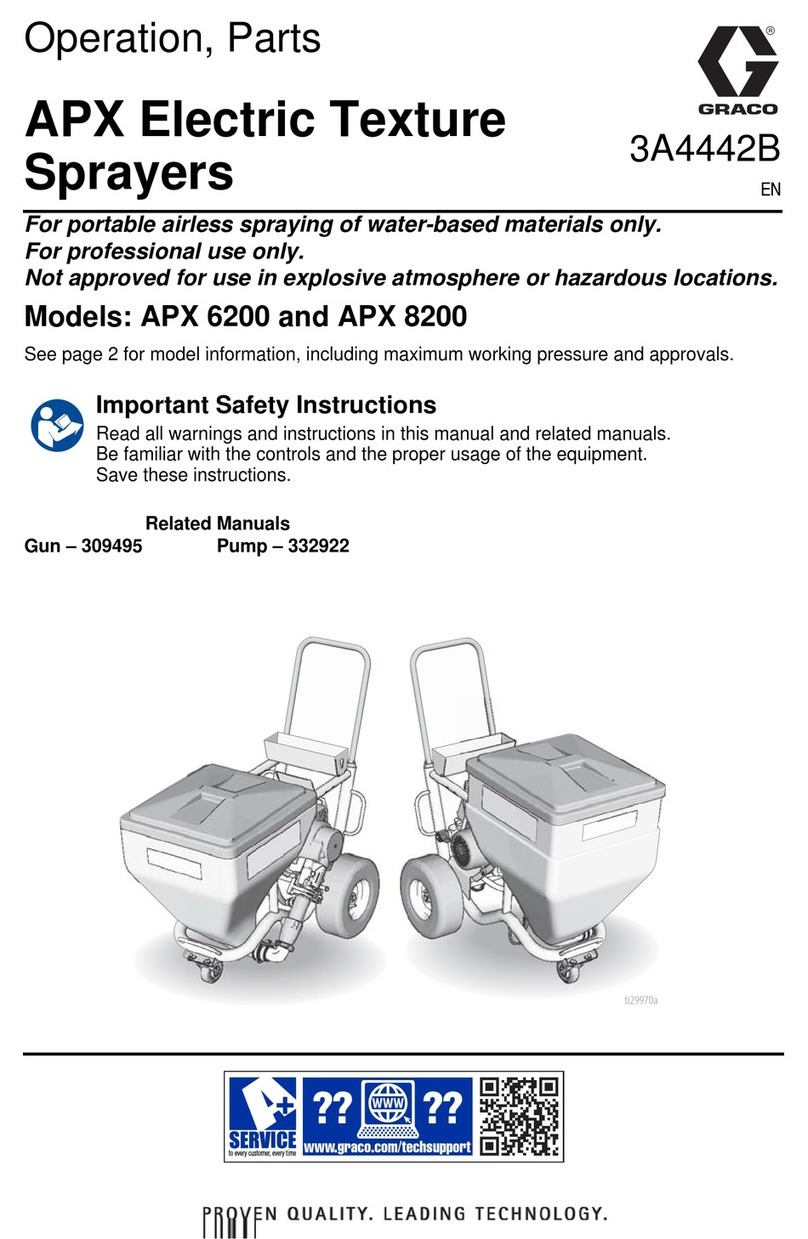

Graco Series E Operation manual

Other Graco Paint Sprayer manuals

Graco

Graco FieldLazer 248942 User manual

Graco

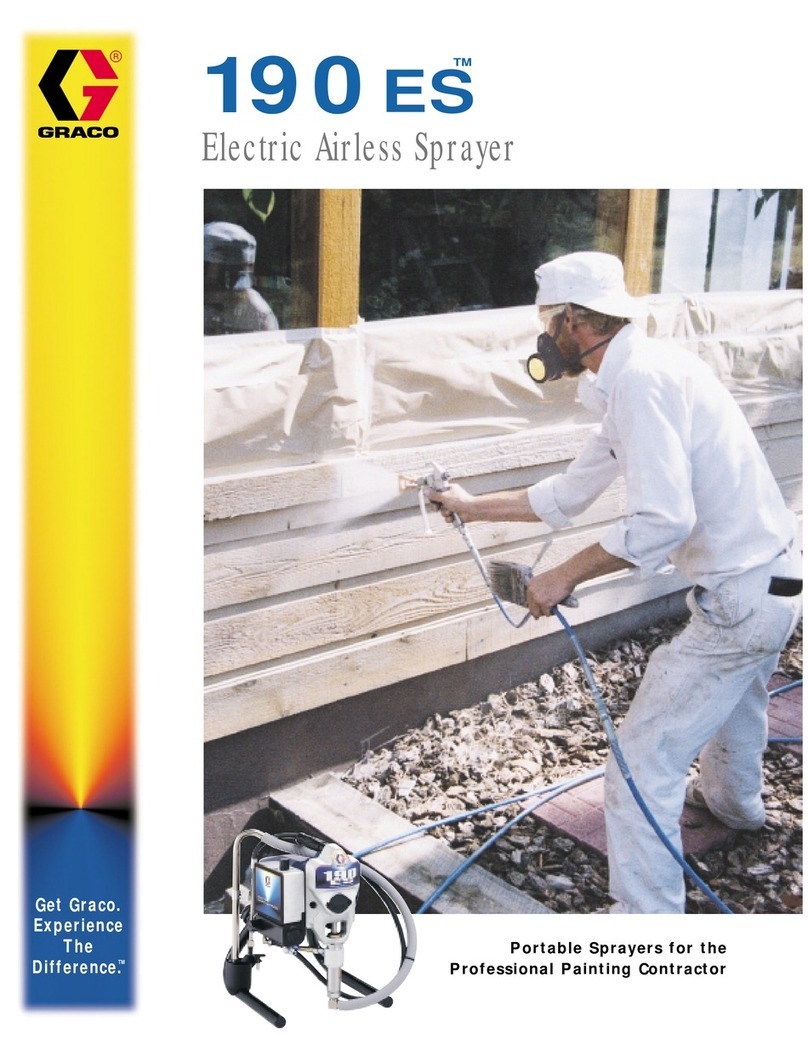

Graco 190ES 261825 User manual

Graco

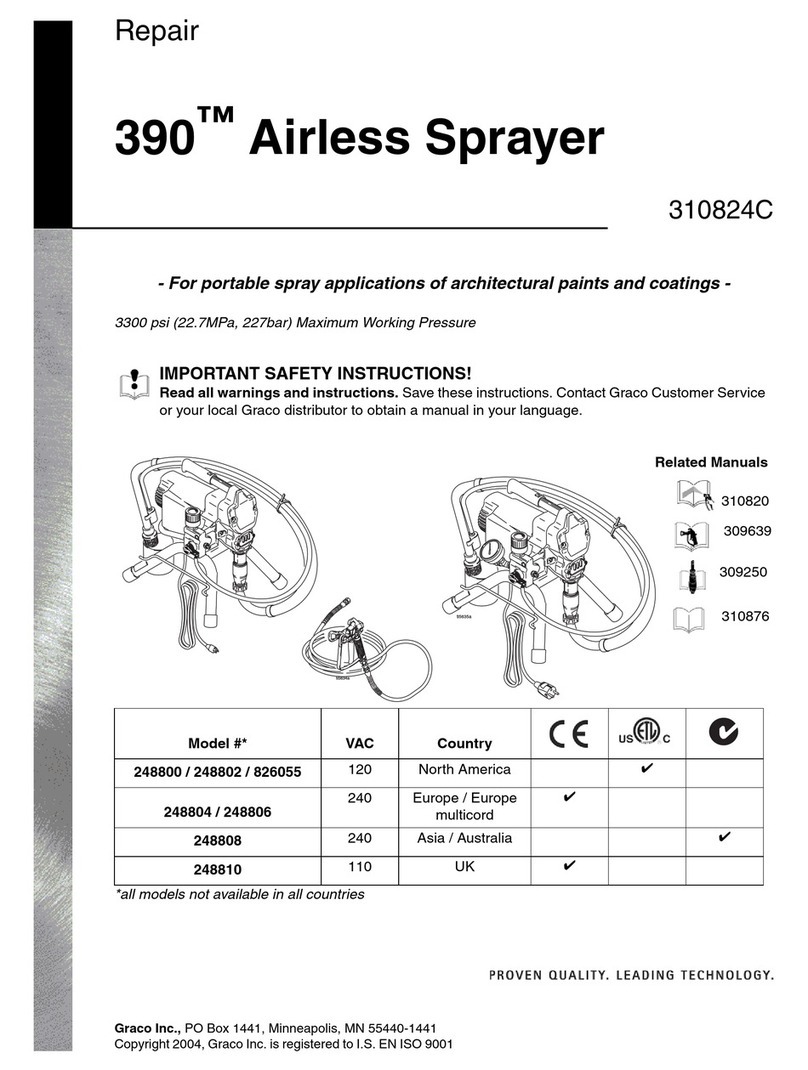

Graco DURON Performance 390 Operating instructions

Graco

Graco 231-034 Datasheet

Graco

Graco Fusion CS Series User manual

Graco

Graco RTX 1500 Instruction Manual

Graco

Graco Xtreme Mix 185 User manual

Graco

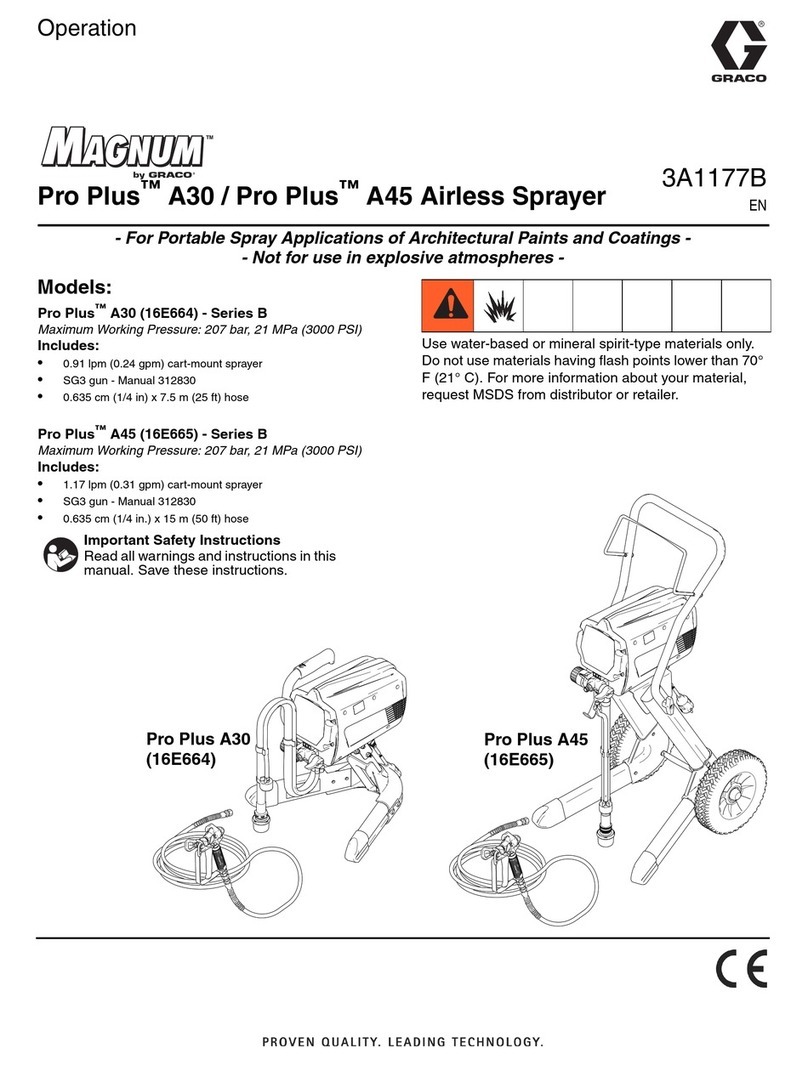

Graco magnum pro plus a30 User manual

Graco

Graco MAGNUM TexFinish 249175 Instruction Manual

Graco

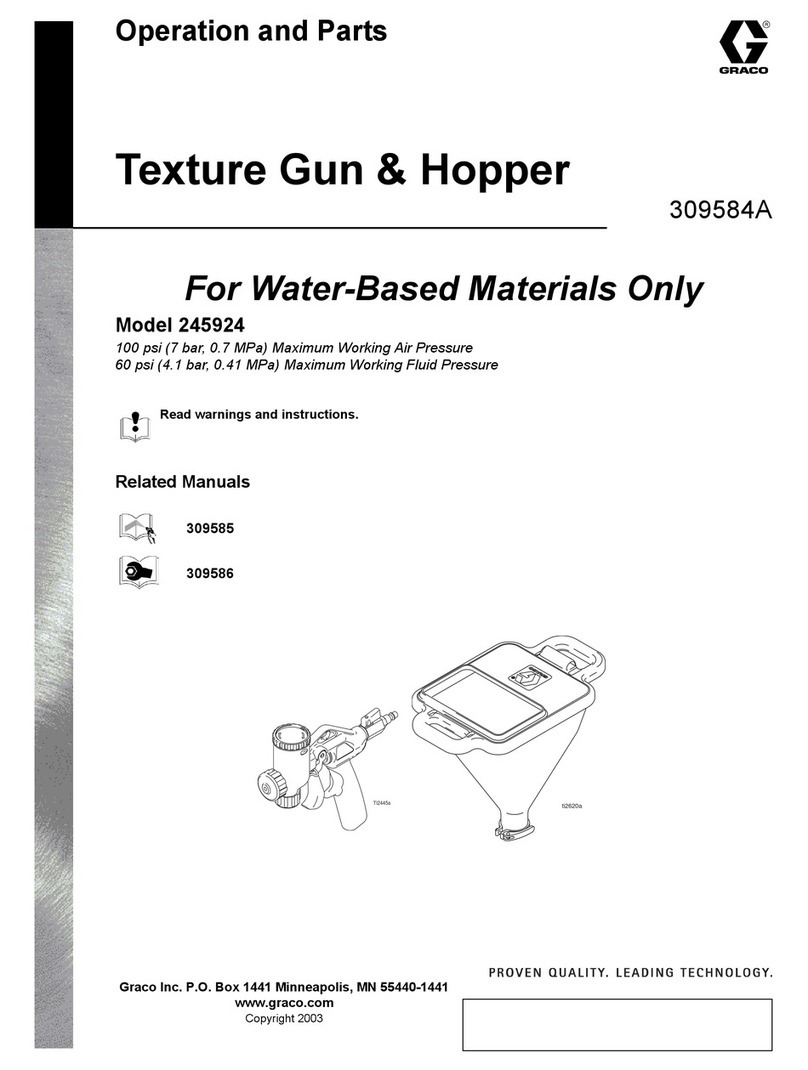

Graco 245924 Guide

Graco

Graco Reactor 2 H-30 Instruction Manual

Graco

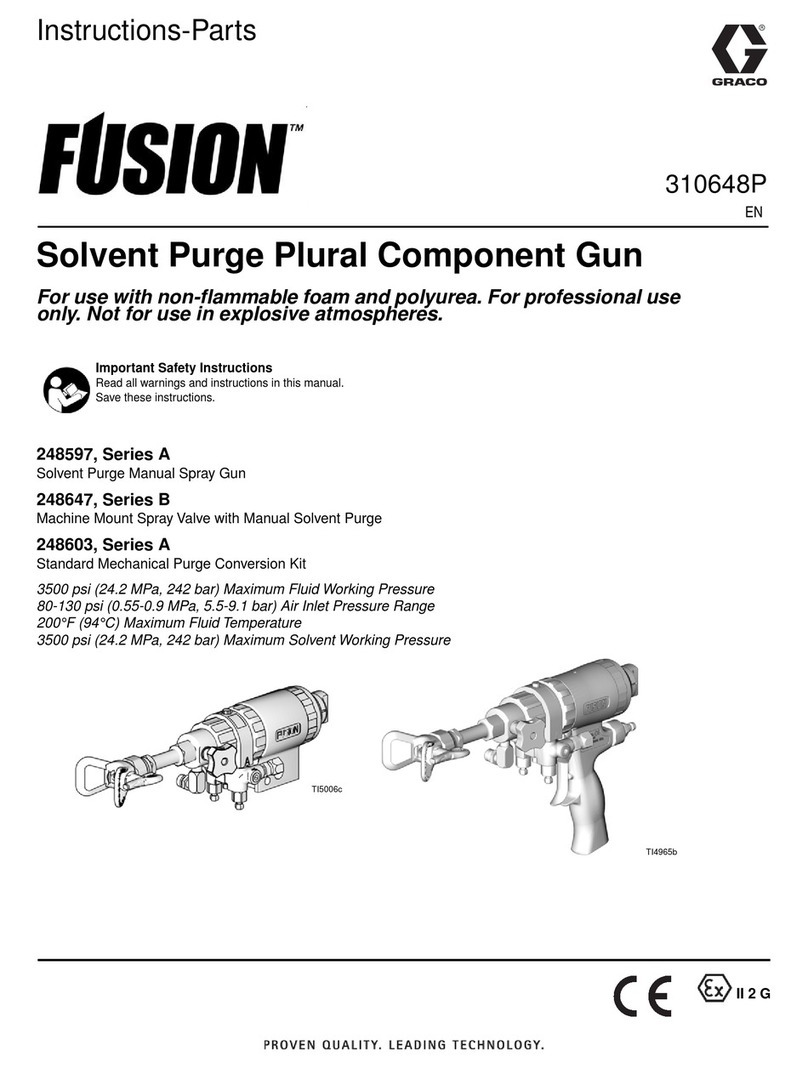

Graco Fusion Operation manual

Graco

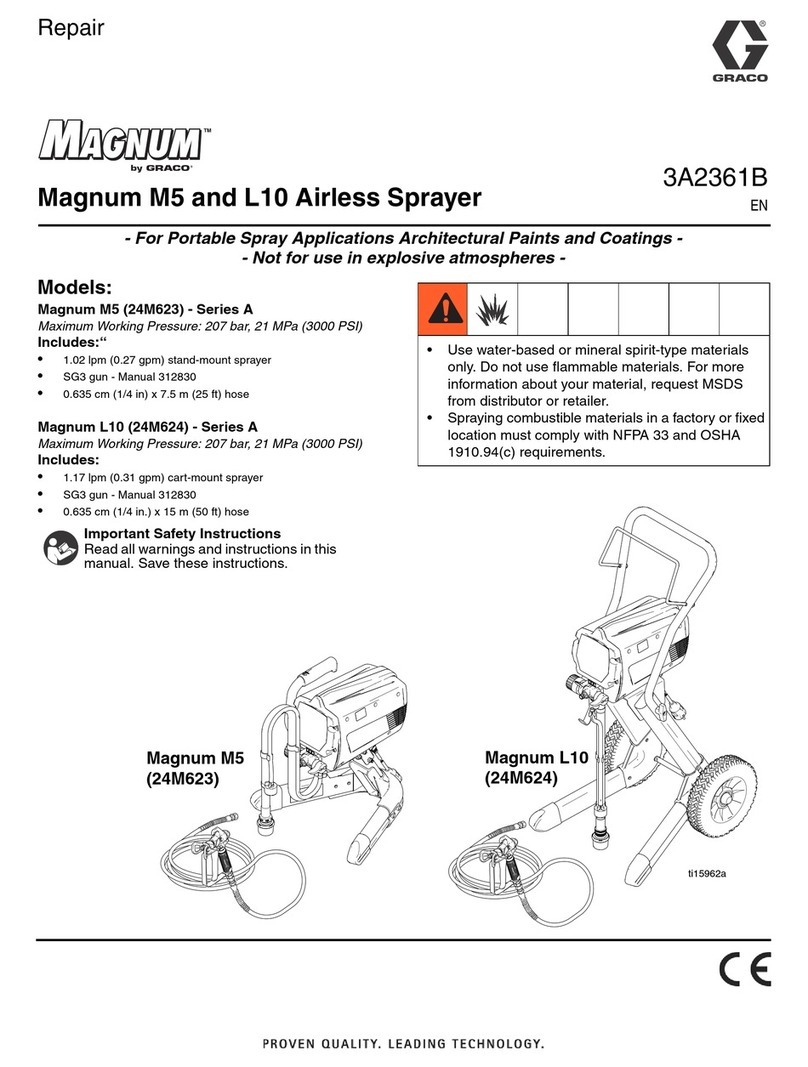

Graco 24M623 User manual

Graco

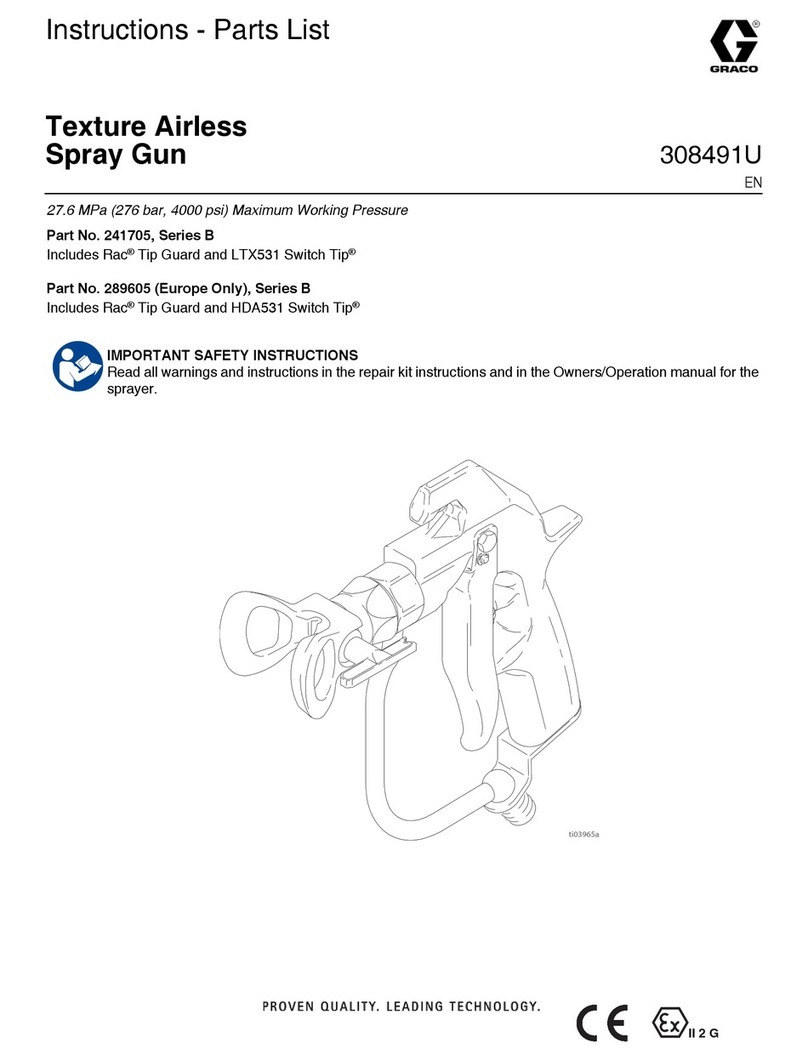

Graco 308491U Operation manual

Graco

Graco Mark V SpackMax Instruction Manual

Graco

Graco Inline HD 245820 Guide

Graco

Graco 390 Hi-Boy User manual

Graco

Graco Finishpro 390 User manual

Graco

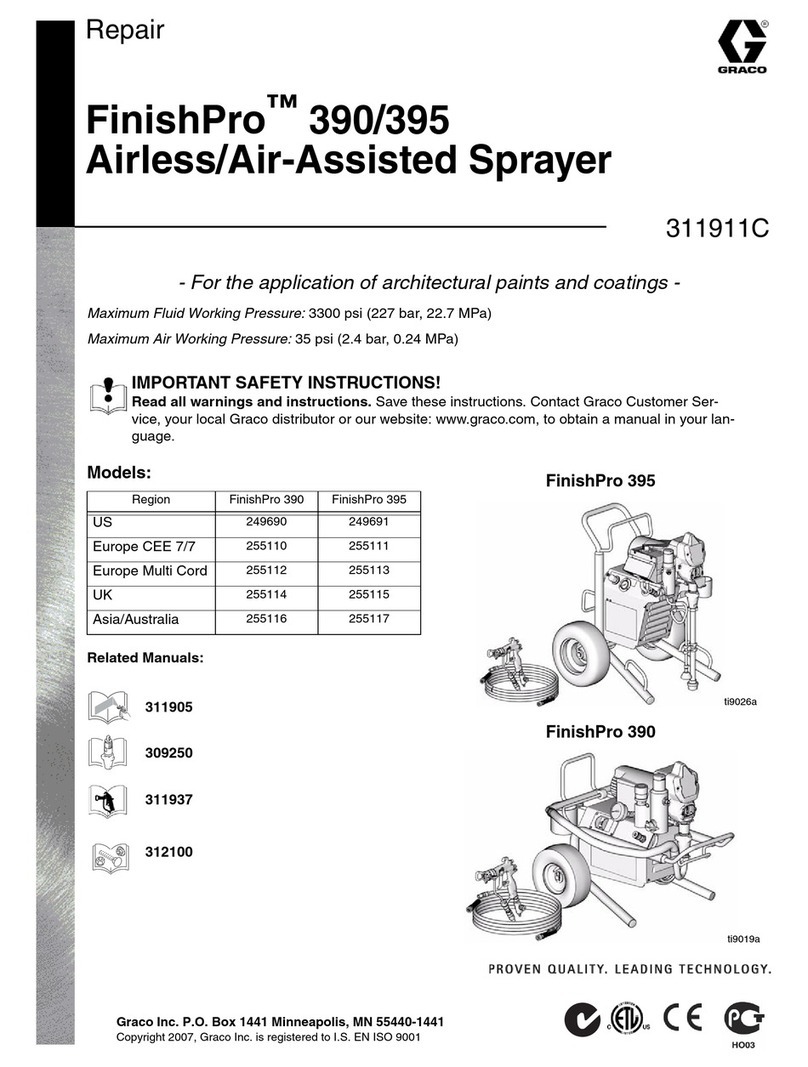

Graco FinishPro 311911C Operating instructions

Graco

Graco 805-074 Series A User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual