Table of content

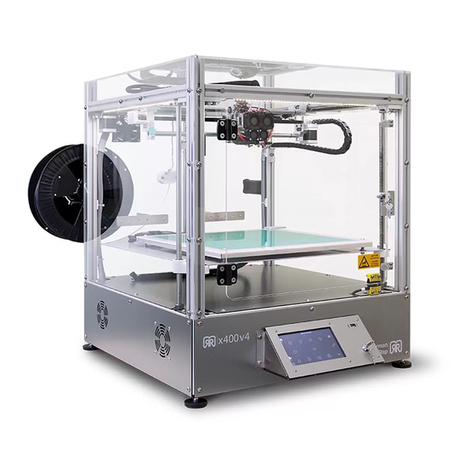

1. General information

1.1 specications................................................................................................................................04

1.2 System requirements................................................................................................................05

1.3 Additional options..................................................................................................................... 05

2. 2.Operating modes of the X 1000

2.1 Red/ Stand-by .............................................................................................................................06

2.2 Green/ work mode ....................................................................................................................07

2.3 Two-hand circuit/removal position.....................................................................................07

2.4 Emergency stop ........................................................................................................................ 08

2.5 Maintenance mode...................................................................................................................08

3. Network and printer set up

3.1 Connection via router .............................................................................................................. 09

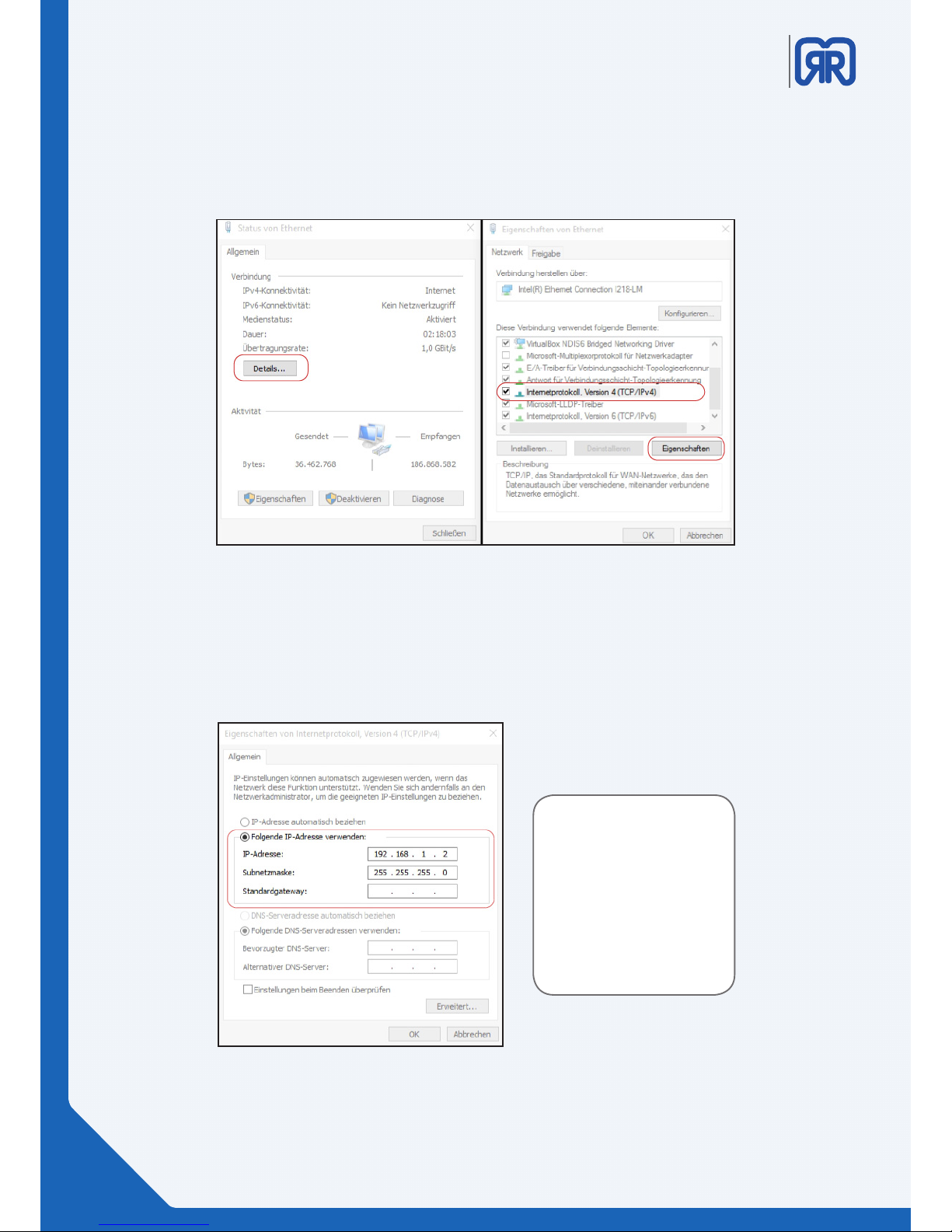

3.2 Direct connection ...................................................................................................................... 09

3.3 Setup routine...............................................................................................................................11

3.4 How to activate the printer and establish a connection ............................................. 16

4. Workow and operation

4.1 Simplify 3D

4.2 Features.........................................................................................................................................18

4.3 Quick Start Guide.......................................................................................................................19

4.4 The Interface Layout ................................................................................................................. 21

5. Repetier Server

5.1 Web interface .............................................................................................................................. 26

5.2 Dashboard....................................................................................................................................27

5.3 Device panel................................................................................................................................ 28

5.4 Device panel operation ...........................................................................................................28

5.5 EEPROM.........................................................................................................................................31

5.6 LOG-Files .......................................................................................................................................32

5.7 Firmwareupdate ............................................................................................. 33

6. Tool heads and cosumables

6.1 Tool head wiring.........................................................................................................................34

6.2 How to set up the second extruder ....................................................................................35

6.3 How to replace the hot end and the extruder .................................................................36

6.4 How to change the laments.................................................................................................38

7. CO2 extinguishing system

7.1 General information..................................................................................................................42

7.2 7.2 Manual triggering............................................................................................................... 43

7.3 Recommissioning after trigger ............................................................................................. 43

8. Tipps & Tricks

8.1 How to determine the X1000s MAC address.................................................................... 44

8.2 How to update Repetier-Server ........................................................................................... 44

8.3 PVA solution for enhanced adhesion ................................................................................. 45

02/51