hager hw+ User manual

Other hager Circuit Breaker manuals

hager

hager h3 x160 User manual

hager

hager Quadro 4 FC110 User manual

hager

hager HNE Series User manual

hager

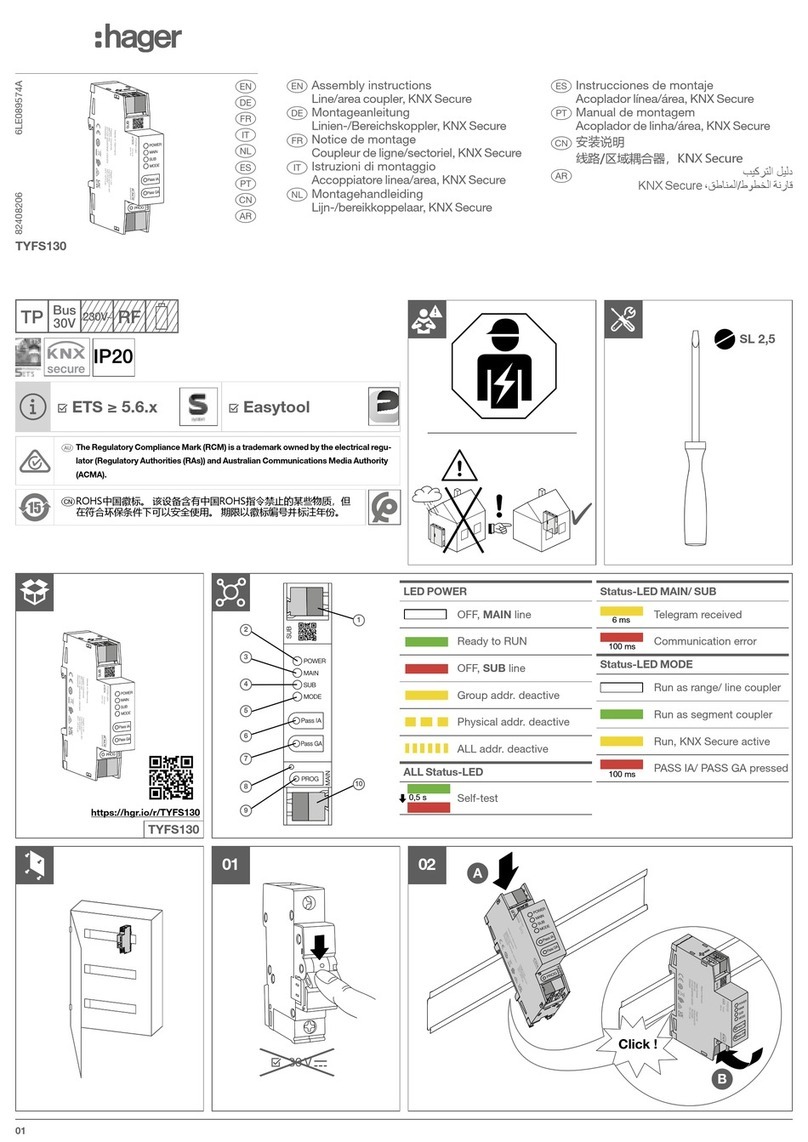

hager TYFS130 User manual

hager

hager CDB D Series User manual

hager

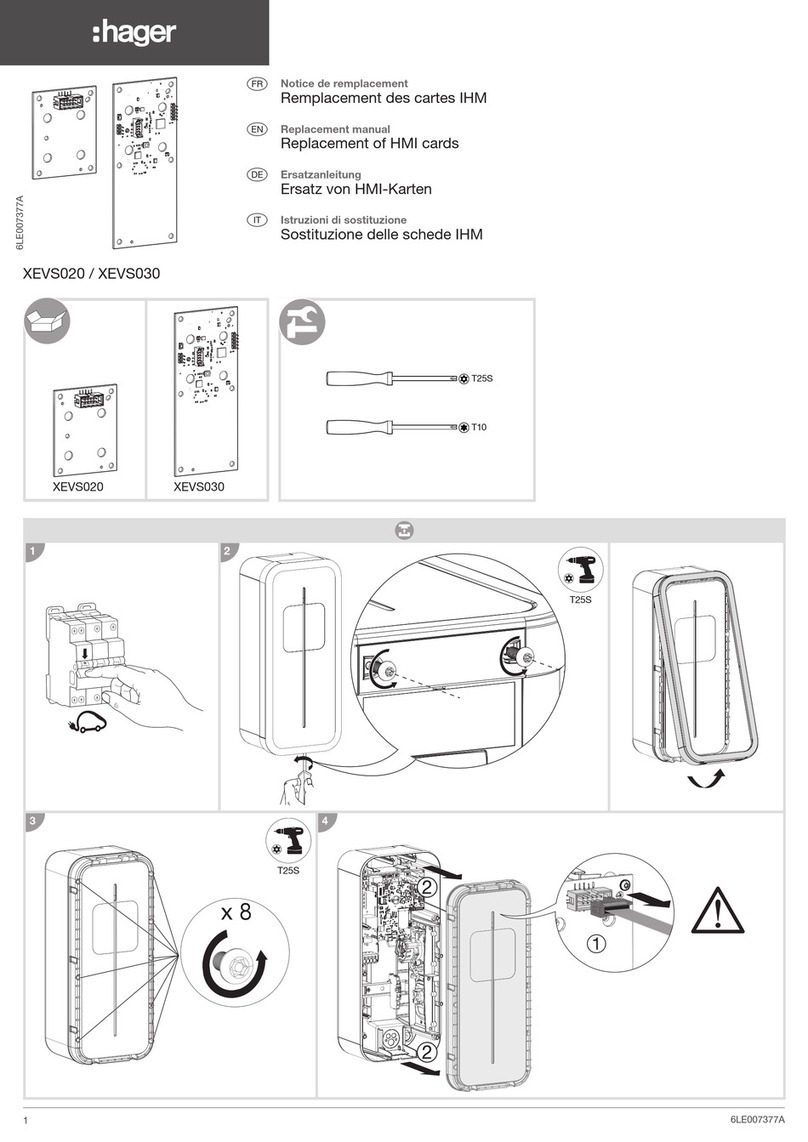

hager XEVS020 Operating and safety instructions

hager

hager CDC740H User manual

hager

hager HY 801, HY 802 User manual

hager

hager TN003 User manual

hager

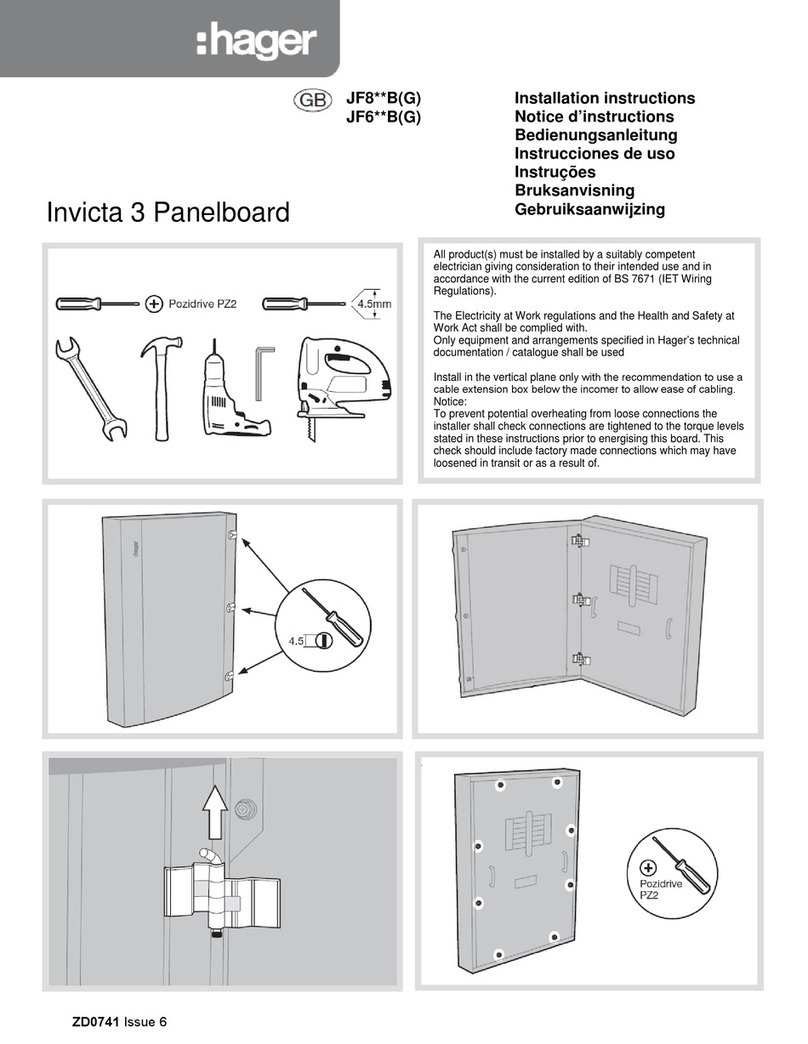

hager Invicta 3 JF8 B Series User manual

hager

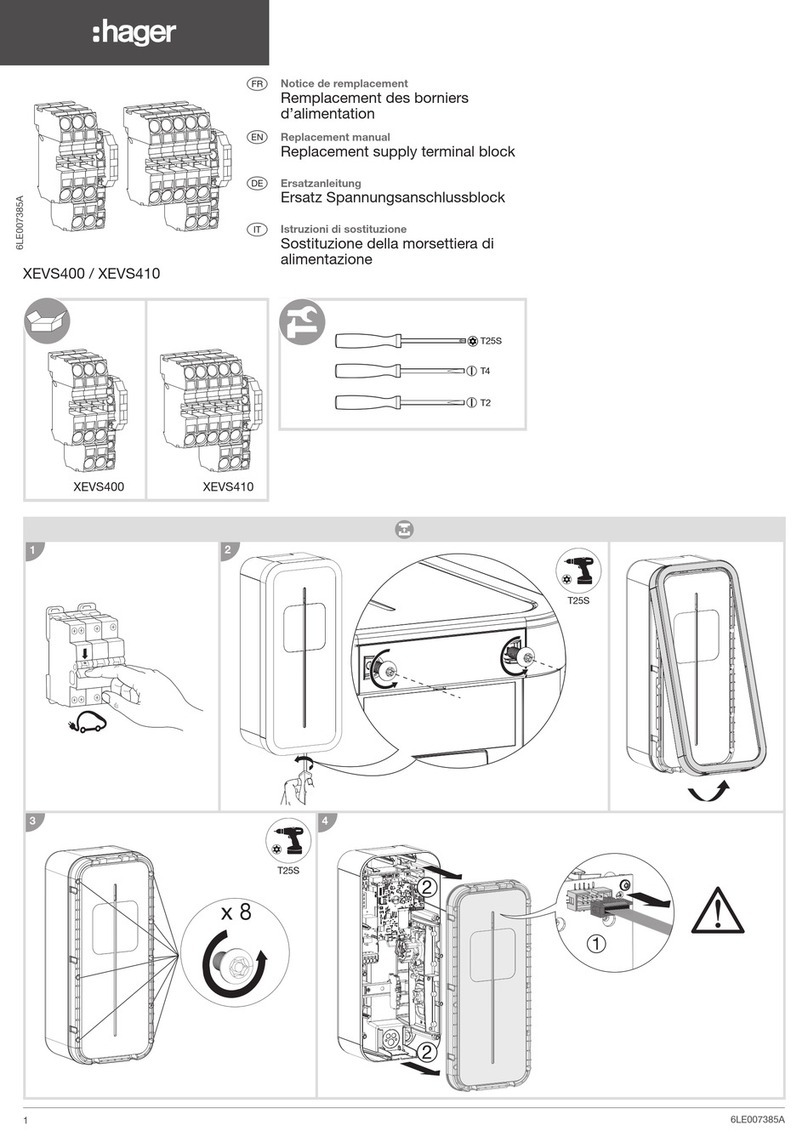

hager XEVS400 Operating and safety instructions

hager

hager HNF Series User manual

hager

hager h3+ HTP610H User manual

hager

hager h3 HNC125G User manual

hager

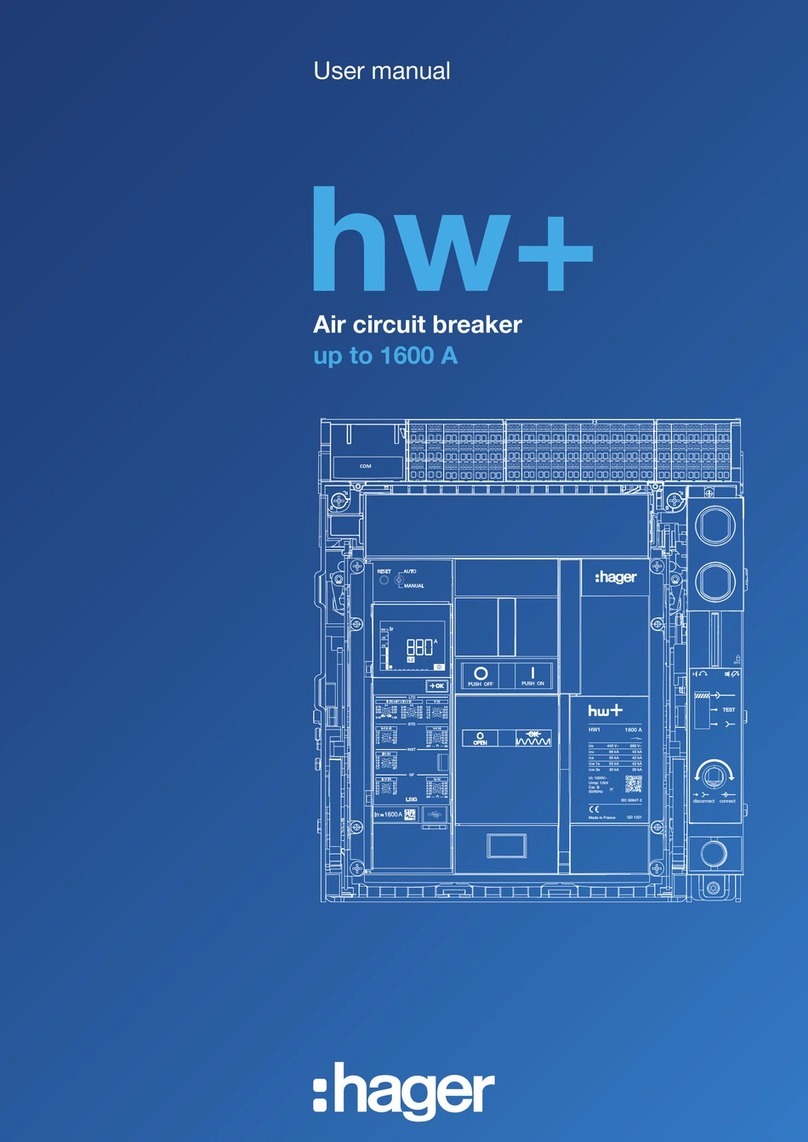

hager hw+ User manual

hager

hager TR521 User manual

hager

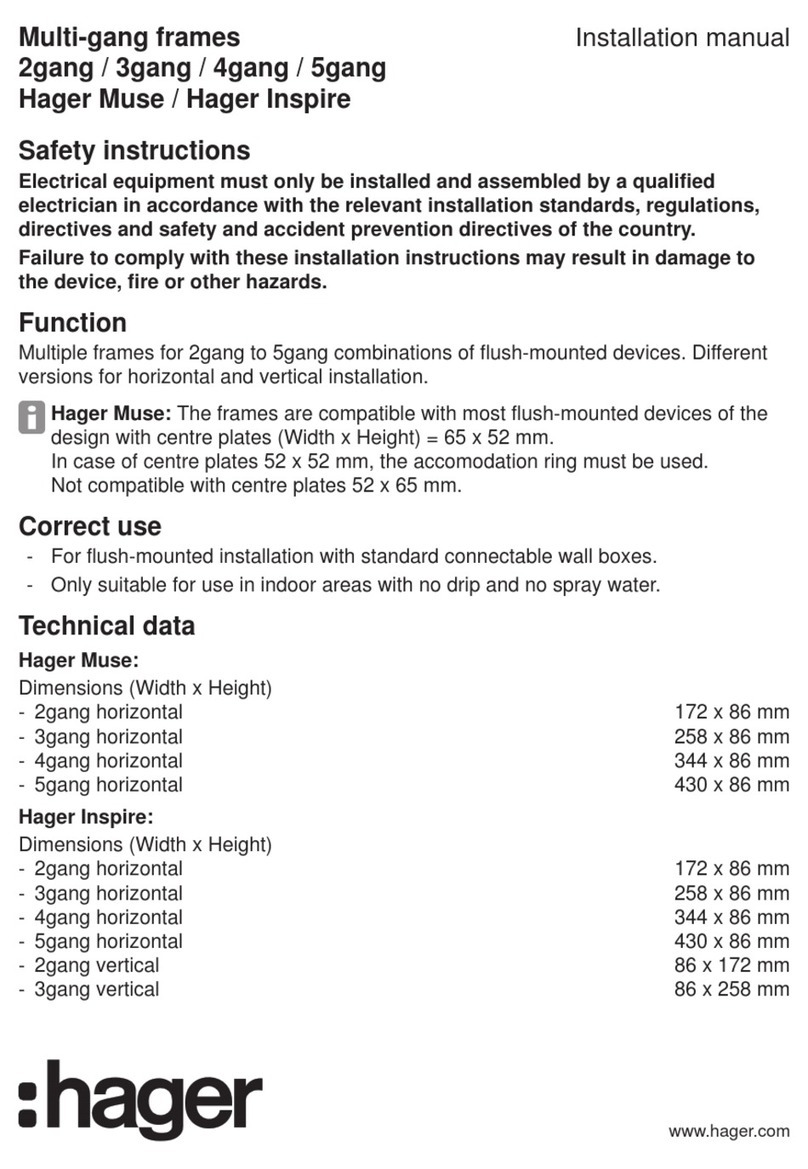

hager Muse User manual

hager

hager CE481J User manual

hager

hager ZY9NK User manual

hager

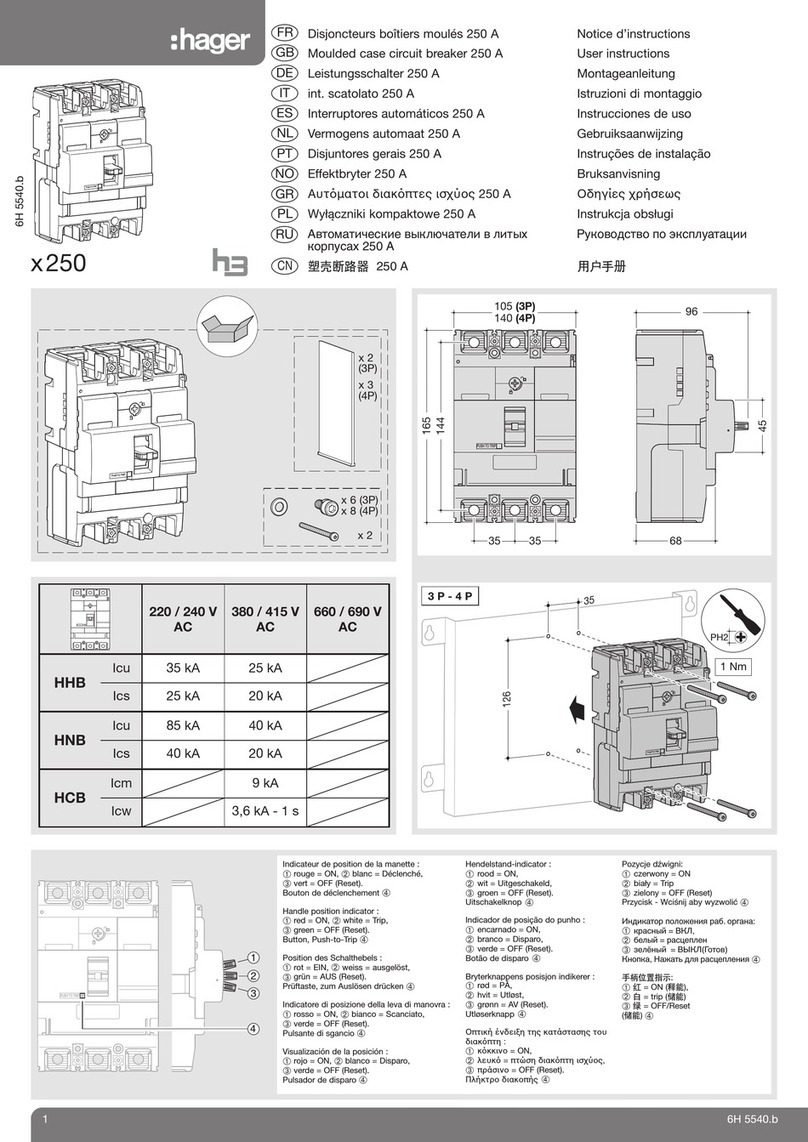

hager h3 x250 User manual

Popular Circuit Breaker manuals by other brands

WEG

WEG FHU ACW125 installation instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

ETI

ETI EFI-4B Instructions for mounting

Gladiator

Gladiator GCB150 Installation instruction

nader

nader NDM3EU-225 operating instructions