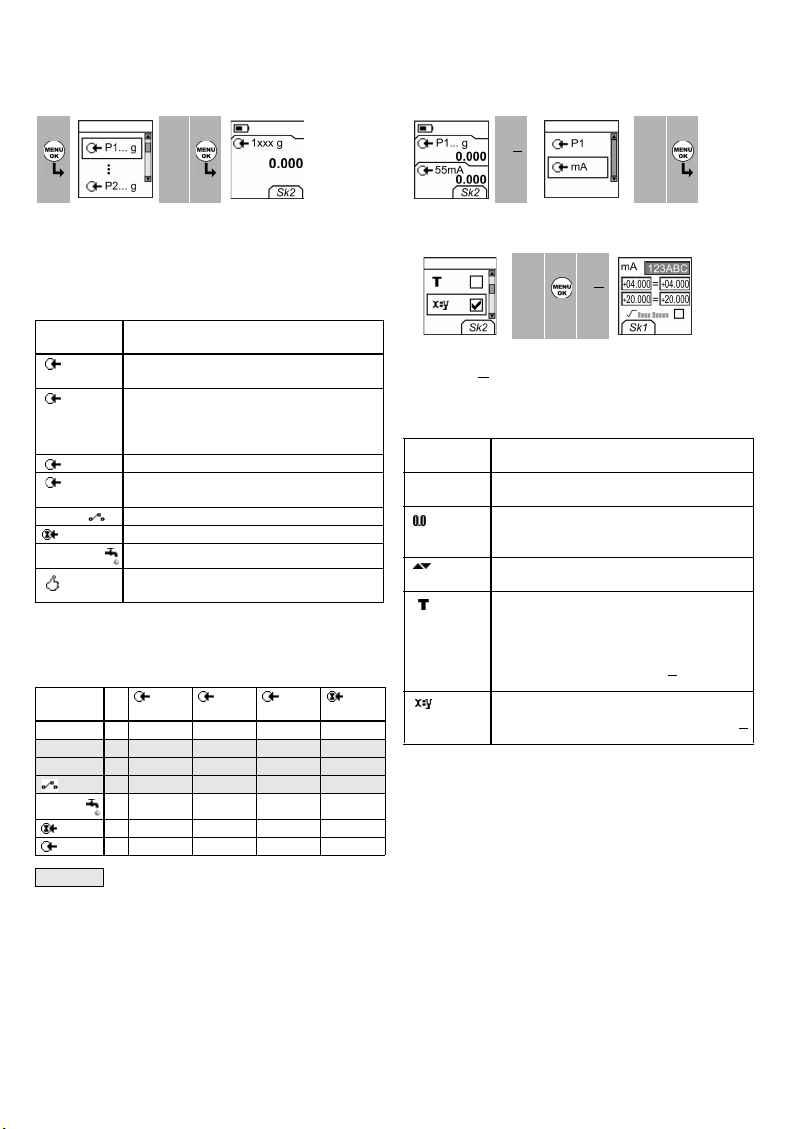

Table 1: Menu options - Set Up

Item Description

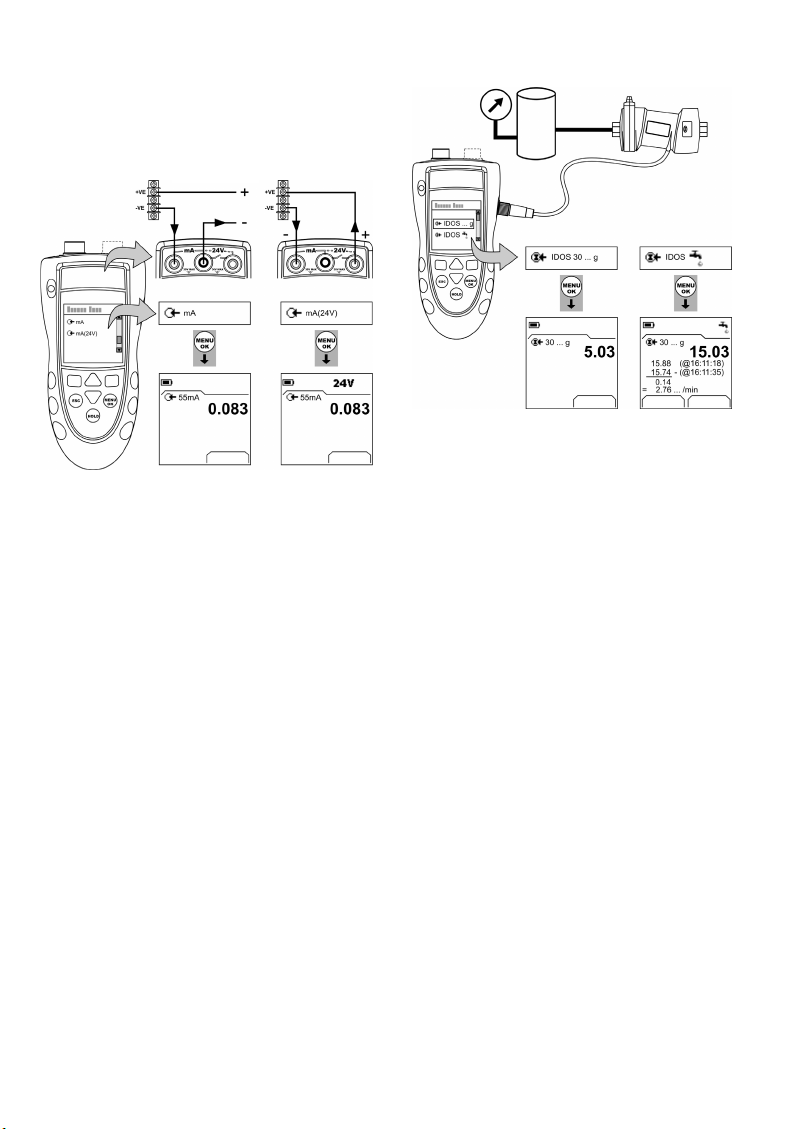

16. DPI 802/802P only. Task indication for the switch test.

= switch closed = switch open

Task indication for the leak test.

Refer to: Select Task (Table 2/3)

17. DPI 802/802P only. The loop power supply is on.

Refer to: Select Task (Table 2/3)

18. The measured value satisfies one of the alarm

conditions. Refer to: Settings (Table 4)

19. The data on the display is on hold. To continue, press

the HOLD button again.

20. Shows the battery level: 0 ... 100%.

21. Identifies the type of data and the measurement

range.

= Input = IDOS input

Refer to: Select Task (Table 2/3)

22. ... 23. Identifies the settings applied to the input.

Refer to: Settings (Table 4)

22. xxxx g The units and the type of sensor (If applicable)

OR a specified scale (x:y).

23. Shows the settings applied to the measured value (If

applicable).

= Filter

= Tare

= Maximum

= Average

= Minimum

24. A soft-key function. To select an available function,

press the soft-key below it. Example:

= Move left = Move right

25. The measured value or values applicable to the task

selection.

26. The Edit display to set up text labels ( ≤6 characters):

x:y Scaling (Table 4).

OK = Accept the new text label

Shift = Change the keys: 123ABC or -_+abc

= Add a space

BS = Back space (Delete character)

A3

1Menu:

Select Task 23 Menu:

Set Up 45

▲

▼▲

▼

(Table 2) (Table 1) [✓]/[ ]

Options

(If applicable)

Description

DPI 802/802P only. To add a series resistor into the

mA circuit. You can then use this instrument

together with a HART®communicator to set up

and calibrate HART®devices.

To select and set up the backlight facility + timer.

Additional data: Select Settings (■■)

To select and set up the power off facility + timer.

Additional data: Select Settings (■■)

To show the battery level (%).

To set the display contrast (%).

▲ Increases %, ▼ decreases %

To set the time + date. The calibration facility uses

the date to give service and calibration messages.

To set the language option.

To calibrate the instrument.

Additional data: Refer to “Calibration”.

To select and show the applicable status data

(Software Build, Calibration Due date, Serial

Number, IDOS Information).