1

1. INTRODUCTION

The Geokon Model 4370 Concrete Stressmeter is designed to measure stresses in concrete.

Conventional ways of doing this suffer from some drawbacks: for instance, strain gages can

measure strains but the conversion of strains to stress is made difficult because of changing

modulus with time, shrinking and swelling due to varying moisture content, and creep under

sustained loads. Most of these problems can be overcome using hydraulic Flat Jack type stress

cells; however, these cells are subject to a strong temperature dependence, which can also cause

de-coupling of the cell from the surrounding concrete requiring a means of re-inflating the cells

after the initial concrete curing period.

The Model 4370 Concrete Stressmeter is designed to overcome these problems by, in effect,

making a stressmeter out of concrete so that it will have the same properties of

shrinkage/swelling, modulus variation, temperature dependence, and creep potential, as the

surrounding concrete.

2. OPERATING PRINCIPLE

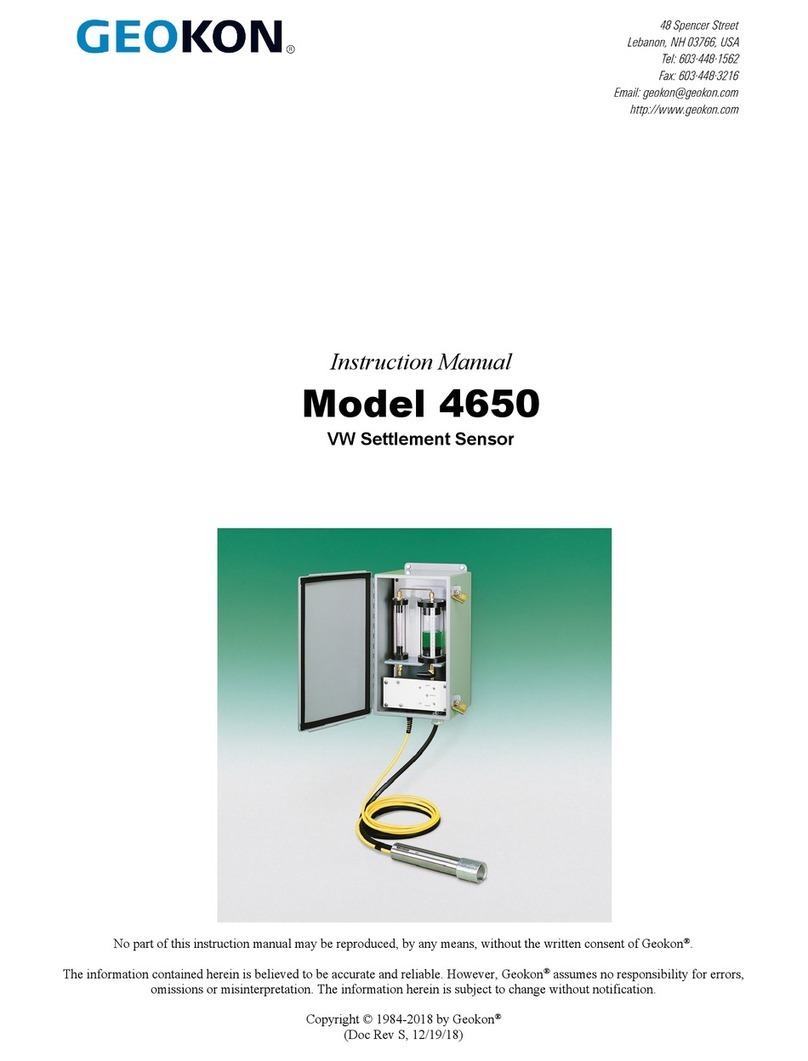

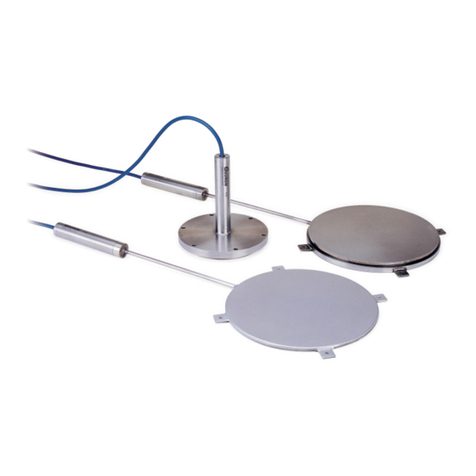

The Model 4370 Concrete Stressmeter is shown in Figure 1.

Figure 1 - The Model 4370 Concrete Stressmeter.

In essence, the stressmeter comprises a short vibrating wire load cell, in series with an 18-inch-

long cylinder of concrete. This concrete cylinder has the same properties as the surrounding

concrete but is de-bonded from it by means of a smooth-walled, porous plastic tube and is

coupled at its ends to the surrounding concrete by means of a flange at one end and a piece of all-

thread rod at the other. The vibrating wire load cell measures the load imposed on the inner

concrete cylinder by stresses in the surrounding concrete. This load, when divided by the cross-

sectional area of the inner cylinder, gives the stress in the surrounding concrete. Variations of

moisture content in the surrounding concrete are felt also by the inner concrete so that shrinkage

and swelling are the same both inside the cell and out, leading to no net change in the load cell

readout. (This is not strictly true due to the short length of the metal load cell portion, which

behaves differently, but the effect is kept small by the large difference in the relative lengths of

the concrete cylinder versus the length of the load cell).

A thermistor is included inside the cell for the measurement of temperatures.