GEK-7302 Installation and operation of Type AK Power Circuit Breakers

L -- -___-- -~

,$e~~~~ing‘~~ay which extends out fromthe

\ enclosure to receive the breaker, Small

“+ breakers have guides on their side plates

which slide in channels in the enclosures.

Both large and small breakers have a test

..~ \1 ,’“:@,.

nrd+ rlrm~~mtt hriXake*s are fastened to a the breaker carriage. This 1s the safety cause the breaker to be trip free. Tighten

position stop where both the primar and

1 the 3/8 inch hex head screws inserted in the

secondary contacts are disengaged. gain front holes of the drawout tray during step

lift the position stop handle. Slide the 5 of this operation, The breaker is now in

breaker slightly forward to remove it from the operating position.

the enclosure. ‘__*_.

--. . .

w itnarawing Breaker AKi50, 75 %id”i%O

Inserting Breaker AK-50, 75 and 100 elease the

I_

position in which the I

are engaged, but the

are not. In this posi

Ln r\snrn+nA n,n”+rinQ

secondary disconnects

primary disconnects

tion, the breaker may

VG uprr a-L== zi&GCL1 IU dly without energizing

the load cable or bus.

IT ncn.TAn ‘--“-icant on the disconnect

the force required to

leerz me VredKC1.

1. Trip-:the breaker to r

positiverackihg interlock.

2. Lift the’ racking handle as

use uwn4 1 iuw I

terminals to reduce

ir I II._ LL_^_l_^..

II .-“_ __..D -.

b=fir+in(l. Breaker AK-15 and 25

1. Lift the breaker to a position ap-

proximately six inches above the height of

the compartment tray. far as it

2. Pull the drawout tray out under the

breaker as far as the tray will travel.

NOTE - When installing an individual

skeleton housing for a drawout AK-500r 75,

locate a bolt head over the two front bottom

mounting holes of the housing to provide a

limit stop for the drawout tray.

Q ‘I ,T.,,PV the, h,.~a~~,. ahnu+ l/2” abc,ve

,.\\ will go. ,,

ThiP‘operation w

interlock to

the remaind

Note that he

+A#-

ill re-engage the trip

hold the breaker trip-free for

ler of the racking operation.

re the cam is rotated by lifting

e handle, whereas in racking the breaker ‘-

in, tile operation is p

>‘- 1

erformer, as’s result

of pushing tl- ’Le nancue down. ‘.

_, _,

0, YYWbI -.I- u__I..__ ----_-

il.” An7.rnl

nine nn the +I-SV and

oush the 3. Reset the handle to ‘its lowered

ULG U”WLI pL”LY .,.. _..I I- _j ---

breaker back into its compartmeit so that position and lift it aa This operation

the rear bottom angle of the breaker is .formed 5at&es to completely

must be per

against the guides on the tray directly back disengage t he cams from their racking

of the dowel pins. pins, After the fi fth lifting stroke let the

4. Slowly lower the breaker onto the handle drop to its normal position.

tray and at the same time guide it so that

the holes in the rear angle of the breaker 4. Pull the breaker out of its com-

fit over the two dowel pins on the tray. If

?a

rfment until the test position stop engages

the

breaker is correctlv positioned 01

lthe co hold the breaker in the “test” posit,ion. ; ”

-._ -- .._~~

dowels, its rear and side bottom frame i’

angles will all *sit firmly on the tray. 5. Depress the test position stop han- ‘, >:+

5. Insert two 3/8 inch hex, head screws dle and pull the breaker out of its corn-

through the holes in the front of the side partment as far as the drawout ,tray will

~nalae

fin

the hrnaker

and thread them part travel.

1. Trip the breaker.

baker until the guides

2. Raise the bre

,,

,.‘,

on the sides of the breaker are level with

their mating supporting chant iels in the

enclosure, and slide the break er part way‘

into its enclosure. (Note - ‘I‘he breaker

will be obstructed by a positior I stop at the

bottom of the enclosr ure after the breaker __

has traveled only a E;hort distance into the

cubicle. Lift the Jposition stop handle,

located at the bottom right of the enclosure,

which will release *the position stop and

&+^..^I F....+Lnr intr. ikn

allow the breaker to navel 1111Lll=jl I_IIcv Lllr

““,, cubicle).

Y \ 3. Raise the rackout handle forward

and up as far as its travel will permit and

push the breaker into the enclosure until

irt.^ .,- nlrn.l+

mine am thn h~nrllcz aqsmnhlv

“Cdl asaruuc CLIb “““r”‘b , --__ “-_ _-___- __. ..-J ----- “~_- -rr---

the side of the enclosmg case. tighten screws fjrmly. This ‘prx

. - -. -A../ _-_^- _.

4. Push downward on the I . ’

. .

6. Remove the two 3/8 hex. head

screws which hold the breaker on the tray.

better alignment 01 me primary s~ailolldl Y

gamut nan- studs and the urimarv disconnects for the : ,‘,a .:.

j

a

S

-_.-..1 -_ .-_- --.- ..-

novement into the en- to prevent further tra;el. (Note f Refler to _

e operator to provide section describing “Test Position” in t

to make the primary instructions.) then pull the breake

ie stationary studs in

orming this operation, 7. Release the test position stop by primary contacts clea

itc:

lever and nush the breaker

..

:

wards as far as its free travel will permit back>

and then pull the racking handle down to,X,bc-t:,zar,,

be sure the trip interlock i-h --,^--^-1P\\

(Note - When the racking handle LL LIL rib

position other than completely down, tl

breaker cannot be c ..--- L-J ^^-I i^ L,.IA

,peraLeu a‘lu ID IICIU

trip-free by the trip interlock.- This ap-

olies to the “fullv in” and “test” positions.)

n+ rackme cam.

‘Y ----“I

le :“,“,,on the cam” which allows the racnk%E TEST POSITION

+r. kn liF+nri nnmrah in o,,nw thp nawl

. .

__-_--.

to engage the first notch on the cam.

,’ ‘_’

*eaker open. If the

. . . ,

8. When the paw1 engages the first

notch on the cam, push the handle down

again to its normal position. This causes’

the cam to rotate about.the racking pin.

Repeat this operation five times to rack the

hTr=csko?

into its *‘Final noeratin@

nosition.

‘i’he “Test Positio n”, as referred to in

the previous mstructn ,ns, is that breaker

position where the pri..a-., =-..--

ma7v ~OWPT

dincon-

-_-_ _.

nect contacts are safely disengaged but the

secondary control disconnects are engaged.

In this position, the breaker may be tested

or operated manually or electrically with- ’

out enereiv;“m

tho nrimarv

newer circuit.

se

1. Trip the br

*breaker is not open, the interlocK lever OX ,,* .,y.IA _..-- __I __._-_ _).

the drawout mechanism will not permit Interlocks hold the breaker trip” free until provided”;hYe”;l”aEi;inerhandit: hss been move6

to the completely down position, thus re-

operation of the rackout handle. it is racked into the fully contactedposition.

The fifth stroke of the handle is only a leasing the trip interlock.

up and for- partial stroke and does not result in any

further movement of the breaker. It does

disengaging serve three usefulpurposes: itpositions the Foramorecon‘ 1 I” *

y disconnects. cam so that it cannot rotate and allow the drawout me

AW3 DRAW

3. Slide the br eaker out until the breaker to back out under short circuit TI^.-”

stresses: the oartial stroke signals that the

2. Pull the racking handle

ward as far as it will travel,

the primar:

position stop engages in the front slot m

the bottom of the breaker carriage. The

breaker is now in the “test

where its primary disconnects

disconnected from tl

minals of the enclosure. (Nott

section describing “Test Positic

instructions.)

--- -----,

racking operation is complete; and it re-

Innroo +ko twin intnrlnrli which wr,=cnrncrpd

qlete aescrlprlon or

chanisms and enclosures see

OUT EQUIPMENT INSTRUC-

VIYS, GEH-1830andAKD5DrawoutEquip-

ment Instructions GEI-90890.

” position,

ITLIYG.3 CIlr CA .p LILLIA *“-.. ,...-%... 1.11 -“.D-D--

are safely by the racking pin during the previous four

pumps of the racking arm, NOTE: Once a DRAWOUT BREAKERS AKD5 EQUIPMENT

le line and load ter- . . ..a. . .

? - Refer to racking operation has been started, it must NOTE: AKD

)n” in these be completed as the breaker cannot be

rn.rnrn~A nn+il the ezickinn oDeration is

letter “A” ap

.

4. To remove the breaker from its

enclosure, lift the position stop handle and

slide the breaker forward until the position

stop engages the rear slot in the bottom of

9. After completing the fifth racking

stroke, lift the handle as high as it will go

and allow it to drop to its normal position.

NOTE: Any strokes beyond this point will

5 breakers are identlfleo Oy $ :\~

lpearingafter breaker number - *’

example, “AK-2A-15”. ,\ \.,; “V

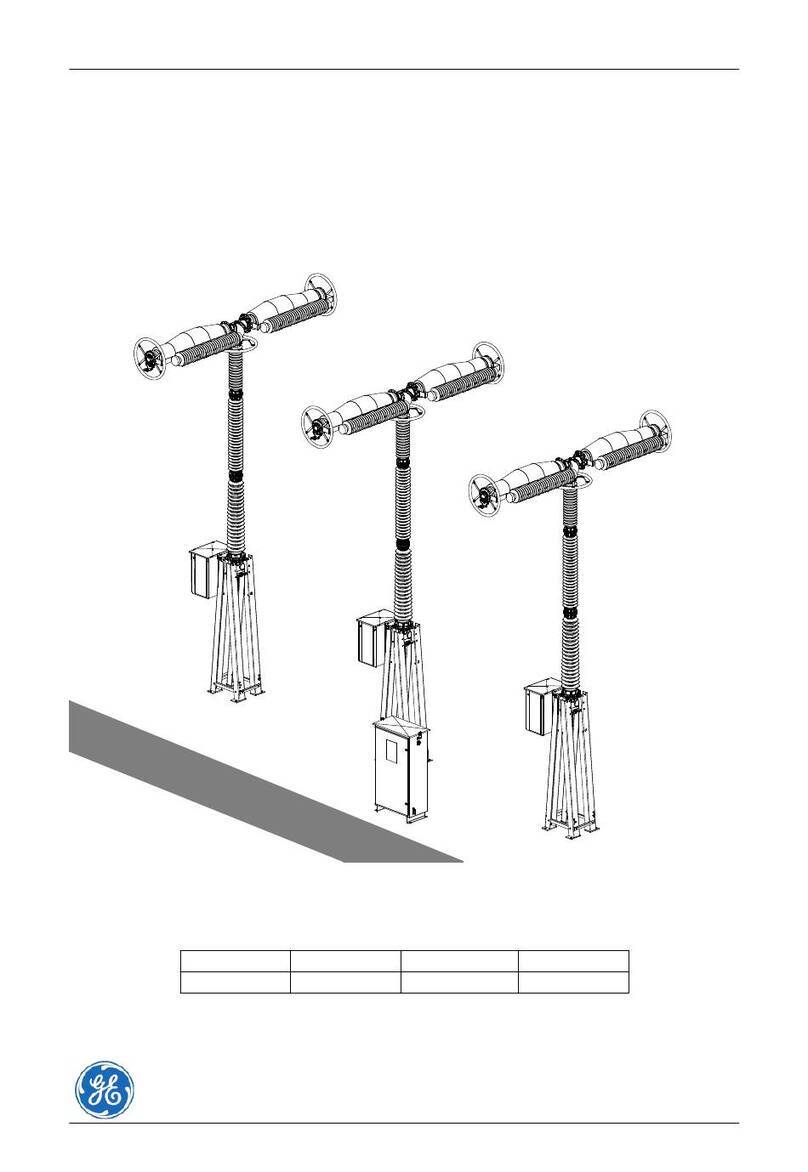

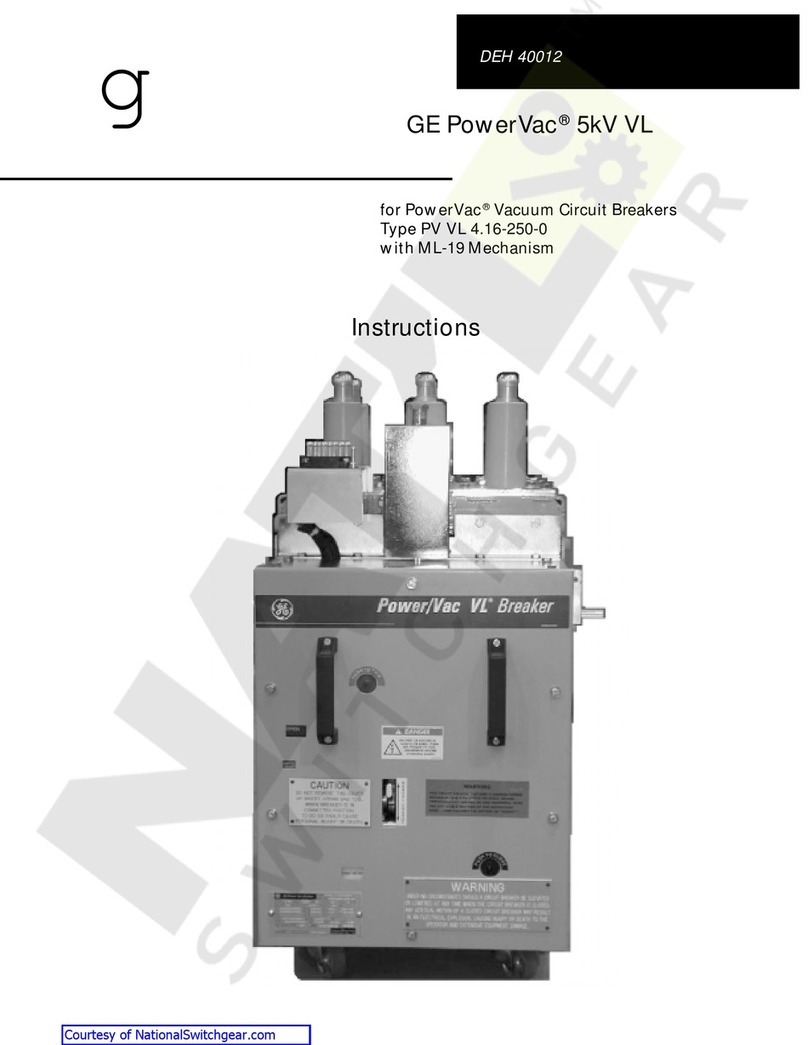

Drawout Mechanism Operation - There are

four positions of the drawout mechanism:

”