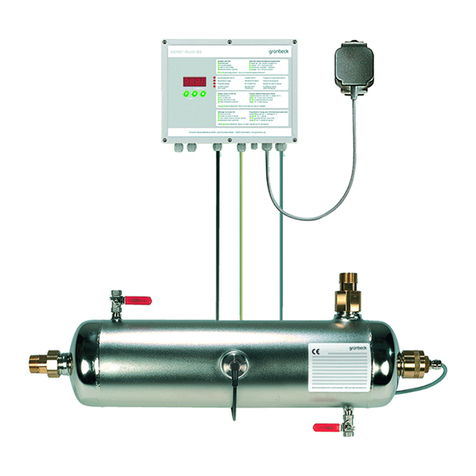

Grunbeck GENO-UV 60 I User manual

Other Grunbeck Water Filtration System manuals

Grunbeck

Grunbeck GENODOS DME 6 User manual

Grunbeck

Grunbeck MXA DN 100 User manual

Grunbeck

Grunbeck violiQ:UV20 User manual

Grunbeck

Grunbeck clearliQ travel User manual

Grunbeck

Grunbeck fermaliQ:MA2000 User manual

Grunbeck

Grunbeck desaliQ basic filling module User manual

Grunbeck

Grunbeck BOXER RX User manual

Grunbeck

Grunbeck FS-B Installation manual

Grunbeck

Grunbeck MXA 1 1/4" User manual

Grunbeck

Grunbeck pureliQ:R User manual

Grunbeck

Grunbeck GENO-mat MN-Z User manual

Grunbeck

Grunbeck pureliQ:K User manual

Grunbeck

Grunbeck GENO-UV User manual

Grunbeck

Grunbeck MR25 User manual

Grunbeck

Grunbeck GENO-mat AK-Z User manual

Grunbeck

Grunbeck GENO-G5 User manual

Grunbeck

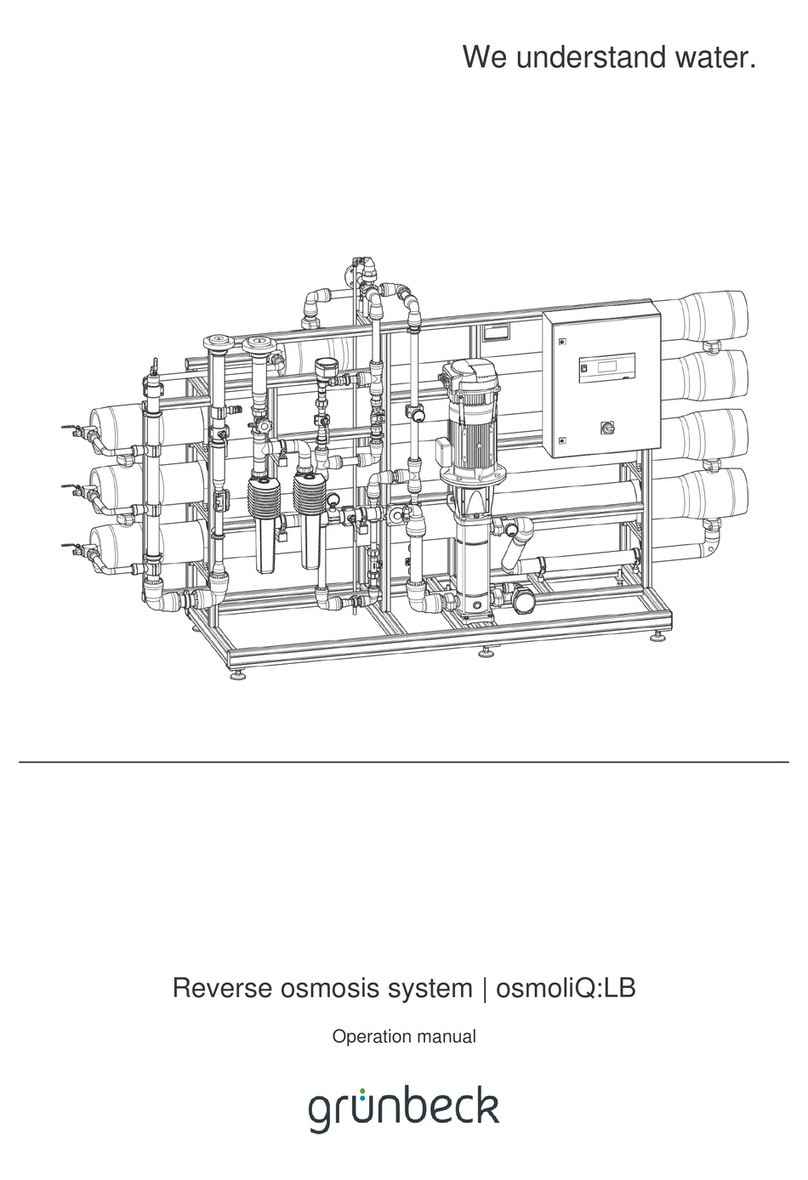

Grunbeck desaliQ:MA User manual

Grunbeck

Grunbeck GENO-OSMO RO 125K User manual

Grunbeck

Grunbeck AVRO 125 TS User manual

Grunbeck

Grunbeck WINNI-mat VGX-N 50 User manual

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual