6 306556

Installation

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Always use Genuine Graco Parts and

Accessories, available from your Graco distributor.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section FIRE OR EXPLOSION HAZ-

ARD on page 4.

Pump: Use a ground wire and clamp as shown in

Fig.1.

Air, and fluid hoses: Use only electrically conductive

hoses.

Air compressor: Follow manufacturer’s

recommendations.

Spray gun and dispensing valve: Ground through

connection to a properly grounded fluid hose and

pump.

Fluid supply container: Follow your local code.

Truck bed or platform: Follow your local code.

Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the

dispensing valve firmly to the side of a grounded

metal pail, then trigger the valve.

To ground the pump, remove the ground screw (Z)

and insert through the eye of the ring terminal at the

end of ground wire (Y). Fasten the ground screw back

onto the pump and tighten securely. Connect the other

end of the ground wire to a true earth ground. See Fig.

1. To order a ground wire and clamp, order Part No.

222011.

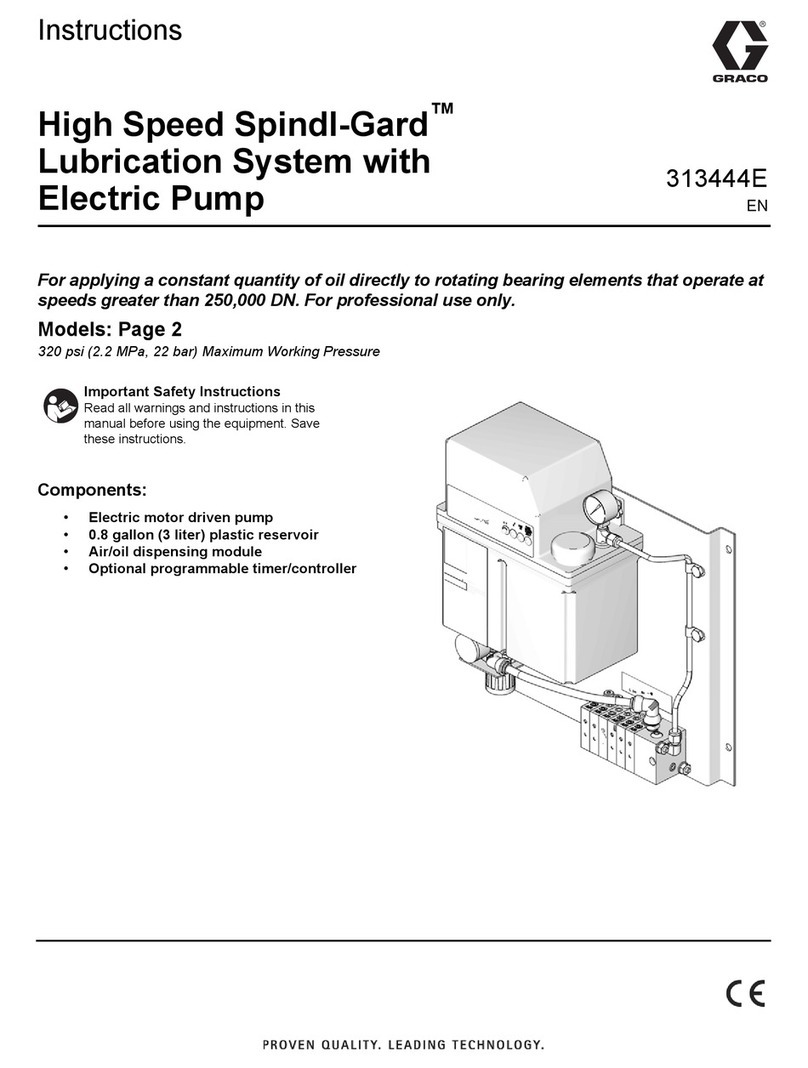

Fig. 1 TI1052

Y

Z

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

Fluid under high pressure can be in-

jected through the skin and cause

serious injury. To reduce the risk of an

injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you

Are instructed to relieve the pressure

Shut off the pump

Check or service any of the system equipment

1. Close the pump’s air regulator

2. Close the supply pump’s bleed-type master air

valve (required in this system).

3. Hold a metal part of the dispensing valve firmly to

a grounded metal waste container and open the

dispensing valve until pressure is fully relieved.

If you suspect that the dispensing valve, extension, or

grease fitting coupler is clogged, or that pressure has

not been fully relieved after following the steps above,

VERY SLOWLY loosen the coupler or hose end

coupling and relieve pressure gradually, then loosen

completely, then clear the clog.