GREAT PLAINS 2400TM Guide

Other GREAT PLAINS Farm Equipment manuals

GREAT PLAINS

GREAT PLAINS Nutri-Pro NP40A User manual

GREAT PLAINS

GREAT PLAINS 3N-4010F Series User manual

GREAT PLAINS

GREAT PLAINS 3N-3010 User manual

GREAT PLAINS

GREAT PLAINS SPARTAN II NTA607-2-3275 User manual

GREAT PLAINS

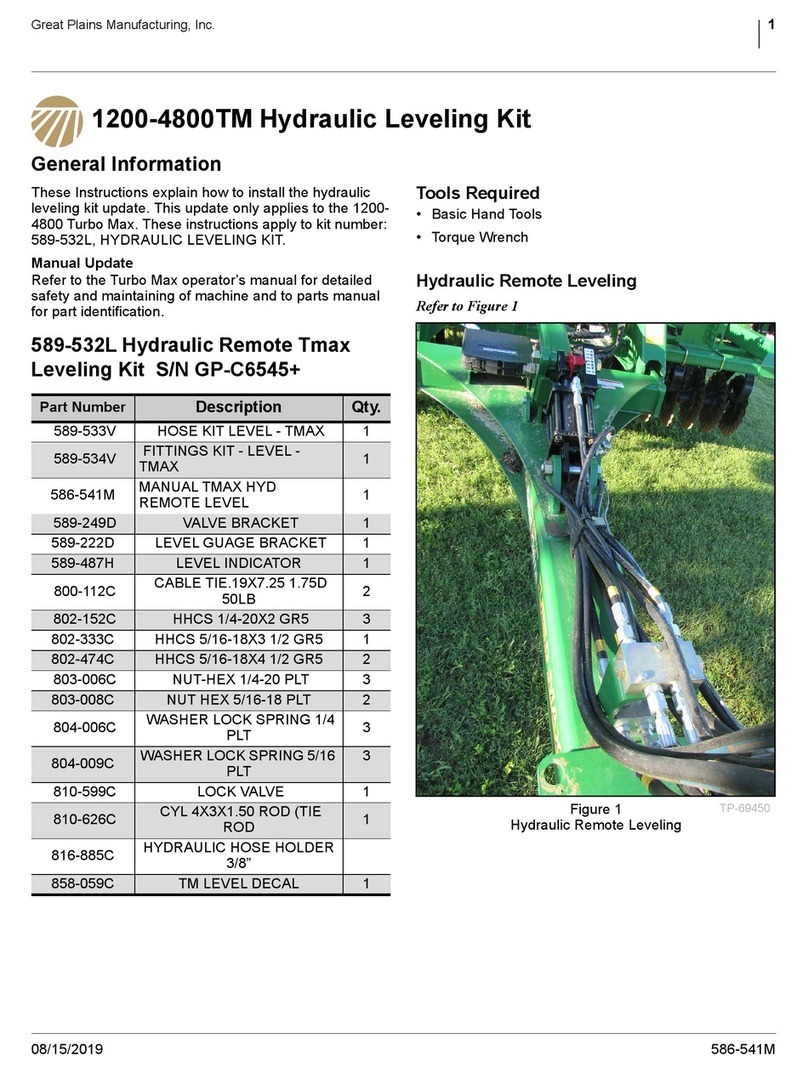

GREAT PLAINS 1200-4800TM User manual

GREAT PLAINS

GREAT PLAINS 1510HDF User manual

GREAT PLAINS

GREAT PLAINS VT1100-35 Turbo Max User manual

GREAT PLAINS

GREAT PLAINS VT1100-40 Turbo Max User manual

GREAT PLAINS

GREAT PLAINS NO-TILL Air DRILL User manual

GREAT PLAINS

GREAT PLAINS VT1100 Turbo Max User manual

GREAT PLAINS

GREAT PLAINS 7000 Series User manual

GREAT PLAINS

GREAT PLAINS 3P605NT User manual

GREAT PLAINS

GREAT PLAINS Turbo Max VT1110-7.5M User manual

GREAT PLAINS

GREAT PLAINS CPH Product manual

GREAT PLAINS

GREAT PLAINS YP-625 User manual

GREAT PLAINS

GREAT PLAINS BD7600 User manual

GREAT PLAINS

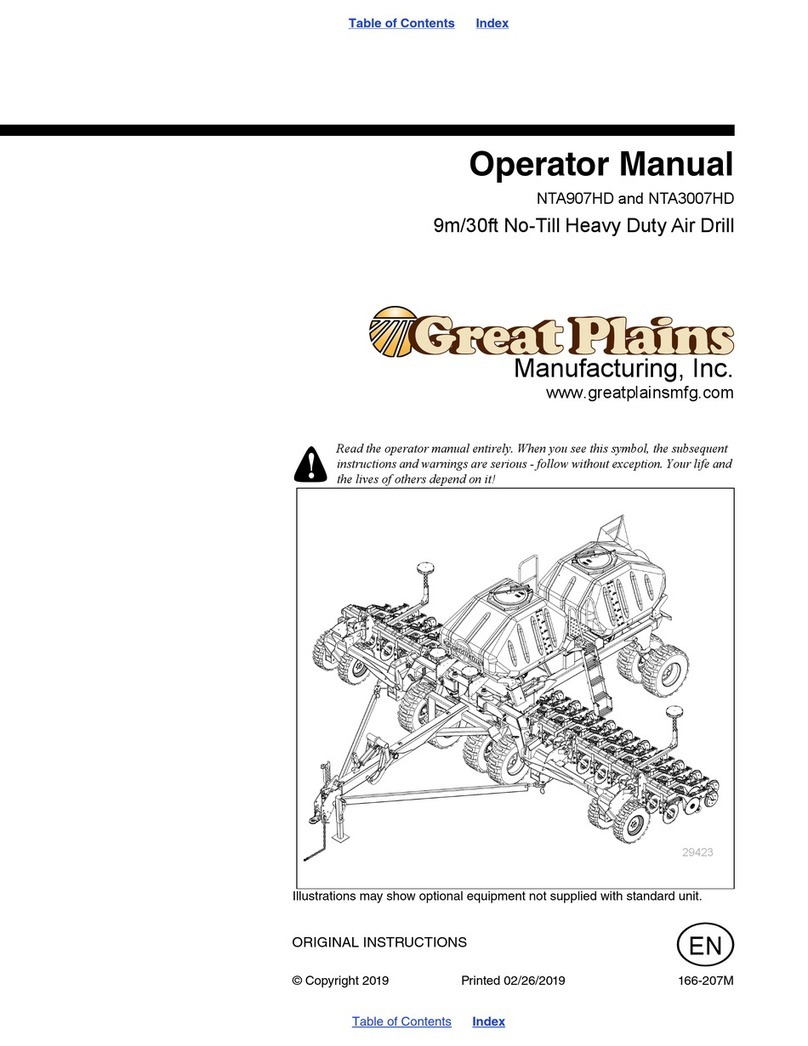

GREAT PLAINS NTA907HD User manual

GREAT PLAINS

GREAT PLAINS RC2515 User manual

GREAT PLAINS

GREAT PLAINS 8321DV Guide

GREAT PLAINS

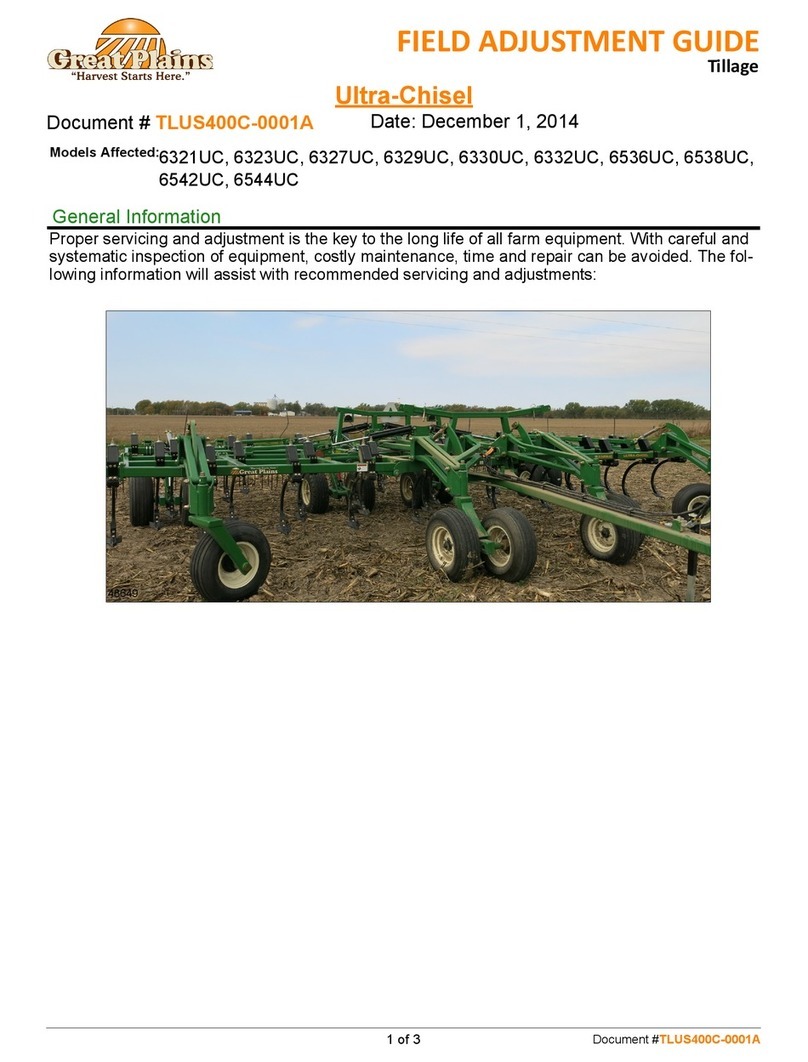

GREAT PLAINS 6321UC Guide