Table of Contents

1 Product Overview .........................................................................................................................................1

1.1 Product Description ..........................................................................................................................1

1.2 Appearance ....................................................................................................................................... 1

1.2.1 Dimension (unit:mm).............................................................................................................1

1.2.2 Introduction to the battery operation panel ..............................................................................2

1.3 Function Introduction ...................................................................................................................... 3

1.4 Battery software upgrade ............................................................................................................... 4

1.4.1 Upgrade via USB ............................................................................................................................ 4

1.4.2 Through inverter remote upgrade ...............................................................................................5

2 Safety ........................................................................................................................................................... 5

2.1 Application ......................................................................................................................................... 5

2.2 Safety Precautions .......................................................................................................................... 6

2.2. 1 Environment requirements ........................................................................................................ 6

2.2.2 Operation and Precautions ..........................................................................................................6

2.3 Warning Labels ................................................................................................................................. 6

2.4 Emergency Responses ................................................................................................................... 8

3 Storage and Transportation ...................................................................................................................... 9

3.1 Storage Requirements ....................................................................................................................9

3.2 Transportation Requirement ..........................................................................................................9

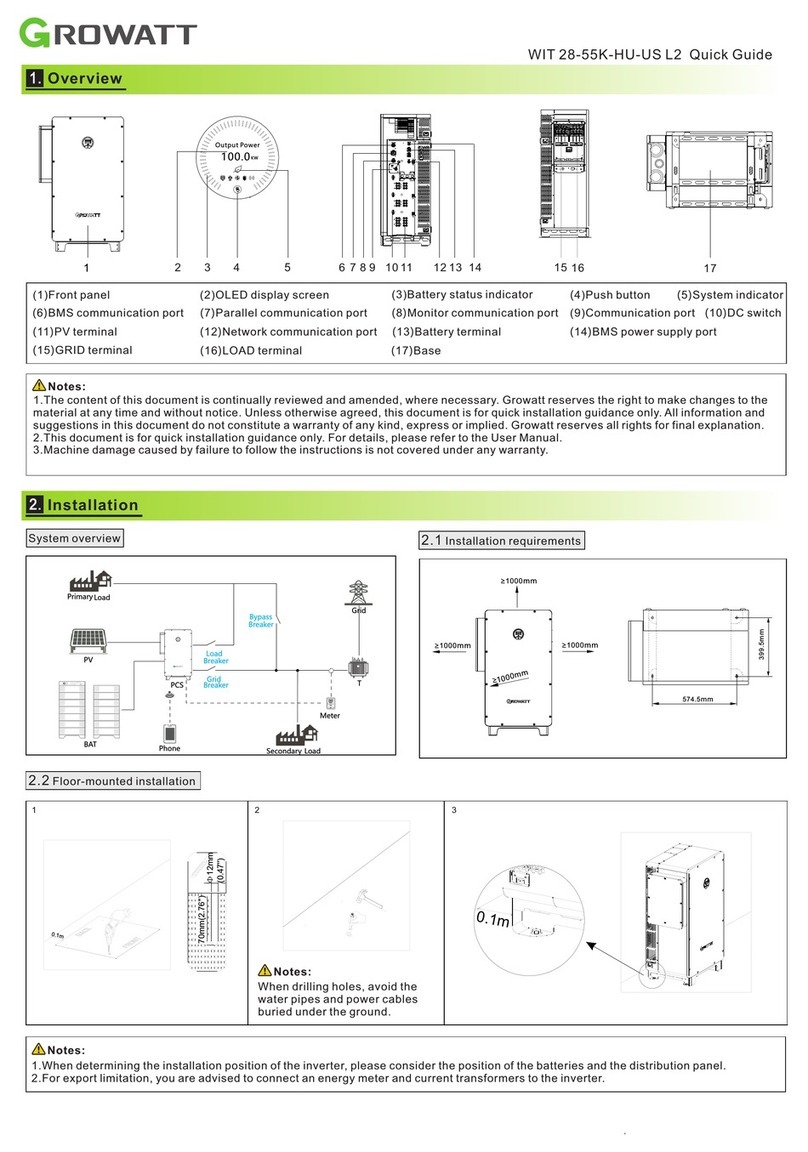

4 Installation .................................................................................................................................................10

4.1 Installation environment ..............................................................................................................10

4.2 Installation Required Tools .......................................................................................................... 10

4.3 Check ............................................................................................................................................. 11

4.3.1 Pre-installation Check ............................................................................................................... 11

4.4.1 Battery Replacement .................................................................................................................13

4.4.2 Electrical Connection (Please refer to the Future-H Series user manual)................. 13

4.4.3 inverter Communication interface definition ....................................................................... 13

5 Power on and off the Battery ................................................................................................................. 14

5.1 Power On ........................................................................................................................................14

5.2 Power off .......................................................................................................................................14

6 Maintenance Guide ................................................................................................................................. 15

System Failure Information List and Troubleshooting Suggestions ..............................................15

7 Technical Specifications ...........................................................................................................................16

Appendix 1 ............................................................................................................................................. 17