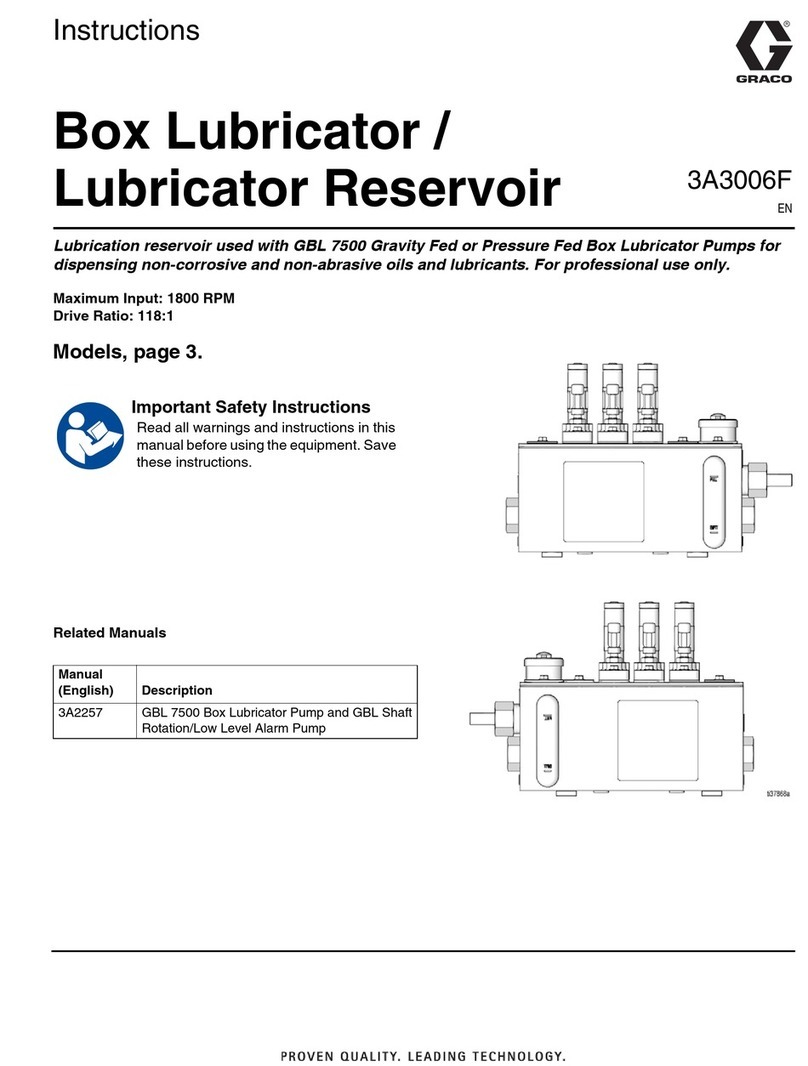

Graco 309015B Guide

Other Graco Lubrication System manuals

Graco

Graco 24W633 User manual

Graco

Graco 24Z764 User manual

Graco

Graco 204867 User manual

Graco

Graco 203-697 E Series Operation manual

Graco

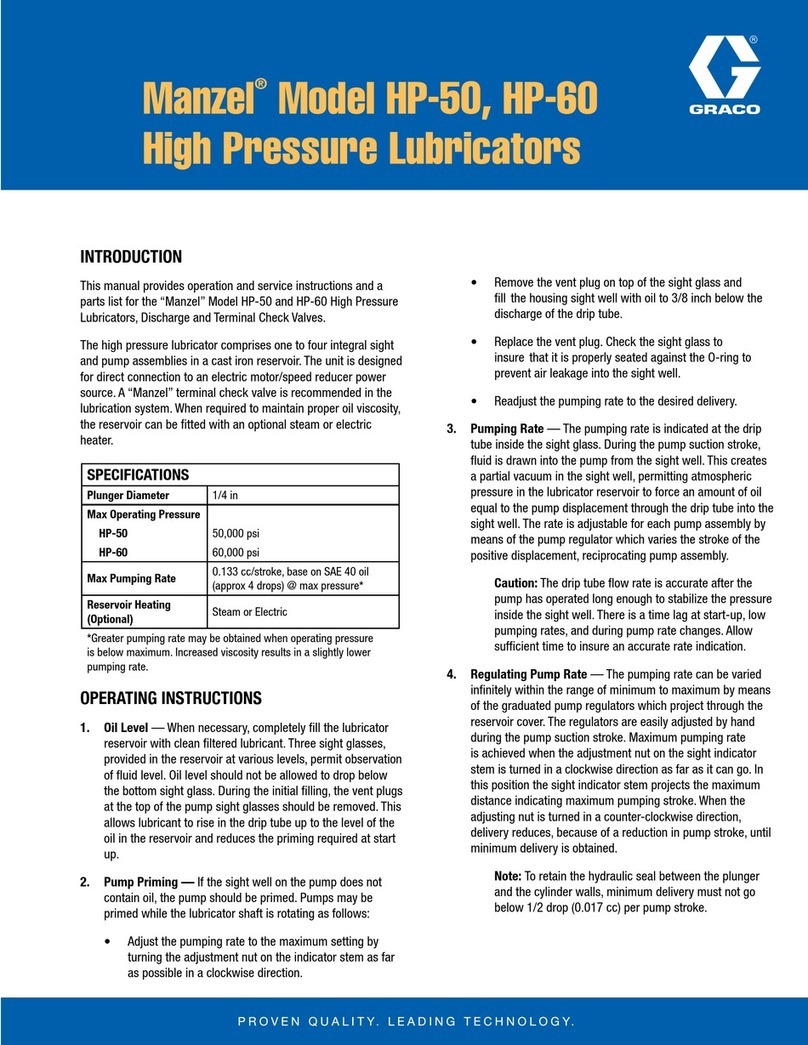

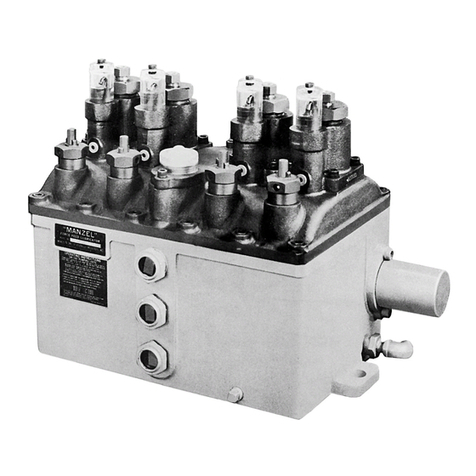

Graco Manzel HP-50 User manual

Graco

Graco Progressive Series User manual

Graco

Graco 24Z764 User manual

Graco

Graco FIRE–BALL 300 Air Motor Muffler Kit Operation manual

Graco

Graco GL-1 X Operation manual

Graco

Graco Manzel HP-50 Guide

Graco

Graco FIRE-BALL Series Operation manual

Graco

Graco Fire-Ball 425 Series User manual

Graco

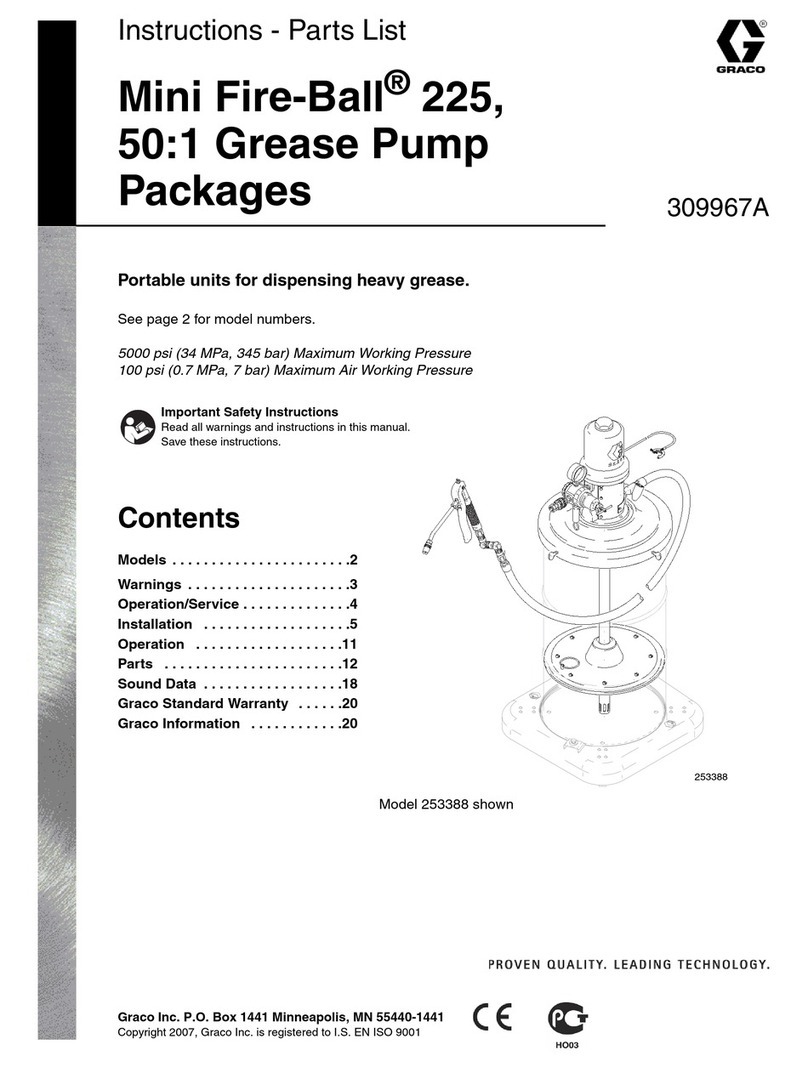

Graco Mini Fire-Ball 225 Series Operation manual

Graco

Graco G3 Series User manual

Graco

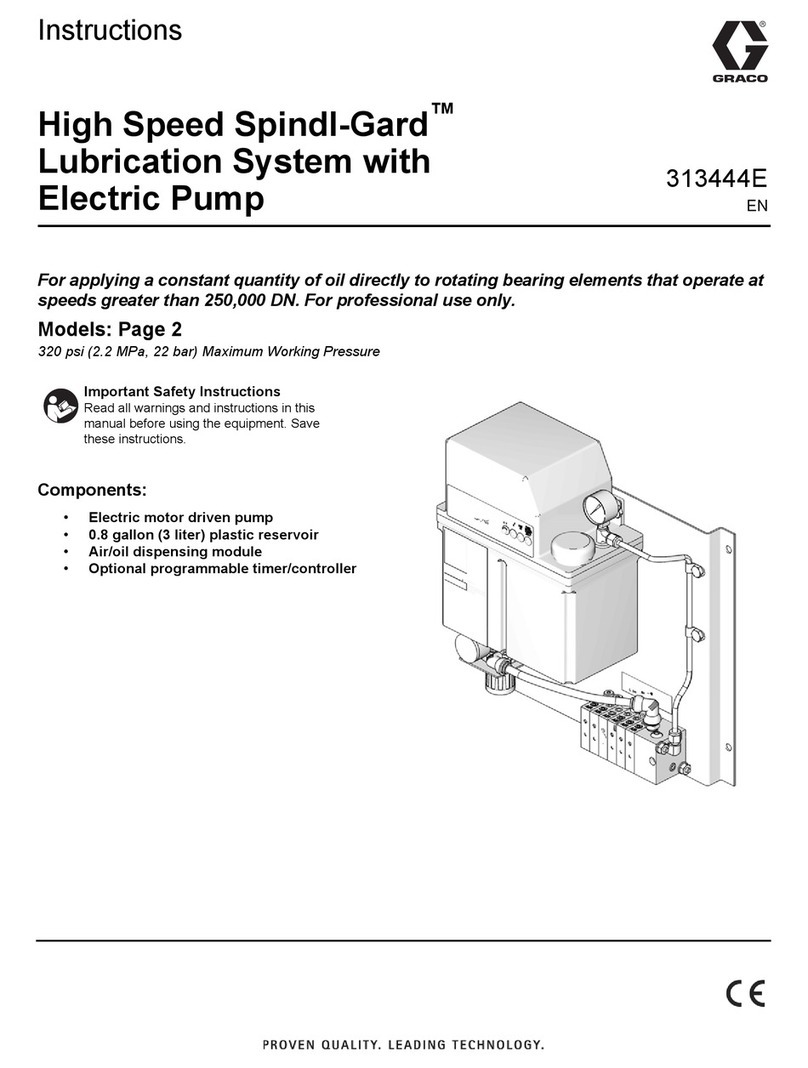

Graco Spindl-Gard 24B219 User manual

Graco

Graco 25 User manual

Graco

Graco GREASE JOCKEY User manual

Graco

Graco FIRE-BALL Operation manual