Gianni Industries Shear Lock P-MU-GS705N-30 User manual

Other Gianni Industries Lock manuals

Gianni Industries

Gianni Industries EB-220-32 User manual

Gianni Industries

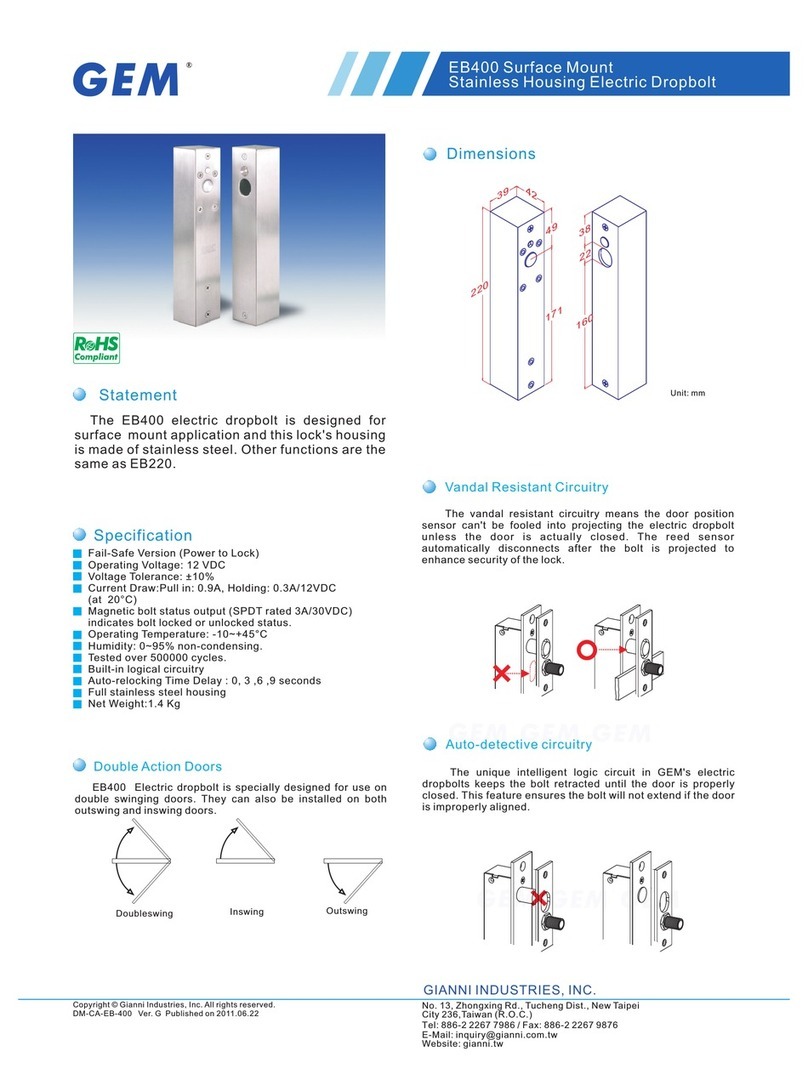

Gianni Industries EB-400 User manual

Gianni Industries

Gianni Industries Electromechanical Lock User manual

Gianni Industries

Gianni Industries EB-300 User manual

Gianni Industries

Gianni Industries 10020 User manual

Gianni Industries

Gianni Industries ML-210 User manual

Gianni Industries

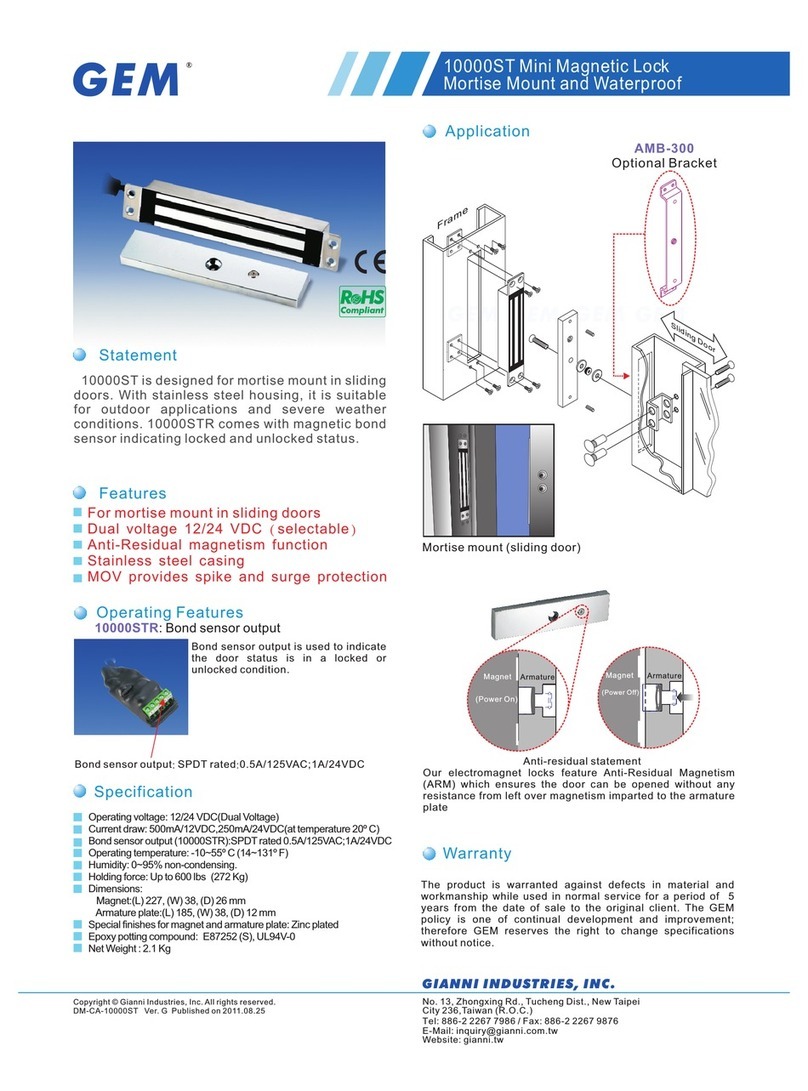

Gianni Industries 10000ST User manual

Gianni Industries

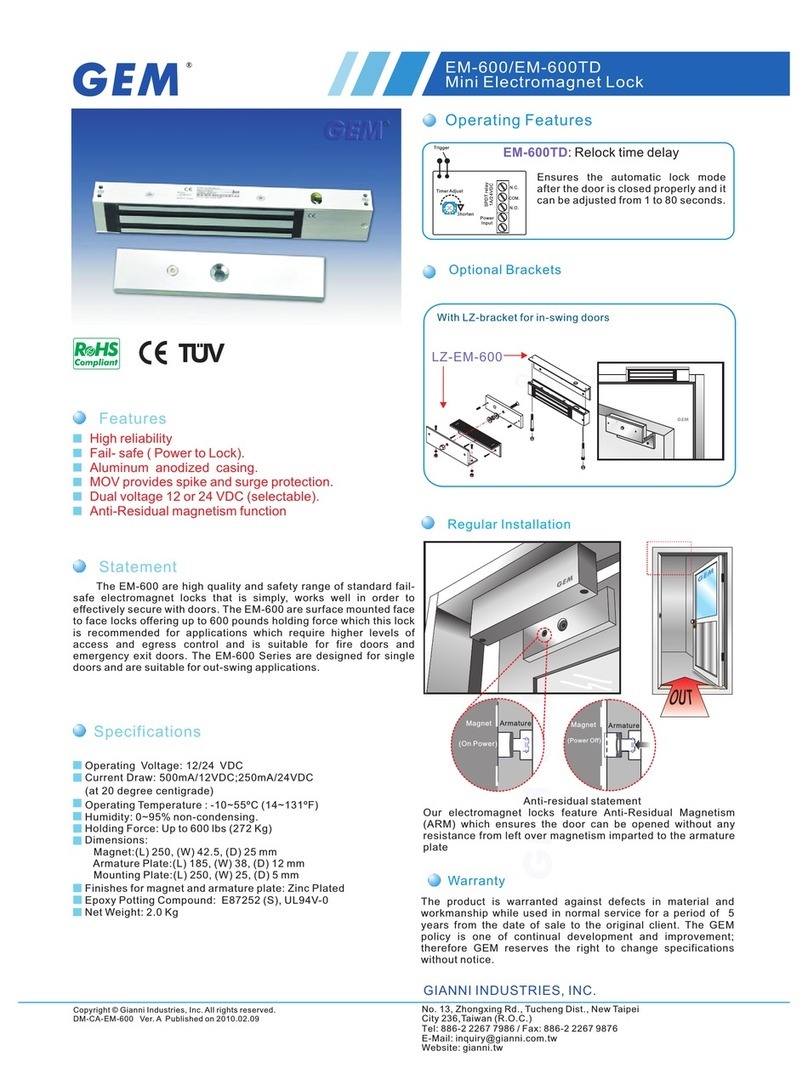

Gianni Industries EM-600 User manual

Gianni Industries

Gianni Industries EM-NH300 User manual

Gianni Industries

Gianni Industries EB-200N User manual

Gianni Industries

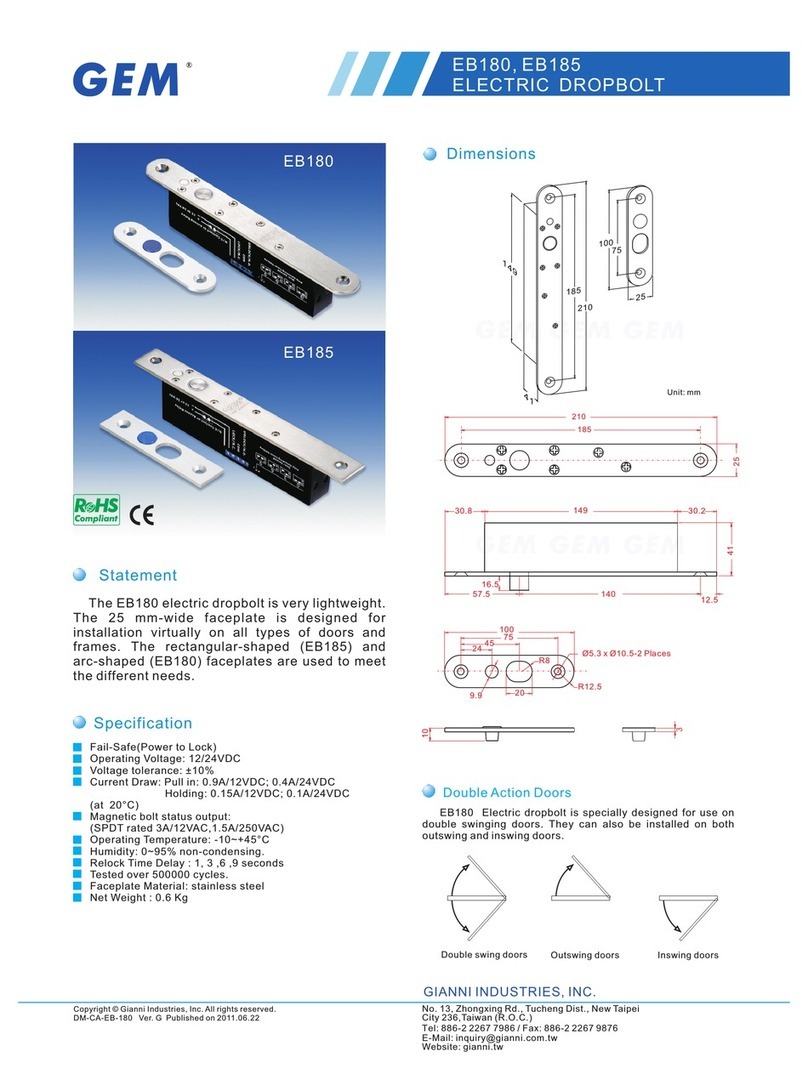

Gianni Industries EB-180 User manual

Gianni Industries

Gianni Industries 10040DS User manual

Gianni Industries

Gianni Industries EM-1200 User manual

Gianni Industries

Gianni Industries EB-262 User manual

Gianni Industries

Gianni Industries GS250 Series User manual

Gianni Industries

Gianni Industries PBT-900 Series User manual

Gianni Industries

Gianni Industries 10003F User manual

Gianni Industries

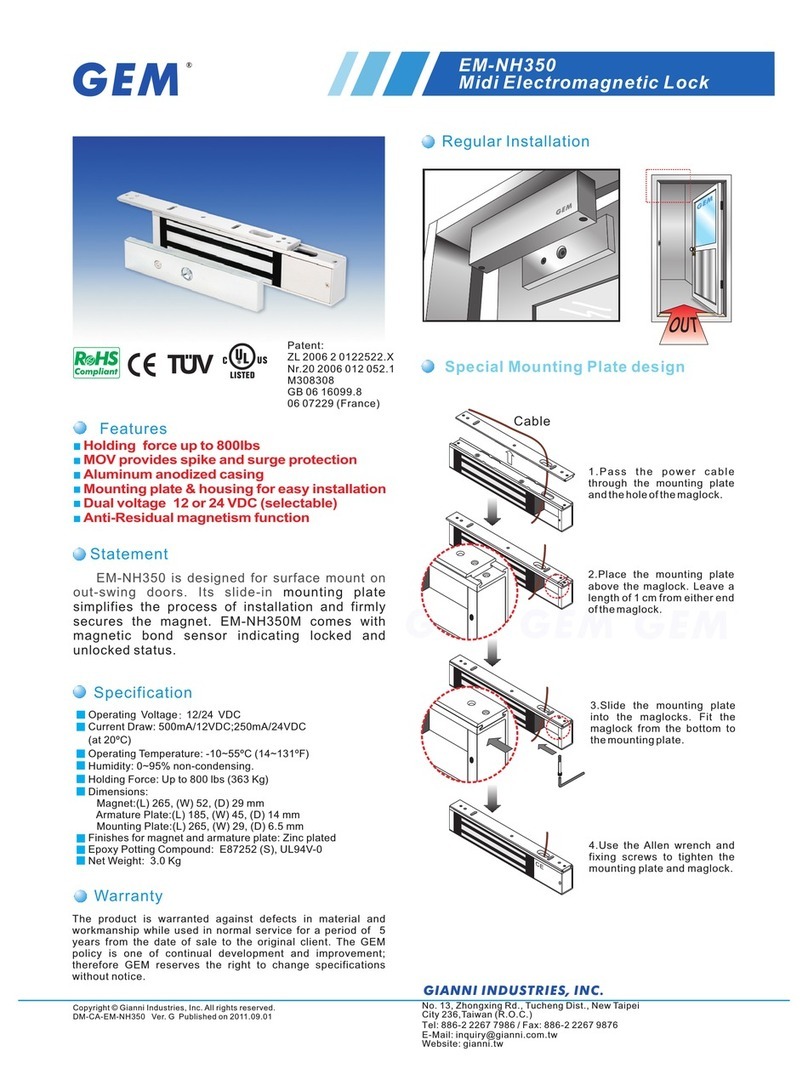

Gianni Industries EM-NH350 User manual

Gianni Industries

Gianni Industries GEM EM-NH2300 User manual

Gianni Industries

Gianni Industries EB-195 User manual