11

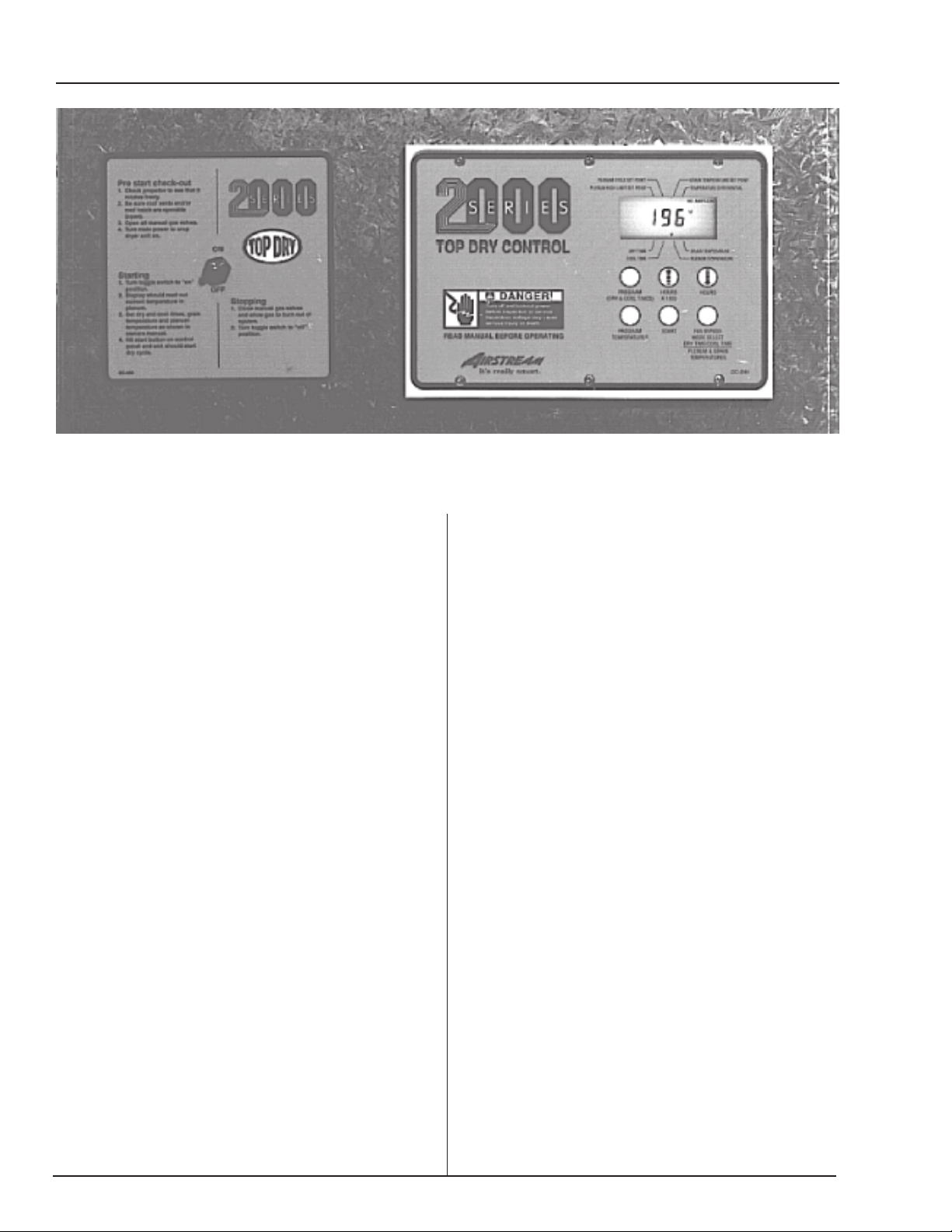

Series 2000 Top Dry Heater Control QUICK START PROCEDURE

1. Raise chutes.

2. Fill drying chamber with grain.

3. Turn toggle switch at fan/heater to "ON" posi-

tion. If using a remote display or economy start,

place that toggle switch to the "ON" position

also.

4. Push "PROGRAM (DRY/COOL TIMES)" but

ton on the series 2000 control panel to enter pro-

gram mode. Arrow should be flashing at lower

left side of screen above "DRY TIME".

5. Set dry time using increase or decrease buttons

as recommended for your grain type and mois-

ture content (see drying rates chart page 20).

6. Push "PROGRAM (DRY/COOL TIMES)" but-

ton to continue to set the cool time. Arrow

should be above "COOL TIME".

7. Set cool time desired by using increase or de-

crease buttons.

8. Push "PROGRAM (DRY/COOL TIMES)" but-

ton to exit programming mode.

9. Push "PROGRAM TEMPERATURES" button

to enter temperature programming mode. Arrow

should be flashing at upper left of screen under

"PLENUM HIGH LIMIT SET POINT".

10. Use the increase or decrease buttons to set ple-

num high limit. High limit should be set 20 de-

grees higher than desired plenum temperature

when drying.

11. Press "PROGRAM TEMPERATURES" button

to continue to set "PLENUM CYCLE SET

POINT".

12. Use the increase or decrease buttons to set ple-

num cycle set point. This is the desired plenum

temperature for normal drying. Use the recom-

mended plenum temperature for your grain type

and moisture content.

13. Press the "PROGRAM TEMPERATURES"

button to continue to set the "GRAIN TEM-

PERATURE SET POINT".

14. Use the increase or decrease buttons to set the

grain temperature set point. On the first batch

20. Monitoring of the plenum, grain temperatures,

dry time and cool times is possible by pressing

the mode select button to alternate between

modes.

21. Immediately after the burner shuts off and the

dryer is in the cool cycle, take note of the cur-

rent grain tempera ture.

22. When the dryer shuts down enter this grain tem-

perature in place of the 140° grain temperature

set point entered earlier.

23. Dump batch.

24. After dumping the batch test the moisture con-

tent of the grain. Average several samples. When

computing moisture content make allowances

for cooling of the grain.

25. If the grain moisture content is lower than de-

sired, lower the dry time by 20% and repeat steps

18-23 again on next batch.

26. If the grain moisture content is higher than de-

sired, increasedry time by 30% and repeat steps

18-23 again on next batch.

27. If the grain moisture content is within the de-

sired range, increase the dry time by 20% on

the next batch. This insures that the burner will

turn off at the proper grain temperature

and allows for a wetter batch.

28. After changing times press the increase and de-

crease buttons at the same time to reset.

the set point should be 140°.

15. Press the "PROGRAM TEMPERATURES"

button to continue to set the "TEMPERATURE

DIFFERENTIAL".

16. Use the increase or decrease buttons to set the

temperature differential. The recommended set

point is 10°.

17. Press the "PROGRAM TEMPERATURES"

button to exit the program mode.

18. Press the increase and decrease buttons at the

same time to reset current settings.

19. Once all times and temperatures have been set

press the start button to begin drying.