H47.0.01.6C-03 Operating Manual GMH1150 Page 4 of 6

3.2 Operation and maintenance advice

•Battery operation

Make sure to apply correct operating voltage as low or damaged battery will lead to measuring inaccura-

cies. If "BAT" is shown in the display or are the measurements obviously wrong the battery has been used

up and needs to be replaced.

Please note: If the battery voltage falls even lower the voltage may not be sufficient for "BAT" to be dis-

played so that there will be no "BAT" indication although the battery has been used up. We recommend to

make it a rule to always check the battery if the values indicated seem to be completely out of range.

The battery has to be taken out, when storing device above 50 °C.

We recommend taking out battery if device is not used for a longer period of

time.

Mains operation with power supply

When using a power supply please note that operating voltage has to be 10 to 12 V DC.

Do not apply overvoltage!! Cheap 12V-power supplies often have excessive no-load voltage.

We, therefore, recommend using regulated voltage power supplies.

Trouble-free operation is guaranteed by our power supply GNG10/3000.

Prior to connecting the power supply to the mains makes sure that the operating voltage stated at the

power supply is identical to the mains voltage.

Treat device carefully. Use only in accordance with above specification. (do not throw, hit against etc.).

Protect plug and socket from soiling.

Make sure that sensor and device are always subjected to the same temperature, i.e. try to avoid hold-

ing sensor plug in your hand for a longer period of time as well as subjecting device to an additional

heat source as this may result in measuring inaccuracies.

The length of measuring sensor (GTF 300) can be reduced as desired so that it will be fully operational

again after sensor has been broken. To do so, please strip both wire ends for approx. 10mm and twist

well. Measurements are not possible as long as wire ends are exposed.

4 Recalibration

The measuring device will be calibrated before leaving our works. A recalibration is, therefore, not

necessary. If you want to calibrate the device for an existing sensor, please proceed as follows: (calibrate

0°C before scale as otherwise correct adjustment cannot be guaranteed)

Normally sensor adjustment by means of 0° C potentiometer is sufficient.

We do not recommend scale compensation in order to maintain the

specified accuracy of the device. If an accurate reference temperature is

available, choose highest temperature possible to calibrate the device.

Calibration point 0°C: Put ice cubes in a glass and pour cold water till ice

cubes are almost covered. Put sensor into glass, wait approx. 15 minutes,

then stir water with a spoon handle. Wait for stable value to be displayed,

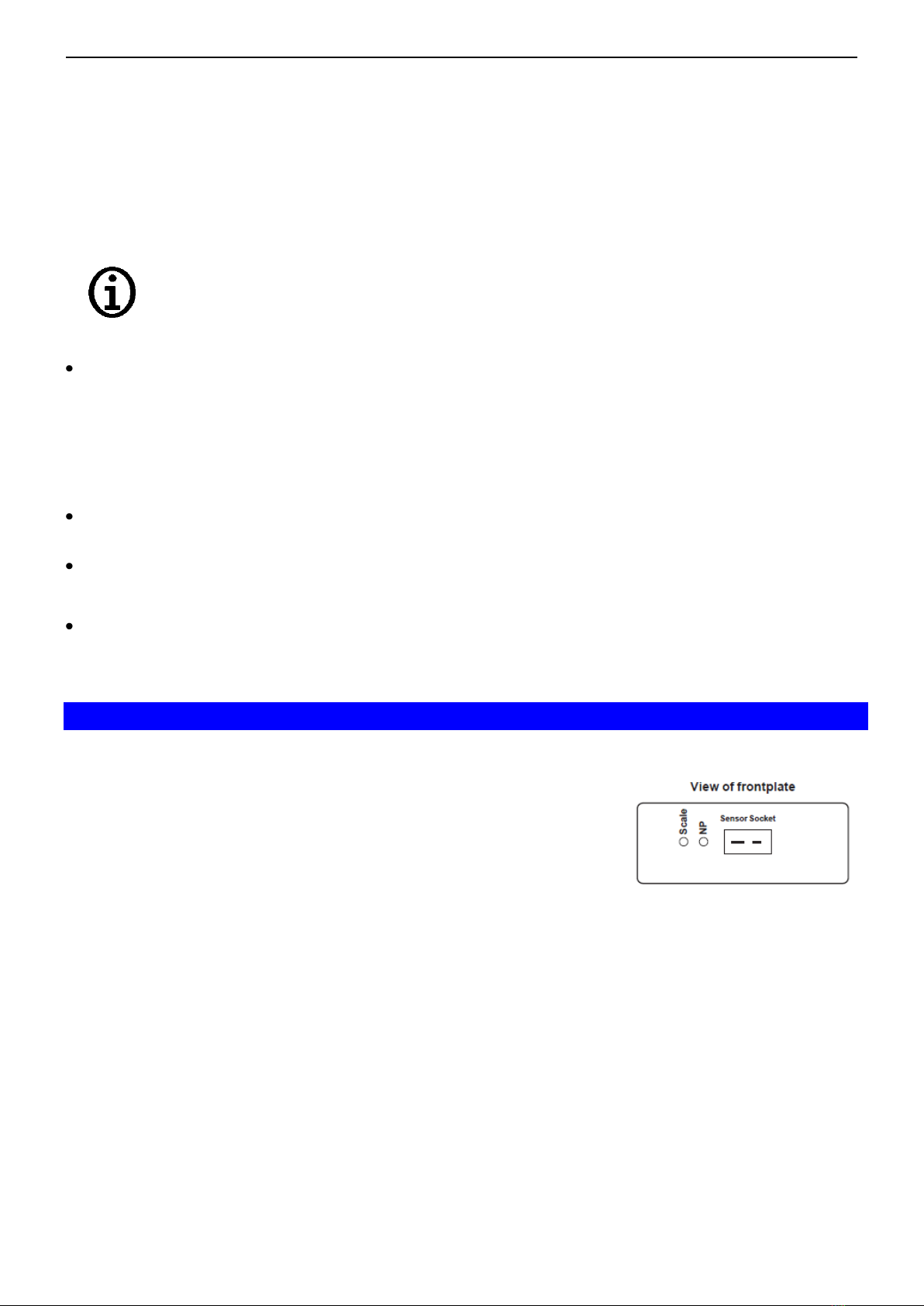

then turn zero point potentiometer (NP, Potentiometer next to sensor connection)

by means of a screw driver till display shows "000”.

Calibration point scale: To set the pitch (Scale) a fixed reference temperature is

required (the higher the better). Subject sensor to this temperature and set respective display value ac-

cording to correction table value (e.g. reference temperature 700°C -> value to be set: 711) by means of

pitch potentiometer (outer potentiometer).

Please note that boiling water should not be used as a temperature reference as the boiling temperature

is dependent on the atmospheric pressure. (If using a reference thermometer stating the precise tempera-

ture you may, however even use boiling water.)

Please note: During the waiting time the device should have assumed ambient temperature (we recom-

mend a temperature of 20 to 25°C). Please avoid holding device in your hand as well as subjecting it to

an additional heat source (e.g. radiator, lamp, sun).