GWINNER MEDIA CONCEPT MC969K User manual

Other GWINNER Indoor Furnishing manuals

GWINNER

GWINNER MEDIA CONCEPT User manual

GWINNER

GWINNER TREVISO User manual

GWINNER

GWINNER FELINO Instruction Manual

GWINNER

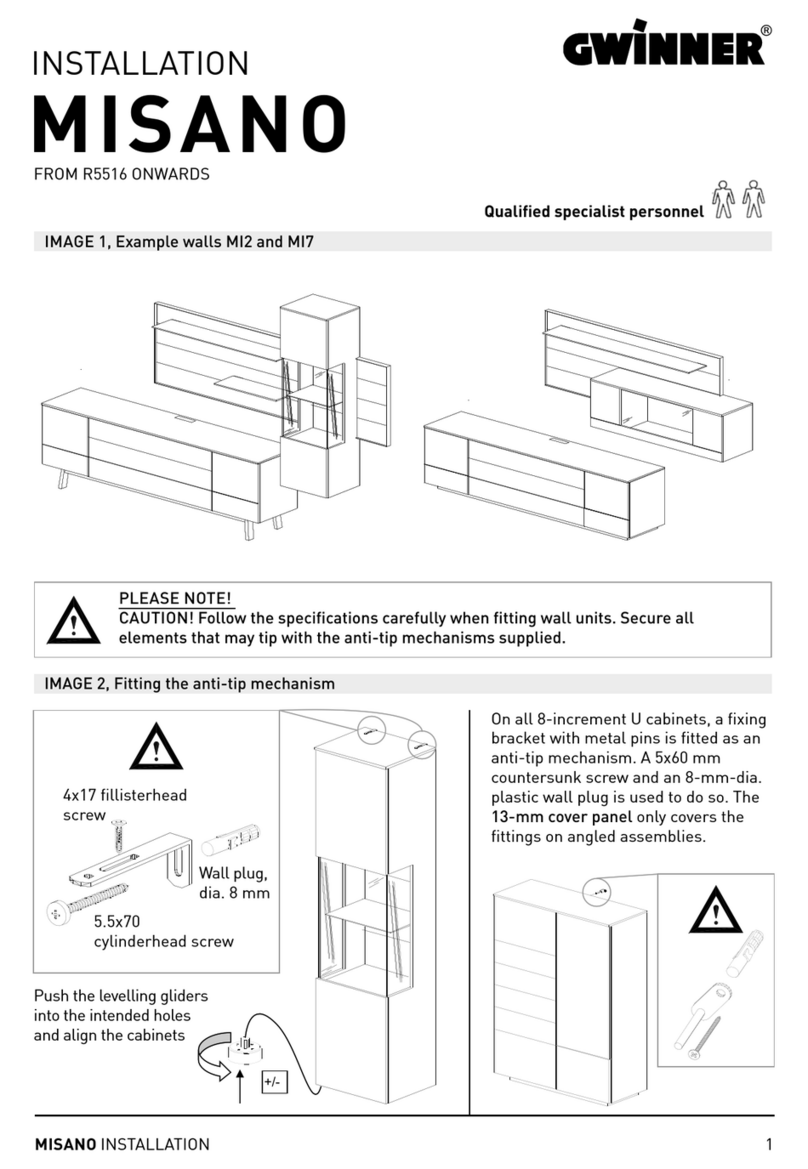

GWINNER MISANO User manual

GWINNER

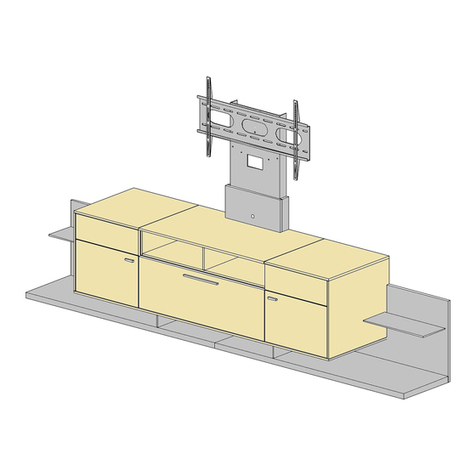

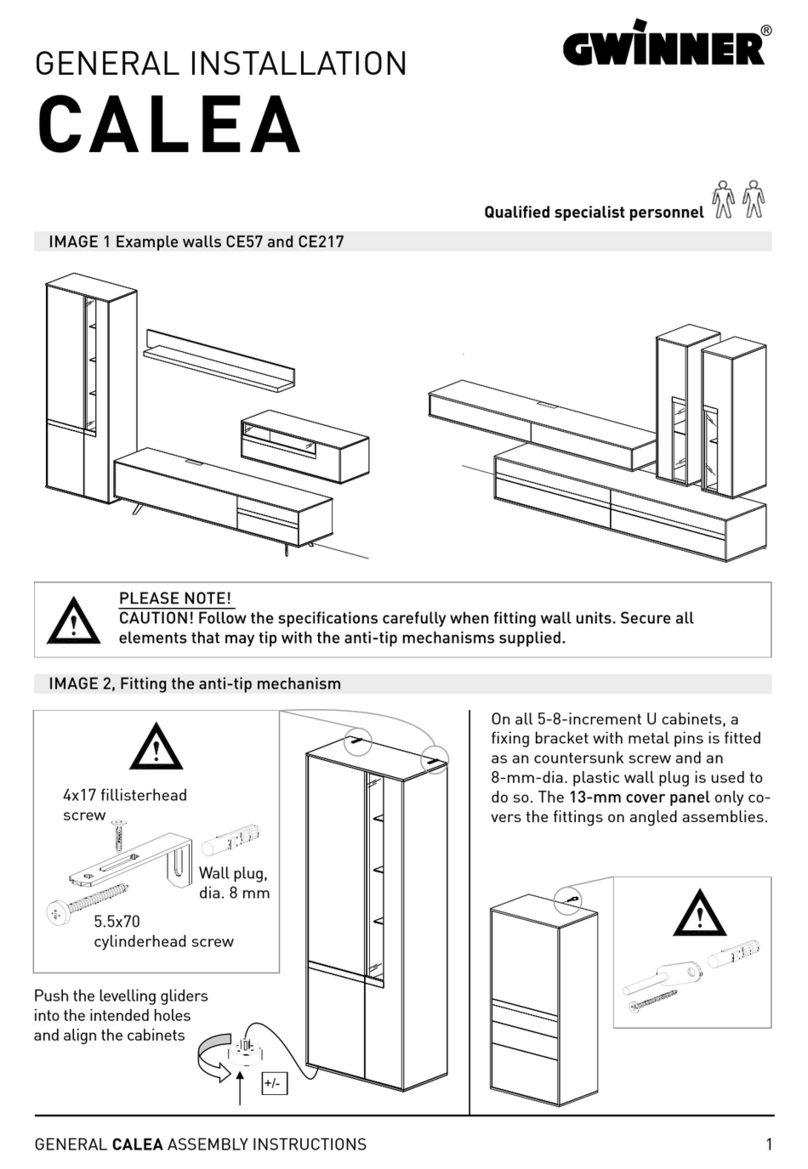

GWINNER CALEA User manual

GWINNER

GWINNER MISANO R5516 User manual

GWINNER

GWINNER ATENA Configuration guide

GWINNER

GWINNER CALEA CE1003 User manual

GWINNER

GWINNER MEDIA CONCEPT SP67 User manual

Popular Indoor Furnishing manuals by other brands

Coaster

Coaster 4799N Assembly instructions

Stor-It-All

Stor-It-All WS39MP Assembly/installation instructions

Lexicon

Lexicon 194840161868 Assembly instruction

Next

Next AMELIA NEW 462947 Assembly instructions

impekk

impekk Manual II Assembly And Instructions

Elements

Elements Ember Nightstand CEB700NSE Assembly instructions