GMG 1330ED - 1530ED

Operator’s manual

Operator’s Manual 1330ED / 1530ED series

October 2018

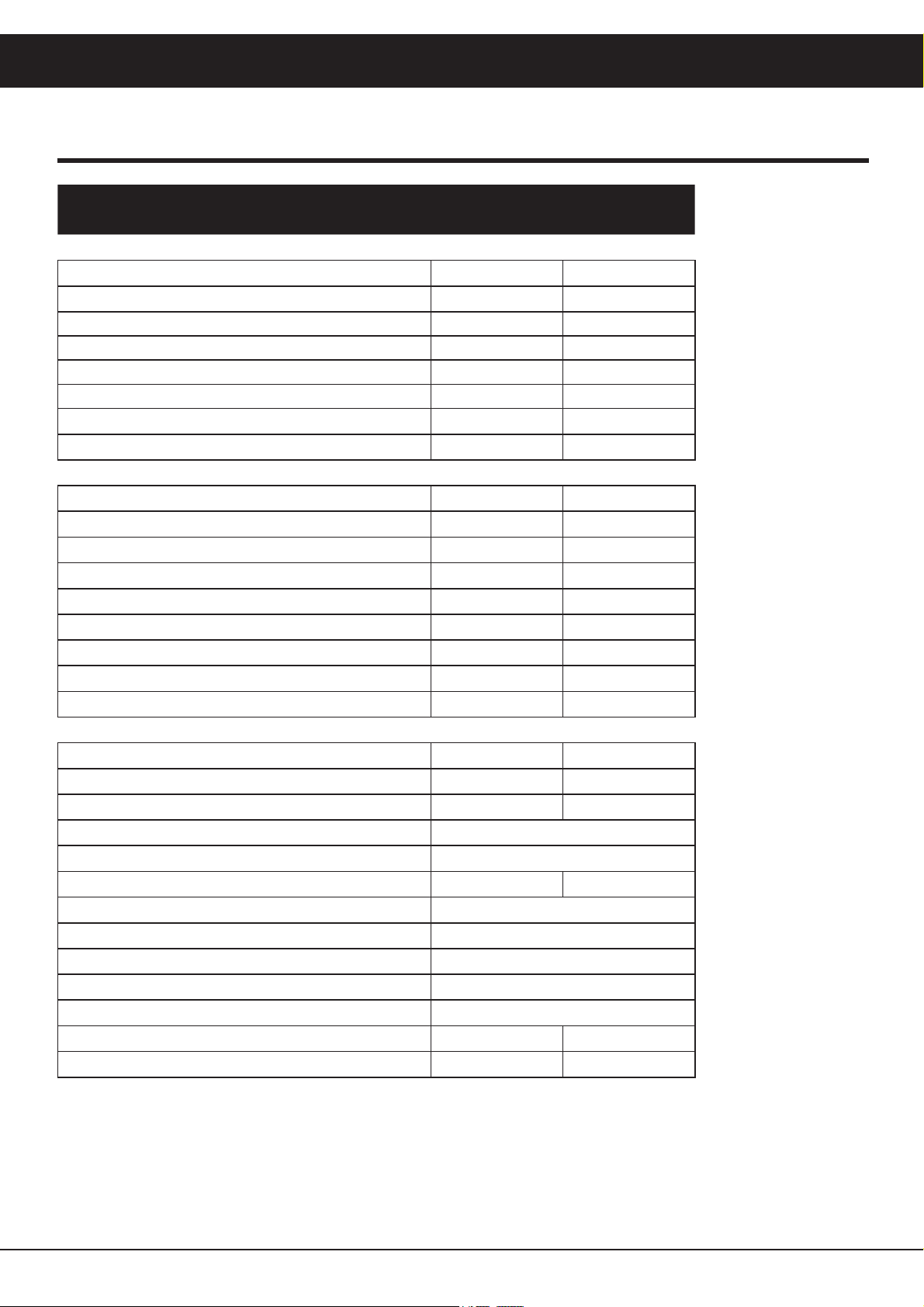

i. Specifications .......................................................................................................................5

1. Introduction...........................................................................................................................7

2. Safety.....................................................................................................................................9

2.1 Safety Alert Symbols ..............................................................................................................................9

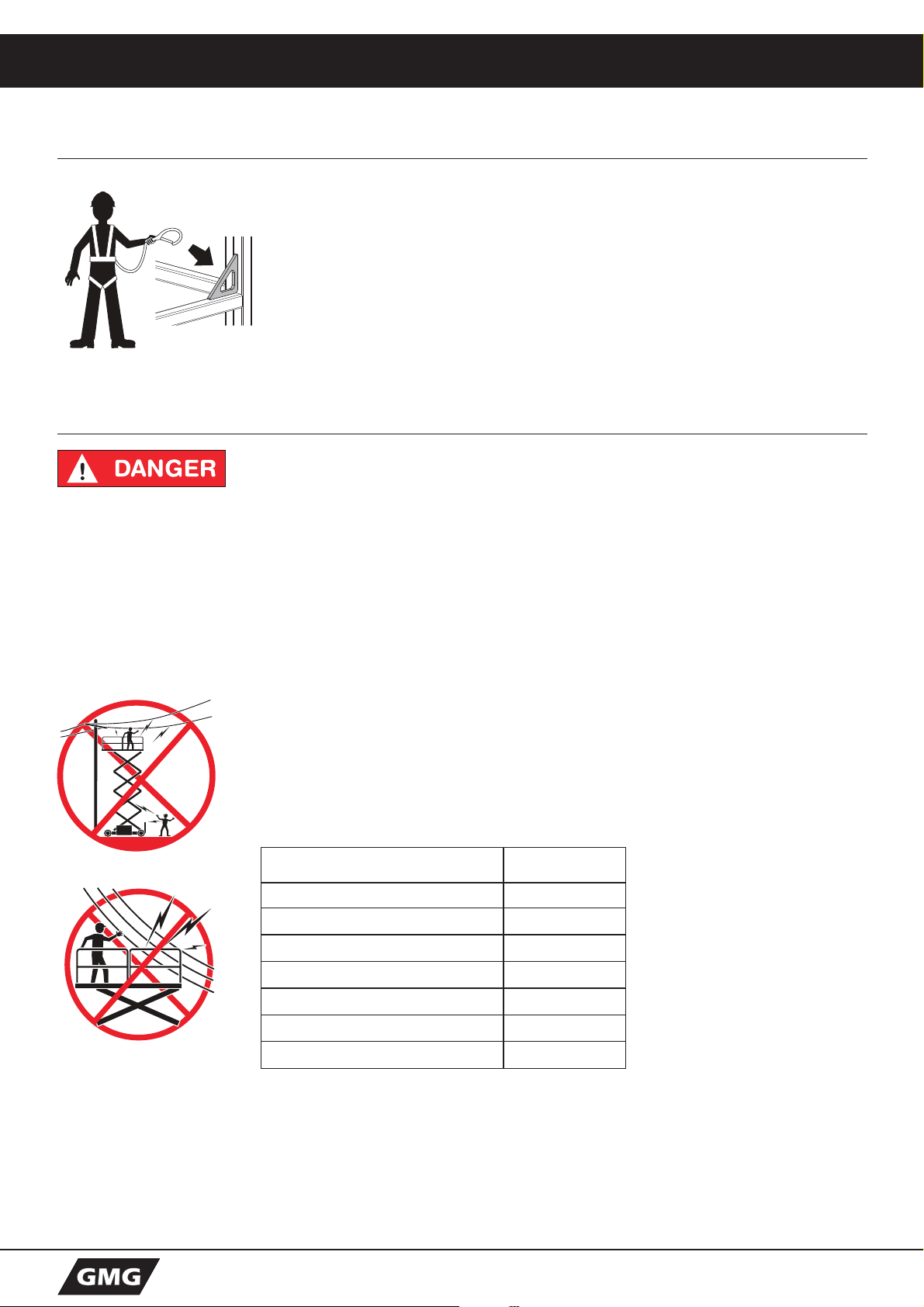

2.2 Fall Protection.......................................................................................................................................10

2.3 Electrocution Hazard ...........................................................................................................................10

2.4 Tip-over Hazards ..................................................................................................................................11

2.5 Fall Hazards..........................................................................................................................................12

2.6 Collision Hazards..................................................................................................................................12

2.7 Additional Safety Hazards ....................................................................................................................13

2.7.1 Explosion and Fire Hazards..................................................................................................................13

2.7.2 Damaged Machine Hazards .................................................................................................................13

2.7.3 Bodily Injury Hazards............................................................................................................................13

2.7.4 Weld Line to Platform Safety (if equipped) ...........................................................................................13

2.7.5 Battery Safety .......................................................................................................................................13

3. Controls & Components ....................................................................................................15

3.1 Component Locations...........................................................................................................................15

3.2 Platform Controls..................................................................................................................................16

3.3 Lower Controls......................................................................................................................................17

4. Workplace Inspection ........................................................................................................19

4.1 Workplace Inspection ...........................................................................................................................19

5. Operating Instructions & Function Tests.........................................................................21

5.1 Prestart .................................................................................................................................................21

5.1.1 Functions Test ......................................................................................................................................21

5.1.2 At the Ground Controls.........................................................................................................................21

5.1.3 Test EMERGENCY STOP....................................................................................................................21

5.1.4 Test Up/Down Functions ......................................................................................................................22

5.1.5 Test the Emergency Lowering..............................................................................................................22

5.1.6 At the Platform Controls........................................................................................................................22

5.1.7 Test EMERGENCY STOP....................................................................................................................22

5.1.8 Test the Horn........................................................................................................................................22

5.2 Test Function Enable and Lifting Functions..........................................................................................23

5.3 Test the Steering ..................................................................................................................................23

5.4 Test Drive and Braking .........................................................................................................................24

5.5 Test Limited Drive Speed .....................................................................................................................24