6

Function – continued –

The logic unit monitors the following times:

nInterval time: This is the time interval at which, depending on the mode (24h / 72h operation), the

connecting lines have to be purged.

nStandby period: The purging process must be initiated during this time. The standby period begins

when the interval time has elapsed.

nPurging time: During this period, the purging process must be performed through actuation of

the valves. Actuation of the valves is signalled by means of the limit switches; similarly, when

the electrode of the low-level limiter is exposed, this is sensed through the output contact of the

corresponding level switch. If a signal is not received within the purging time, the safety circuit is

opened. Since a low-level limiter may be bypassed for a maximum of 5 minutes, monitoring of the

purging time is a safety-relevant function.

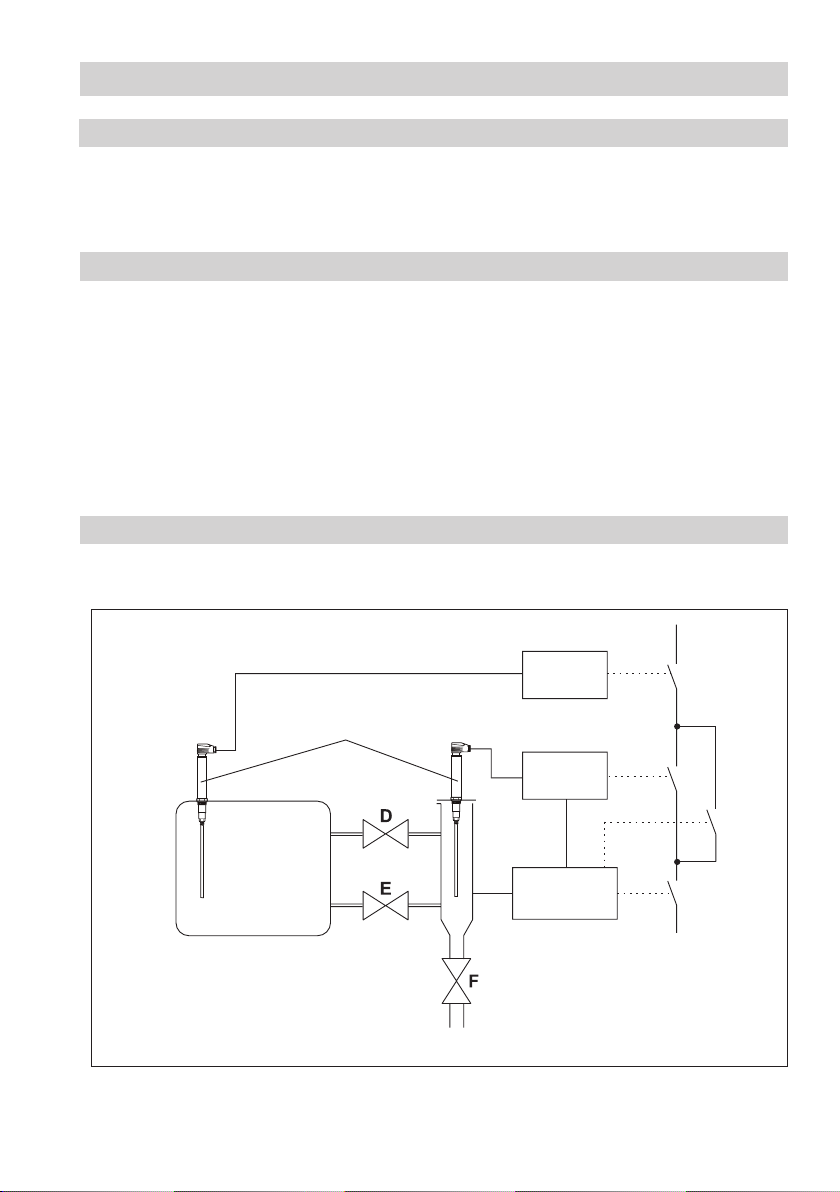

nSynchronisation: By closing an interconnection valve (E or D) the interval time can be synchronized

at any time: The purging time starts, and when it has elapsed the interval time is reset to its initial

value (e. g. 24h / 72h etc.).

The interval time is started when the logic unit is switched on. The display of the PLC shows the full

hours of the remaining time.

During operation, the standby period is started at the end of the interval time, which is immediately

reset to its initial value (e.g. 24h, 72h etc.). The PLC then starts the purging time when an interconnec-

tion valve (E or D) leaves the end position “Open”.

During the purging time, the output contact of the low-level limiter is bypassed. This bypass is triggered

by the undelayed contact of the safety time-lag relay and limited to 5 minutes by the delayed contact of

this relay.

Once all valves signal that they have reached their initial positions and the level switch of the low-level

limiter senses that the level electrode is exposed, the purging process has ended and the bypassing of

the low-level limiter is terminated.

In the event that the mains supply fails during the purging time, the bypassing of the low-level limiter is

cancelled and the safety circuit is opened. If the mains supply is switched on again, the bypass remains

deactivated and the safety circuit is only closed again after the purging process has been completed

properly.

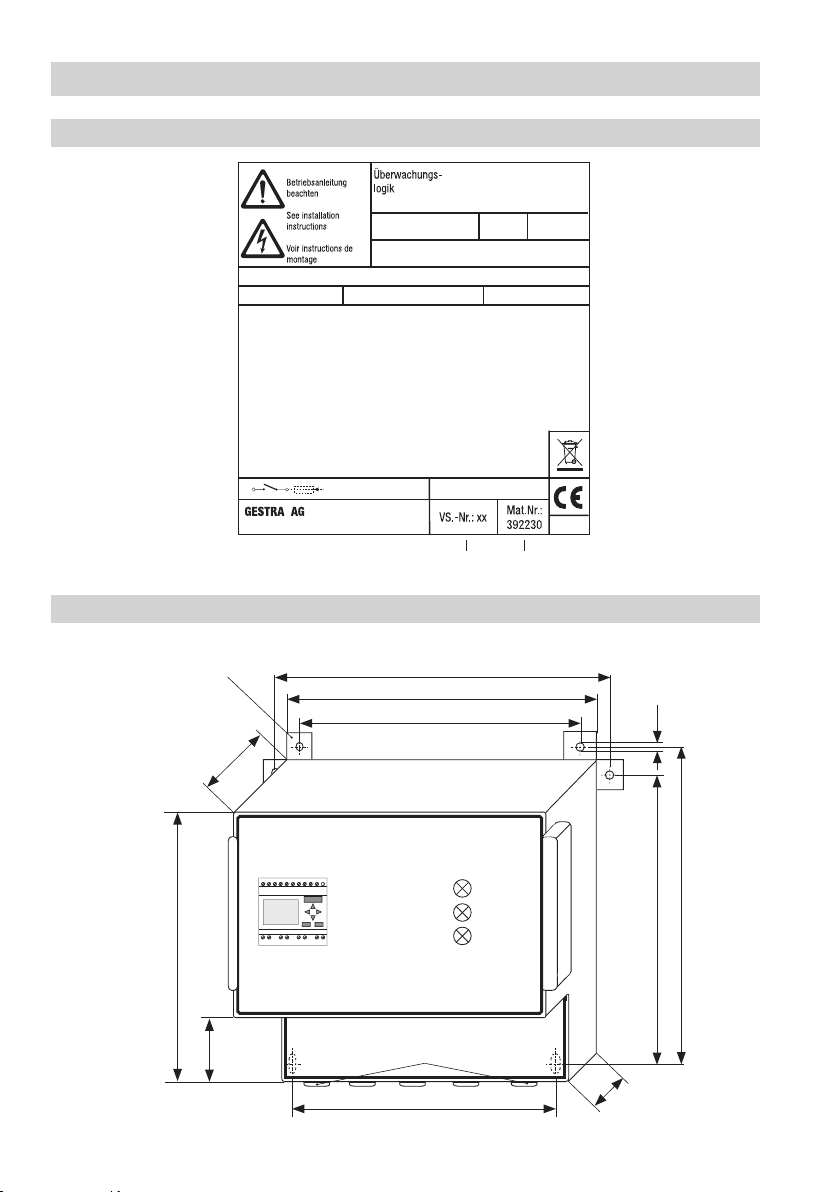

Expiry of the purging time and standby period, as well as deactivation of the safety circuit, are indicated

by means of pilot lamps.

Explanatory Notes – continued –

The safety circuit is opened when the standby time or the purging time is exceeded, and

it is only closed again when the purging process has been completed properly.

Note