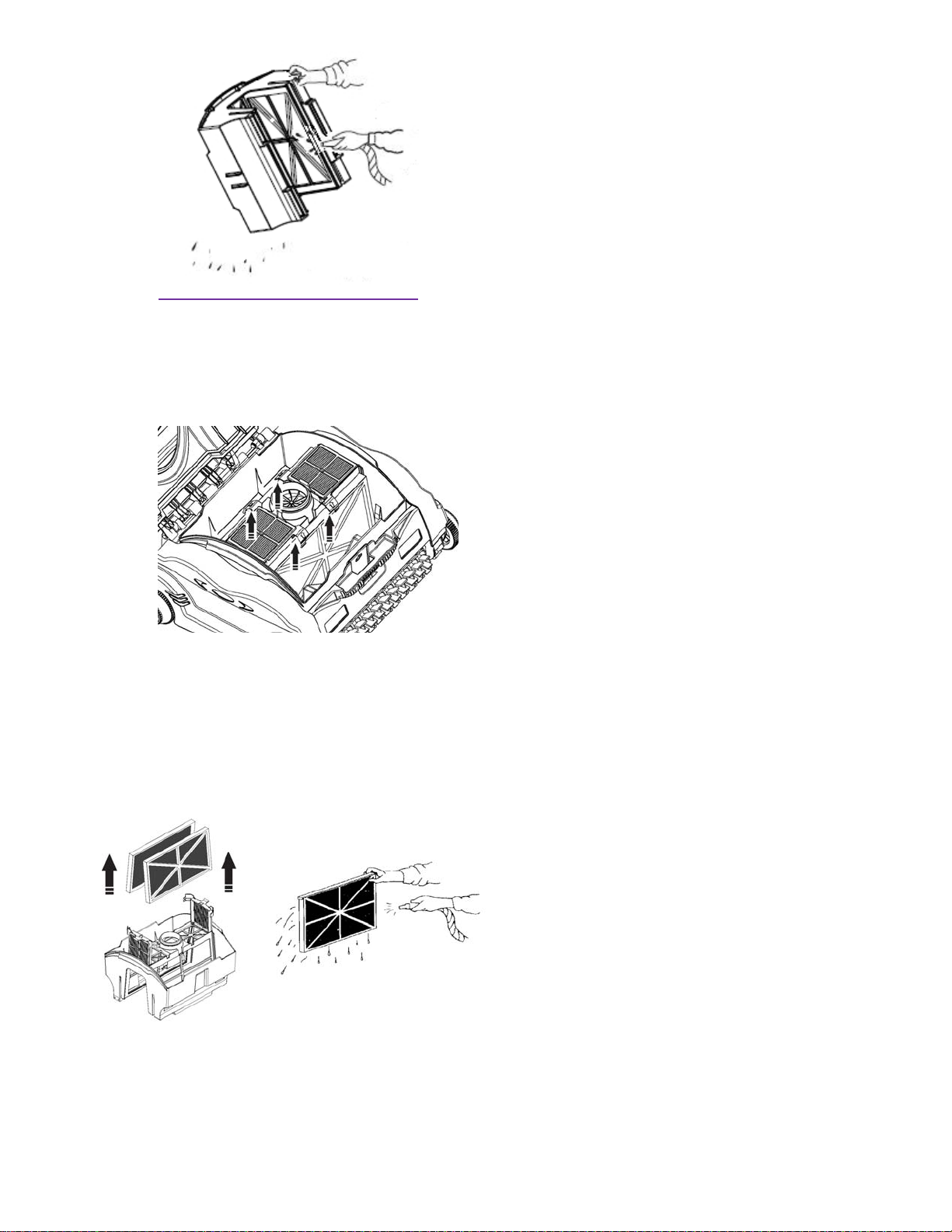

Remember: The cleaner your filter is, the more efficient your cleaner will

perform.

Periodic Cleaning of Moving Parts.

WARNING: Disconnect the power supply from electrical outlet before cleaning

moving parts.

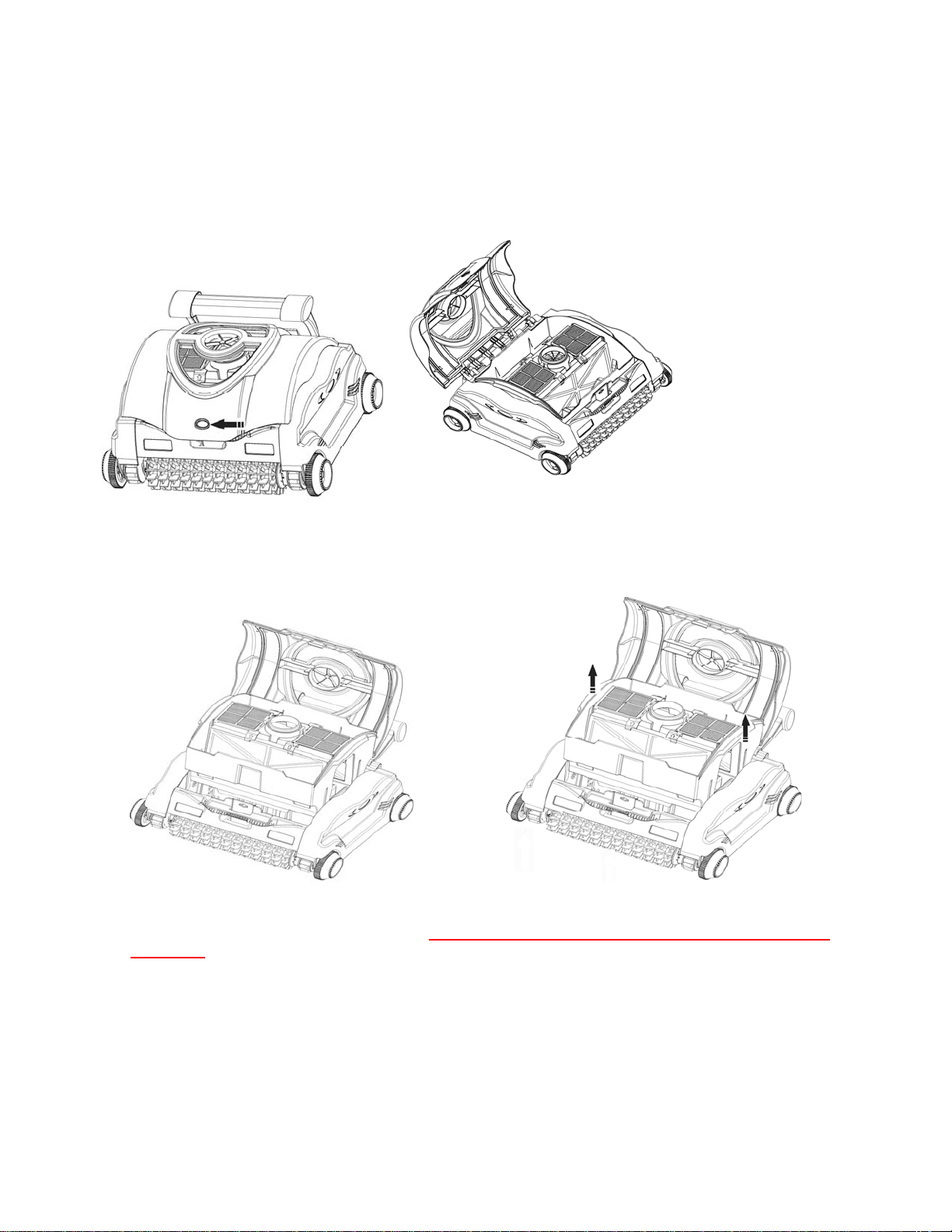

Inspect the venturi to ensure that no debris or hair has clogged the impeller.

•The impeller can be cleaned by spraying it with a garden hose

•Remove any debris that has accumulated between the tracks and wheels

Storage

When out of the water, store the SharkVAC in a dry, shady location at

temperatures between 40F - 115F

Cable Care

With continued use, the cable may become coiled (like a telephone cord). To

correct this, periodically stretching the cord out in the sun should remove any

cord twists.

IMPORTANT: The cable should be checked periodically for any external damage.

Important Tips.

•Cleaning the filter cartridge after every use maximizes the unit’s

performance.

•Replace worn brushes

•If granular chemicals are used in the pool on a daily basis, an automatic or

floating dispenser is recommended, as it retains the calcium sediment

sometimes contained in granular chlorine.

•It is recommended not to operate the SharkVAC until all chemical powder is

dissolved because it can clog the filter.

•In a pool with usually high calcium content, more frequent cleaning of the

filter is recommended.

•Save the SharkVAC original carton for extended storage or shipping

requirements should your SharkVAC require dealer service

•The sealed Motor Unit and the Power Supply contain no user-serviceable parts.

Opening them will automatically VOID your warranty.

•Remove items such as thermometer, toys and the like from the pool before

using the unit. Such items can jam the unit and cause damage to the unit

and/or your pool.

TROUBLESHOOTING.

If SharkVAC fails to pick up fine or heavy debris:

•Clean the filter. It may be clogged. A filter cleaning solution can be used

to remove D.E., excessive dirt and/or sand

If SharkVAC starts working momentarily but then stops working:

•Check and clean if necessaryImpeller may be clogged or jammed with debris.

following the instructions in the maintenance section.

•Brush roller or drive tracks are stuck. Check for debris and clean if

necessary.