GSK983M-H/M-V Milling CNC System Connection Manual

I

CONTENTS

Precautions for Connection ............................................................. 1

1 Interface Layout of the System ....................................................... 3

2 Interface Layout of CPU Board ........................................................ 4

3 Interface Layout of Position Control Board ........................................... 5

4 Interface Layout of I/O Board ........................................................ 6

5 Interface Layout of MDI/LCD Panel .................................................... 7

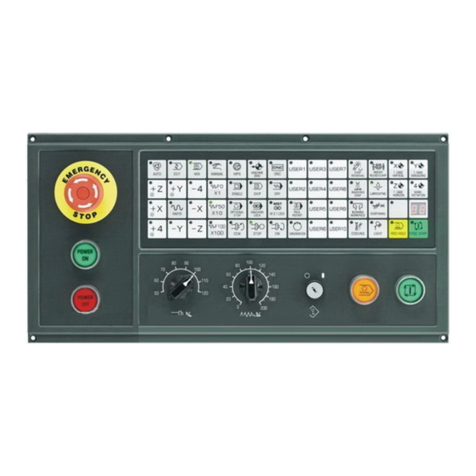

6 Interface of Machine Operator Panel .................................................. 8

7 Connection Layout .................................................................... 9

8 PC Communication cable .............................................................. 10

9 Connection Scheme for External MPG .................................................. 11

10 Signal Cables for Keyboard ......................................................... 12

11 Display Signal Cables .............................................................. 13

12 Communication Cables of Operator Panel ............................................. 14

13 Signal Cables for Connecting DA98D Drive Unit ...................................... 15

14 Z Axis Connecting Holding Cable of DA98D Drive unit ................................ 16

15 Connecting with Spindle Transformer ................................................ 17

16 Spindle Servo Signal Cable Connecting .............................................. 18

17 Installation of spindle orientation in position input signal from mechanical side .. 19

18 Installation of Z axis 2nd reference point in position input signal from mechanical side

...................................................................................... 20

19 Z Axis Hold and Control connecting method with power on ............................ 21

20 External I/O Unit (X1) ............................................................. 22

21 Communication Cables for I/O Unit .................................................. 23

22 I/O Unit (X1) Input/Output Signal Connection Scheme ................................ 24

23 Definition of I/O Unit (X1) Input/Output Interface ................................. 25

Appendix: Installation dimension ...................................................... 28

GSK983M-V Connection Manual Version Upgrade Registration Form ......................... 34