094275_f_gb_zstwin_s haacon hebetechnik gmbh Phone +49 (0) 9375 - 84-0 Fax +49 (0) 9375 - 84-66 1

GB

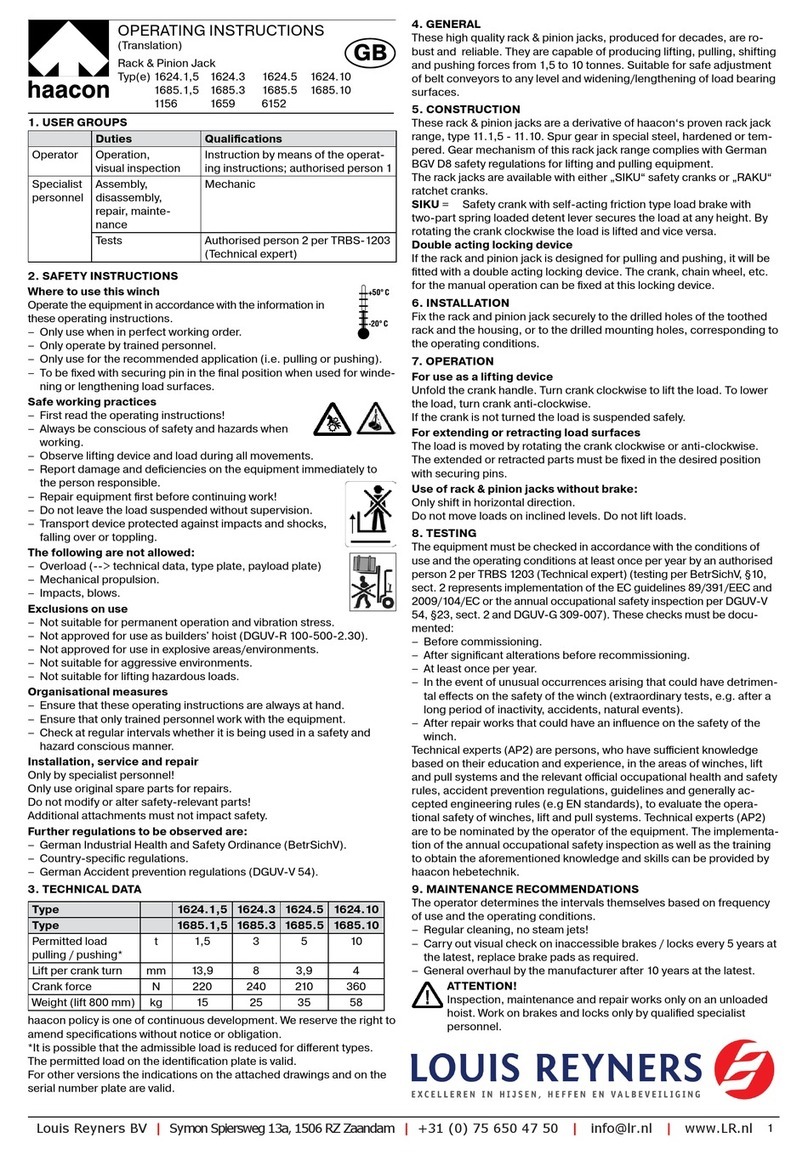

OPERATING INSTRUCTIONS

(Translation)

Rack and pinion jack

Type 1624.10 - 210804

1. USER GROUPS

Duties Qualifications

Operator Operation,

visual inspection

Instruction by means of the operat-

ing instructions; authorised person 1

Specialist

personnel

Assembly,

disassembly, repair,

maintenance

Mechanic

Tests Authorised person 2 per TRBS-1203

(Technical expert)

2. SAFETY INSTRUCTIONS

Intended Use

Only use the rack and pinion jack according to the specifica-

tions contained in the operating instructions.

– Only use for lifting or lowering.

– Only use in a sound technical condition.

– Only to be operated by instructed personnel.

– Only use for the intended application (pulling / pushing).

Safety-conscious working

– First read the operating instructions.

– Always be conscious of safety and hazards when working.

– Observe lifting device and load during all movements.

– Immediately report any damage or defects to the person in charge.

– Repair equipment first before continuing work!

– Do not leave the load suspended without supervision.

– Transport device protected against impacts and shocks,

falling over or toppling.

The following is prohibited:

– Overload (--> technical data, type plate, payload plate)

– Exceeding the maximum lift.

– Impacts, blows.

Use exclusions

– Not suitable for permanent operation and vibration loads.

– Not approved for use as builders' hoist (DGUV-R 100-500-2.30).

– Not approved for use in explosive areas/environments.

– Not suitable for aggressive environments.

– Not suitable for dangerous loads

Organisational means

– Ensuring that these operating instructions are available at all times.

– Ensuring that only instructed personnel works with the rack and

pinion jack.

– Checking at regular intervals whether work is carried out in a safety-

and danger-conscious manner.

Maintenance and repair

Have maintenance and repair work carried out by skilled personnel only.

Only used original spare parts for repairs. Do not carry out any modifi-

cations or conversions on safety-relevant parts.

Additions must not jeopardise the safety of the winch.

Further instructions that must be observed

The rules and regulations valid in the respective country of application in

their respectively valid version have to be observed. In Germany, these

are currently:

– German Industrial Health and Safety Ordinance (BetrSichV)

– Accident Prevention Regulation DGUV-V 54

– DIN 7355 Steel Winches; DIN EN 1494

– EC Directive 2006/42/EC

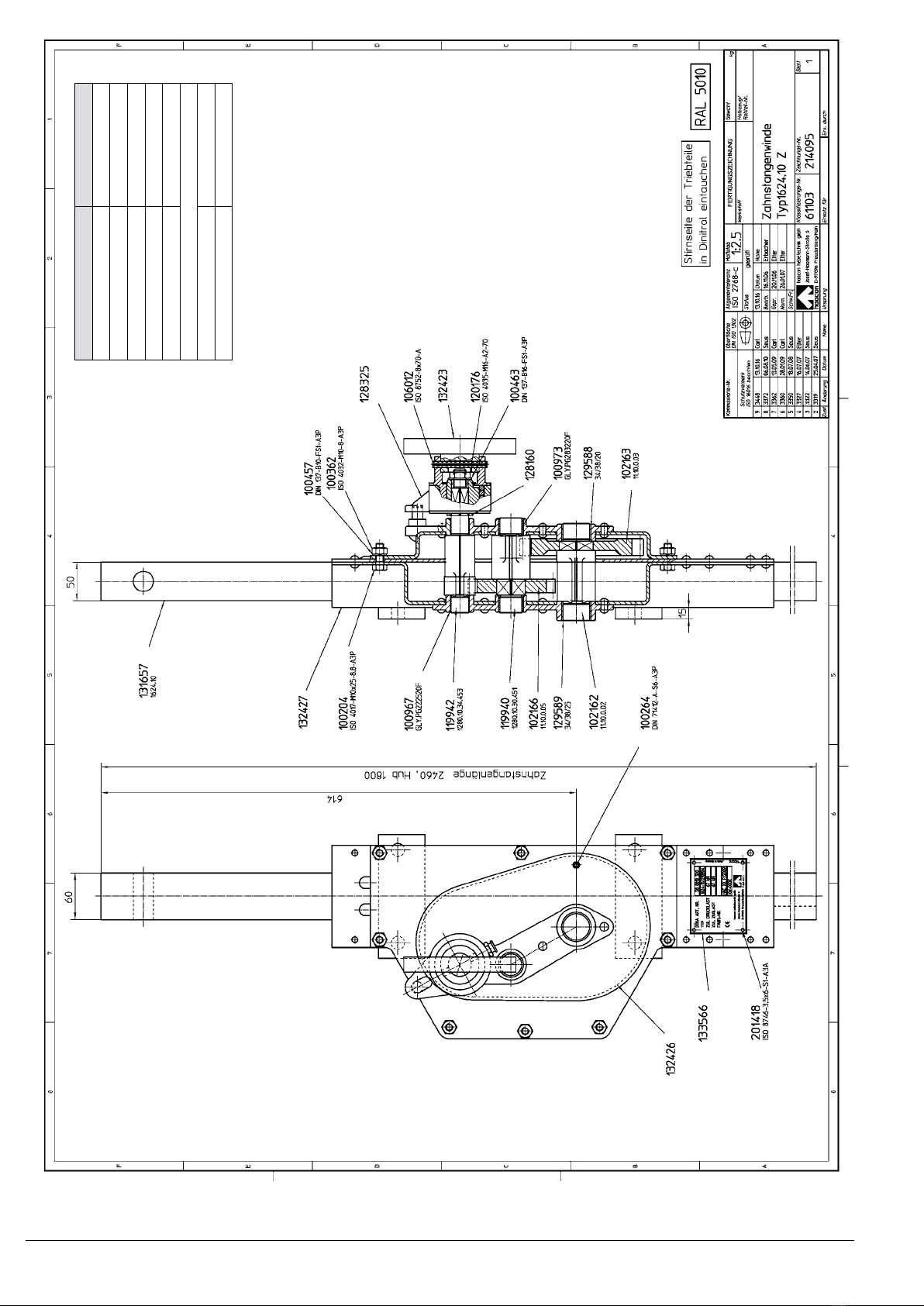

3. TECHNICAL SPECIFICATIONS see drawing.

4. SETUP

Modification of steel winch series type 11. Reliable spur gear made of

high-quality hardened or tempered steel . Equipped with a bilaterally

effective brake head. Complies with the accident prevention regulation

"Winches, lifting and pulling devices“ DGUV-V 54.

The brake head mounted on the winch reliably retains the load in any positi-

on. Clockwise turning raises the load, anticlockwise turning lowers the load.

Two lugs on the shaft and a drilled hole in the rack permit (the custo-

mer) to bolt it to the load to be lifted. The design on hand permits a

motor drive to be mounted onto the brake head.

CAUTION!

The operator is responsible for the safe assembly, the correct

selection of mounted parts, the secure seat of the drive motor

and observance of the permissible speed!

5. OPERATION

Use with motor

Before it is used, securely fasten the winch in the drilled holes intended

for that purpose. Push on the drive such that the winch drive shaft only

has to absorb the torque and no other forces. It must be ensured by

on-site means that the drive is reliably switched off before it reaches its

final position.

CAUTION!

Observe permissible input speed!

Prevent overload using suitable measures.

This applies along the lifting path and on reaching the end of lift.

No permanent operation! Keep the declared load cycle.

6. TESTING

The equipment must be checked in accordance with the conditions

of use and the operating conditions at least once per year by an

authorised person 2 per TRBS 1203 (Technical expert) (testing per

BetrSichV, §10, sect. 2 represents implementation of the EC guidelines

89/391/EEC and 95/63/EC or the annual occupational safety inspection

per DGUV-V 54, §23, sect. 2 and DGUV-G 309-007). These checks

must be documented:

– Before commissioning.

– After significant alterations before recommissioning.

– At least once per year.

– In the event of unusual occurrences arising that could have detrimen-

tal effects on the safety of the winch (extraordinary tests, e.g. after a

long period of inactivity, accidents, natural events).

– After repair works that could have an influence on the safety of the

winch.

Technical experts (AP2) are persons, who have sufficient knowledge

based on their education and experience, in the areas of winches, lift

and pull systems and the relevant official occupational health and safety

rules, accident prevention regulations, guidelines and generally accept-

ed engineering rules (e.g EN standards), to evaluate the operational

safety of winches, lift and pull systems. Technical experts (AP2) are to

be nominated by the operator of the equipment. The implementation

of the annual occupational safety inspection as well as the training to

obtain the aforementioned knowledge and skills can be provided by

haacon hebetechnik.

7. MAINTENANCE RECOMMENDATIONS

The operator determines the intervals themselves based on frequency

of use and the operating conditions.

– Regular cleaning, no steam jets!

– Carry out visual check on inaccessible brakes / locks every 5 years at

the latest, replace brake pads as required.

– General overhaul by the manufacturer after 10 years at the latest.

ATTENTION!

Inspection, maintenance and repair works only on an unloaded

hoist. Work on brakes and locks only by qualified specialist

personnel.

Gears (toothed, pinion)

Intervals Maintenance and inspection work

Daily, or before

every use

Visual inspection and functional testing

After every field

works

Clean the rack jack, check for wear and regrease

Every six months Regrease

Check the fixation points.

Annually Open the gearbox, check the rack jack and the

gear parts for severely worn parts , replace

them if necessary and regrease with lubricating

grease.

Check type plate for legibility

Professional inspection

Lubricant: lithium soap-based grease (acc. to DIN 51502, identificati-

on K3 K-20, by Rhenus.

-20° C

+50° C