6 OM-GSSP-BL-E BOILERLESS STEAMER

CLEANING

WARNING: DISCONNECT THE POWER SUPPLY BEFORE CLEANING THE OUTSIDE OF THE

STEAMER.

KEEP WATER AND CLEANING SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER HOSE OR STEAM CLEAN ANY PART OF

THE UNIT.

AVOID CONTACT WITH ANY CLEANERS, DELIMING AGENT OR DEGREASER

AS RECOMMENDED BY THE SUPPLIER. MANY ARE HARMFUL. READ THE

WARNINGS AND FOLLOW THE DIRECTIONS!

EVEN WHEN THE UNIT HAS BEEN SHUT OFF, DON’T PUT HANDS OR TOOLS

INTO THE STEAMING CHAMBER UNTIL THE FAN HAS STOPPED TURNING.

DON’T OPERATE THE UNIT UNLESS THE REMOVABLE STEAM LID HAS BEEN

PUT BACK IN ITS PROPER LOCATION.

DON’T USE ANY CLEANING AGENT THAT CONTAINS ANY SULFAMIC AGENT

OR ANY CHLORIDE,INCLUDING HYDROCHLORIC ACID (HCL). TO CHECK FOR

CHLORIDE CONTENT SEE ANY MATERIAL SAFETY DATA SHEETS PROVIDED

BY THE CLEANING AGENT MANUFACTURER.

IMPORTANT

:

DO NOT USE ANY METAL MATERIAL (SUCH AS METAL SPONGES) OR METAL

IMPLEMENTS (SUCH AS A SPOON, SCRAPER OR WIRE BRUSH) THAT

MIGHT SCRATCH ANY STAINLESS STEEL SURFACE. SCRATCHES MAKE THE

SURFACE HARD TO CLEAN AND PROVIDE PLACES FOR BACTERIA TO GROW.

DO NOT USE STEEL WOOL, WHICH MAY LEAVE PARTICLES EMBEDDED IN THE

SURFACE, WHICH COULD EVENTUALLY CAUSE CORROSION AND PITTING.

WARNING: ALLOW THE STEAMER TO COOL COMPLETELY BEFORE CLEANING. HOT

SURFACES CAN CAUSE SEVERE BURNS.

WARNING: FAILURE TO CLEAN THE STEAMER AS SPECIFIED COULD NEGATIVELY

IMPACT THE PERFORMANCE OF THE STEAMER OR WILL NOT ALLOW UNIT

TO HEAT.

To keep your Boilerless Steamer in proper working condition, use the following

daily procedure to clean the unit.This regular manual cleaning will reduce the time

and effort required to clean the water reservoir and cavity.

SUGGESTED SUPPLIES

1. Mild detergent

2. Stainless steel exterior cleaner

3. Cloth or sponge

4. Brush with soft bristles

5. Spray bottle

6. Measuring cup

7. Nylon pad

8. Towels

9. Plastic disposable gloves

10. Funnel

EXTERIOR CLEANING

1. Prepare a warm solution of the mild detergent as instructed by the supplier.

Wet a cloth with this solution and wring it out. Use the moist cloth to clean the

outside of the unit. Do not allow freely running liquid to touch the controls, the

control panel, any electrical part, or any louver on the rear panels.

2. To remove material which may be stuck to the unit, use a ber brush or a

plastic or rubber scraper with a mild detergent solution.

3. Stainless steel surfaces may be polished with a recognized stainless steel

cleaner. Do not scrub across the grain of any stainless steel.

INTERIOR CLEANING

Daily cleaning must be done in order to enhance the performance and prolong the

life of your Boilerless Steamer.

1. Press the power button to off and open steamer door.Allow the steamer to cool

completely before cleaning.

2. Remove steam lid by grasping the horizontal ange located on the lid front and

sliding pan forward. Wear heat resistant hand coverings if the steam lid is hot.

3. Remove left pan rack by lifting rack up and pulling away from cavity wall.

4. Remove right fan shroud and rack assembly by lifting rack up and pulling

away from cavity wall.

5. Clean steam lid, left pan rack and right pan rack/shroud assembly to remove

food soils. These three parts may be cleaned in a dishwasher.

6. Use a mild detergent to wipe down the entire steamer cavity to remove food

and scale particles. Carefully clean probes if food residue or loose scale is

present.A thin layer of tightly bound scale is normal and will not affect steamer

performance. If scale is excessive, then refer to deliming instructions below.

7. Clean cup and overow drains per instructions in “Cup & Overow Drains”

section.

8. Remove drain strainer and clean thoroughly to remove any build-up of debris.

9. Replace pan racks and steam lid. Steamer is now cleaned and ready to use.

DELIMING

The steamer control monitors the water level probes for cleanliness and to ensure

continuous steamer operation and reduce the need for service repair due to

probe cleaning issues. The control will display an advanced cleaning warning in

the event probe cleaning is required. Despite the warning, the steamer operation

will continue for a limited period of time of 8 hours and countdown clock will

be displayed. The countdown clock indicates how much time is available to the

operator to complete cooking process or regiment before the clock expires and

unit shutdowns automatically.

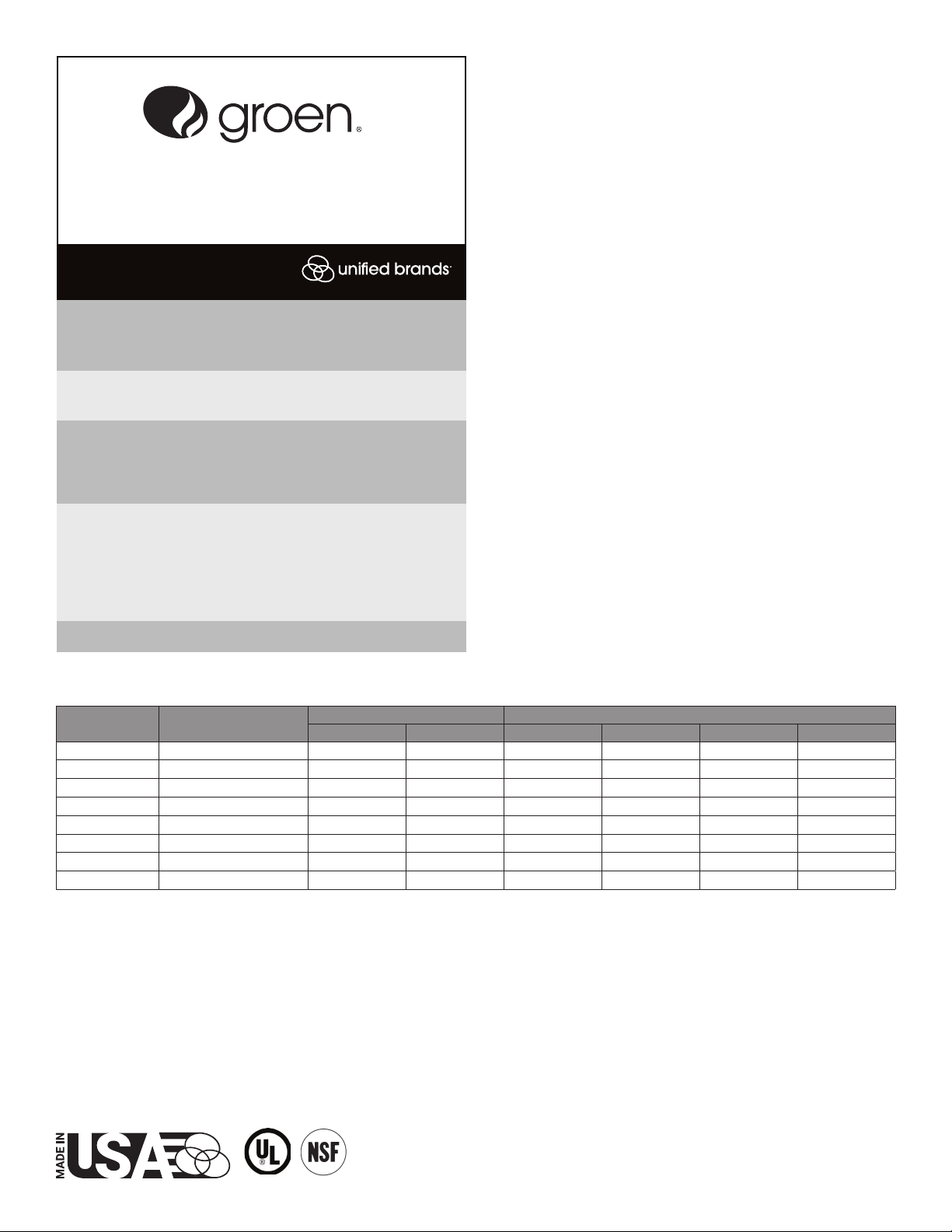

Settings

Performing self-diagnostic

DELIME button is only displayed during startup if the DELIME button is turned to

ON in settings menu. The default setting for DELIME button is OFF. The DELIME

REMINDER will provide you status visuals of where you are in the deliming

schedule. When the reminder is ON, the DELIME button will do the following:

•When 75% of the delime schedule has been reached, the DELIME button will

turn yellow

•When 90% of the delime schedule has been reached, the DELIME button will

turn yellow

•Upon expiration of the DELIME schedule, the DELIME button will turn red

•the DELIME button will return to normal after deliming has been completed or

the reminder is reset

Delime

Prepare Cavity

Remove Fan Shroud, Racks

and Steam lid. Please wait

a few minutes to allow

reservoir to fill with water.

WARNING

Hot Surfaces. Exercise caution

when removing hot components.

Delime

In Progress

Delime process has

begun. Process will take

approximately 60-90

minutes to complete.

Delime

Add Solution

Using caution, add specified

amount of approved

Deliming Solution into

water reservoir. Close door

and press continue.

WARNING

Hot Surfaces. Exercise caution when

touching interior compartment.

Delime

Complete

Allow unit to cool prior to

wiping out interior. Clean all

probes, steam lid, drip cup

and overflow drains. Replace

interior components. Press

restart to use the steamer or

push the Power Button to

turn off the unit.

WARNING

Hot Surfaces. Exercise caution when

touching interior compartment.

Delime

Process Note

Prior to starting the

Delime process, review the

Operator's manual for

detailed instructions and

warnings.