SUB Universal, SBB boiling, JB and PB unstirred water baths

Part No. 15133/Issue 14 Page 6 January 2010

2.2.4 PB

Fit the mains cable into the IEC power socket on the rear of the unit.

Fill the bath with water. The minimum level is 10mm above the top of the perforated tray and

the maximum level is 40 mm from the top when bath is fully loaded.

A lid or layer of polypropylene spheres must be used with baths above 60C.

Plug in and switch on power to the unit.

Fit the unit inside the raised edges of the plastic case at one end of the bath.

3 Operation

3.1 SUB baths

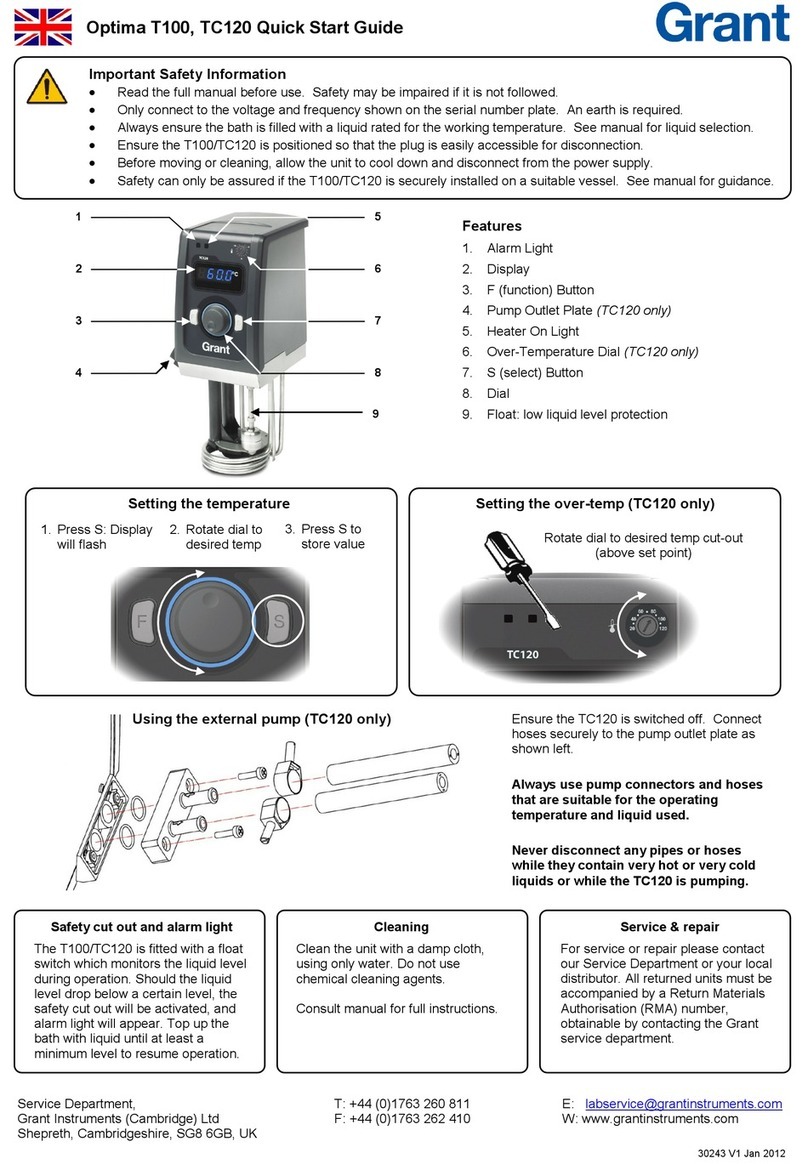

3.1.1 Controls and indicator lamps

The temperature display shows the water temperature in C.

Set temperature control knob sets the required operating temperature.

Display set temp shows set temperature when pressed.

Heater lamp (orange) indicates when the heater is on.

The heater lamp is on continuously while the water is heating up. As the required temperature

is approached, it starts to flash. When the unit is controlling at set temperature, the heater

lamp flashes intermittently.

Alarm lamp (red) illuminates when the over temperature cut-out has operated.

The set over temperature control sets the operating point of the over temperature cut-out.

The cut-out operates if the bath temperature rises above the temperature at which the cut-out

is set. When it has operated, the red alarm lamp illuminates and the heater is switched off.

The temperature continues to be displayed to warn of possible high temperatures.

3.1.2 Setting the temperature

The display normally shows the water temperature. To show the set temperature at any time,

press the display set temp button. To set the required operating temperature, push the

display set temp button, whilst turning the set temperature control knob until the required

temperature is indicated on the display.

3.1.3 Setting the over temperature cut-out

To protect both the unit and your samples, the over temperature cut-out should be set each

time the required operating temperature is changed. Using a screwdriver, adjustment is via

the hole in the push to reset knob. Turn the control fully clockwise and press to reset. The

cut-out is now set at its maximum. Allow the bath to stabilise at the required operating

temperature. Turn the control slowly anticlockwise using the screwdriver until the red alarm

lamp comes on. Press the outer knob to reset and slowly turn the control clockwise until the

alarm lamp goes out. Turn the control anticlockwise three quarters of the way back towards

the point where the alarm lamp came on. The over temperature cut-out is now set

approximately 10°C above the required operating temperature.

Note: If the required operating temperature is above 95°C turn the control fully clockwise.

3.1.4 Resetting the over temperature cut-out

If the over temperature cut-out has operated, the bath needs to cool to below the set

temperature before the cut-out can be reset. Reset by pushing the outer knob.