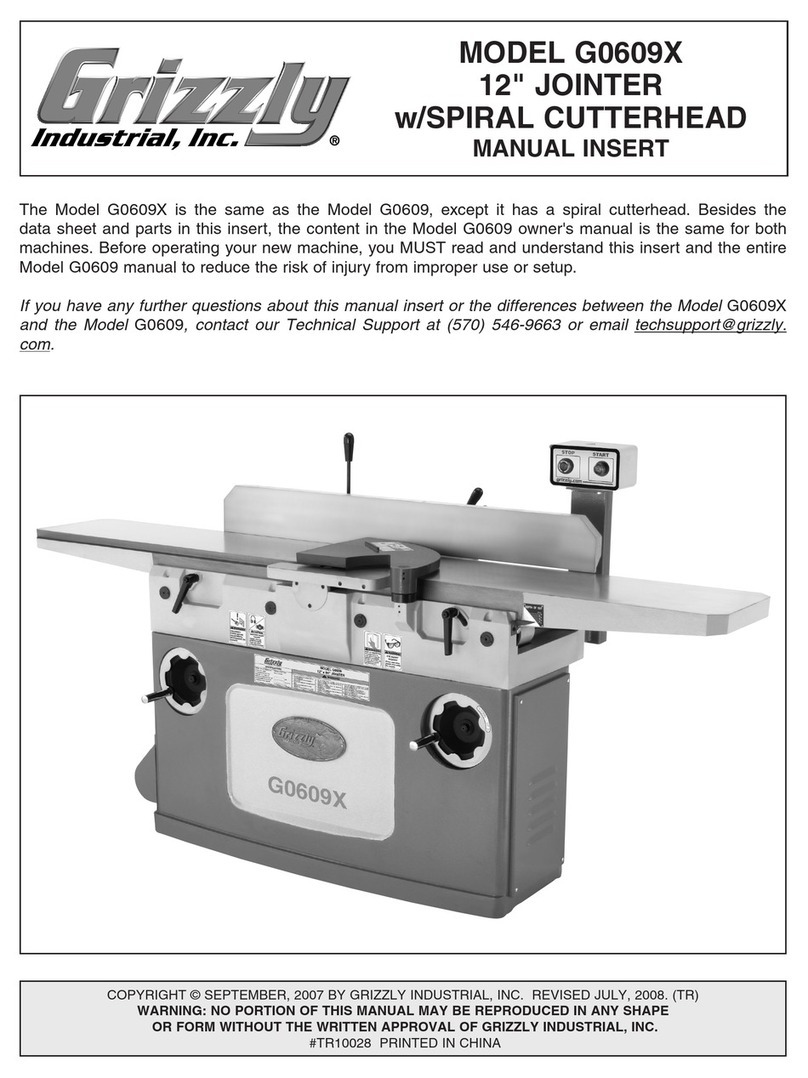

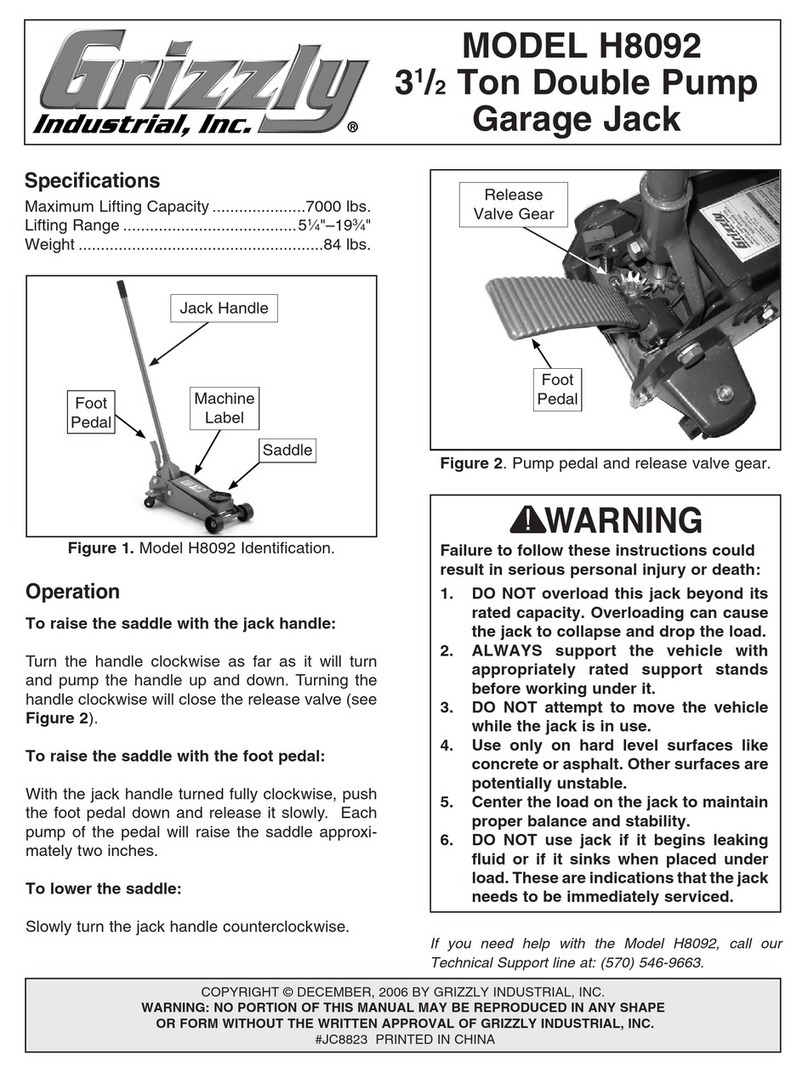

Figure 8. Rotating indexable carbide inserts.

Reference Dot

T32057 8" Helical Cutterhead Assembly -5-

Installing or adjusting a carbide insert:

1. DISCONNECT MACHINE FROM POWER!

2. Remove any sawdust from head of carbide

insert Torx screw.

3. Remove Torx screw and carbide insert.

4. Clean all dust and dirt off insert and cutterhead

pocket from which insert was removed, and

replace insert so a fresh, sharp edge is facing

outward.

Note: Proper cleaning is critical to achiev-

ing a smooth finish. Dirt or dust trapped

between insert and cutterhead will slightly

raise insert, and make noticeable marks on

your workpieces the next time you cut.

5. Lubricate Torx screw threads with a light

machine oil, wipe excess oil off threads, and

torque Torx screw to 48-50 INCH pounds.

Note: Excess oil may squeeze between insert

and cutterhead or in screw hole, thereby lifting

insert or screw slightly and affecting work-

piece finishes.

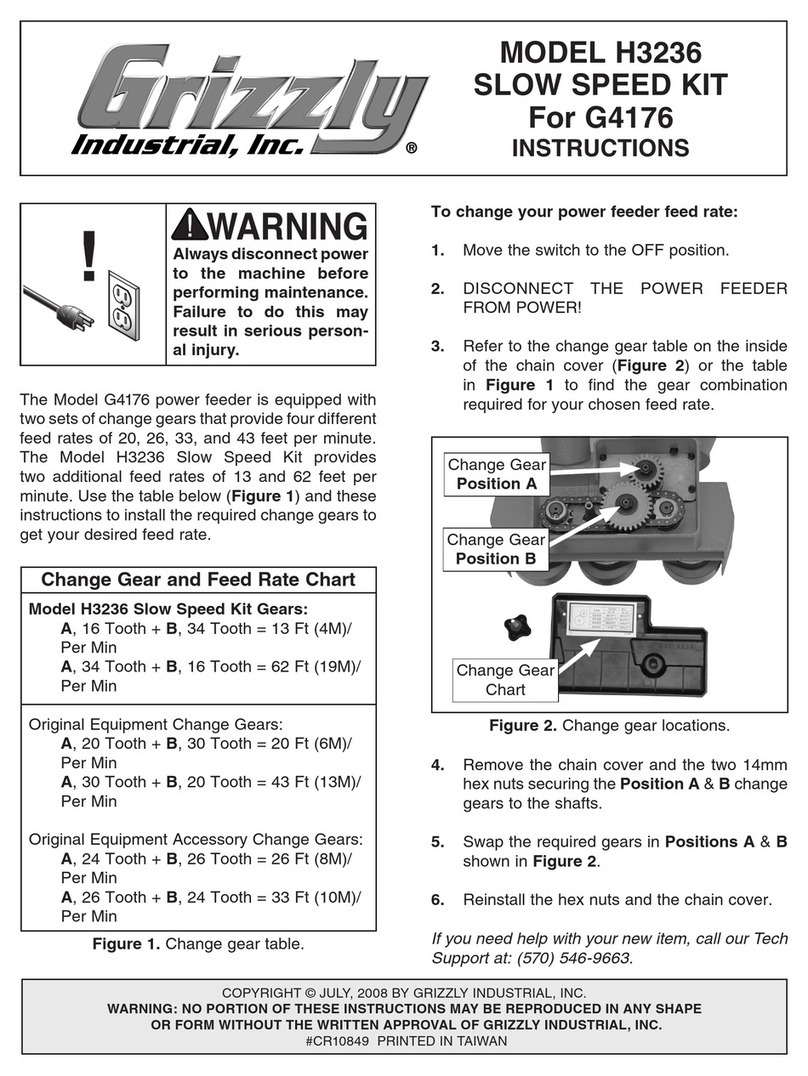

In addition, each insert has a reference dot on

one corner. As the insert is rotated, the reference

dot location can be used as an indicator of which

edges are used and which are new. The insert

must be replaced when all four edges are dull.

Rotating Inserts

The cutterhead is equipped with 36 indexable car-

bide inserts. Each insert can be rotated to reveal

any one of its four cutting edges. Therefore, if one

cutting edge becomes dull or damaged, simply

rotate it clockwise 90˚ to reveal a fresh cutting

edge (see Figure 8).

Tools Needed

• Pair of Heavy Leather Gloves ..................... 1

• Safety Glasses (per person) ........................ 1

• T-Handle Torx Driver T25 ........................... 1

• Torque Wrench 0–50 in.-lb. ......................... 1

• Shop Rag .................................... As Needed

• Degreaser .................................... As Needed

• Light Machine Oil ........................ As Needed