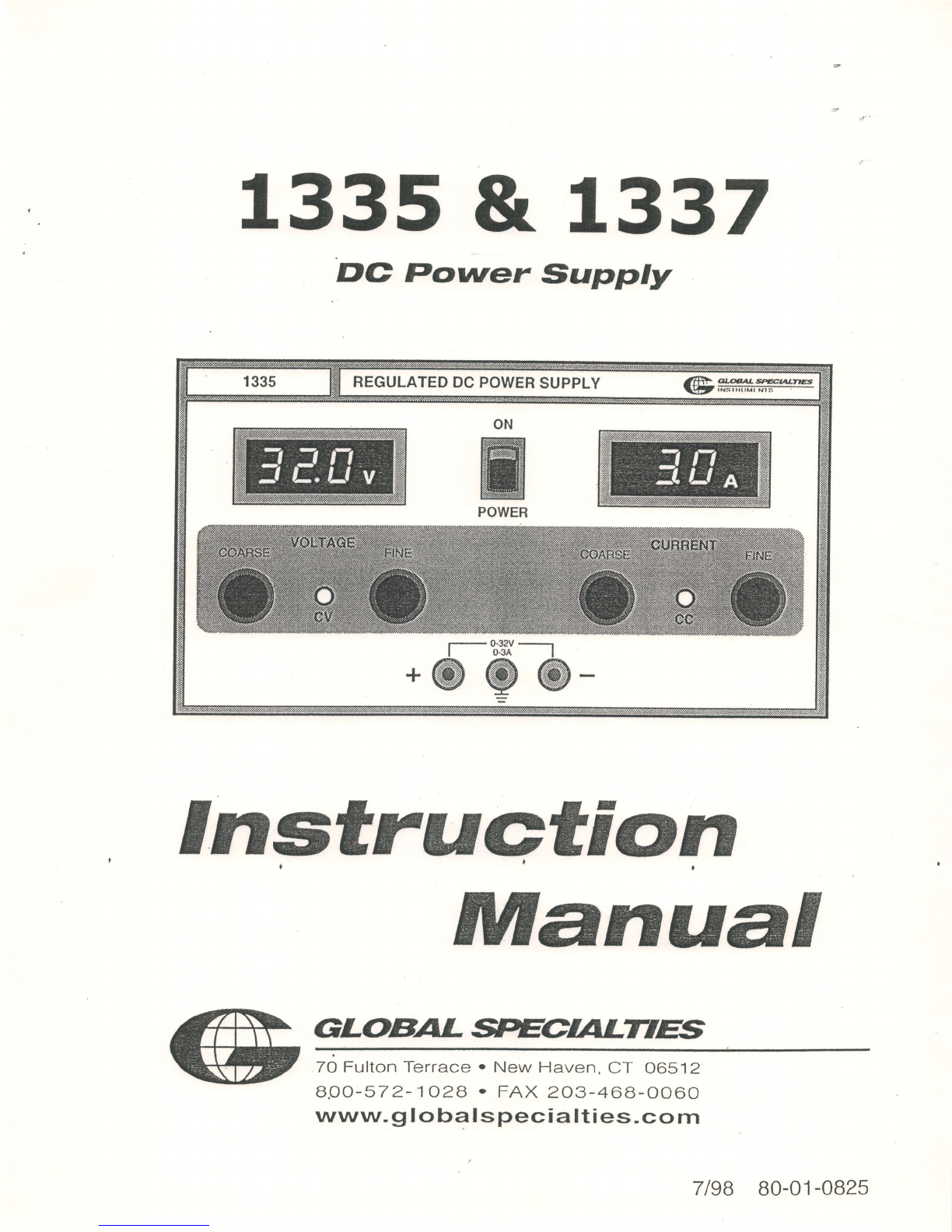

Global Specialties 1335 User manual

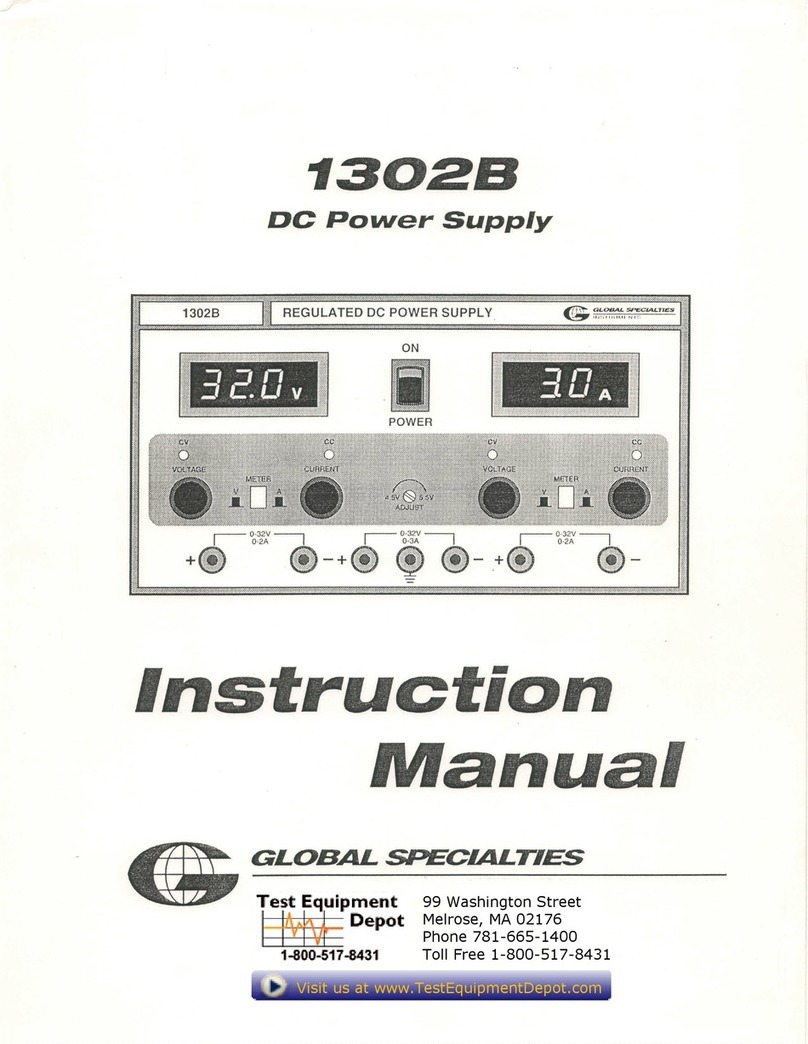

Other Global Specialties Power Supply manuals

Global Specialties

Global Specialties 1412 User manual

Global Specialties

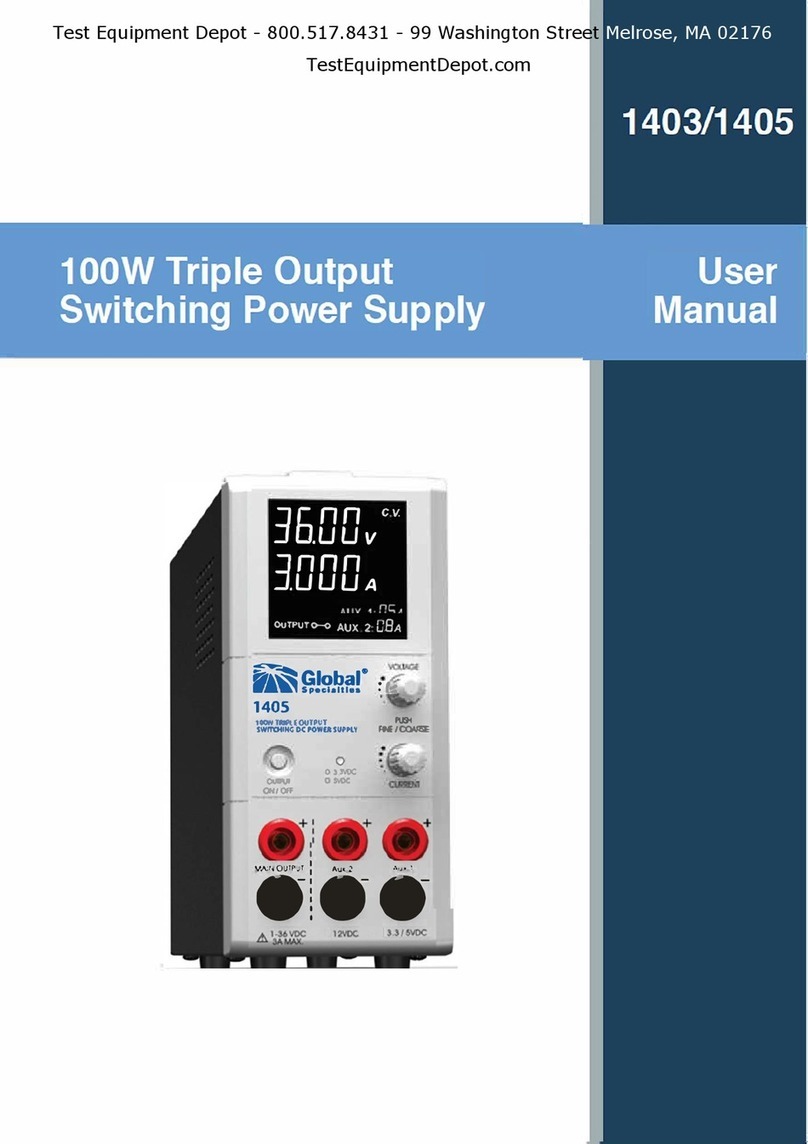

Global Specialties 1403 User manual

Global Specialties

Global Specialties 1320 User manual

Global Specialties

Global Specialties 1410 User manual

Global Specialties

Global Specialties 1403 User manual

Global Specialties

Global Specialties 1315D User manual

Global Specialties

Global Specialties 1310 User manual

Global Specialties

Global Specialties 1505 User manual

Global Specialties

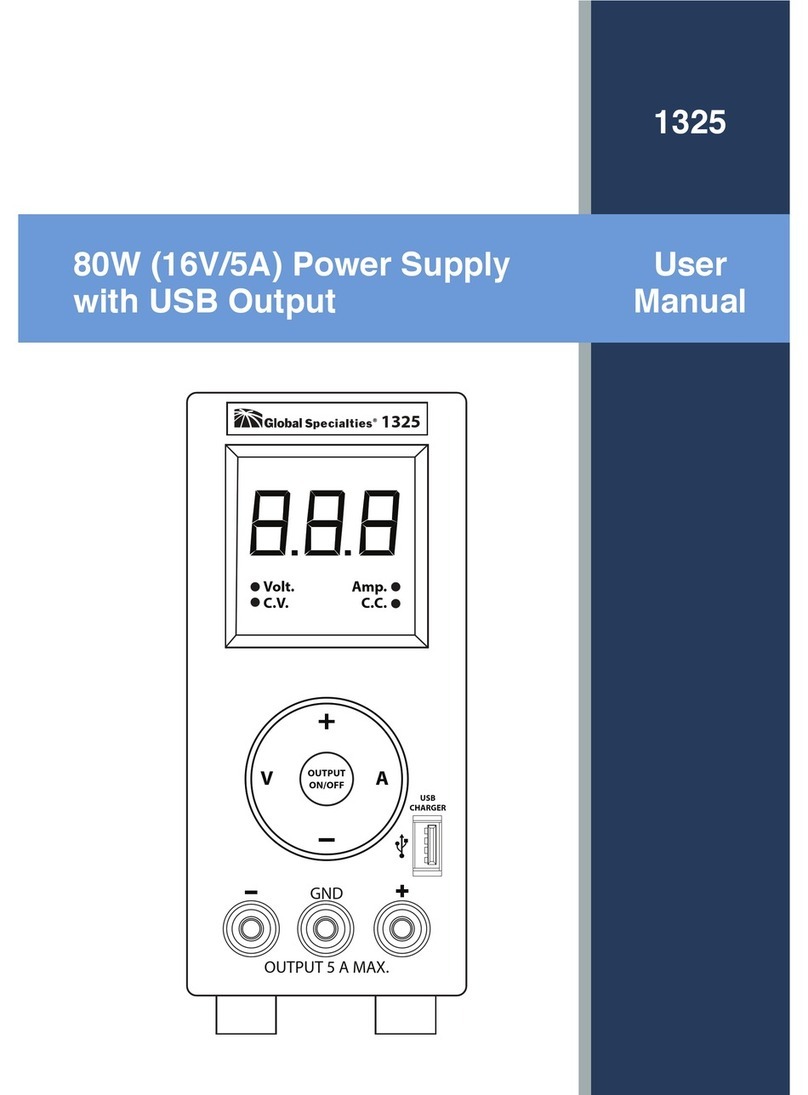

Global Specialties 1325 User manual

Global Specialties

Global Specialties 1415 User manual