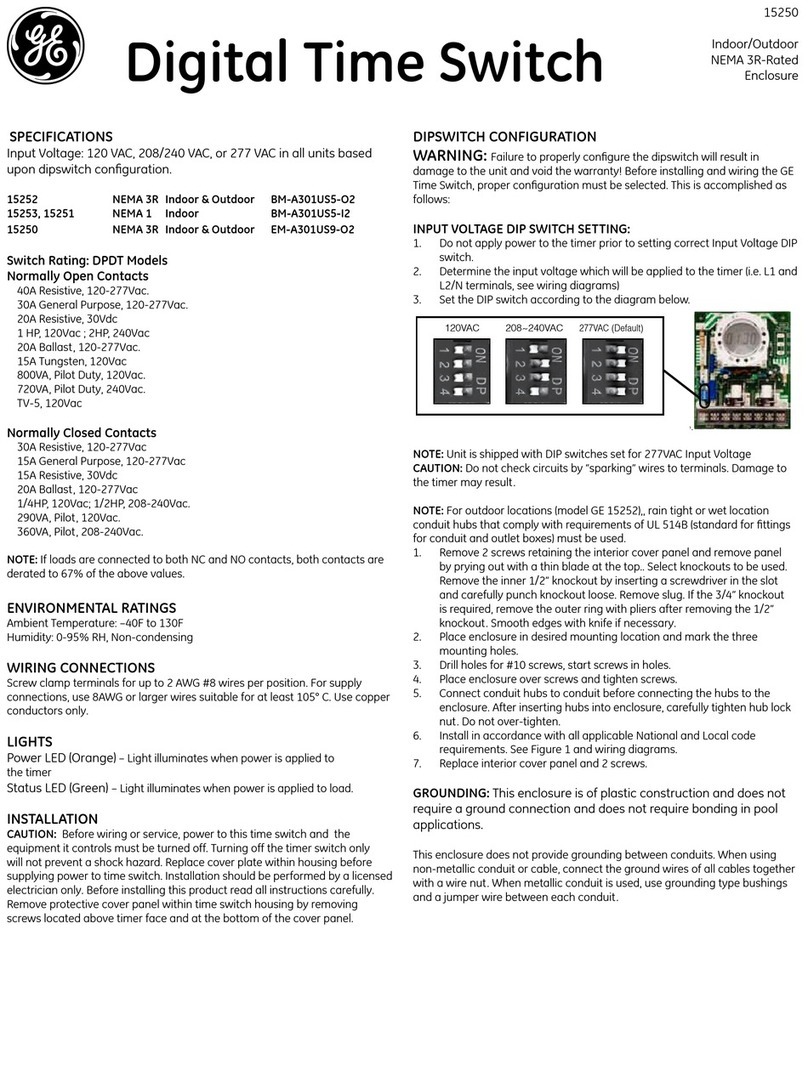

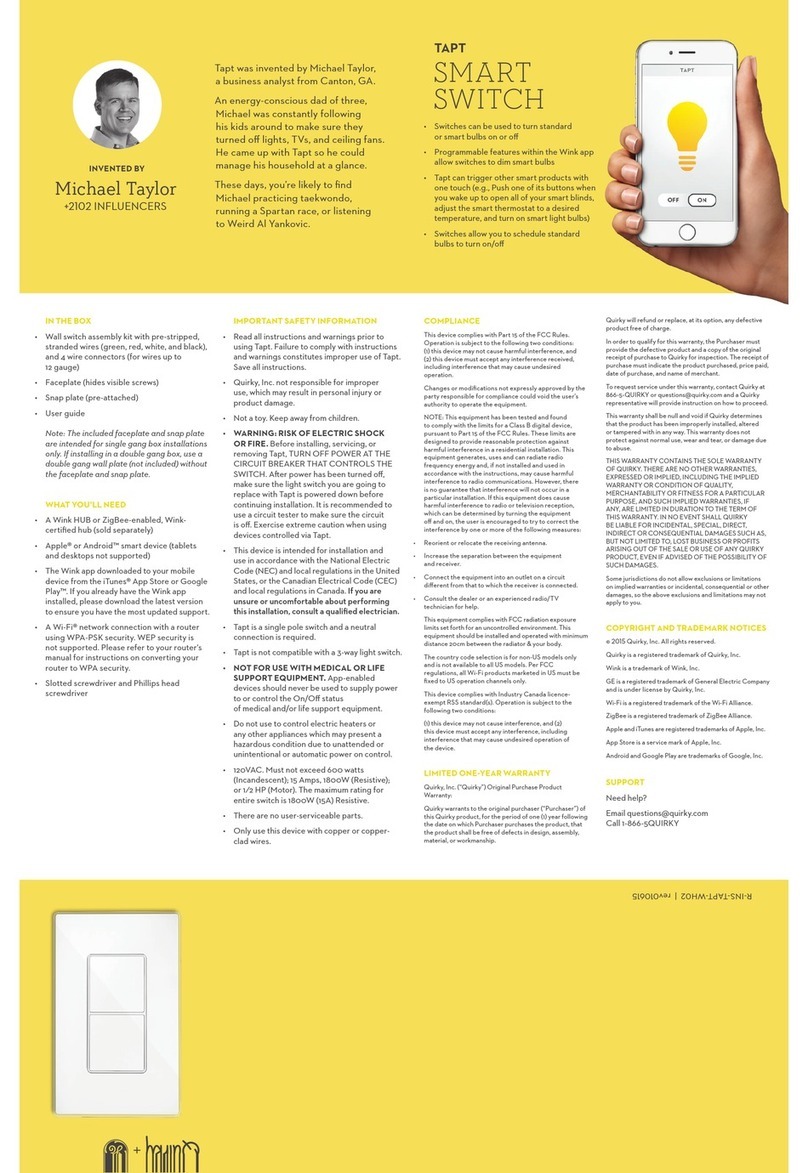

Wiring Diagram for Category 4

Inputs shown with safety gate/guard in closed position. Two Series 300-B GuardSwitches™ with one INT relay are required for each safety gate.

When first applying the INT Safety Monitor Relay, the inputs must be cycled to check for proper operation before the output contacts close. To cycle the inputs, the guard must be

opened and then closed. This start-up test is sufficient; however, we recommend that the proper operation of the switches and relay be checked at least every 24 hours.

*300-BLT-

*Or other DPST GuardSwitch

(See the 300-BT Series

installation instructions)

(–)

(+)

INT-03-230: 230V AC

INT-03-120: 120V AC

INT-03-024: 24V DC

Required Fast or

Slow-Acting Fuse:

(250V, 5x20 mm F)

INT-03-230: 40mA

INT-03-120: 80mA

INT-03-024: 1/4A

Required Fast or

Slow-Acting

Fuses: 4A (250V,

5x20 mm F

W

H

T

B

L

K

R

E

D

B

L

U

*300-BLT-

W

H

T

B

L

K

R

E

D

B

L

U

Note – The LED on the BLT model

will be ON when the guard is open

Fuses: 1A (250V)

RESET

ASAFE AUX.

BCD EFG

OUTPUTS

230 VAC

60 VDC

120 VAC

30 VDC

LOADS

–+

L1 L2 1 2 X1 X2 Y1 Y2

N.O. N.C.

Safety Monitor Relay

INT-03

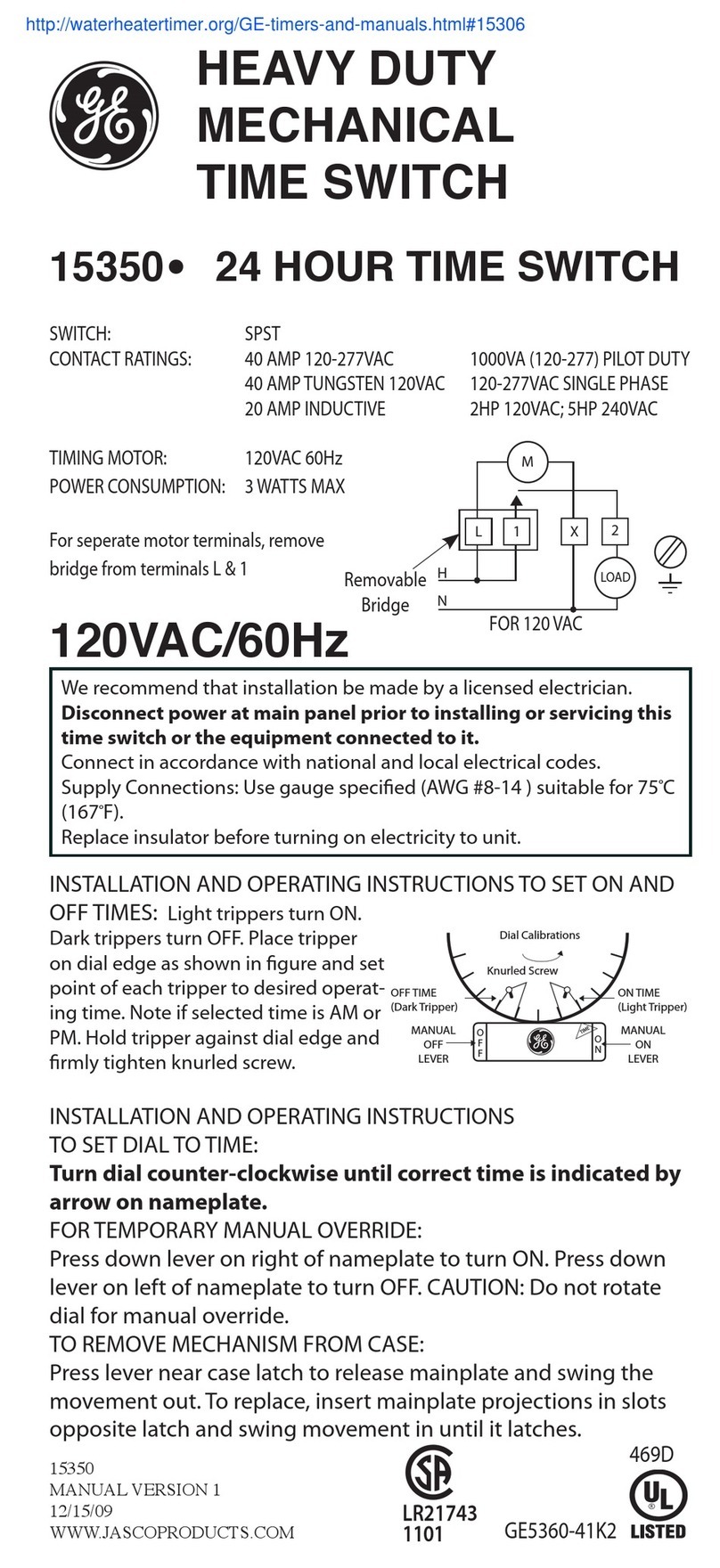

These switches are TUV certified for CE applications only when used with the INT

Safety Monitor Relays. See Risk Category 3 and Category 4 wiring diagrams above.

CE Compliance Information General Specifications

Enclosure Kynar®, Polyvinylidene Fluoride

Temperature Range 14°F to 150°F (-10°C to 65°C)

Environmental Hermetically Sealed Contact Switch

Encapsulated in Polyurethane

NEMA Rating 1, 2, 4, 4X, 5, 12, 12K, 13

Protection Class IP 67

Response Time 1 msec

Individual circuits The two circuits do not switch simultaneously, and depend

on the speed of the guard closure. Based on closure speed

of 1' per second and a gap of 1/8", a delay less than

50 msec is typical.

Life Cycles 100,000 Under Full Load;

Up to 200,000,000 Under Dry Circuit

Lead Types/O.D. 18/4 SJTOW (K)/0.34" (0.86cm)

22/4 PVC Jacketed (J)/0.19" (0.48cm)

22/6 PVC Jacketed (J)/0.21" (0.53cm)

UL/CSA/TUV All Models

File E 122942 LR89176

European Directives

Machinery Directive (89/392/EEC)

EMC Directive (89/336/EEC)

Low Voltage Directive (73/23/EEC)

Specific European Standards

EN60204-1 Safety of electrical equipment of

industrial machines

EN292 Part 1, 2 Safety of Machinery, basic

terminology, technical principles

EN954-1 Risk Assessment Category 3 or 4 depending

on wiring method, see diagrams

EN55081-2 Electromagnetic Emissions

EN50082-2 Electromagnetic Immunity

EN1088 Interlocking Devices

EN947-5-3 Control Circuit Devices

EN50178 Safety of Electrical Equipment

IEC 664-1 Insulation requirements

IEC 68, part 2-1, 2-2, 2-3, 2-8, 2-14, 2-27, 2-30

Declaration of Conformity

available upon request.

GE Security Industrial

GuardSwitch

TM

Series 300 www.ge-security.com/industrial