Page 5

GMG 2646E-OR --- 4646E-OR

Operator’s manual

Series: 2646E-OR --- 4646E-OR

November 2020 #81250.1

8ǂljLjǏƾNj,ƺǓƺNjƽnj

DO NOT exceed the maximum platform capacity. The weight of options and

accessories will reduce the rated platform capacity and must be factored into the

total platform load. Refer to the decals on the options.

DO NOT elevate the platform when the machine is on a surface that is soft

and / or on a slope.

DO NOT depend on the tilt alarm as a level indicator.

STOP if the tilt alarm sounds and the red light illuminates when the platform is

raised. Use extreme caution to lower the platform. Move the machine to a rm,

level surface.

Driving: DO NOT drive the machine on a slope that exceeds

the maximum uphill or downhill slope rating. Slope rating applies to machines in

the stowed position.

Driving in stowed position: use extreme care and reduce speed when driving

across uneven terrain, debris, unstable or slippery surfaces, and near holes or

drop-offs.

Driving with the platform elevated: DO NOT drive on or near uneven terrain,

unstable surfaces, curbs, drop-offs or other hazardous conditions.

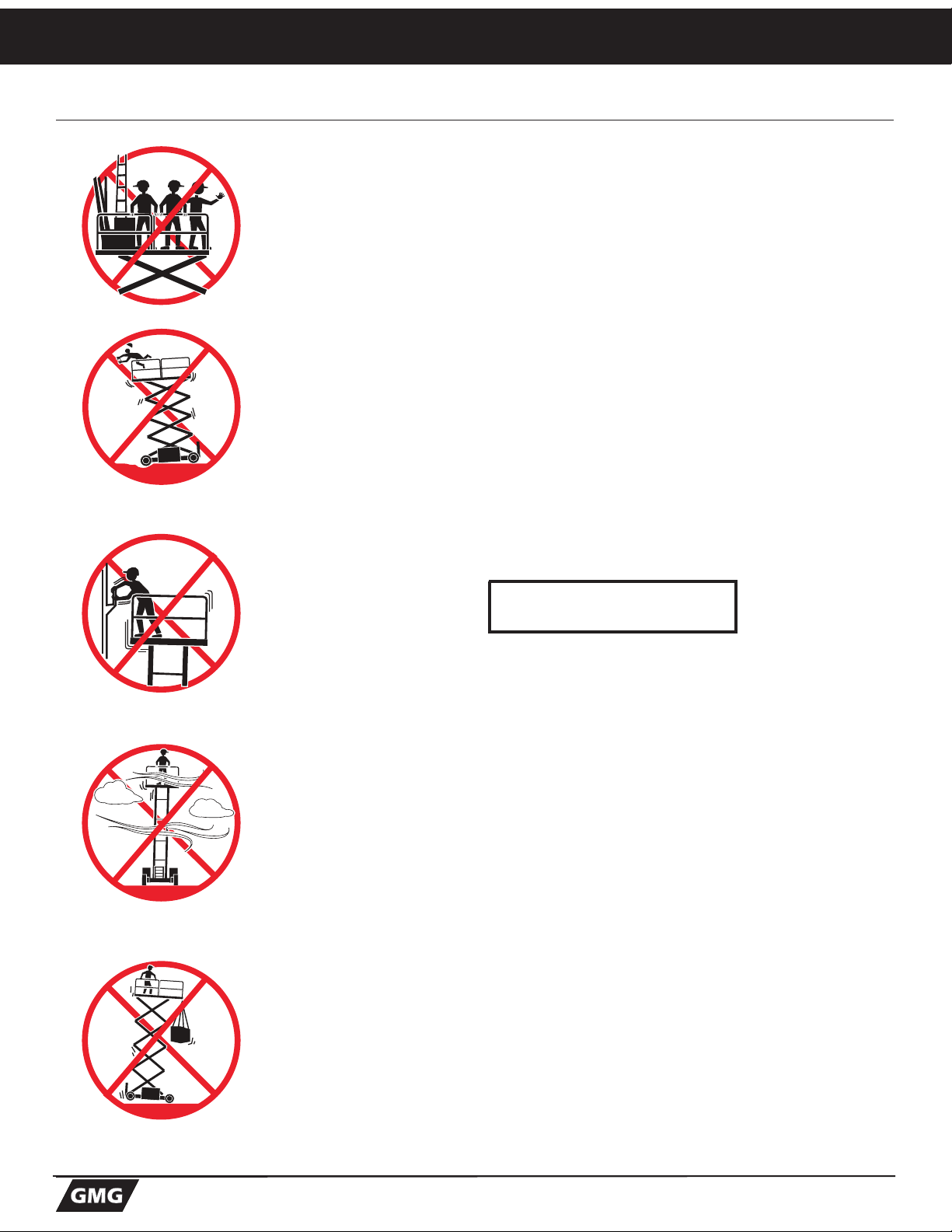

DO NOT push or pull toward any object outside the platform.

DO NOT push the machine or other objects with the platform.

DO NOT contact adjacent structures with the platform.

DO NOT use the platform controls to free a platform that is caught, snagged or

otherwise prevented from normal motion by an adjacent structure. For outdoor

rated machines, DO NOT elevate the platform when wind speeds are in excess

12,5 m/s. If wind speeds exceed 12,5 m/s when the platform is elevated, carefully

lower the platform and discontinue operation.

DO NOT increase the surface area of the platform (i.e. cover the rails with tarp

or plywood). Increased surface area exposed to the wind will decrease machine

stability.

DO NOT attach overhanging loads or use the machine as a crane.

DO NOT place loads outside the platform perimeter.

NEVER transport tools and materials unless they are firmly secured. Secure all

tools and loose materials.

NEVER alter or disable any machine components.

NEVER replace any part of the machine with items of different weight or

specification.

NEVER modify or alter the work platform without written permission from GMG.

NEVER place ladders or scaffolds in the platform or against any part of the

machine.

NEVER use the machine on a moving or mobile surface or vehicle.

Ensure that all tires are in good condition and lug nuts are properly torqued.

DO NOT operate the machine with the chassis trays open.

DO NOT alter or disable the limit switches or machine components that in any

way affect safety and stability.

DO NOT replace items critical to machine stability with items of different weight

or specification. DO NOT modify or alter this machine without prior written

permission from the manufacturer.

DO NOT use batteries that weigh less than the original equipment. Each battery

must weigh 25 kg. The batteries must weigh a minimum of 50 kg.

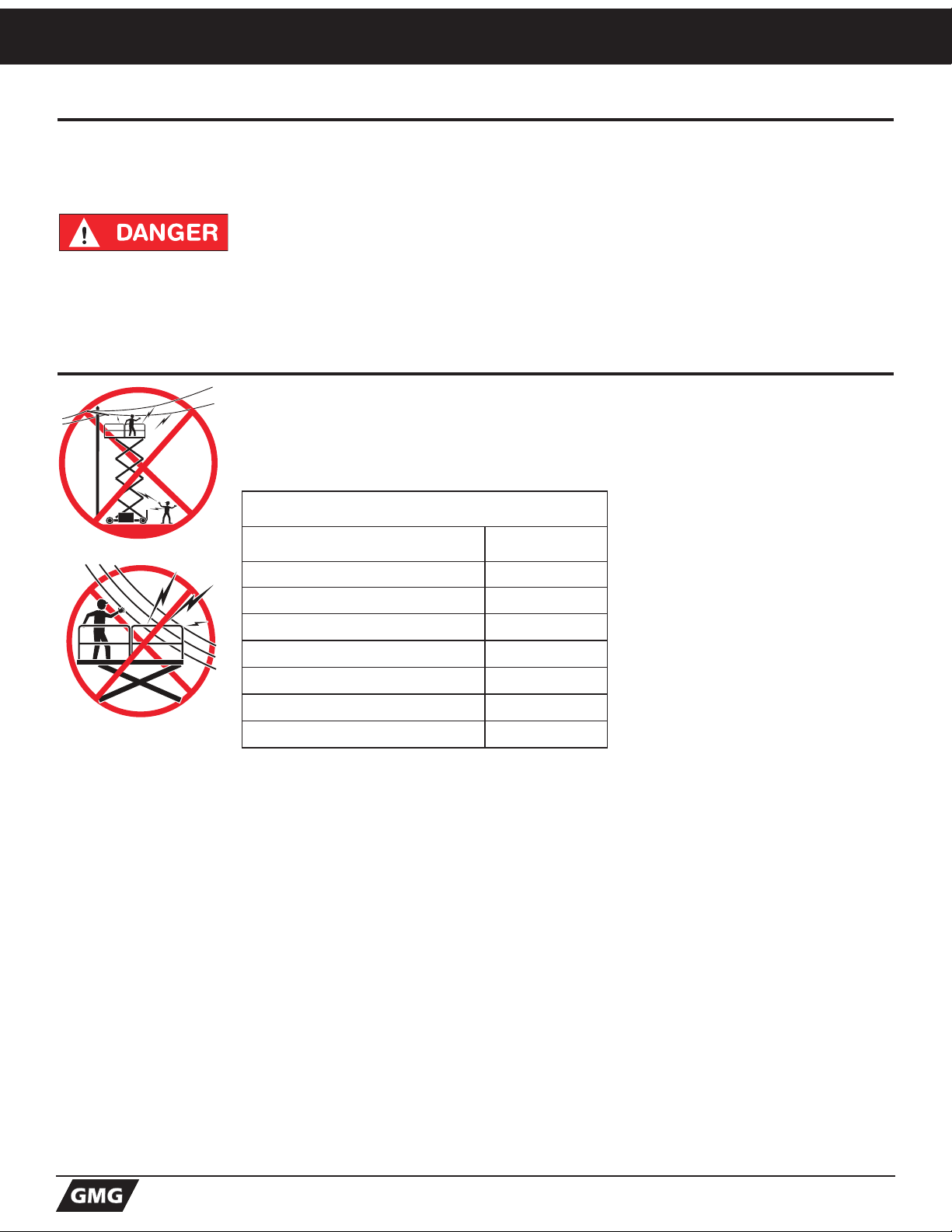

Maximum Allowable Side Force

45lbs (200N)

13304

13306

13305

13307

13308

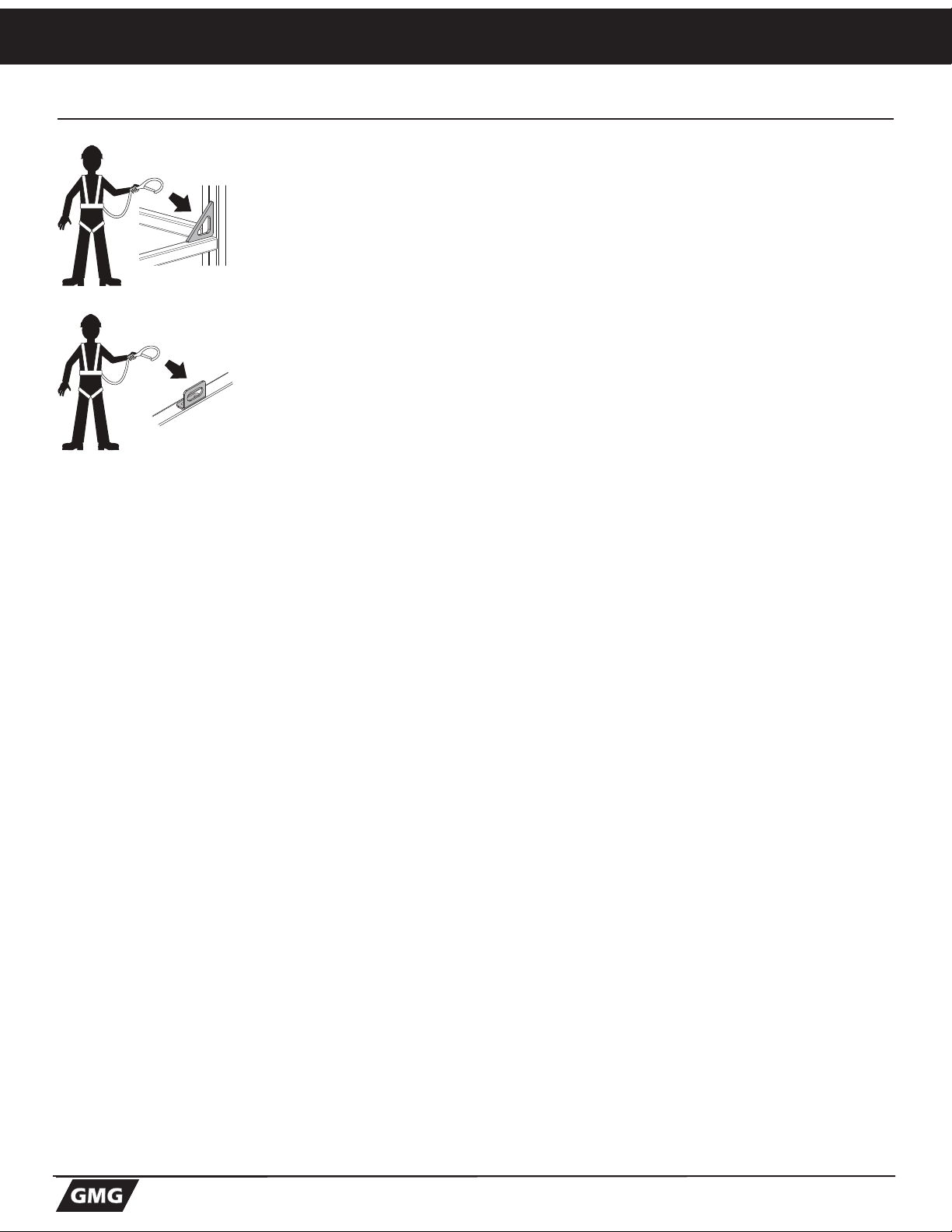

DO NOT OVERLOAD

DO NOT DRIVE ON IRREGULAR

OR UNSTABLE SURFACE

DO NOT PUSH OR PULL

OBJECTS OUTSIDE PLATFORM

DO NOT ELEVATE IN

WINDY CONDITIONS

DO NOT USE AS CRANE