Hach Lachat BD40HT User manual

Other Hach Laboratory Equipment manuals

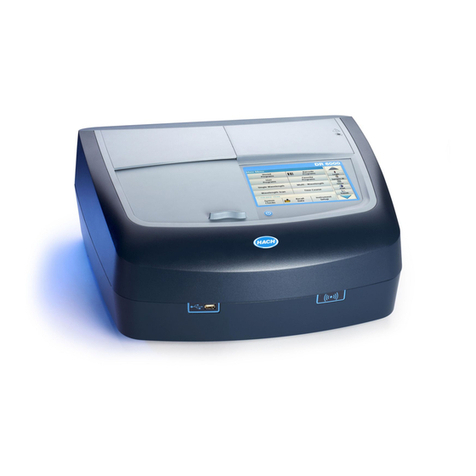

Hach

Hach LZV902 User manual

Hach

Hach LS 120 User manual

Hach

Hach DRB 200 User manual

Hach

Hach SIGMA 900 User manual

Hach

Hach sensION MM340 User manual

Hach

Hach ORBISPHERE 29122 User manual

Hach

Hach sensION+ MM374 User manual

Hach

Hach LT 200 User manual

Hach

Hach AutoCAT 9000 User manual

Hach

Hach TitraLab User manual

Hach

Hach QuikChem 8500 2 Series User manual

Hach

Hach BODTrak II Quick manual

Hach

Hach HQ440d User manual

Hach

Hach AS950 AWRS Instruction Manual

Hach

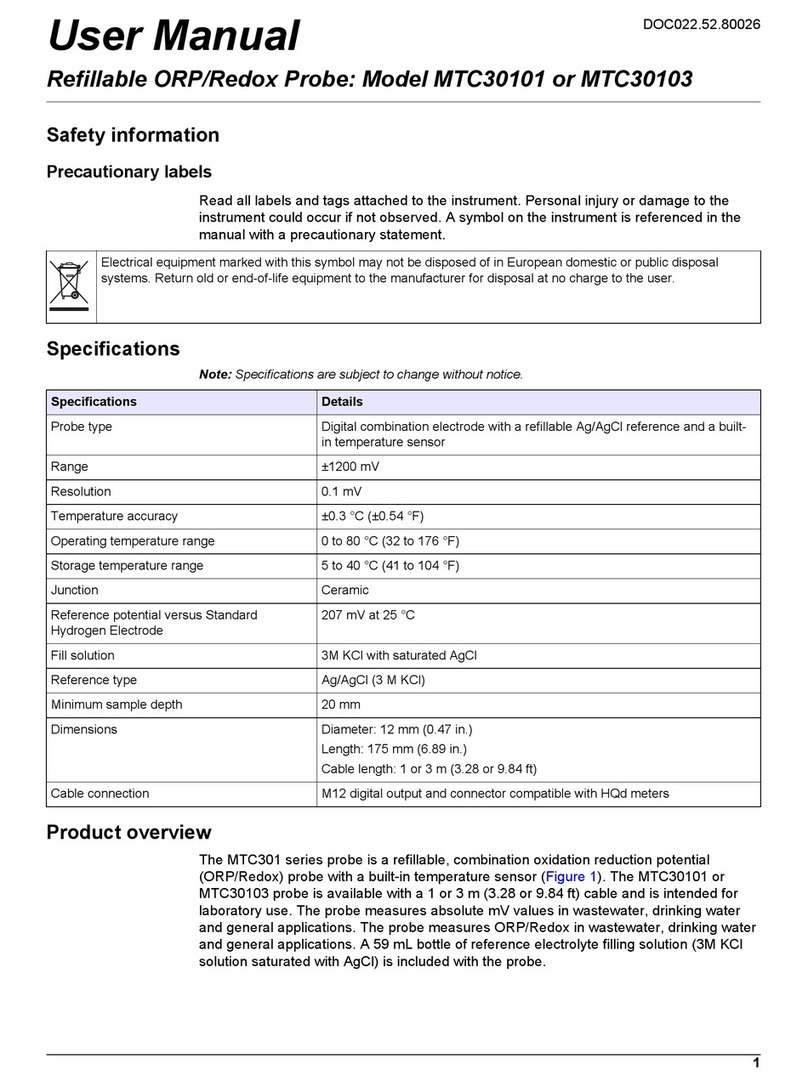

Hach Intellical MTC30101 User manual

Hach

Hach PHC281 User manual

Hach

Hach GANIMEDE P User manual

Hach

Hach sension ph31 User manual

Hach

Hach AS950 AWRS Instruction Manual

Hach

Hach PHC745 User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide