Official GSK Agents in South Africa

Preface & Precaution

VII

SAFETY PRECAUTIONS

■Transportation and Storage

zDo not pile up the carton over 6 layers.

zDo not climb, stand on the carton; do not place heavy objects on it.

zDo not drag or move the products using the cables connected with the product.

zDo not impact, scratch the panel and screen.

zAvoid from the damp, the sunshine and the rain on the product carton.

■Unpacking inspection

zCheck whether it is your purchased product after unpacking the carton.

zCheck whether the product is damaged during transporting.

zCheck whether the components are prepared or damaged comparing with the

packing list.

zIt is necessary to contact our company immediately if the product type is

inconsistent with the packing list, lack of accessories or damage in

transportation.

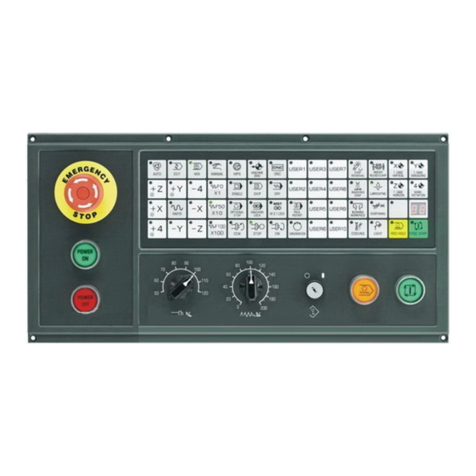

■Wiring

zThe person who executes the wiring and inspection should have the

corresponding professional capacity.

zThe product should be reliably grounded, and its resistance should be less than

0.1Ωand can not be used the neutral conductor (zero cable) to replace the

ground wire.

zThe wiring should be correct and firm, otherwise, possibly causing the

malfunction in product or unexpected result.

zThe surge absorb diode connected with the product should be linked based upon

the described direction, otherwise, it may damage the product.

zBefore Inserting/pulling out the plug or opening the main cabinet of the product, it